Hi everyone,

I've got a project that geared me towards this site. It's a '50 Chevy 3600, original engine is cracked and no transmission. I also have a '47, but that's going a different route (original, simple). Since the 3600 isn't as desirable and because I have had a slight itch to build an IRS vehicle, that's what my plan is. I'm collecting parts for the suspension and drivetrain, currently I have my spindles, engine, T5 transmission, and differential. However, since this is the engine section, I'll stick to my engine.

The goal of this vehicle is to have a daily driver style of a build, no crazy cams, boost, or ultra-high compression. Since the engine block was cracked, I kept an eye on Craigslist for an inline 6. I found one listed simply as Chevy 6 with a 3 speed tranny for $150 bucks. Picked it up (got a free bottle of wine with it!) and sold the transmission (minus bellhousing) to a friend who uses them in circle track cars. Tore apart the engine to see if it was buildable, so far so good. Ran the numbers and it turns out to be a 230 CI. Although I would love to have the 250 for just a little more oomph, since I'm more concerned with good fuel mileage it's not a big deal to me. That being said, if I come across a 250 crank for a reasonable amount, I'd pick it up.

Anyways, my plan is to rebuild it with a mild ISKY cam (one that requires no head mods) and to try to bump the compression a bit. I'd like around 10:1 so I can run premium fuel and still get the benefits of higher compression. I'll run the original carb and etc. However, I'm going to collect parts on the side and build a fuel injection swap for it. I'd like to pick up an Offy intake (I bought one, but it didn't have the injector flats molded), a spare head that will receive roller rockers (reduced friction equals higher mileage), lump ports, and a valve job, some cast headers, etc etc.

I plan on running a Megasquirt computer, sequential injection, etc etc. All the fuel injection is a ways away but the engine rebuild to stock is happening currently. Thanks tax return!

This build is fighting for my time with my '85 C10, '79 Z-28, and 3 customer vehicles ('70 Datsun 2000, '68 C10, '79 Trans Am). However since everything is in parts, I can sneak it in when we are slow at my normal job (auto mechanic) since I don't have to push an entire vehicle in.

I have read the Inline 6 book, studied what I can on here, but could use some help from the seasoned vets. Like I said, it's not a high HP build, I'm just basically trying to increase the volumetric efficiency as much as possible on a 50 year old engine to result in increased mileage and a little extra power.

A 250 crank would be a good upgrade for sure. Be careful on how you choose to increase your compression. The traditional methods of raising compression in a SBC by swapping to a smaller chamber head do not result in the same kind of gains for the Chevy 6 as you see in the V8's. Just remember that more compression doesn't equal more power in all engines.

That was a question I had, what is the best way to go about it in the inlines, pistons or plane the head or...? I don't have the inline book by me currently to reference. I hope to find a 250 crank, I need to start driving around the local farms and look for abandoned trucks.

Well, the inline book doesn't really guide you in this area, it just helps you identify what is available and leaves the selection process to you. As for the gain your seeking, an open chamber head can be resurfaced to give you close to what you want with a flat top piston and zero deck if you find a 250 crank.

Mitch,

Before you spend a whole lot of money on rebuilding the 230 have a look here:

[url=http://www.bangshift.com/forum/showthread.php/26529-Gary-Hart-s-1951-GMC-Half-Ton-now-with-Teaser-video!/page32][/url]

You may have to copy and past the link to get it to work.

For equal or less money you would end up with 275 or 290HP with better gas milage that the 230 will give you.

Complete drop out engines can be had for $1200 to $1800 complete with wiring, PCM and gas pedal.

EFI-DIY, I actually have a 3.5L inline 5 that is going to be turboed and installed in my '85 C10. I recently purchased the injectors and base tune from Limeswap. I'm doing this for the uniqueness and fun of building EFI from scratch. I'm going to try and hide the EFI components as much as possible.

CNC-Dude, any idea how much should be taken off the head or which pistons are recommended? I have found re manufactured crankshafts for just under $200 (I have no core, so I'll have to pay that).

Keep in mind that boring the engine oversize and adding larger valves increase your compression as well. But if you shoot for a 70cc chamber and some budget 307 flat top pistons at zero deck you will be well above 9-1/2 to 1. You can fine tune it from there if you want more.

Thanks for the specs, I will keep them in mind throughout my build. It's easy to snowball, but I'm trying to keep the project moving by doing the restoration-style rebuild so it's drivable, then collect another head, get my intake, injectors, etc etc. When I have everything I will pull it apart and swap to my performance/fuel injection parts. However, I'd like to have the bottom end done first (crank, pistons, etc) so I don't have to go that deep when I swap to the newer setup. Clear as mud, right?

Mitch, you may want to read up on sequential port fuel injection system and the Chevy 230/250 engine. Even fuel distribution may be an issue with the 1&2 and the 5&6 pairs of inlet valves. With the 1-5-3-6-2-4 ignition firing order, these pairs of Siamese ports due not have equal timing between opening sequences of the intake valves. Throttle body injection may be an alternative. Not to say there may be another work-around for a good functioning port injection system with the Siamese valve head. Later years of the Brazilian Chevy 250 had port fuel injection with a different cylinder head, using 6 individual intake ports

"greg64" at the following link initially installed port injection, then swapped in throttle body injection.

http://67-72chevytrucks.com/vboard/showthread.php?t=276823

Hmmm... I had read something that hinted at that situation earlier. TBI would be much easier to swap and easier to hide, maybe I'll have to save sequential for another project.

So no one has had a successful sequential injection set up on inlines?

Yes, but not with a siamese port head.

Although it's a bummer that I'll have to wait until another project comes along to build a full sequential system from scratch, it is a relief that I can use my current Clifford manifold and will be easier to build. I do appreciate the help from everyone, considering the small crowd of inliners I am amazed at the timelyness of the responses and getting the answers I need. I should put up some pics of my '85 C10 that I'm swapping the 3.5 into, that will look a little more finished.

Way back in'08 efi diy and I did a demo at the Inliner Picnic at Bonneville. We put a temporary GM TBI with a Megasquirt on the 270 GMC in my '53 Chevy pickup. I never made the permanent switch because it was intended for another truck. The '53 is just a couple of hours away now. I guess I should just do it. There are some posts here about it and about the help that Marc gave me on putting my Megasquirt together. Here are some pictures that may help. I could try to dig out some of the old posts if you want.

DONOR CONVERSION

Thanks for the pics, I'm sure they will be of help. I'm a "new generation" mechanic and have lots of experience with fuel injection, looking forward to trying this out. That's kind of the theme of the build, old and new combined. The pickup will have a few other things along those lines. My goal is appearing old with modern functionality.

Does anyone have experiences with crankshafts from Crankshaft Supply? Found this

http://www.northernautoparts.com/part/ck-18028and thought it may be the easier route vs trying to find a 250, pull the crank, hope its good, etc...

Is the non-tapped 1.250 neck a problem with the 230 swap, or is that the way the 230 is?

Is the non-tapped 1.250 neck a problem with the 230 swap, or is that the way the 230 is?

None of the crank snouts are drilled and tapped on any of these engines, you have to do that yourself. Also, many cranks that come as kits from companies like that have had some sort of repair done to them, thats how that get them, they are usually cranks turned in for cores that had journals spun or thrusts burned up and needed to be welded up. You just don't know what you are getting when you buy one.

Mitch, Here is a link to page 14 of a 15 page thread I started here several years ago. I never got finished but there is a lot of good information and links to other goo stuff. The basic idea was to build a turbo injected 292 using a turbo from a 1981 Firebird and TBI injection from a 1989 GMC 305. I built a Megasquirt and rebuilt two laptops and bogged down trying to use Windows and get my head around the Megasquirt software. There are several old threads here that might help you. Our search feature sucks so they are hard to find. Two ways that work but take time are to Google a topic and to search the posts of guys that post a lot and check the topics. Efi dyi did a lot on Megqsquirt and EFI conversion.

LINK

Mitch, we borrowed and used Beaters stripped out wiring harness at the inliner convention in South Texas a few years ago and Mark came with his Megasquirt ECU. Some one else had a wide band O2 sensor and a Computer control Dist. It took about 2 hours to remove the dist,carb and install all the pieces on the door prize 250 Chevy already mounted on a run stand and fire it up. We also had a Painless wireing harness and swtched it in and it worked just fine.Once you have all the pieces together it is not a hard job

Very nice! I'm going to start keeping an eye out for these parts, I believe I know where I can find most all of them. For now it's all the planning.

Jerry, That harness was brought from BC to Bonneville by Marc in "08. I got it from him there. You and I shipped it to Texas and back. I doubt that there is another wire harness in the country that has traveled farther while disconnected than that one.

So, just got the word from the machine shop that my engine needs to be bored .060 over. Will these pistons work with a 250 crank and 230 rods in a 230 block?

http://www.summitracing.com/parts/slp-295p60?seid=srese1&gclid=CI3l3pebmr4CFckWMgodug0AlAI don't plan on running boost or nitrous, I believe cast will work just fine for my plans.

The Rods are the same Your 230 block will now be a 250 Because of the crank. And those pistons are list for USE in a 307 So yes they will work.

Great!

Earlier in the thread, 307 pistons were recommended to me. Is this because they are higher compression ratio than the 250 pistons or...?

Mitch,

GM did on the 4200..

On the early engines, as noted the intake runner really mess with the fueling.

Great!

Earlier in the thread, 307 pistons were recommended to me. Is this because they are higher compression ratio than the 250 pistons or...?

If that picture of the 307 pistons you posted a link to, those would be less compression than the stock 6 cyl pistons.

http://www.summitracing.com/parts/slp-295p60?seid=srese1&gclid=CI3l3pebmr4CFckWMgodug0AlAProbably 8:0

MBHD

Hmm... well now I'm confused as to why they were recommended. When I compare them to the 250 pistons

http://www.summitracing.com/parts/stl-w403p20/overview/make/chevroletit looks like the 307's would have higher compression since they are not dished.

Also, I do not want and will not put a 4200 in this vehicle. The idea is to update an old engine for fun and uniqueness. I'm already running an Atlas engine in another vehicle as well.

I have not looked at any piston catalogs lately.

You just need to find out the total dish in cc's.

Yes the 307 are flat tops, but have 4 valve reliefs & a large chamfer on the outside top edge of the piston..

If you can research, you need to get the 307 pistons that are flat tops w/the 4 valve reliefs, but,,, have no chamfer on the top side of the piston.

Maybe some guys here have the correct P.N. you need?

Guys!

MBHD

To make things more confusing, when I go to the Federal-Mogul (Sealed Power) catalog and look them up, they show a pic without the chamfer.

http://fme-cat.com/overlays/part-detail....T%20CAMARO&vin=I had already ordered the pistons, so I'm really hoping they are correct. I ordered W295P60, I'm assuming the W is for with or without rings. The 295P60 was only available in a set of 8.

Notice that both 403 and 295 pistons have a chamfer. I don't know if they are they are the same size or not. The dish on the 403 piston is listed as .085. The dish on the factory piston measured by Crow is .060. The 403 piston has a height of 1.640 and the 295 is 1.655. Mitch can you provide by measuring the dish depth and compression height of the pistons that came out of the engine? Thanks Jay 6155

Well if they look like that piston on the link you posted, those are the ones you want, good luck.

MBHD

I've found that same Sealed Power piston on several sites now, from around $18 to $27 per piston. They all have the same picture of flat top with no chamfer, except for on the Summit Racing site that has a picture with a chamfer. I suspect the Summit pic might be a generic piston pic on not the 295 piston.

I guess this used to be easy. You just got TRW forged 307 pistons with no chamfer and that was it. My understanding is they are no longer available. When Mitches pistons come in we will all know if the pistons match the picture or not. Jay 6155

Forged is a little above my budget right now! I'll let everyone know, maybe get a couple measurements when they come in.

Yeah, I'm on a budget street/daily driver build. Forged is more of a street/strip build. I don't plan to race, and forged are a little noisy from my experience in small blocks, so cast is my interest anyway. Fingers crossed for no chamfer.

Make that two sets of fingers. Jay 6155

.060 OVER WILL BE A HOT RUNNING ENGINE. I,D FIND ANOTHER BLOCK OR SLEVE THIS BACK TO STOCK. MY .040 ENGINE WOULD RUN HOT BUT I RUN A 160 STAT AND A 4 CORE RAD WITH A "BIG" GM 6 BLADE FAN.

I'm not worried about the .060 making it run hot.

I'm not worried about the .060 making it run hot.

X2

My .030 over block would run hot also, but my cooling system had some problems, was not up to par.

Custom pulleys incorrect size, no fan shroud,, fan too far away from radiator, etc.

MBHD

Piston's are supposed to be here tomorrow so we will know. Also, if anyone was curious, W295P60 is a single piston, whereas 295P60 is supposed to be a set of 8. Took me a while to find that out, finally dug out our Sealed Power book and looked. I have found places that list the 295P60 for sale individually, I don't know if they are breaking up sets or just don't want to put 2 numbers in for the same piston.

And the verdict is......chamfered. Bummer. I'm going to try and contact Sealed Power to see why they don't have the correct picture for the piston.

Did a little measuring with an electronic caliper. Not saying it's perfect, but it's just to give me an idea of how much the chamfer takes up.

Overall diameter - 3.90"

Height of chamfer - .085"

Diameter to inside edge of chamfer - 3.75

What I did is calculated the volume of the overall diameter and height of the chamfer, then calculated the volume of the diameter of the chamfer and the height of the chamfer. I subtracted the latter from the former and divided by 2 since it is at an angle. I came up with .08 cubic inches and converted that to 1.3 CC's.

My math or how I went about it could be completely off, feel free to correct me if you'd like. Also, the overall height from the top of the piston to the top of the first ring groove is .25", and the height from the top of the first ring groove to the bottom of the chamfer is .165". I subtracted those 2, that's how I got the height of the chamfer.

I imagine the only way to calculate the volume of the valve reliefs would be to fill them with a liquid of some sort, I don't really have anything accurate enough for that.

And the verdict is......chamfered. Bummer. I'm going to try and contact Sealed Power to see why they don't have the correct picture for the piston.

Bummer, the chamfer means that you can't get true quench off which limits dynamic compression ratio to below 8.25:1 with premium fuel.

That is too bad.

Those pistons will probably give you 7.5 - 8.0 compression.

I would not run them, but that's up to you.

You should be able to get the correct pistons w/out that big chamfer.

I personally had used those same style pistons but were forged TRW's. At the time (I was young) I had told a shop to order me 307 high compression flat top TRW forged pistons, well, they did not, I got stuck with running those pistons & was really disappointed in the engine output, sluggish throttle response etc.

Part of the reason I tried all those different manifolds, 2 & 4 bbl carbs, carb spacers etc, trying to get the combo to work, well it didn't.

It did not run good until I installed the correct 307 flat tops, then I was over 10:1 compression. My head had been shaved/milled/surfaced.

Those knuckle heads did not know anything about how to get an inline 6 to run good.

I was young & ignorant, lesson learned.

MBHD

That's definitely not the news I want to hear! I still have to have my head work done, would milling it down help any? The 250 pistons are dished, I can't imagine that they are going to be much better on compression and I don't want to dish out the money for forged pistons just to get a higher compression. Maybe I'm SOL.

I just talked to my machinist and he hasn't decked the block yet. Does anyone know the measurements of max allowable decking? Sorry if my terminology is incorrect. Trying to squeeze all the compression I can! Max I want is 10:1

You should keep the decking of the block to a minimum, because it is already pretty thin compared to other engines, and has a weak spot at the front left head bolt that usually is cracked. The head can be cut a good bit, but expect other issues to start compunding it you cut an excessive amount. In a race prepped engine, a half a point of compression can make a difference, in a stock street engine, the difference couldn't even be measured. Since your stuck with the dished pistons instead of being able to upgrade to flat tops, there really isn't much gain to be had at this point that will be of any benefit.

Can you return those cast pistons & get the better 307 cast pistons?

It would be worth it to try.

Your compression is going to be really low, lower than stock.

MBHD

Can you return those cast pistons & get the better 307 cast pistons?

It would be worth it to try.

Your compression is going to be really low, lower than stock.

MBHD

I agree with Hank. That would be the best scenario for getting your compression higher.

What/where are the better 307 cast pistons? I've checked Summit and Jegs with no luck. I have no problems sending the pistons back (if Summit will allow) as long as I can find some replacements.

This thing is starting to get closer to seeing boost...

What/where are the better 307 cast pistons? I've checked Summit and Jegs with no luck. I have no problems sending the pistons back (if Summit will allow) as long as I can find some replacements.

This thing is starting to get closer to seeing boost...

I do not have any catalogs here.

If the pics are correct. Then these are the ones to get.

http://www.ebay.com/itm/Chevy-307-Sealed...7c71a72&vxp=mtrMaybe these?

http://www.ebay.com/itm/68-73-Chevrolet-...4b2734d&vxp=mtrOr ?

http://www.ebay.com/itm/1968-1973-Chevy-...0c847c6&vxp=mtrOr ?

http://www.ebay.com/itm/Federal-Mogul-TR...0934453&vxp=mtrSeeing some boost could be a good thing, & an easy way to get a bunch more power, just keep the boost low w/cast pistons & other preventative measures to prevent detonation.

MBHD

None of your links worked for me... I'll have to try them at my home computer later.

Strange, they worked before , but not now.

HMMM

Alright, I asked the first Ebay listing if it has a chamfered edged. It's listed as Sealed Power piston and our book only shows 1 option, the ones I have. The second listing is the same part number I have and the same stock photo as on the Federal Mogul site for the piston number I already have so I'm going to pass. The third listing I asked if he would split the set into 6 pistons since it is around $100 more than the ones I currently have, although I don't currently have rings. Hope to hear some good news, although I leave for my military training tomorrow I'm hoping I can stay on a computer and get this stuff straightened out.

First listing already replied! Unfortunately, it does have a chamfered edge.

Second listing response

I cannot guarantee that on this piston. F-M tends to change styles from time to time without telling us..........just go with it being square cut, and if there is a champfer then that's a plus. It's a stock type piston at a fair price. Thanks, Don

Third listing response

No Sir, our pistons for V8 engins are offered in sets of 8 only.

Grumpy's

I was hoping for some better news, back to the drawing board.

They probably phased out the lesser popular 307 piston over time so they wouldn't be wasting resources offering 2 types and only offer the one style(chamfered edge)piston now. Think about it, how many people actually spend money to rebuild a 307.

Probably just the straight restoration crew.

Well, it just so happens that I received my "Modern Engine Blueprinting Techniques" book in the mail this afternoon. While looking through block decking I found the formula to figure out zero deck. 1/2 stroke + rod length + piston compression distance. I'm sure this isn't news to many of you, but it seemed perfectly timed to me.

My inputs came to be (.5 X 3.53125) + 5.7 + 1.655, totaling out to be 9.12065. I'm not around my parts, so the stroke was based off Wiki for a 250, rod length was from this page

http://users.erols.com/srweiss/tablersn.htm#Chevyand piston CD was from Summit Racings specs on the ones I just ordered.

Should I tell my machinist to deck it to 9.12? Would that be a good starting point?

I'm sure some of my writing may seem simple to the more experienced inline crew, but I'm just learning as I go here. I would like to thank everyone for the help so far, it's been great!

That really isn't how shops do it, and by doing so can open up a huge door of liability. You have to physically install the crank in the block and all other components in their respective cylinder bores once everything is final machined and check it that way.

I personally do not like to take much off the deck. That is why the Forged flat tops I offer have a taller CH of 1.670.

This usually means .015 is needed to be shaved with my pistons.

With a stock type piston, can you imagine taking .035 or more from your block? These blocks are thin, don't sacrifice strength in the deck.

I do not know the original deck height.

So, a shop would do it how? Install crank, put piston at TDC, measure deck, remove what is necessary?

I currently have my block at the machinist, but my crank, rods, and pistons here. I'm sending the pistons up to him for boring the cylinders, but I don't have the 250 crank yet. I was hoping to have the block work done, then down the road bring the rotating mass to be balanced.

I should mention my machinist is an hour away. One of the downfalls of living in a small town in the boonies.

I do not know the original deck height. That's one of the doors of liability that is opened up by saying, "Here, cut this block to this dimension."

So, a shop would do it how? Install crank, put piston at TDC, measure deck, remove what is necessary? Yes, this is the only accurate and correct way to do it as you eliminate all assumptions based on theoretical dimensions. But bringing each piston to TDC is only half of the process, as each piston is checked in several locations for deck height. And some of them may also have to be cut to correct the deck height along with the block

I currently have my block at the machinist, but my crank, rods, and pistons here. I'm sending the pistons up to him for boring the cylinders, but I don't have the 250 crank yet. I was hoping to have the block work done, then down the road bring the rotating mass to be balanced.

I should mention my machinist is an hour away. One of the downfalls of living in a small town in the boonies. Then it would be best to gather all the parts first, and then proceed with everything all at once to eliminate excess spending and potential mistakes as well as trips back and forth.

Hmmm... ironically trying to spread costs out by machining in sections would cost more in the long run.

Most shops don't like engine builds to become projects, they like to keep the ball rolling and get it done once they start.

Mitch, for what it's worth my 1980 stock truck engine has a chamfer also. Please correct me if I am wrong but won't the increased compression height and lack of dish help some with compression? Mitch were the pistons that came out of the engine chamferd? Another question that hopefully someone with more knoledge than me can answer, does a chamfered edge kill off quench even at 0 deck height? Jay 6155

Mitch, for what it's worth my 1980 stock truck engine has a chamfer also. Please correct me if I am wrong but won't the increased compression height and lack of dish help some with compression? Mitch were the pistons that came out of the engine chamferd? Another question that hopefully someone with more knoledge than me can answer, does a chamfered edge kill off quench even at 0 deck height? Jay 6155

As I understand quench, the chamfer will kill it just like a dish since the air/fuel mixture will squeeze out between the flat top and head, but at the chamfer the lack of squeeze will counteract it. So you can't get the extra dynamic compression out of it, most sources estimate that you can go between 8.25:1 and 8.5:1 with proper quench.

True, you can have ideal quench and higher compression, but poor piston design and still not have as good of an engine output compared to an engine with less compression, but good quench and good piston design. All the pieces of the puzzle have to work together to be beneficial or you end up with more equally less.

I think that I get it. When the piston gets to the top of the stroke with a chamfer the "squish" goes 2 ways, part of the charge goes the right way toward the combustion chamber to create turbulance and part goes the wrong way towards the chamfer. This (if I understand it corectly) would have the same effect as not as much quench with a straight edged piston. Like .040 with a chamfer is maybe the same as .060 without one even if the 2 compression ratios were the same. Am I on the right track? Jay 6155

I managed to get a little time on the computer during my training. I received an email from Federal Mogul, the valve dishes and chamfer take up a total of 2.76 CC's. Should help me being able to calculate things, however I'm out of commission on this project until the beginning of June, so for now it's just info.

Thanks a lot Mitch. Can someone tell me how much loss 2.76cc would be or please point me to a forumla to figure it? Thanks Jay 6155

I just use this one to plug numbers into and get static and dynamic:

https://www.uempistons.com/index.php?main_page=calculators&type=comp

If I am doing this correctly, with a 0 deck height the difference would be about .25 of a point of compression loss compaired to a flat piston. Please feel free to corect me if I am wrong. Jay 6155

Just picked up a complete 250 engine to steal the crank out of. I took out the crank and will be bringing it to my machinist soon. I have lots of spare parts now!

I just used Summit Racing's compression calculator. Going with a cylinder head volume of 72 CC's (I won't know for sure until I see which head I'm going to use and if it needs planing), bore of 3.935, stroke of 3.53125, 2.76 cc dish, .041 compressed head gasket size, and 0 deck clearance I come up with 9.49:1 compression ratio, which is exactly where I want to be. Can someone verify my findings, or am I missing something again?

Now that I have my 250 crank, I should be able to bring it and my rods up to be balanced. I can also have the deck height set accurately since I will have my rotating assembly there. I may ask the machinist to check the deck measurements out of my own curiosity to see how close it is to the "assumed" measurements I had earlier.

I would again like to thank all who have helped thus far. This project is years away from being anything, but it's fun to plug away at and since I'm not in a rush I have time to figure out more details.

All the parts are at the machinist except for the rod bearings and main bearings. I'm waiting to hear if the crank or rods need machining before I order them. Starting to get slightly excited, although it's a little bit away yet.

Alrighty, in what little free time I have lately I've been browsing the web dreaming of parts. I found a great deal on a cam, the Clevite MPG/Performance (.273/.282 @.004, .461/.491, 194/204 #.050, 110 LS) and was curious on everyones opinion on this.

My engine is going to as close to 9.5 as I can get it, I plan on doing a lump port on the head, as well as a performance valve job and possible larger valves. I have a Clifford intake, although I may consider switching to a Offy, and I plan on running a TBI injection. I may run roller rockers, but that's somewhat undecided, and I will run headers, although I don't know if I'm going cast or tube.

It's going to be a summer driver, I'm not concerned with huge amounts of power. Honestly, a lot of what I'm doing is for fun/experience more than anything. I'm trying to create an efficient setup that has a little more power than stock. It'll be run through a T-5 and 3.4ish rear end, tire height around 28-29.

Do you guys believe this would be a good cam for my goals/set up?

Not a bad choice. I got one of those for a near-stock 250 build I was planning just in case, still sitting new in the box.

I used that same grind on our 289 Mustang, still gets 20mpg highway thru an auto trans and runs over 87mph in the 1/4, very happy with it.

Of course, given your engine that little cam will leave a lot on the table but as an everyday cruiser car, better to undercam than overcam.

Thanks for the reply Deuce! I will definitely not be using the most of the engine with that cam. Most of the mods I'm doing are in the name of efficiency. The compression is about as high as I can go while staying on pump gas (91 octane locally), so I'm getting the most "bang for the buck" there. The lump port and valve job will help make the air flow "easier" which should increase volumetric efficiency, although I might have too much volume and be sacrificing a bit of intake velocity. The roller rockers will be reducing friction, which is increasing horsepower without adding additional fuel making it even more efficient. Although I could go strictly for efficiency with an even smaller cam, I do want it to have a little snort and growl to it! The fact that it's on a very good sale doesn't hurt either!

If anyone else has helpful hints or critiques, throw them in! I'm trying to learn as much about these sixes as possible.

Just got a call from the machinist. He said it would take .175 to zero deck it, which is too much. I told him to take off whatever he is comfortable with. We shall see!

Are you sure he's measuring it with the new (250) crank?

You have the wrong crank or wrong pistons.

Just confirmed it again, 175 thousandths. He is going to check the stroke of the crank to see if I was sold the wrong crank.

So the compression height of the 307 pistons are 1.655, the compression height of 230 pistons are 1.780. Am I mistaken to believe I would have been better off with 230 pistons? That would bring my deck height from .175 to .050 which would be much better.

Currently

Block - 230

Crank - 250

Rods - 230

Pistons 307

I show compression height of the 250 piston at 1.655, same as the 307 piston. So that would put your deck at .030"

Actually I have 1.675 for some 307 & 327 pistons, that would bring it even closer to .010" deck.

Either way, if your deck is .175" something is wrong, that would jive with using a 230 crank and 307 or 250 pistons. Should be easy enough to measure the stroke and find out!

Actually I have 1.675 for some 307 & 327 pistons, that would bring it even closer to .010" deck.

Just wondering who is going to bore to 4.0" & use 327 pistons?

MBHD

So... my fault, sort of. The engine being sold as a 250 was, apparantly, not a 250. The machinist checked the numbers and it is a 230 crank. This sucks to say the least. I should have checked myself, but I was in a rush to get it apart and up to the machinist... that's what I get for trusting someone!

New (re-manufactured) crank is ordered and on the way to the machinist. Not a good day...

Actually I have 1.675 for some 307 & 327 pistons, that would bring it even closer to .010" deck.

Just wondering who is going to bore to 4.0" & use 327 pistons?

MBHD

Actually I have wondered about this -

Since the six and SBC are the same bore spacing, and the SBC comes at 4.000 bore and goes to 4.030 or even 4.040 if youre lucky, why cant the sixes in general take a 4.000 bore? Are the walls deliberately thinner? I guess so, I will have to recheck my drill-bit data but I know the space between cylinders on a 350sbc is pretty small.

Maybe if you did a sonic and lucked out, will any of the sixes take a 4.000 bore and still have .100 wall left?

People have done it.

My friend Douglas has in Brazil, but the engine let go & his was just for racing only.

He also was using a low percentage of nitro methane fuel.

The walls are too thin to go that much of an overbore.

I would not recommend it for street use.

You could hard block fill the whole block might work for racing?

MBHD

Hank,

Yup now I remember. The drill bit for a 350 Chev is about 1/8", so a perfect 350 block with no core shift would have a cylinder wall thickess of

(4.400-4.000-.125)/2 = .137" - .020" roughness = .117"

So at 30-over your 350 walls would be .102" thick, maybe even .082" if you had some core shift.

The 230 six I measured had a 13/64 drill slip in between cylinders thru the freeze plugs. So at 4" bore, the wall thickness would be

(4.400-4.000-13/64)/2 = .100" - .020" roughness = .080"

So a Six bored to 4.000" would have walls of .080" in a PERFECT block with no core shift, and as thin as .060" in a more typical core shifted block. That's too thin.

So the 230 cylinders ARE cast thinner than 350v8 cylinders.

Not sure on the 292, I will see if I measured any.

Not that any of this affects Mitch, he just needs a 250 crank!

I enjoy reading your posts, don't worry about a little wander of the thread especially when it's thinking of trying something new or different.

That being said, I will probably have a freshly ground .010 over 230 crankshaft for sale in the future along with a set of main bearings for it. Still angry about the whole deal, money is already tight since summer time is when I catch up on house renovations. Just shingled part of the house and the whole garage, along with new aluminum soffit and fascia. Grrr....

Just received word from my machinist, it is at .055 deck height with no deck work being done so far. I told him to deck it as low as he is comfortable with.

According to my calculations, if it stayed at .055 and I did no head machining, it would be 8.5:1 compression.

If he decks it to .035 deck height and I take 2cc's out of the combustion chamber, it'll be 9.02:1 compression, which would be pretty good in my book.

I'll know more once he gets done, for now I'm just hoping he isn't overzealous and I'm not mis-calculating!

.055 DH is huge. I like to keep the DH as strong as possible. That is why my pistons offered on my site have taller compression height.

What piston are you using? The .055 seems like a bunch.

Hank,

Yup now I remember. The drill bit for a 350 Chev is about 1/8", so a perfect 350 block with no core shift would have a cylinder wall thickess of

(4.400-4.000-.125)/2 = .137" - .020" roughness = .117"

So at 30-over your 350 walls would be .102" thick, maybe even .082" if you had some core shift.

The 230 six I measured had a 13/64 drill slip in between cylinders thru the freeze plugs. So at 4" bore, the wall thickness would be

(4.400-4.000-13/64)/2 = .100" - .020" roughness = .080"

So a Six bored to 4.000" would have walls of .080" in a PERFECT block with no core shift, and as thin as .060" in a more typical core shifted block. That's too thin.

So the 230 cylinders ARE cast thinner than 350v8 cylinders.

Not sure on the 292, I will see if I measured any.

Not that any of this affects Mitch, he just needs a 250 crank!

Yeah, the thickness between the cylinders is thin, but more importantly is how thick it is on the cylinders thrust side. Because of core shift and the shape of the cylinder barrel is often cam shaped, the cylinder walls are often between .150"-.180" thick on a non-Mexican block, but i've seen then way thinner before boring also. The Mexican blocks are often as thick as .230" or more(depending on core shift on the thrust side). So after an overbore, as long as you are still above .125" thick on the thrust side, this will be acceptable for a performance or race application. Filling is also better if your toward the low side of thickness.

The pistons are Sealed Power cast units for a 307. The 250 pistons from Sealed Power actually had a lower compression height!

I realize this is an inliner site, but to be brutally honest if I wanted to build a incredibly powerful engine I would go with a LS-style of engine. I actually have a 6.0 LS style engine that would push over 400 HP just by putting a regular carburetor on it, stock everything else! I am building this as "budget" as possible, except for certain areas where I can have a drastic (IMO) effect by spending a slight bit more, like roller rockers, multi-angle valve job, lump port, etc. Things that will directly affect efficiency. If I can get 9:1 compression with the cheap pistons (under $20 a piece) it isn't worth me spending bigger dollars to get it to 10:1, which is probably my limit on pump gas. I'm sure some will disagree with me, but that's just my thinking!

If you install a decked 194 cyl head you can have 9:1. But that will cost you more money towards your build.

I do not think anyone is suggesting for you to build an incredibly powerful engine, & they are not suggesting any incredibly powerful engine parts for you to purchase.

You can build this engine anyway you like to.

We are just giving you suggestions so you would glad about your engine build choices.

Anyone can throw in an LS, or SBC engine & be just like everyone else.

It is even standard practice to put an LS engine into a Mustang.

Nobody will notice your LS or SBC there are just too many of those out there IMO.

As far as making an engine efficient, compression ratio has a lot to do w/that, you might save some $$ by using cheap pistons, but by doing so you have to do other machining processes or purchase a 194 cyl head to bring the compression up to where you are going to have a more efficient engine, in the end, IMO, you are not going to be saving a lot by using the wrong pistons.

Good luck w/the rest of your build.

I don't feel like anyone is pressuring me, I just don't want people to feel like I'm ignoring their opinion either! There is just a certain path I'm going with this engine, and certain things are just not in my budget for this. I'm learning quite a bit from this site, and I don't want to offend people and bring my learning to halt.

This build is, as you pointed out, to be a little different. Yes, the '50 3600 it is going in would have had an inline 6 cylinder, so it will look, to most, like it's just a prettied up stock pickup. However, underneath the shiny engine paint and maybe a few shiny pieces on it, haven't decided yet, there will be a updated version (250 instead of 216/235) and upgraded with as new of technology that can be used. The TBI I am planning will be hidden and look like a carb to most, the roller rockers will be concealed, and the electronic ignition will look stock from the exterior. Lump ports will not be seen, the 5 speed will not be seen (aside from new shifter location) and the IRS will be hidden as well, although the bed floor may be raised. The whole concept of my build is new technology that will not be seen or noticed by most. I'm going to keep steelies on it with white walls, it'll hurt the handling but I'm more concerned with keeping the vintage look. People will know it's modified, but will almost always underestimate the severity.

Well, all that being said, I hope it's clear. I never intend to offend!

I really am just guessing for now, until the engine comes home (the machinist said it's ready to be picked up) I won't know my final dimensions. However, once I do get them, I'll be sure to pass along the info. Hell, once it's done (a long ways down the road, I have another pickup ahead of it) I even have a friend with a dyno so I can give out some final numbers. I'm not building it for power, but it'll still be fun to know.

Just to make sure I have it right. With the 295+.060 307 piston in the block with a correct 250 crank you are .055 down in the hole at TDC without anything removed from the block. Is this right? I wonder if they took a little off the top of the piston because it is .060 over. Enginetech says that they do this on their pistons. Too bad we can't know what height the pistons that came out were. Jay 6155

You are correct, at least that's what my machinist told me! In theory, you could check the 295 piston with no overbore and compare compression height to the 295 with .060 and see if it's different.

Does anyone know what the stock compression is on a 250? Going by a replacement piston with no dish or dome and my deck height, it would be around 8:1, as a guesstimate. 9:1 or more would be quite the improvement by itself.

Worse case scenario, I will still have more compression than factory which falls under my goal of updating the original engine. It'll be light years ahead of the 216/235 that was originally in it.

Thanks Mitch, Enginetech says that they cut about .010 off the top of the piston. Jay 6155

Yes, they do it intentionally to retain the stock compression when you bore an engine. Since boring an engine increases its compression, they compensate for it by a shorter compression height piston for overbores.

You are correct, at least that's what my machinist told me! In theory, you could check the 295 piston with no overbore and compare compression height to the 295 with .060 and see if it's different.

Does anyone know what the stock compression is on a 250? Going by a replacement piston with no dish or dome and my deck height, it would be around 8:1, as a guesstimate. 9:1 or more would be quite the improvement by itself.

Worse case scenario, I will still have more compression than factory which falls under my goal of updating the original engine. It'll be light years ahead of the 216/235 that was originally in it.

That's exactly the advertised static compression ratio for my '78 Camaro 250cid. I haven't cracked it open to check it yet.

Sweet, good guess me!

According to Summit Racing's website & specs, the 295 pistons have the same compression height. I suppose it's possible that there isn't a chamfer or something on the smaller pistons, but that's pure speculation.

Ordered my camshaft, I went with the MPG Performance cam. For $50 new, I couldn't turn it down. It fits with my plan of increased efficiency with a little more kick as well. If anyone else wants one, there is one more on Rock Auto. They are discontinued otherwise.

Just curious what the specs are on the camshaft?

$50 Bucks, great price. Score!

MBHD

Is this the Cleavite cam talked about on page 2? If so that is the cam I have for my build. Part # CS1033R ? Jay 6155

That looks like a decent cam,

if these are the specs.

Very mild.

Intake Duration: 194 Deg.194 Deg

Intake Lift (inches): .265"

Intake Lift (mm): 6.731 Mm

Intake Valve Lift 1 (inches): .464"

Intake Valve Lift 1 (mm): 11.786 Mm

Lobe Centerline (exhaust): 115 Deg115 Deg.

Lobe Centerline (intake): 105 Deg105 Deg.

Lope Separation: 110 Deg.110 Deg

Overlap: 45 Deg45 Deg.

Cam Type: Hydraulic

Exhaust Duration: 204 Deg204 Deg.

Exhaust Lift (inches): .280"

Exhaust Lift (mm): 7.112 Mm

Exhaust Valve Lift 1 (inches): .490"

Exhaust Valve Lift 1 (mm): 12.446 Mm

Looks like normal price is $120 & up, great score , again!

MBHD

Thats what I have. Just a little more than the Comp 240 but not as much as the comp 252. Except for lift it's really close to the "929" sbc cam. For $50 I may get a spare. Jay 6155

Y'up, it's definitely mild. If I go larger and larger, I'll lose my MPG aspect of my build and driveability! I could have stayed with a stock cam even, but I had to give her a lil more grunt...

Engine is back from the machine shop!

Clean Block - $40

Bore Block - $85

Surface Block/Check Piston Height - $100

Check Line Bore - $35

Grind Crank - $50 (Unfortunately was done before we found out it was a 230 crank)

(2)Check Rods - $10

(4)Recondition Rods - $48

Balance Engine - $110

Total Labor - $478

Haven't had the chance to tear everything open yet, currently putting the finishing touches on my garage redo. Glad to have it all back, hopefully start piecing it together in the next few weeks.

Checked main bearing clearances, all right at 0.00175. Washed block all out to make sure there wasn't any shavings from the machining process. I love assembling engines, something calming about it.

Crank and rods are in. All top rings were around .013, all second rings were around .018, all oil rings were around .019, give or take .001 here and there.

I didn't check my rod bearing clearance, didn't think about it until I had all my rods lubed up and put in. It would have been easy (and smart) to do it when I had all the parts laying there. As close as all the mains were, I'm hoping the rods were similar.

Installed the pistons on the rods using a electric rod heater, all went well except pistons 1, 4, and 5 didn't seem as loose on the pistons as the other cylinders. They do move, and after they were installed the entire rotating assembly moves easily enough, but it's just sticking in my head.

Next up, cam, water pump, and freeze plugs. After that I'm out of parts to install until funds come in.

Forgot to add, deck height came out to be around .025. According to my calculations, this brings compressing to 9.45:1 assuming a 72 CC head. I won't know my head's specs for a while, that'll be a fund raising project of it's own since it seems to be an area where great improvements can be made. Lump ports, roller rockers, larger valves, etc etc.

Is there any certain areas that these heads were known for having cracks? Something I can keep an eye out for before I send it to be magnafluxed and the like?

You should have put the cam in right after you installed the crank. The cam will hit the rods all the way in and make it much more difficult to install it after the rods are installed.

That's a lowrider for sure! Looks good.

Thanks. It has air ride, when fully aired up it's pretty close to a stock 2wd, maybe a couple inches lower. I have heavily modified the stock frame, but after a certain point it was just polishing a turd. I am going to step away from it, get my other work done, then come back and build a frame from scratch.

Small engine update, freeze plugs are in!

Very cool truck. Is it the picture or is the i5 on a slant like a Dodge slant 6? It,s very nice to see the engine come together.i am very curious to see how that cam runs. Jay 6155

It's level, it's probably the front of the valve cover that makes it look slanted. The pickup is on a slight pitch, but I took the pic level.

Cylinder head has arrived at Toms, the build has been resurrected!

Just received the head back from Tom's, along with some roller rockers and an engine stand!

Now I'm trying to achieve the correct pushrod length. The original length is 9.68". I installed them to see how they lined up

Seemed a bit short. I made an adjustable pushrod out of an old one and tried again.

Those are the pushrod at 10", which seems high to me but I've never built an inline 6, much less with roller rockers either. The block has been decked .030, Tom re-worked the head so I'm sure it lost a little, and it also has a new cam. The lifter was tack welded to stop it from collapsing during testing.

For those of you who have done a roller conversion, does this seem about right or am I way off.

Just browsing I found that the Ford 300 takes a 10.14" pushrod, and they make a shorter 10.080 version. The number is RP-3260, may be an easy to find push rod vs having custom length ones made!

By roller conversion, are you meaning roller cam or just roller rockers? You are showing a measurement of more than a .300" longer pushrod than what you started with. And by all accounts decking the block and probably the head by the amounts you mentioned should have taken you the other way. You might want to re-check your length again. You should also put a precision straight edge across the tops of the valve tips to see how closely they are to one another and make sure you don't have any too much shorter or longer than others to make sure you are being as accurate as you can be.

Roller rockers.

I put in the original pushrod, tightened down the large nut on the rocker arm until I could not spin the pushrod, then locked it with the small inner allen set screw. The first 2 pictures are what the valve looked like on full close and full open. The lifter was the tack welded one, so it can't be collapsing.

Am I doing something wrong? I was assuming so far that the different rocker arms were the reason for the change.

I use Smith Brothers pushrods. They will sell to you also. Tell them I sent you.

With the combination of:

Different rocker arm

New cam

block decked

Head cut

Head rebuilt with all new parts

It stands to reason, stock pushrod length is too short. 10" does not sound out of line to me. Each engine is different. Your pics look like the roller is centered.

All my engines use longer than stock pushrods. Heck, the 292 pushrods are getting close to 12".

Good job.

I got my pushrods from Smith bros. Great set for sure!

Found a great video on measuring pushrod length, I might re-check everything with that.

https://www.youtube.com/watch?v=o5is9BsH5OU

Alrighty, just returned from my deployment. Paid off all my loans (house, car) while I was there, and had planned on spending 1 year loan free before buying anything else so I could spend money on family trips, car parts, etc. Well, a shop came up for sale in town and it's too perfect to pass up so I'm purchasing it for my side business of restoring and customizing cars. It is across the street from my day job (auto part sales and repair) and literally less than a block from my home. Gotta love small towns! Well, I made it 3 weeks loan free anyways...

I had just started buying car parts when the shop became available, however I hadn't stocked up much for the inline. I bought a 6.0 ls engine, disassembled, for an 86 Chevy K10 I picked up for $200. Then I found a 6 speed auto tranny and ls3 top end for that same project. I bought new taillights for my 3rd gen Camaro, had all the machine work finished for my other 6.0 shortblock (all ARP, Callies Compstar rods, forged pistons, etc), etc etc.

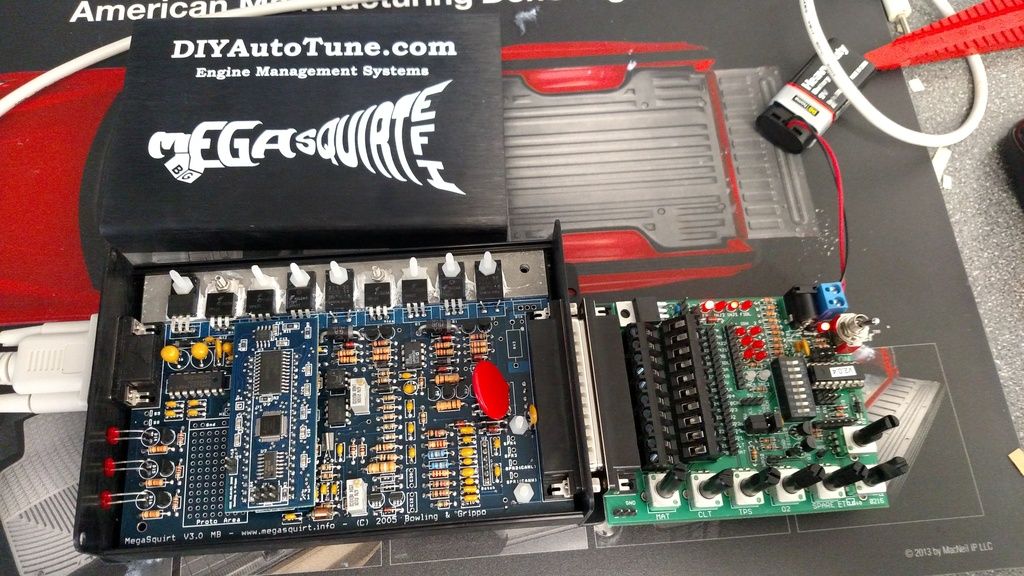

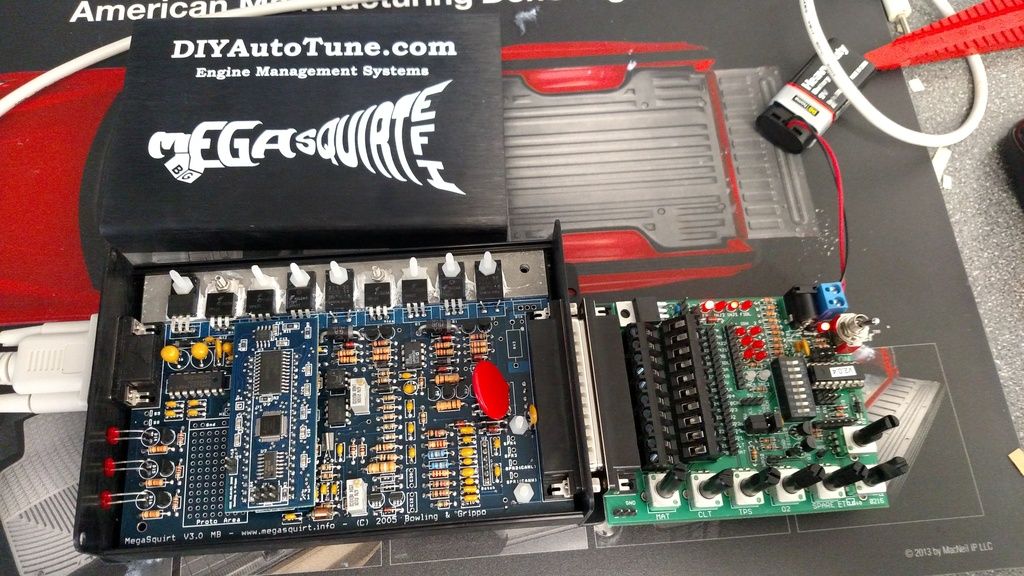

My inline six only received a a MegaSquirt 2. I bought the disassembled version because I love tinkering! Got it all assembled, set up for HEI ignition and electric cooling fan. I had planned on buying intake and exhaust manifolds, tbi unit, HEI ignition, etc etc so it would be ready to run, but the business came and took all my spare money.

After a couple months I will re-evaluate my finances and hopefully start funding my own projects. Worst case scenario, it's on a 5 year contract for deed so I'll go project free for 5 years (except labor items).

Anyways, here is a pic of the MegaSquirt 2, and a video if I can figure it out!

[img]http://i160.photobucket.com/albums/...slaut.mp4

[img]http://i160.photobucket.com/albums/...slaut.mp4[/img]

You have a bunch on the plate. Don't forget, adding a family with kids can also throw a wrench into plans. But usually in a good way.

Good luck on your shop!

I use Smith Brothers pushrods. They will sell to you also. Tell them I sent you.

With the combination of:

Different rocker arm

New cam

block decked

Head cut

Head rebuilt with all new parts

It stands to reason, stock pushrod length is too short. 10" does not sound out of line to me. Each engine is different. Your pics look like the roller is centered.

All my engines use longer than stock pushrods. Heck, the 292 pushrods are getting close to 12".

Good job.

When my engine builder measured the pushrods for my 292 and had them made from Smith Bros, He said they were the longest pushrods he's ever seen. lol

You have a bunch on the plate. Don't forget, adding a family with kids can also throw a wrench into plans. But usually in a good way.

Good luck on your shop!

I have a wife and 2 kids currently and we are going to try for a 3rd soon! Another reason for the shop is so I can have a space for the kids to play, that way I can still spend time with them.

Unfortunately, I will probably be selling this engine. I have decided I would rather pay off all my business loans right and do a build down the road when it wont have to be in the backround, so to speak. Probably will sell some of my other engines too...