Can I braze instead of weld the notch in? I'm not that great at welding and I'm afraid of burning through...

Braze, even silver solder is good enough if the mechanical fit is excellent and well planned, a joint flanging block set may help here to make an overlapping seam if you're not sure. Typically, the pan is weak enough to dent on a big impact rather than transfer the stress to a joint.

Braze, even silver solder is good enough if the mechanical fit is excellent and well planned, a joint flanging block set may help here to make an overlapping seam if you're not sure. Typically, the pan is weak enough to dent on a big impact rather than transfer the stress to a joint.

Thanks for the info. I think I'll give it a shot them. I'll post pictures so you can see how it comes out.

what gauge metal should I use for the notch?

you use 20-22 gauge body sheet metal Yes you can braze it BUT it will add much more heat and could very well warp th eoil pan even more then just welding it. Use low heat and just do one tack at a time and over lap each tack weld. If your that worried about looks or a leak Run JB wled over it after your done and Paint it.

Hi Larry,

Thanks for the help.

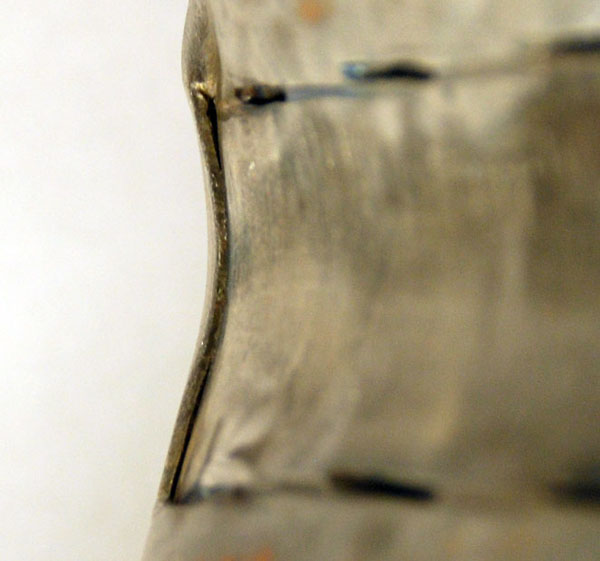

How much clearance do I need to create? Do you think this is enough?

What I did is marked out the area that I wanted to dimple. I then used my dremel to 'score' an outline of the area and purposely went all the way through is some spots.

If it's dimpled enough, I'll just have to fill in the slots I cut with some weld.

You have to go all the way to the ends/sides of the pan. I just finished another one and I'll have some up dated photo posted soon. And I'll post them here as well.

I actually dimpled the side too. I'll see if I can get a better picture.

Why can't you just reuse the original pan and oil pump pickup?

The 292 has the oil dipstick in the back, so you have to either modify a rear sump oil pan to clear the drag link or drill the block to accept the dipstick in the center.

http://www.t6racing.org/id9.html

Would that be easier? how is your ground clearance? Does the block have a boss on it in that area?

I converted my 194 from Nova to "normal" before putting it in my '53 sedan. Perhaps a little easier to do than the other way around.

I'm not sure gearhead. I'll take some pics of that side of the block. For some reason the idea of drilling the block didn't appeal to me.

I have a non nova 250 that was installed in a 63. I didn't really like how they did it. I will take some pictures.

What you're doing is fine, I'm just "thinking out loud"...

haha... no worries. I was thinking the same thing as I started to cut up the oil pan.

Any pics of what you did?

The welder ran out of wire so, it's not as pretty as I was hoping. As far as I can tell, it won't leak. I will run some JB Weld over the rough spots.

To get an idea of how much I dimpled the pan:

I'm hoping this will provide enough clearance.

Gearhead, here is a picture of that 250 I was talking about.

busted off dipstick??

Here's what the 292 block looks like:

that should work out just fine for you. When i dimple the pans with a peice of round stock the pan isn't dimpled that much. and it clears the drag link.My knotched pans have more clearance then what you have there.

thanks for the input Larry. I didn't think that you dimpled the your pans all that much, just wanted to get a confirmation from you before painting it.

With these pans, do you need to install the engine without the oil pan?

same locations on the dipstick as what's on my 194...

Perhaps filling it with oil and letting it sit for a few days will help determine if there are any leaks?

If you want to find a leak put diesel in it!

Or water, easier cleanup.

Like beater said use diesel fuel to fine any leaks. Install the mptpr with the oip pan in place. Other wise you will need to drop the drag link and the cross member.To reinstall the oil pan.

I thought I was going to get the 292 buttoned up tonight, but I ran into another snag

250 oil pickup support

250 oil pickup support

I still don't understand why you have to drill your block for oil dipstick? On that 230 engine I installed in my nova, it had that rear sump pan that I sold you and the dipstick in the back. All I did was install my front sump pan, install my orig oil pickup, and moved my dipstick tube to the front location. The block was already drilled in both locations I just had to knock out a plug from the front boss, and move it to the back boss and install my dipstick into the front location.

I could be wrong, but I think all of the 292's were rear sump - there isn't a plug in the front of the block for a nova style pickup and oil pan. You can either drill the block and use a nova style pan, or use a 230/250 rear sump pan and notch it to clear the drag link.

Yeah maybe that's true for 292's? I'm not that familiar with the 292 version. I've just heard of people saying that they had to drill the block when switching from an inline 6 with front pan to engine with a rear pan. I don't think that's necessary on 194-230-250's. It wasn't on mine anyhow. Isn't the block for a 292 the same as the smaller 6's? I thought the only difference was the head?

The extra height is actually in the block. IIRC, I don't think all of the 230/250's were drilled for the front location.... I think I read that somewhere.

All 292s are rear sump Pick-up 90% of all 250s are rear sump pick-up

I still don't understand why you have to drill your block for oil dipstick? On that 230 engine I installed in my nova, it had that rear sump pan that I sold you and the dipstick in the back. All I did was install my front sump pan, install my orig oil pickup, and moved my dipstick tube to the front location. The block was already drilled in both locations I just had to knock out a plug from the front boss, and move it to the back boss and install my dipstick into the front location.

What was the original application for that block?

what is the stamped code behind the distributor?

What was the original application for that block?

what is the stamped code behind the distributor?

It was in an early Chevelle 64 I think. I'll have to check the code tomorrow. I do know it was a Counter Exchange engine. Has a CE in the code.

when looking up the codes, do you just use the last two letters?

so F0813RE = RE - 292cid w/manual trans

F0889CCA = CA - 230cid w/manual trans (I was told this one was a 250)

Someone just posted this page:

http://no25.chuckthetruck.com/page3.html

What was the original application for that block?

what is the stamped code behind the distributor?

It was in an early Chevelle 64 I think. I'll have to check the code tomorrow. I do know it was a Counter Exchange engine. Has a CE in the code.

Remanufactured engines are often modified to suit more than the original application.

I have a 350 V8 that was remanufactured by Jasper that has been modified to accept both right and left hand dipsticks, for example.

when looking up the codes, do you just use the last two letters?

so F0813RE = RE - 292cid w/manual trans

F0889CCA = CA - 230cid w/manual trans (I was told this one was a 250)

Someone just posted this page:

http://no25.chuckthetruck.com/page3.html starting in 1969, they used 3 letters, so the last would be CCA, not CA...

CCA comes up as a '73 Chevelle 250. Are the pistons dished or flat top? what is the casting date code?

when looking up the codes, do you just use the last two letters?

so F0813RE = RE - 292cid w/manual trans

F0889CCA = CA - 230cid w/manual trans (I was told this one was a 250)

Someone just posted this page:

http://no25.chuckthetruck.com/page3.html starting in 1969, they used 3 letters, so the last would be CCA, not CA...

CCA comes up as a '73 Chevelle 250. Are the pistons dished or flat top? what is the casting date code?

I'll have to get back to you. I'm in the middle of moving, so it might be a while.

With some of the snags I've been hitting with this engine install, I've decided to focus some attn to some other things on my car:

https://www.inliners.org/ubbthreads/ubbthreads.php?ubb=showflat&Number=52023&Main=6884#Post52023

CCA comes up as a '73 Chevelle 250. Are the pistons dished or flat top? what is the casting date code?

no idea on the pistons. Here are some more numbers off of the engine:

HEAD

3927763 I48

DIST

F0889CCA

33W107370

BLOCK

328575

G72

68-84 250 out of Chev/Old/Pont/etc. Check the casting numbers on the Home Page

do you know what the 33W107370 means?

I'm back to working on this again. It looks like the 194 will be pulled out of the nova around April 11, so if I want to drive, I'll have to complete the 292 conversion.

I haven't found any leaks in the oil pan. The outside is looking kinda rough (my welding/metal finishing skills are nearly non-existent). What do you guys think would be the best material to finish off the pan before paint? Someone suggested JB weld and I've been thinking about fiberglass. Which one would hold up the best if there was a leak (considering pressure and heat)?

The JB weld will hold up alot better then fiberglass.

I'm back to working on this again. It looks like the 194 will be pulled out of the nova around April 11, so if I want to drive, I'll have to complete the 292 conversion.

Would you want to sell that no good, bad performing 194 cyl head to The kid ,snowman4839,looking for a cyl head on the BB here?

MBHD

when $ allows, I plan on getting the 194 head rebuild. The head on the 292 is just the stock 292 head.

I'm back to working on this again. It looks like the 194 will be pulled out of the nova around April 11, so if I want to drive, I'll have to complete the 292 conversion.

Would you want to sell that no good, bad performing 194 cyl head to The kid ,snowman4839,looking for a cyl head on the BB here?

MBHD

I finished up the oil pan and installed it this weekend. I will hopefully be placing the engine in the engine bay this week.

I will post more details later, but there is a finished pic of the oil pan in this gallery:

04.13.10 - 04.18.10~ Progress pics

I didn't notch my oil pan nearly enough. It looks great if the wheels are pointing straight ahead, but when I turn the wheel, you can see the engine moving up and down(engine is bolted to mounts, but mounts aren't bolted to the frame).

I took a hammer and piece of round stock to it yesterday, beat the heck out of it and it is still rubbing. I'm also thinking there's not way I'll be able to change oil because the nut in the oil pan will hit the drag link. I'm thinking I'll have to move the part of the pan that is rubbing a inch or so back so that I can change oil and it won't rub when I turn the wheel.

Now, I'm just wondering if I should drill the block for the 194 pan/dipstick, rather than modifying the 250 one. Or maybe put the dipstick on the outside of the block and into the pan, which I think would be the easiest. I'm afraid of drilling the block.

Anyone have any input?