I have a couple of Canadian Pontiac 261ís both of which have 3836848 heads with steam holes that I am certain left the factory that way from GM Canada in Oshawa. I have also read several times that the usual practice for using this head on a 261 in the U.S. is to simply use a head gasket as a template for drilling. The steam holes in both my heads are at a 12 degree angle toward the manifold side which has me wondering if the holes on a U.S. 261 are drilled perpendicular to face or tilted and if anyone who drilled them straight had difficulty intersecting the water cavity on the one very close to a head bolt?

Hereís what Iím talking about and thanks for insight from anyone who knows whatís up with this.

Ive used the 261 Pont. heads opn a 235 a couple of times. one with no holes and one with the holes drilled perpindicular to the block. No problems. I will check my 261 blocks and see if there suare or angled for you.

Hi Curt,

I came across your post through the search as I'm looking to put an 848 head on my 261. It seems like a few people have asked the question regarding drilling steam holes into an 848 head but I haven't found the definitive answer yet.

I understand I should use the 261 head gasket as a template and from your findings it looks like the holes should be drilled at 12 degrees.

What I'd like to know is how deep they need to be drilled? Again from your pic it looks like they don't go all the way through.

Any help is much appreciated!

I put an 848 head on my 261 engine. Being the trained master machinist that I am, I place a head gasket on the head, took my 3/8 hand drill and said that must be the right angle and drilled the holes. It's been running that way for 3 years now with no problems. But now that I have said that I'm sure that Mr Murphy will come calling. I know that you have to be careful for the water jacket when you do it. I sure that wasn't much help but it worked for me.

Ahh OK, so how deep did you drill? And you're trying not to hit the water jacket right?

No, the idea is to drill into the water jacket. You are relieving a steam pocket created in the top of the water jacket in the block by a bigger bore plus cylinder wall, thus letting coolent travel from top of block into the cylinder head. I hope you can understand what I'm trying to say. 1 OL REDNECK

OK thanks Popper that makes sense. I also read somewhere that only 3 out of the 6 holes hit the water jacket? Does that sound correct or should all 6 hit the water jacket?

Because of the bigger bore of the 261" the casting has 'siamesed' cylinders on 12,34,and 56. This caused areas that did not allow good coolant flow, causing steam pockets, so the 261" block and gasket were vented to the head cooling jacket in 6 places.

The 235" gasket doesn't have the 'steam hole' provision so you must use the 261" gasket when modifying the '848 head.

Titen; Thank you, you said it much plainer than I did! 1 OL REDNECK

MARK; I don't think that is correct.The idea is to create 6 passages between head and block. There is no coolant flow between the cylinders[1-2][3-4][5-6] which in turn creates a steam pocket on each side of these cylinder wall joints. Thus needing to vent each seperate steam pocket and creat a passage from block to head. 1 OL REDNECK

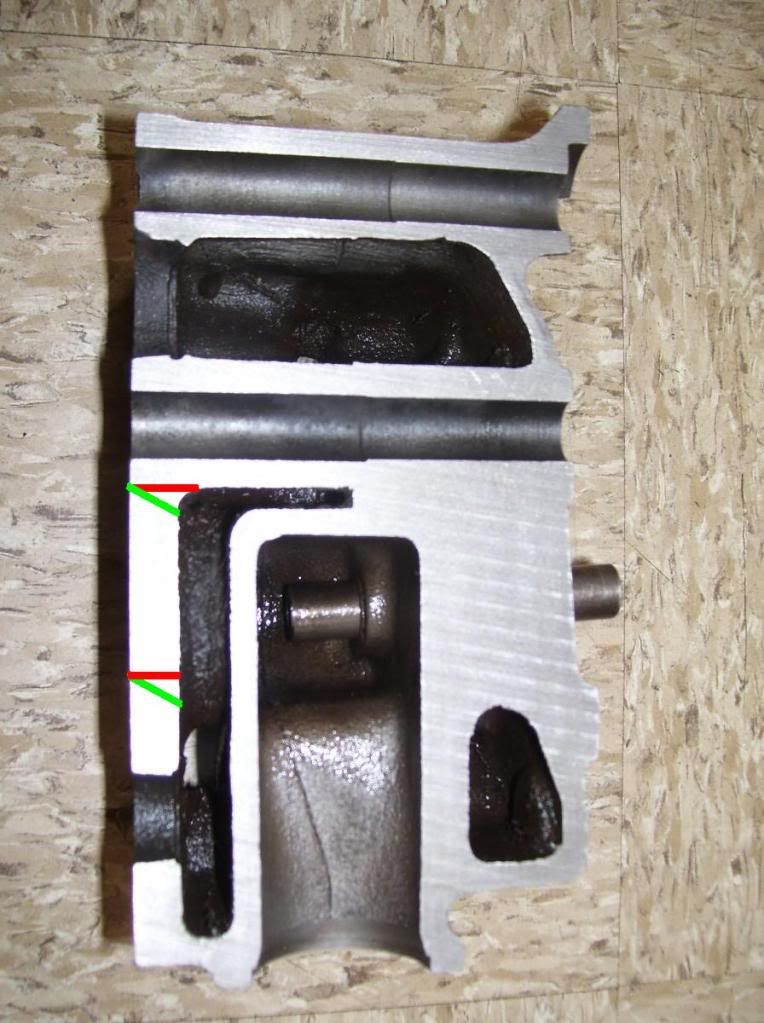

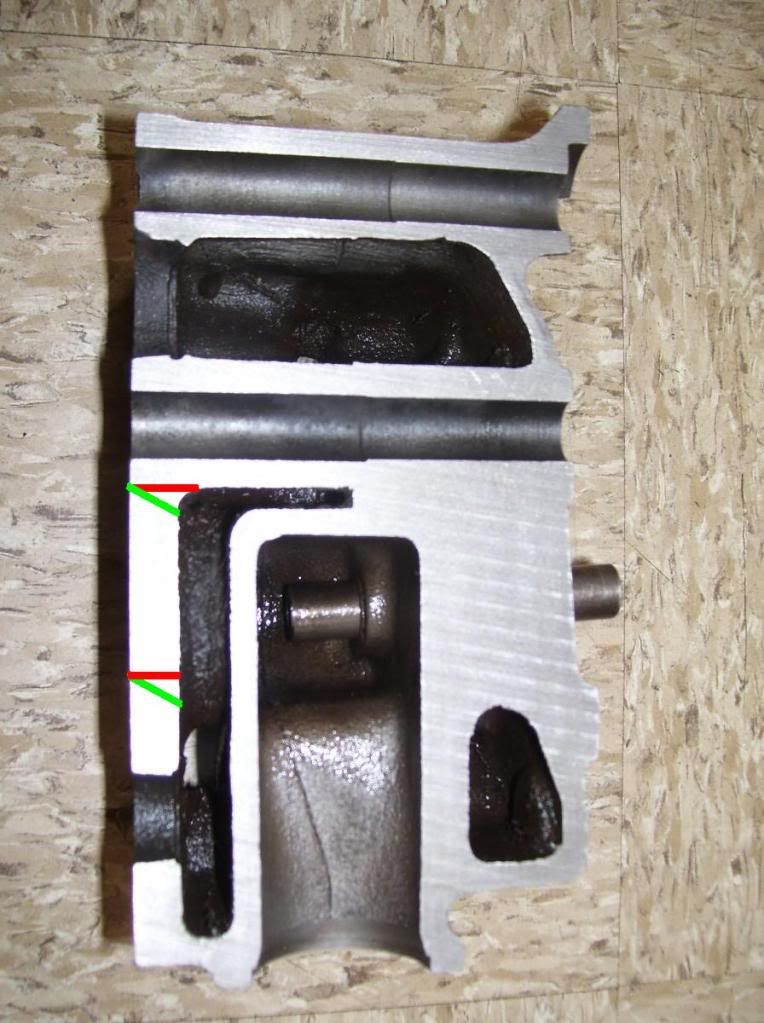

The 848 head I cut up was a 235 version that did not have steam holes however I cut it right where they would be which clearly shows that the 3 holes nearest the plug side are unlikely to intersect the jacket if drilled perpendicular to the face. Angling the drill a bit toward the manifold side will increase chances of coolant flow considerably. The 848 head album in my signature has a clear cross section picture and if you go in further than 7/8Ē you are drilling into the port roof.

Well thanks Titen, Popper and Curt, that helps immensely and answers all of my questions. Looks like the 12 degree angle is critical to have all of the steam holes function as they should on a 261 head.

Gentlemen;

Mark is correct. Hence the name;

"steam holes" etc.

Just use the 261" head gasket as

a template and drill into the water

jacket.

-------

The 261 CID engine does have a larger

bore (as posted) but was designed for

'commercial' usage, in large trucks/

Busses. When pulling heavy loads on

hills, the steam would have a place to

escape to (with this improvement)over

the 235", wich was for cars/Lt. trucks.

Good luck.

Here is an

illustration of the steam holes in the 261 block. This is from Tim Lederman's

website in the Stovebolt page.

Thanks again for all of your help fellas. I went back and looked at the 235 head I have on the bench and it's now obvious where the water jacket is and drilling into it. The illustration on Tim's website is interesting too in illustrating just how deep the steam holes go into the block. All very useful information.

In all of these posts I haven't seen anywhere what size drill to use to drill the steam holes?

The same size as the hole in the gasket.

The holes are 3/16" and GM put all of them are at a 12 degree angle. I would think the gasket hole has to be at least a little bit bigger to allow for minor misalignment.

Straight in vs. angle shows why 3 may not intersect jacket:

THANK YOU CURT, for posting the pics to show us the 12 DEGREE ANGLE which these holes need to go in at. I've wondered about this for years - since I bought a 261 in a basket. "...drill the holes at a slight angle..." does not cut it for me!!! Thanks to you, NOW THE WORLD KNOWS!

Take Care, Tim