Hey every one me again tried searching to no good end

Going to start building my own multi port injection intake out of alluminum

Its going on a turbo charged 292 and was curious as to runner length and intake volume and shape. I have a D shaped extrusion with oval runner and very noce velocity stacks

Does length hinder performance and the volume of the plennum is there a rule of thumb for any of this?

Thank and happy inlining

One thing, you do not want to have the end of the plenum close to the velocity stack.

There is a rule of thumb. Can't remember the formula off hand.

MBHD

Here's a recent test session with one of the original Ramcharger engineers using their formula from back in the day to create the optimum runner length.

Ramchargers Here's a Slant 6 EFI intake....effective runner length will be between 15-1/2" to 16" long. [img]

[/img]

How do you get around room in the engine bay being an issue. How much volume should the plennum have?

And how stable are intakes when they're hanging out 16 " away from the block?

Every engine depending on compression, cam and desired rpm point will want a different length ram tube.

Using pipemax for my OHC Pontiac six with my cam and compression spec's say the ideal length for the 3rd harmonic is 14.942", including the port length in the head which is between 3 and 4 inches. So a 10" intake tube. Metal, especially light weight aluminum, shouldn't have any issues supporting it's own weight as long as it's not paper thin.

The bigger question I had was if you were using a 12 port head or if your intake ports are combined? If still open then that is another whole set of crazy air flow dynamics I don't know what software/calculation would model that well.

From PipeMax.

- Induction System Tuned Lengths - ( Cylinder Head Port + Manifold Runner )

1st Harmonic= 37.709 (usually this Length is never used)

2nd Harmonic= 21.402 (some Sprint Engines and Factory OEM's w/Injectors)

3rd Harmonic= 14.942 (ProStock or Comp SheetMetal Intake)

4th Harmonic= 11.760 (Single-plane Intakes , less Torque)

5th Harmonic= 9.542 (Torque is reduced, even though Tuned Length)

6th Harmonic= 8.028 (Torque is reduced, even though Tuned Length)

7th Harmonic= 6.928 (Torque is greatly reduced, even though Tuned Length)

8th Harmonic= 6.094 (Torque is greatly reduced, even though Tuned Length)

Note> 2nd and 3rd Harmonics typically create the most Peak Torque

4th Harmonic is used to package Induction System underneath Hood

Plenum Runner Minimum Recommended Entry Area = 2.032 to 2.286 Sq.Inch

Plenum Runner Average Recommended Entry Area = 2.337 Sq.Inch

Plenum Runner Maximum Recommended Entry Area = 2.387 to 2.825 Sq.Inch

Minimum Plenum Volume CC = 525.3 [typically for Single-Plane Intakes]

Minimum Plenum Volume CID= 32.1 [typically for Single-Plane Intakes]

Maximum Plenum Volume CC = 4093.2 [typically for Tunnel Ram Intakes]

Maximum Plenum Volume CID= 249.8 [typically for Tunnel Ram Intakes]

The actual runner length also includes the length inside the intake ports, so you are likely to not have the entire length as an external dimension. But for tight engine compartments, automakers like Ford and others sometimes have a 2 pc. intake with the plenum being removable and often the runners come outward from the head by a certain amount and bend back over the engine in a U shape. You still can get the desired runner length in a tighter more compact space. Engines that rev much higher and need a higher RPM peak manifold need a much shorter runner, so they usually don't have clearance issues under the hood. I have one Slant 6 race EFI intake i've made have adjustable Ram Tubes so it can be fine tuned a little more precisely.

Look for a Ford 300 EFI upper intake on ebay and you can size your plenum around that as a baseline, since they are close to the same cubes as the 292.

This example:

[img]

[/img]

Is exactly what you do not want, the last intake runner too close to the end of the plenum.

MBHD

What does it do to the intakerunner being close?

Mine will have to be very close to the end as i have limited space under the hood now that te engine is raised an the body dropped

Here os the 16 inch runner with 3" in the hole the other 13" out not including the 4 " for the D shaped plennum extrusion

also why does a custom intake have to be 16 inches out when clifford and offy and such have short runners? is it because it is a turboed application? so many questions because i am just not understanding my apologies i get there are flow harmonics hmmm as homer would say... doh!!

This example:

[img]

[/img]

Is exactly what you do not want, the last intake runner too close to the end of the plenum.

MBHD

That isn't an actual representation of the final product, its just a teaser for the Slant guys for port spacing and to show runner dimensioning for those purposes only. The real deal won't be shown publicly until after its finalized and tested. And then probably not even on here. It doesn't even have port flanges on it or even the TB flange, its just generic, nothing more.

You've been on forums long enough to know you don't throw ideas out there or somebody else will take them.

What does it do to the intakerunner being close?

The # 6 port would not get equal flow of air to that port, it would get less air & be more turbulent.

The #6 intake port on the picture is too close to the end of the plenum.

You would want a couple of inches past the last intake port, then you can put a plate on the end of your plenum.

MBHD

also why does a custom intake have to be 16 inches out when clifford and offy and such have short runners? is it because it is a turboed application? so many questions because i am just not understanding my apologies i get there are flow harmonics hmmm as homer would say... doh!!

If you want to make the most amount of HP, you would make your intake port runners short.

The Clifford & Offy are short runners just so they will fit on almost any car or truck.

I do not know how well or how bad this will work.

MBHD

Looks like a manifold from Mr. Hotrod6? NICE!!!!

MBHD

First, and EFI intake and a carb intake have two entirely different needs. Trying to create an EFI intake using carb thinking usually doesn't equal a good intake. And EFI intake only has dry air to pass thru it, and is called a "dry" intake, while a carb intake has fuel/air mixed together and is much heavier than just the dry air in an EFI intake, and is considered a "wet" intake. The runner length tunes the intake to make its peak torque based on that determination. Read through the link of the article I posted early on to get an understanding of how it works. For a turbo 292, you will want the peak power to be around 4500 or 5000 RPM for a street engine probably, and a runner length of 15" to 16" will provide that. If you want peak power to be at 8000 or so, then a 10" to 11" runner will be what you want.

In a nutshell, the Ramchargers formula for calculating the optimum runner length for a particular RPM is as follows:

84,000/N=L, where N is the desired RPM to tune for, L is the length in inches from the valve head to the opening of the ram tube, and 84,000 is a constant. Example below:

84,000/7000 RPM= 12" runner length

Yes its an spa turbo manifold from mrhotrod6 its really well crafted! Just needs a good ceramic coating

Okay read the like and your last post scott its making more sense but danv i'm really going to have to pull some magic to get it all under the hood:0

The picture looks like paired intake ports to me, I'd be shocked if someone can calculate a runner size for that will give harmonic benefits anymore accurately than me randomly saying 4". 8" 12.324", 53". If anything I'd expect the harmonic length to either need to halved or doubled, but the port shape can't be great for harmonic tuning.

Its a turbo engine, don't over think it as the harmonic benefit will really only have a very tight range of rpm for noticeable benefit, assuming you can even figure out what the common ports want. That all said, I'm going to be building an intake for my turbo engine using the same logic and data I posted above, but if I find fitment issues, I'll shrug my shoulders and shorten the tubes as needed, writing it off as a nice idea.

**IF someone has ran real world testing (not calc's or models) of various lengths of the common port intake with similar cam spec's, THAT is the data you'd like to see and use.

Not sure how this idea will work based on a siamese intake port, but for a IR cylinder head design, it is very accurate. Many top Chrysler engineers used the Ramchargers results when they designed and developed the Hyper Pack intake manifold that has runners that are 18"+ or longer back in 1961.

Josh, the factory Ford 300 EFI intake has runner lengths that are close to 16" or 17" in length. The only reason the Slant 6 can have runners that extend straight outward is because the center of the engine is practically inline with the glovebox and not the center of the engine compartment.LOL Think of extending the runners outward about 6"-8" and then do a 90° bend upward and maybe back toward the valve cover to get the rest of the length. The Atlas 4200 engine and many others engines use this design very successfully, and have since EFI became the norm 20 or so years ago.

Well the head will be divided ad i am going to divide the runners all the way down i'll have to take pictures of the dividers i have in the head maybe i'll look at looping it around and see what i can make fit as i am limited like i said an ou can see from the pictures

Since your dividing the ports you should be in good shape then. Just check out ebay or google images for the Ford 300 EFI intake and you'll get the idea of how they get long runners to fit in a small engine compartment.

but for a IR cylinder head design, it is very accurate.

100% agree!

Since the runners are in fact divided, carry on!

so what i have learned in some of my own searches is that the air moving down a runner (depending on runner volume) gains velocity and somewhere around 300 mph is top speed before it gets restrictive to flow? correct me on that if i am wrong

so when the piston is at bdc and all the air is in the air gains inertia and crams just a little more air into the cylinder before the valve closes and when is does is send a sound wave up the runner and if it is tuned ( which is the reason for the mathematical equations above stated) because if it is tuned right is will come back at the exact time the valve is opening again.

which this seems all honky dory to me but if it is a turbo application ( obviously off idle for arguments sake) does all of that just go out the window since the turbo is forcing air into the cylinder instead of tuning the runner to have all its ducks in a row for optimum flow?

This is an manifold designed for naturally aspirated, the best inline design IMO. It's a 4 cyl, but just add a couple more velocity stacks & its for a 6 cyl.

http://www.bing.com/images/search?q=turb...electedIndex=11Try & make something similar, but your velocity do not need to be offset side to side, they can be all in a row & the velocity stacks should be raised up from the plenum floor for best flow.

Also note is has a tapered plenum, larger in the front & gets smaller towards the back cylinders.

Note the short runners. Something you should go with.

Something of what your "D" plenum should look like w/raised velocity stacks.

http://www.bing.com/images/search?q=turb...lectedIndex=240

Does the tappered plennum gain velocity to the rear stacks? And why does a rais velocity stack and better flow then flush? I would think it would cause trbulance down the plennum am i backwards on that?

Great pictures thanks hank

Mine is made this way.

I made it this way, just because it was easier to fab.

I believe it will work just fine, but have read having the velocity stacks raised up from the plenum floor is ideal. Better/more equal airflow to all stacks.

Having a tapered plenum is supposed to create equal flow & have equal temperatures to all velocity stacks IIRC.

MBHD

How much tapper should the plennum have is there a rule of thumb per foot or somethjng of the sorts?

Not sure about the taper rule of thumb, but here is a good shaped plenum to get you an idea.

http://www.ebay.com/itm/2JZGTE-intake-ma...45107da&vxp=mtrSince you have a "D" shaped plenum, I would only cut a small chamfer like this one.

http://www.ebay.com/itm/2JZ-GE-FFIM-SUPR...686cd19&vxp=mtrWorrying too much about all these dimensions, plenum taper, velocity stacks even with the plenum floor is really not too much of a concern unless you are really going to try & set a new record.

Same for the turbo exhaust manifold, having individual exhaust header tubes will give you the most amount of power over your SPA manifold, but how much more?

You can have a very, very ugly log type exhaust manifold, that can look like it cannot flow well at all & still make a lot of power.

I had told Douglas to have his fuel injectors installed right in the center of the velocity stacks about 1-2" above the stacks.

He did do part of the idea, but his injectors were a bit further away from the velocity stacks than what I wanted.

If you look at the video, you can see one set of 6 injectors directly over his velocity stacks, IIRC, his other six were placed in the intake runners.

He still made great power & ran w/a blown up engine before the end of the 1/4 mile, & ran a 8.6 @ 165 MPH.

Here is his old car .The yellow Chevy Opala w/a 250 inline Chevy 6.

https://www.youtube.com/watch?v=R825adfxyq8&index=53&list=FLC47WILAMLZIhl7pE8DUelgMBHD

A lot of unnecessary worrying. More importantly, the runners should have taper in them instead of just being straight. The plenum being tapered isn't a deal breaker, there are many that are and aren't, and the runners being tapered are of more importance than the plenum being tapered. The radius' increases airflow and is necessary to help the air make the transition when changing directions and going around corners.

I think i will do a gradual tapper in the plennum runn the velocity stacks flush

But how sever does the tapper have to be on the runners?

Have you guys heard of air boundry on none tapered runners?

The taper doesn't have to be extreme, it just helps keep air velocity from stalling. Again, look at any factory EFI intake design. Many that you see are the result of millions of dollars of R&D testing, and will provide an excellent comparison. This will eliminate having to try and go off in a tangent to create one for yourself. The Ford 300 EFI intake is an excellent comparison because it is near identical cubic inch, and they did what Chevy never did do, and that is they actually made one from the factory.

Starting from scratch for a new design though, its helpful to have a 3D modeling software package that can do stress analysis and air flow analysis like I have, it will save hundreds of hours in chasing dead ends and will help get you on track the first time out.

Mine is made this way.

I made it this way, just because it was easier to fab.

I believe it will work just fine, but have read having the velocity stacks raised up from the plenum floor is ideal. Better/more equal airflow to all stacks.

Having a tapered plenum is supposed to create equal flow & have equal temperatures to all velocity stacks IIRC.

MBHD

I think for your intended use of wanting good upper RPM power your intake will work real good for that.

I'll have to trade aome pieces woth ross machine racin but i will be able to get the taper into the runners

Mine is made this way.

I made it this way, just because it was easier to fab.

I believe it will work just fine, but have read having the velocity stacks raised up from the plenum floor is ideal. Better/more equal airflow to all stacks.

Having a tapered plenum is supposed to create equal flow & have equal temperatures to all velocity stacks IIRC.

MBHD

I think for your intended use of wanting good upper RPM power your intake will work real good for that.

That is what I am looking for. Cross my fingers.

MBHD

I don't think you have to worry, it looks well thought out.

So today i cut and tappered the plennum send back my velocity stacks for round ones ordered some u bends so i can make the turn around to gety runners to length now i jist need to find some sheet alluminum to make the dividers out of

Well have pictures of the plennum here soon

So how does manifold runner length vary from the formula if you are using a carb?

I am not sure maybe scott will chime in i know it is affected by the fuel vapors in with the air because its has more mass and inertia i don't think the harmonics are quite as bad since its going through air with more density and the runners can be shorter? I could have it all backwards..

What kid of fuel spark control are you guys using multi port intakes

I know there are a few of you out there!

Thanks ahead of time

Happy inlining

Im sure there is some baseline for calculating this, but early manifold manufacturers usually just took a factory manifold and added more carb flanges or just grafted a 4 bbl flange onto them without any additional engineering or modifications to the runners or plenum and called it good. Until Clifford came along and began increasing the runner size and plenums in their manifolds that this trend changed.

So for the Packard, I would likely follow the same path by using the factory runner length and volume since this is going the be a relatively low RPM engine, and just add additional carb flanges or have a one off intake cast for it.

What kid of fuel spark control are you guys using multi port intakes

I'm using a Megasquirt 3. The details can be found on my Hacking together an OHC thread.

How har was it to get the mega squirt set up?

It's my third install so find it fairly straight forward and simple. The hardware side of things (fabricating the sensor brackets, mounting the trigger wheel, etc) the difficult side as I'm not much of a fabricator and certainly not a mechanical engineer.

What makes the megasquirt simple in my mind is it works with dang near any kind/brand of sensor for each input. It's not picky.

IMO, the hardest part of the install is setting up the ignition settings, once the ignition settings are setup it's pretty simple. This was the first engine I fired up with a megasquirt without previously running it with a carb, and it was also the first engine I setup that I ran distributorless without previously had running. I was quite pleased when the first time I commanded fuel and spark at the same time it fired up instantly.

Is there more involved running an hei unit i wiuld like to go megasquirt on my peoject jist haven't obsorbed enough info on it to pull the trigger

You need to use a 10 gauge wire. Needs to see full battery voltage.

MBHD

You have to use 10 guage on everything?

You have to use 10 guage on everything?

Just the power lead to the distributor.

I have pretty heavy wire i don't remember what i had ran to it when it was carbed and being broke in

What kind of destructions come with the ms3 are they good if any?

What kind of destructions come with the ms3 are they good if any?

All kinds if you tune it wrong! =P

The main source of all information for the megasquirts is the first link below. Their are so many options because it can fit dang near everything you have to be willing to learn or willing to write large checks to someone to do the work. I like learning. I recommend downloading Tuner Studio for free, and loading up the latest version of MegaSquirt in it and just go through the menu's to familarize yourself with it. That can be downloaded at the second link. If you like fully analyzing data and want to fully customize the gauge layouts I think the registration cost is well worth it. It can be purchased well after you have it running and know you want to stick with it(datalogging and reviewing is free, but there are extra auto-tuning and data processing features available). The third link is where I buy my MegaSquirt and associated wiring harness from. It's a bit more money, but I like the relay board, and keep hounding them for an improved one, but I have used them on two installs and tried my hand on my Firebird to go without it (another first for me with the OHC L6), and I'm on the fence between setting up my own relays and fuses versus using the relay board. I can certainly do it cheaper than purchasing the relay board and cable, but it was nice having it centralized, particularly for my first install.

http://msextra.com/http://www.tunerstudio.com/https://www.diyautotune.com/

Randal, I may have a relay board that I first had on the Stude. If I still have it, you can have it. I will check and see if it's still in the shop, will let you know.

As a total novice I built a Megasquirt for a project that never got done. The MS was completed and I fired my old '89 GMC with it but it was my computer skills that made things tough for me. Some day I'll get back to it. Although the number of pieces and tiny solder joints were intimidating I did it. If you can read the instructions for a model car kit you can do this. You really don't have to understand how it works just follow directions and learn as much of the special vocabulary as you can so you know how to ask questions and understand the answers.

nice beater motivated me to do it i just need to figure out how the fuel injection work i think i will have to run semi sequential on this with three pairs of injectors 16 52 34 hope fully Randal will chime in and let me know

really would like to tune my own engine although it may be difficult i think with determination i will be able to work this one out! hopefully it doesn't take forever

some stuff i read makes me feel really dumb... haha but on the other hand some things i really understand;) will ms work with a regular hei unit to control timing? and do i need a crank trigger and cam or just crank if I'm going semi sequential also ports will be divided just fyi

nice beater motivated me to do it i just need to figure out how the fuel injection work i think i will have to run semi sequential on this with three pairs of injectors 16 52 34 hope fully Randal will chime in and let me know

really would like to tune my own engine although it may be difficult i think with determination i will be able to work this one out! hopefully it doesn't take forever

some stuff i read makes me feel really dumb... haha but on the other hand some things i really understand;) will ms work with a regular hei unit to control timing? and do i need a crank trigger and cam or just crank if I'm going semi sequential also ports will be divided just fyi

Tuning is easy if you do it in steps.

First step is simply getting the engine running. It is far easier to tune from rich to lean than lean to rich. Lock out the timing on the timing table (or there is an option under ignition that says "fixed timing" or "Table" and set it to fixed, to like 15*). Set the required fuel value based on your injector and engine sizes (it calculates it for you with that information).

I like to set the lower left corner of the fuel table to a flat 30, then the top right corner to 100 and use the interpolate tool from about 2,000rpm up and 50kPa up. Then fire it up. You'll probably have to pedal it some to keep it running, but as soon as the AFR's start reading you'll be able to tell if you need to increase or decrease the 30. Once it is at a stable idle at a reasonable AFR (like 13:1 to 14:1), let it warm up to operating temperature. It may lean out as it warms up due to the warm up enrichment turning off. So watch for that and richen it up as needed to keep it running. While it's warming up, check the timing with a timing light and verify it matches what the MS is commanding, if not make the necessary adjustment to the Trigger Angle until it matches.

Once warmed up, you're ready to tune. You may need to adjust your kPa and RPM bin's to match your engine's operating range. I have no problem sharing my fuel, spark and AFR tables, but understand the kPa and RPM bins may need shifting. For reference, I started my Firebird up on my Skylark's 455 tune, lol, then adjusted from there.

When in doubt, the MS3 has very quick AFR correcting abilities, so you can technically turn on the EGO corrections, set the controls to a lot of authority and come on at low temperature and it'll meet the AFR's you specify in a table. That can get you driving fairly quickly, but is a LARGE crutch. I may of done that to get my Firebird driving shortly after start up =)

Back to tuning, it's pretty difficult to hurt the engine at idle and low rpm and loads. Get the AFR's working nice with gentle increases in throttle while in neutral/Park. Once there, you'll get a feel for the slope that the fuel table will want. You'll want to turn the timing table back on if you are controlling timing and have a very conservative table, like no higher that 32* for now. Then put it in gear and make sure it keeps the AFR's decent and doesn't stall by adjusting the fuel. Then give it a little engine braking, adjust, a little more, adjust, and that'll get it so with gentle throttle from a stop it should drive nice. From there go for a drive and be gentle on the throttle (don't put yourself in a place you may have to hammer the throttle, like a busy street if you can help it). If you have a helper, have them adjust the fuel as you are driving or you can datalog it and see afterwards where it leans or richens up and adjust it. This will get you a decent tune at part throttle and up to say 3,000rpm depending how you drive it.

Now you'll want to work on the accel enrichment from the AE menu. I use pure TPS when one is available. From an idle, hit the throttle at various rates and watch the dot on the graph/chart. If the engine leans out or *POPS*, move the point up where ever that dot went, if it bogs, move the point down. Once the accel enrichment is decent, back to tuning fuel.

By now you should have a decent idea on the slope of the fuel table and make a decent estimate of what WOT and high RPM fuel values should be. So raise them up to match the slope, then add another five to ten points to it to make sure it goes very rich. Then go out and test by watching the AFR's or datalogging and reviewing, slowly lowering the amount of fuel until you are happy with the AFR at WOT across the rpm range. Then you can start on the timing table.

This process can take a full day or spread it out over a week or two depending how much perfection you are trying to achieve. Even my first time EFI'ing a car (my Buick) I was driving it around town the afternoon of the morning I got it first started.

If you want the MS to control timing with an HEI it can do it in either batch fire mode by simply hooking it up to the pickup coil, or if you want semi-sequential you have to have a crank trigger. If you want full sequential you'll need a crank trigger and modify the HEI to be a cam sensor.

The semi-sequential pairing is fine. And actually, since installing the engine in my Firebird my cam sensor has a fault and isn't reading, so I've been running in semi-sequential mode (it does it automatically when it can't read the cam) since I started driving it. I've been too busy/lazy to figure it out, but I'm suspecting the sensor failed based on my minimal troubleshooting of it.

Tuning is easy if you do it in steps.

First step is simply getting the engine running. It is far easier to tune from rich to lean than lean to rich. Lock out the timing on the timing table (or there is an option under ignition that says "fixed timing" or "Table" and set it to fixed, to like 15*). Set the required fuel value based on your injector and engine sizes (it calculates it for you with that information).

I like to set the lower left corner of the fuel table to a flat 30, then the top right corner to 100 and use the interpolate tool from about 2,000rpm up and 50kPa up. Then fire it up. You'll probably have to pedal it some to keep it running, but as soon as the AFR's start reading you'll be able to tell if you need to increase or decrease the 30. Once it is at a stable idle at a reasonable AFR (like 13:1 to 14:1), let it warm up to operating temperature. It may lean out as it warms up due to the warm up enrichment turning off. So watch for that and richen it up as needed to keep it running. While it's warming up, check the timing with a timing light and verify it matches what the MS is commanding, if not make the necessary adjustment to the Trigger Angle until it matches.

Once warmed up, you're ready to tune. You may need to adjust your kPa and RPM bin's to match your engine's operating range. I have no problem sharing my fuel, spark and AFR tables, but understand the kPa and RPM bins may need shifting. For reference, I started my Firebird up on my Skylark's 455 tune, lol, then adjusted from there.

When in doubt, the MS3 has very quick AFR correcting abilities, so you can technically turn on the EGO corrections, set the controls to a lot of authority and come on at low temperature and it'll meet the AFR's you specify in a table. That can get you driving fairly quickly, but is a LARGE crutch. I may of done that to get my Firebird driving shortly after start up =)

Back to tuning, it's pretty difficult to hurt the engine at idle and low rpm and loads. Get the AFR's working nice with gentle increases in throttle while in neutral/Park. Once there, you'll get a feel for the slope that the fuel table will want. You'll want to turn the timing table back on if you are controlling timing and have a very conservative table, like no higher that 32* for now. Then put it in gear and make sure it keeps the AFR's decent and doesn't stall by adjusting the fuel. Then give it a little engine braking, adjust, a little more, adjust, and that'll get it so with gentle throttle from a stop it should drive nice. From there go for a drive and be gentle on the throttle (don't put yourself in a place you may have to hammer the throttle, like a busy street if you can help it). If you have a helper, have them adjust the fuel as you are driving or you can datalog it and see afterwards where it leans or richens up and adjust it. This will get you a decent tune at part throttle and up to say 3,000rpm depending how you drive it.

Now you'll want to work on the accel enrichment from the AE menu. I use pure TPS when one is available. From an idle, hit the throttle at various rates and watch the dot on the graph/chart. If the engine leans out or *POPS*, move the point up where ever that dot went, if it bogs, move the point down. Once the accel enrichment is decent, back to tuning fuel.

By now you should have a decent idea on the slope of the fuel table and make a decent estimate of what WOT and high RPM fuel values should be. So raise them up to match the slope, then add another five to ten points to it to make sure it goes very rich. Then go out and test by watching the AFR's or datalogging and reviewing, slowly lowering the amount of fuel until you are happy with the AFR at WOT across the rpm range. Then you can start on the timing table.

This process can take a full day or spread it out over a week or two depending how much perfection you are trying to achieve. Even my first time EFI'ing a car (my Buick) I was driving it around town the afternoon of the morning I got it first started.

If you want the MS to control timing with an HEI it can do it in either batch fire mode by simply hooking it up to the pickup coil, or if you want semi-sequential you have to have a crank trigger. If you want full sequential you'll need a crank trigger and modify the HEI to be a cam sensor.

The semi-sequential pairing is fine. And actually, since installing the engine in my Firebird my cam sensor has a fault and isn't reading, so I've been running in semi-sequential mode (it does it automatically when it can't read the cam) since I started driving it. I've been too busy/lazy to figure it out, but I'm suspecting the sensor failed based on my minimal troubleshooting of it.

If you are not too far from Beater, maybe you could help him get the Megasquirt working.

Just a thought.

MBHD

Glendale is like 12 hours from here. I'm not close to anything =/

Beater is in northern nevada i'm in glendale haha thanks mate really appreciate all the jnfo you just layed out there i am going to print it for my records

To keep it short since its bed time for me what is batch firing and out of the 3 injection options which woul be best for me semi secquential and have 3 pairs of two injectors?

Is there a lot o wiring for the ms? Whoch version of ms would i need the 3 to controle timig an fuel and be able to handle boost? I am not escared to solder so i can get a disassembled kit for less monies

Thanks a head of time!

Glendale is like 12 hours from here. I'm not close to anything =/

I believe Beater lives in Northern Nevada.

Might be closer?

MBHD

Glendale is like 12 hours from here. I'm not close to anything =/

I believe Beater lives in Northern Nevada.

Might be closer?

MBHD

D'oh, right. I seem to recall he is near Reno (5 hours), but if he's around Elko (2.5 hours) or such I'd gladly lend a hand.

I seem to recall him saying Carson City is just down the mountain from him.

So i have been looking i am goin to call today bit i think a mega squirt 2 will beable to handle fuel and spark for my project its also a bit cheaper and i THINK that it will allow a knock sensor aswell for insurance!

But i don't think my gm 4 pin hei will work for will except the computer controled spark i think i need a 7 or an 8 pin gm hei

Its kind of a pain to find info on megasquirt

My vote would be to skip using a 4 pin, 7 pin or 8 pin module all together.

Ignition settings are by far the most confusing aspect of MegaSquirt. Once the ignition input and output settings are right, everything else is cake.

http://www.msextra.com/doc/ms2extra/MS2-Extra_HEI.htm7-pin HEI

8-pin HEI

http://www.msextra.com/doc/ms2extra/MS2-Extra_Dizzy.htmhttp://www.msextra.com/doc/general/tachin.html#vr

http://www.msextra.com/doc/ms2extra/MS2-Extra_Dizzy.htmhttp://www.msextra.com/doc/general/tachin.html#vrUsing points for a tach signal

or run without the power wire and use the internal pullup jumper on the MS board

and the coil wiring for spark control

Or my favorite, how it's wired in the full wiring diagram and two wires to the pickup coil in the distributor (grey line to pin#24)

It IS written in a way over complicated manner. That is because MegaSquirt is designed to be very flexible and work on dang near anything. For our simple old engines:

You only need two wires to control timing. Pin#24 is the tach signal in from the points, pick up coil, crank trigger, etc. Then Pin #36 goes to the negative side of the ignition coil to control dwell and spark timing. Done. Make sure the jumpers on the MS board are set up for the input you are using (just stick with the VR input, it handles practically anything), and set your coil dwell to 2.5ms and you'll be golden.

The 7 and 8 pin modules just add extra wires and an extra module.

Hmm, I hadn't posted this picture in this thread yet.

This is the setup I've been running in my Skylark since 2009, though in 2012 the pickup coil was converted to a cam sensor, but looks the same as pictured. Wire and all.

So you need to turn a points distributor into a reluctor? Or what i like the wiring diagrams thanks silver buick but how does it actually get to the spark? Are you saying it can control a 4 pin hei dizzy?

The lobes on a points distributor is a reluctor, just a mechanical one. Connect Pin#24 to the points.

You can control timing with a 4-pin HEI if you ditch the 4-pin module and connect Pin#24 (like in the picture) to the pickup coil and ground the other side like in my distributor.

^^ Both these methods tell the MegaSquirt RPM and when a cylinder is at TDC.

To get spark, connect Pin#36 to the negative side of an ignition coil. If the cylinder type, just connect to the negative side terminal, if an HEI, spade connector to the Negative side terminal (left side, closest to the cap). On both coils, hook a switched 12v to the positive side. It's best if the postitive side is relayed from the Fuel Pump wire, so the coils don't stay energized with the key on, engine off. It can burn them up (much like a points distributor can).

Then follow the setting of the Trigger Angle directions to get the timing commanded to match the timing seen with the timing light. Once they match you can control ignition timing.

Do i have to do anything to the mechanical and vaccum portion of the hei?

Yes, both have to be disabled.

You can simply unplug the vacuum line on the vacuum advance to disable it, or you can remove it like I did in my photo.

The mechanical advance needs to be locked out. I removed the weights and drilled holes and inserted roll pins to lock it out. Others have wire tied or installed ridiculously stiff springs in place of the springs. Another nifty method I've seen is using a small piece of aluminum and drilling 4 properly sized and spaced holes in it and sliding it over the posts the advance springs would go on. Locks it right in place and the rotor makes sure it doesn't go anywhere.

These two modifications go for any engine, points or electric, that utilized a vacuum and mechanical advance system.

Alrigh well i might work on that then thank you so much randal you really have helped me a lot i think i'll stick woth m 4 pin as i already own it and just jump the modual and make that the reluctor

Sure am lucky you are here

Do i nee to keepthe compasitor in the dizzy also i see you only have one wire coming in is that still on the plug for the cap or where is that coming from?

That one grey wire goes to Pin#24 on the MegaSquirt, like the diagram. No capacitor needed.

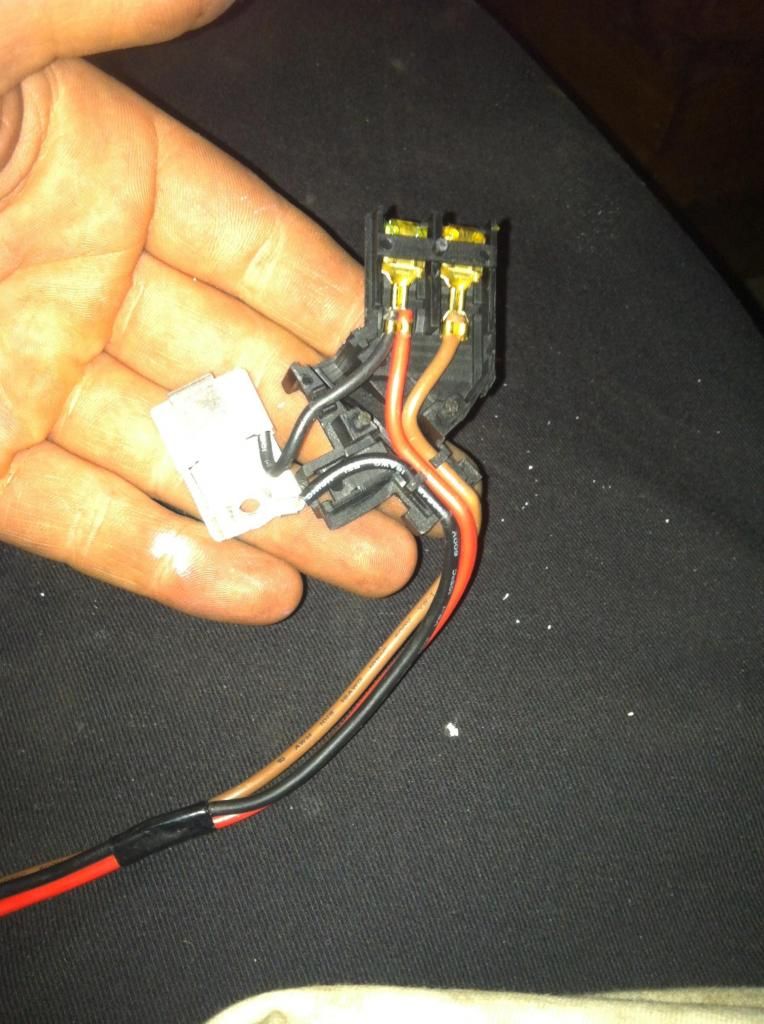

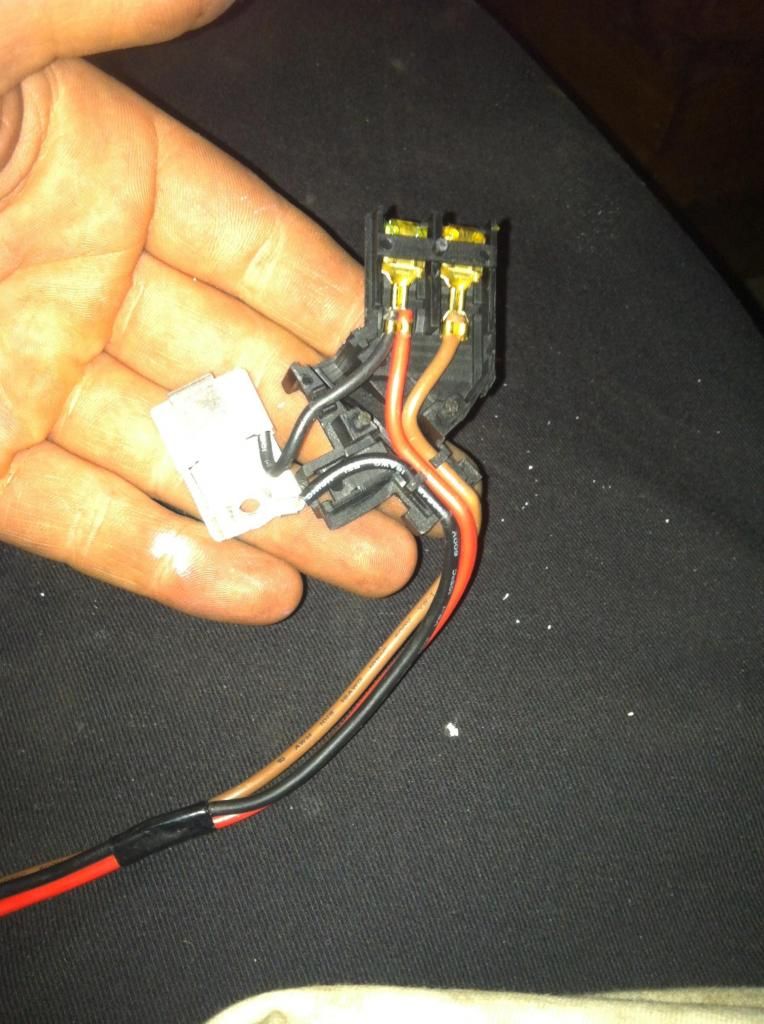

Cool so i can tap into the brown wire and run it to pin24 i'm waiting for me mea squirt to show up just looking for projects to passthe time!

No, that piece there requires the 4-pin module to plug into. Get rid of that whole assembly in your hand, and get rid of the module. Use a spade connector on the wire that will go to Pin#24 and slide it into the pickup coil's plug like I did. It doesn't really even matter which side of the pickup coil. Then the other side needs to be grounded, which you can see I did with a short piece of wire and a spade and hole connector. It ain't pretty, but it works.

Your pickup coil will have a bigger plug than mine in the picture because mine is a 7-pin pickup coil. The ONLY difference between the 4-pin and 7-pin pickup coil is the size of the plug.

Actually, I forget, are you controlling fuel at the same time your are upgrading spark control? I recommend picking either fuel or spark to control first and then move to the other one once you are comfortable with the one you have started on. Makes it so you only have to troubleshoot half the system if problems arise, being as it's your first one.

If you just start with fuel control, and leave timing control alone, aka mechanical and vacuum, 4-pin module, for a while, then just connect Pin#24 to the TACH port on the HEI cap and call it done until you go to upgrade for spark control. Then follow everything I've been saying in previous posts for spark control. If you are leaving the carb in place for a while, then do spark control first.

I guess is would help of my truck was drivable too wouldn't it thats why i figired i could tune it while i am gathering the parts tht make my truck go and stop

It's just easier to troubleshoot if you have problems getting it running, or to stay running, if you are only controlling fuel OR spark. My OHC engine was the first engine I started from scratch, without previously running the engine, that I was controlling both fuel and spark. It was my third MegaSquirt install.

Looking at some of my YouTube videos, here is one from when I went distributorless on my Buick 455, you can see the grey wire coming off the pickup coil, which is now acting as a cam sensor for my MegaSquirt.

http://youtu.be/iGSrYLsvxPM

Sweet video! Maybe when i'm done building my intake deviders i'll slap the head back on for good( i hope install my cab intake and exhaust mani get the spark control working while i finish building my intake an fuelinjection/ turbo and see about getting the fuel going then! I still need some minor brake parts to put my clutch in a drive line and a steering column i need a whote board in my shop!!

Oh and since i'm going for spark first i built a piece pf alluminum to stop the mechanical advance and have a piece made that holds the reluctor where it hooks up to vacumm advance

Mechanical shown here

Haha its pretty rough but its held in by e clips an you won't see it anyways

Hot rodding is best when it's home made. Pretty is nice but not necessary.

Hot rodding is best when it's home made. Pretty is nice but not necessary.

I live by that rule =P

Yeah i'll have a picture up of the vaccumm advance brace tonight! Mega squirt should e here soon

Randal is it easier to get the cable from the mega squirt to the relay board or to jist get them both and wore it your self?

It's far easier to purchase it if you aren't hurting for the money or adhering to a budget.

With a 8' engine wiring harness kit from DIYautotune, and a couple of the end connectors (also sold there for cheap) there is more than enough wire to make the engine harness and the relay board cable. Just have to be extra careful making sure you solder the pins to the right place. The numbers on them are hard to read.

Glad to see you check in on me beater!

I'll probably buy a harness and cable ends i was wonderin if this is the cable you can buy is it already wired for spark and fuel to the relay board?

http://www.diyautotune.com/catalog/megasquirt-relay-cable-p-47.htmlThen you wiul just wire whats needed to the relay board

Yup! If you look at my Firebird thread, and see the pictures of my Skylark, you can see my relay board mounted on the firewall behind the air filter.

Here is an old picture of my relay board before I went full sequential injector and distributorless (aka a lot more wires). This is ALL the wiring that my V8 had for the EFI. Keep in mind, each sensor has two wires, the signal and the ground, and looking at this picture, it was actually taken during the brief time I used a 7-pin module as that is what the relay on the firewall was for (so ignore the relay!).

The blue and green wires at the bottom are the two injector driver wires, and the two black wires at the top are the +12v to the injectors (in my more recent pictures you can see I changed the wires to yellow). The purple wire is the fuel pump control wire (use it to control a relay that activates both your fuel pump AND +12v to the ignition coil). The 4 wires alternating blue and green with white stripes above the fuel pump wire are the 4 wires to the idle air control valve (IAC). Then I loose track of which color wire is which of the two temp sensors, and which three go to the throttle position sensor (it's all labeled on the board). But pictures like this make it easy to hook it back up (by color) after I re-install the engine. You can see the grey wire with the sheathing pulled back, and that is the wire from the pickup coil. Then one of those other wires is the ignition control wire output.

Awesome picture i'm super excited to get the ball rolling!

Was it hard to solder ip your mega squirt? I have soldered a bunch before just don't want to spend the money and mess it up

For a little bit more money, they can provide one for you already done.

MBHD

No, it's pretty simple, especially if you've soldered things before. I've assembled three of them now and the last one took me maybe 5 hours total to do. I set a card table up in the living room and worked on it after work while watching TV or a movie. The trickiest part is a few connections are very close to each other, so take care that they are not bridged, and having some copper solder wick to undo connections is handy.

My work station. The laptop has the assembly instructions on the screen (http://www.megamanual.com/ms2/V3assemble.htm) This is very much like LEGO's for adults.

First night, after setting up the table, etc. And actually nothing here is soldered yet, just pieces put in place.

Second night.

Third night done with a MegaSquirt 3 and expander board. This is the unit in my Firebird today.

The bottom side. The black and white wires are the 4 idle control wires.

The deal that I think is great about assembling it yourself is how much you learn about it's construction. The directions are set up so you assemble it essentially by circuit type. Power, communication, intake and coolant temp, Spark, Fuel, MAP and accessory inputs. So if something is wrong with one of the inputs, you know where to look on the board (and refer back to the assembly manual). If you read my thread, and I mis-wired my alternator on my Firebird (always wire it directly to the battery!!) and I fried my Megasquirt's power system. I opened the case, checked the power circuit's components with a simple digital multi-meter, replaced a couple capacitors and diodes, and I was back in action. I knew exactly where to trouble shoot. Having a relay board on my Firebird probably would of prevented the toasting of my MegaSquirt. I like the extra layer of protection the relay board provides.

The key take away is, this isn't rocket science. One thing though is, if you solder it yourself, you'll want to purchase one of the Stim/Jim Stim's too. Which is additional costs. If you plan on possibly doing more than one build, its worth getting the stim, if you think this will be the only megasquirt you'll likely ever use, it may be worth saving your money on the stim and put it towards a pre-built unit. I've built three, so the cost of the stim has been amortized over three units and I'll probably build at least one more if not two (my Centurion, and possibly one other car). Or if you don't mind the cost, I recommend assembling it yourself.

Have not checked lately, but how much more for one already put together for you?

MBHD

Complete 445 unassembled 279

The way I would look at it is if you have a problem and you soldered it together, they more than likely won't warranty it. If you purchase it ready to go and have an issue, they probably will warranty it.

Complete 445 unassembled 279

I have little time to do things as it is.

Plus, if you have no experience, you could cook the components, damaged the board, there is some finesse involved when it comes to soldering, not everyone can do it.

Personally I would not mind doing it myself, but like I said, $166 more all assembled, best way to go. I.M.O.

Save up a little more $$$ no worries.

Plus like CNC said, if there is a problem after they assembled it, you can get it taken care of.

MBHD

Or, if there is a problem with it after it's assembled you fix it yourself and save the week and a half sorting out the shipping, the testing time, etc.

There are only three or so things that can fry the processor, and it's spelled out in the assembly guide. And also as it's being assembled there are testing steps, aka "Do not proceed until 'X criteria' is met." So by the time you finish assembly it's going to work or you only have to back track five or so steps.

I'm probably approaching 100,000 miles on my self-assembled MegaSquirts. 80,000+ on the Skylark alone and the only time I've had a hiccup was with my recent alternator wiring screw up with the Firebird, which would of toasted anybody's fuel injection computer and likely wouldn't be covered under a warranty. I had it back running that same night because I just opened the assembly guide and started doing the power system test, like it was a new build, and back tracked it from there.

I'll look and see if i can find someone selling one localy but if not i think i will still buy a unassembled kit i'm not extremly worried about a waranty specially if i can fix it by testing

So if i am running the reluctor from the hei do i need to run a crank siglan as well? And do the reluctor points have to be ground down besides one or just as is?

Also will of know that its registering at cam speed not crank speed? I seen in your diagram it was one or the other

Nope, no crank signal needed for batch fire. It will trigger the ignition and fuel off the distributor reluctor just fine.

I'm a little confused about settin up batch fire i know its a little ways down the road but still i ordered my MS 2 v3 on saturday with a relay board hopefully it will be here this week so i can get started on it i honestly need a more reliable carb than the one that i have i made it work for break in purposes but it just isn't going to fly for down the road type tests lol got a long way to go and a short time to get there.. (Whistles tune)

Batch fire only needs one trigger.

Sequential needs two triggers.

Sequential was made to further reduce emissions.

Batch fire & Sequential will give you the same amount power output.

MBHD

http://www.hotrodders.com/forum/sequential-fire-vs-batch-fire-injection-47271.html

Batch fire will get you 95% of the HP. Sequential with AFR balancing will get you another 3%, proper injector timing phasing will get you another 2%.

Basically on a 900HP engine you can pick up another 40HP with sequential and proper injector phasing. In tight racing classes that can be the difference between winning and losing. On the street, not so much difference. There are obviously some small variances in the percentages gained depending on the engine and horsepower output, but my friend has had pretty repeatable results with racing Hemi's and engine master's competition. Both competitions where every last HP is searched for.

For the street it is tough to beat the simplicity and improvement over a carb that is gained by TBI injection.

http://www.vems.hu/files/Port_sequt.txthttp://www.sdsefi.com/techseq.htmSequential injection attempts to only spray fuel while the intake valve is open for the cylinder that is about to fire, which in most cases is only possible at low engine speeds between idle and low speed cruising. It can have benefits in emissions, drivability, and fuel economy at these low engine speeds.

Batch injection (which is what the MegaSquirt-I and and most MegaSquirt-II versions do) does not attempt to spray only when the valve is open. It's a fact that at higher engine speeds you won't have enough time to spray all fuel while the valve is open, making this somewhat pointless, particularly for a performance oriented application. At these higher engine speeds 99% of sequential systems (exceptions being race only systems with super massive injectors) cannot spray all of the fuel needed while the valve is open anyways, and sprays it both while the valve is opened and closed, very much like a batch system such as the MegaSquirt I and II. We've dyno tested several cars with using batch fire and sequential injection on the same motor. Peak power was the same without using individual cylinder tuning. The sequential fire setup did run a bit more smoothly at idle and at light throttle angles, however.

That said, the MegaSquirt III system with the MS3X Expansion board or MS3-Pro will do full 8 cylinder sequential fuel and ignition. If you're looking for the absolute best possible emissions and fuel economy, as well as the ability to fine tune each cylinder individually, then the MS3 system is the way to go.

There is generally no significant performance difference with a sequential system over a batch system unless you use individual cylinder tuning. There can be minor emissions and fuel economy benefits at very low speeds though. If your tuning budget allows for individual cylinder tuning, it may be possible to pick up 3-4% more power depending on how much cylinder to cylinder variation your engine has.

So basically, if you have a poor designed intake manifold that gives more air to some cylinders, or cylinder heads flow unequally, you could gain more power, but,, if all cylinders are getting the same & equal amount of air, you are not going to benefit any power gain from using a sequential over a batch fire F.I.

Hopefully my ms 2 gets here soon so i can start assembling it and get the engine running again i need a push of motivation as the trucks has been sittin as i rebuild it its tough to want to work on it till i see others driving theirs

So i got my ms ll in and relay board got the relay board together last night a heavy base stand with gater clips and a magnifying glass helped a lot! Was starting in the main board and it asked about jumpers for a iac stepper motor? Thats what i need help on and the ignition stepper they have umteens amout of info and you really have to dig haven't been successfull finding any diagrams yet

That is why I suggested getting am assembled unit for only $166 more.

Don't have to go through the hassle.

Good luck with that.

If you stick with it, you will get it done.

MBHD

Its not a hassel at all and even with the assembled unit this might be an "option" that you would have to solder on anyway..

I guess to be more specific is do j need to hook up the jumper for the iac stepper it couldn't hurt?

And on the ignotion with the reluctor running the spark do i hook up sj10 to ign

Or do i hook it up from sj10 to ignin woth ignoit to ign on the pcb it is step 22 on the v3 assembly manual

Maybe randal woll chim in before i'm in work

Thanks in advance

Sounds like you're using the same set up as I am.

The four wires electrical taped together are the IAC wires. You can see the jumpers in the picture. The long yellow wire above the IAC wires is the JS10 to IGBTIN, then jumper IGN to IGBTOUT. Then at the bottom jumper TachSelect to VRIN. And in the middle of the board TSEL to VROUT.

IMO, ignition setup is by far the hardest thing on the MegaSquirt, fortunately 99% of the setups can be set just like I have it jumpered because the VR circuit can process Hall sensor's just fine.

Randal

thanks so much for the photo i had started assembling the board and just as i got to that step and started searching you came on and posted saved the night got the power circuit set up!

Randal

thanks so much for the photo i had started assembling the board and just as i got to that step and started searching you came on and posted saved the night got the power circuit set up!

hey randal i am running a mac computer and hyperterminal doesn't work as it is a windows product are you using windows? also my computer that is a windows doesn't have a db9 connector or a db25 are you using usb to db9 adapter which one and what driver?

thanks for any more help you can give i really appreciate it

also do you have to have a jimstim do to all the comtests and such or can you power the ms without it some how?

You can probably do the power and com testing without the stim, but I am unsure how.

I use a USB to serial port adapter. I'm not sure which one, but it was about $20, so I'm sure as long as it's not like a $2 chinese special it ought to work fine.

I use windows. XP, Vista and now Windows 7 are the three operating systems I've used. I know zilch about Apple stuff, but starting with Vista Microsoft stopped supplying Terminal as a standard installed program, so the last two I've assembled I've had to search the internet for one and I think I used a trial version last time that expired after a month.

Well i am just having one heck of a time trying toget the communication cable to work plugged away at it a bot last night so i can test the mega squirt i don't think i have the communication com/ driver set up right

Is this on the Mac? I don't know crap about Mac's =/

Perhaps triple check the various parts installed for the communications circuit are in the right place and diodes and capacitors are in the right orientation and move on. The next step is with the MS chip in place and using the boot loader and Tuner Studio. Then you just need to know what the comm port number is and tell TunerStudio. The bootloader will search for the comm number if you tell it too. Worse case, if you can't get it to communicate at that point then you back track through the comm check. If it communicates then, then you know it works. No Hyper Terminal needed if it works.

Just watch for the warnings in the power circuit assembly about what can fry the processor and double check those conditions aren't happening before installing the processor. There is ONE pin that needs power for the MS2 chip and not the MS1 and mixing them up would fry an MS1 chip. Otherwise, I think it's pretty straight forward.

I finally got it the driver for the cord wasn't working right got it through the comm test and tuner studio got the chip flashed and all the way up to step 50 then i went and whacked some golf balls and relaxed hopefully i get off work early tomorrow and can put some serious time into it tomorrow feel good about it And i ammvery excited!

No ended up using a windows based laptop

Das what i'm sayin buddy!!

Well now that is t not 120 degrees out side its time to get back at it!!

Just cleaned out the garage and got all of my intakes parts together gunna take them to my shop and start doing a little after work peace work time for parts on my truck;)

Also got the mega squirt done only took 9 hours including the fuse block and stimulator took 3.5 hours to get the DB9 to usb cable to bind what a pain in my well i'll let it be

Happy inlining !

Bringig thos one bak from the dead!

Hey all

Was curious at to what soze injector bungs to buy 14mm or 15mm?

I am not sure on what size body of injector. But be sure to get injectors that can supply enough fuel. My engine has 42LB x 6 of them.

Was looking at the bungs i guess i should look at i jectors and see what size they are for 42 pounds! Are yours bosh or any partiular brand?

Thanks tom!

Mine were for Ford Motorsports. Probably by Bosch.

Did you get them off summit or something?

I'll have to look them up and see if the mega squirt will accept them iirc it had some sensors it was specific about but i could be way wrong its been known to happen before

MegaSquirt will run just about any injector. Some peak and hold injectors will require a "peak and hold" box, and low resistance injectors may or may not require some jumper or resistors to ensure the injector driver doesn't short out, but that is dependent on which Megasquirt setup you have (MS3 Pro, MicroSquirt, MS3.0, MS2.2, etc).

Practically anything below 80lb/hr injectors are likely just plug and play with the MegaSquirt. I run cheap-o Accel injectors from Summit on my Skylark and Firebird. The Skylark has 44lb-hr injectors and the Firebird has left over 32 lb/hr injectors in it, which will probably need replacing when I put serious boost to it, but for now are way oversized for the application.

What about these ones silver buick?

Summit Racing Street & Strip® High-Flow Fuel Injectors SUM-240042-1

That one looks mint. Standard high-impedance. Just install and go.

If this is your first EFI rodeo, remember the MegaSquirt triggers the injector by supplying a ground signal, so one pin gets a full 12v, and the other pin goes to the MegaSquirt. They aren't sensitive to which pin gets the 12v or the ground.

Awesome thanks for the help again hopefully here in a week or so i'll have em in. Then to figure out the fuel rail hmmm

How are tyou guys drilling the fuel rails out jist regulardrill bits some sort of srep bit or do you have the actuall bit for fuel injectors?

Happy inlining

Throttle body choices

Okay so here we go I am just about done building my intake I know it's been forever but you know how life gets I the way

So at ross machine racing the D shaped plenum I

Extrusion I bought they sell a throttle body for it but it's 90 mm

Its a ford 5.0 l throttle body that bolts up to it that they make in house now I am only going to have 2 1/2 intake piping from the turbo through the Internet cooler and to the intake that's a 1 inch jump from 2.5" to 90mm

Will it loose noticeable velocity at that throttle body into the intake I found d a calculator and it was saying 65mm what it's just a smidgen over 2.5"

If I do use a 65 mm throttle body it will still be going into the same plenum that will fit the 90 mm

So what do you guys think about that I know bigger is not always better it's a multi port design devided I that are ports ms2 fuel control

Plenum is tapered towards the ear to keep velocity up as it travels down the Plenum maybe 6 lbs of boost

If you go that much bigger on throttle body size slow down the gas pedal ratio or you will likely encounter an "all off / all on" effect under your loud foot.

How are tyou guys drilling the fuel rails out jist regulardrill bits some sort of srep bit or do you have the actuall bit for fuel injectors?

I just bought an appropriate size drill bit (17/32"?) and used my drill press. The idea is not to drill them all the way through so you can start with say a 1/2" bit and drill into the fuel passage, then use the drill press to stop a bit short of the fuel passage with the larger drill bit so the o-ring has something to stop against. Then I simply used a dremel to bevel/round the edge, then followed it up with a light sandpaper and scotchbrite pad to keep from cutting the O-rings when installing.

My opinion on the throttle blade is bigger is okay, so long as your throttle linkage geometry doesn't cause that ON/OFF problem with the gas pedal. I wouldn't worry so much about air slowing down from the charge pipe to the plenum so long as the runners are of sufficient volume and length for the cylinder.

When you use (3) 40MM Weber sidedraft carbs on a Chevy inline, they have a total of 240MM of throttle bores, so I don't think having (1) 90MM throttle bore would be too large.

A friend of mine has 4600 cfm worth of throttle body on his N/A small block chevy, lol. Runs 9.60's in the quarter and drives fine down the street. As I said, I wouldn't worry too much about plenum speed as long as you have good runner volume.

Nice fuel Raul Randy I like it!

Thanks i'llike Ullman he trigger on the end pieces for the throttle body then

What's a good volume for the runners the Plenum is big enough then it will be to a 2" rouND bend then grafted into a 2 1/8 by 1 1/4 oval that will be devided to split the siamese heads that have deviders

So it will be 1 1/4 tall by 1 and 1/16 before heading into the port

And Randy what do you mean by on off problem with the gas pedal like sticking?

Sorry ftf I didn't see your post you stated the on off as wellike I am just using a stock pedal 1972 gmc truck to a cable driven butterfly with tps

Randy that will work with the ms2 correct as long as it has a test sensor?

What do you guys think and or have done about holding in the intake deviders? I was thinking maybe I could Weld a small plate to the devider drill and tap through the mouth of the intake and lock tight them in I am worried about them falling over or losing nuts or and seperate pieces I have see photo attached for drilling location

Both sides of the flat spot into a small plate on both sides of the devider no twisting or falling no bolts or nuts to be eaten

Throttle body and adapter for the Plenum came in today time to get that welded in and the injector bungs

every thing is at the welders hes been off hunting but o can't wait too see it getting almost impatient but i have to be hope to hear from you guys !i can't see the forum from my phone for like a month now so only when i get on to the computer can i chit chat

happy in-lining

Just going to leave this here

Tapped the rear Plenum last night for vacuum ports just need to tap the end of the fuel rails for an fittings

Looks good Josh, I think I mentioned to you a few months ago that I figured about the time you got this far with yours mine would start showing up.

I know I was so excited to see yours I have another 292 I need built for a long term reliability

I had two welders try to build this they got no were so I just did it my damn self self taught my self to tig Weld and all sorts of other things

Thanks I am 1 devider away from putting it on permanently and a bit of wiring a battery and should have a running truck again

How soon till yours are for sale?

Thanks Randal!

Josh, not too far out on having them ready. I'll leave the TB end as a custom operation to accomodate the actual TB the user has in mind, since most all habe different bolt patterns.

Perfect, a blank flange and a ready to "port to size" hole.

I had you in mind when I did that.

You are a saint

I like them I am excited and definitely buying one for my next project hehe