Just thought some might be interested in the build I have started on. It is a military 302 GMC that was overhauled in 1963 at Ft. Riley Kansas. I am going to bore it .060", have purchased aluminum rods from Howards Rods. Have intake and exhaust flanges water-jet cut, I am going to turbocharge with efi. It will go into my 1953 Studebaker and race on the salt flats. I am in no hurry to finish the GMC as I am still racing the Stude with a BBC engine for now..Will keep you informed. Cya

GH,What a great Homepage. The straight 8 cars are awsome. I look forward to future information and updates. Very much enjoyed your Bio section; And those records. Wow.

Welcome to this Forum, Gary!

That Buick is an inspiring piece, and some of us are eager to see what you will do with the GMC.

God's Peace to you.

d

Inliner #1450

I bought a steel cam from Doug Robinson, he sent it to Chet Herbert Cams, Donnie Johansen will grind it for a turbocharger. Am in the process of ordering pistons from Venolia, timing set has been ordered. Am going to grind clearance in lower end of cylinders for aluminum rod clearance. Also bought a copper head gasket from Doug Robinson. Cya

GH When Doug runs out of copper head gaskets or you need a different thickness. Order them at

www.Husseycopper.com ..They even have a part# for them..Good luck. JD

gh

i am in the planing stage of doing a 302 my self. how long are the rods you got ? are you going to grind the crank for smaller rod bearings or use stock size bearings ?

i have had time to looks around but my self i was thinking of using chevy big block rods that way i could off set grind the crank to get a zero deck.

any ideas would be helpful !

Dew,

The stock rod is 7.0 inches long so to get a decent piston compression height, and a light weight piston, you need a rod about 7.75-8.0 inches long. I'm sure you could get a set of BBC rods made that long but they would cost $$$$.

Plus the BBC rod isn't wide enought. I did like GH did and ordered a set from Bob Johansen. In fact I had him offset bush the small end of the rod and will end up with a 7.850 inch rod.

302 info:

I flowed the stock 302 head (983 casting)with stock valves and got the following flow numbers:

Intake 175 cfm @ .500 lift(gag,puke,spit)

Exhaust 115 cfm @ .400 lift.

Both the intake and the exhaust leveled out at those lifts and wouldn't flow any better even though I flowed them to .750 lift.

Now I have to figure out how to get more flow or

buy a bigger rubber band for the dragster.

Ron are you related to a Denny Golden out of St. Louis? He raced on the salt flats a few years ago, I don't know him but have talked on the phone with him.

Gary, Denny Golden must be from another clan. All of my family is in the Kansas City area and Grand Junction, Colorado.

By the way how is your 302 Jimmy coming along?

Jerry Gilpin says "Hello".

Ron

Ron, my machinist was closed last week, will get the block and crank back today. Pistons was ordered last week. Now I can grind clearance for aluminum rods in the lower end of the cylinders. Timing gears are here now. Rick Pope, a freind of mine will cut the O ring grooves and install the stainless steel O rings in the block. After all that, I will be on hold until I receive the pistons. Tell Jerry and Ruth I said hi. There is an indoor car show in Joplin, Missouri sometime in February, I think I will take the Stude with the twin turbod big block chevrolet to it, maybe.. Cya

Nothing new to report, had to take time to remodel bathroom, it has been on my honey-do list for quite some time....Cya

Gary,

I still haven't got my rods from Bob Johansen yet. I called yesterday and he said they should be shipped next week. The block is bored and I'll be starting on the head this week. Lots of things to do. I'm going to build an aluminum roller rocker/shaft assembly. I want a 1.8:1 rocker in the engine. I hear you got a lot of ice from the storm going thru this weekend.

Ron

Lots and lots for ice, no power since Friday 8:30 PM, trees down all over the 5 acres, knocked down power from transformer to house, running insert fan with 12 Volt battery out of race car using an inverter. Things are looking up, insurance adjuster was here yesterday as was the electician and the power company came late yesterday to cut limbs off power lines on their side of transformer. All work on cars have come to a screeching halt... Cya stay warm.

Power has been restored, received pistons from Venolia yesterday. Will start grinding lower end of cylinders for rod clearance today. Will Egge sell a partial gasket set???

Gary, I only buy what I need. Pan set, side plate, valve cover, & timing set. Chev 6 will do for that one. All are from Fel Pro. I have bought single 302 head gaskets from Napa also before I went to oopper. Rock Auto is good on the net but their shipping is a little high for me. I make all the rest.

You've never said what you are going for a rear main seal. I still like rope; others like the 360 Dodge.(with a little work) Fergusons have made some big block Ford work. With a dry sump or a vacuum pump the rope sill works for me. If you are going for rope tell the crank grinder to leave the serations? on the crank in tact....Good Luck..J.D.

JD, I've had good luck using the old style rope seal and the crank has been turned down for the rods and the mains are std. and the cross hatch is still in the rear seal area. I started grinding for rod clearance, getting close, but not quite there yet. Is there any danger of grinding too far on the side opposite the cam shaft??

The one block I had for aluminum rods was ground only in the area where it was needed. As I remember it was not that much. The grinding and smoothing went up into the cylinder about an 1" and arround on to the botton about 3/4" I don't remember how deep but 3/8" would be close. The rods were never touched. When I went to use the block for another engine I found it to be cracked up in one of the cylinders probably happened when the crank broke between # 4 and 5. I bought the engine with the car. The only component I have ever used was the injectors. Some day I'll see if the Racer Brown cam and the head works.

Here it is the last day of February, still sawing downed trees, hauling and burning brush from last months ice storm. Bathroom remodle complete. Just finished grinding lower end of cylinders for aluminum rod clearance. Block goes back to the machine shop today for finish bore and hone to fit new Venolia pistons. Will get O ring grooves cut in the block and Stainless steel O rings installed next week. Will take all rotating pieces to be balanced next week also. Finally making some progress.

Gary

What class are you going to run in? If you run in XXO turbos and EFI are not legal. If you run those you will have to go heads up against others with the same C.I.

$UM FUN, I will be running in the XO/BGALT & XO/BGCC in the modified catagory not the ventage class with a 53 Stude or the classic class with efi. I am pretty sure I am correct. Cya

Gary, I believe if you run XO or XXO they will class you as a vintage engine and the turbo and the EFI arenít legal in that class. Itís a shame but thatís the rules as they are today. I would double check with the powers to see if this is the case. Maybe JD will chime in on this one.

A 53 Stude and a XO motor, WOW! What more can you say!

Turbos are not allowed in vintage bodys with vintage engines. They are allowed with all other classes. Bottom of page 15 in the last rule book. Gary is OK. I would add a diaper to catch the pieces.:^)

There have been countless inlines in Studies over the years. I'm glad to see another one. J.D.

Here's the latest update on the 302 GMC. Just got the block back with the 0 ring grooves cut. Sent it to the other machine shop to be honed and cleaned one more time. Still waiting on the cam from Donnie Johansen.

Got the block back yesterday, honed, cam bearings and freeze plugs installed. I painted it and now I will start assembly. Still waiting on Donnie Johansen for the cam.

I started on the assembly Saturday. Didn't get very far, ARP sent the wrong size nuts for the main studs, 7/16" instead of 9/16". Talked with them yesterday, they will send correct size today.

Can't wait to see this one. Gary is the only person on here I've ever met. He had the Buick at the Tulsa stop of the 2000 Power Tour. Back then it had a homemade tunnel ram. Thousands of cars there, and it was the only one me and my brother stopped to look at. I think my brother Ross has hung out with you at Kansas City Goodguys show with his primered/flamed/blown 55 Chevy. I thought he was just this cool guy with a unique car, and here I was talking to the famous Gary Hart!

The crankshaft is in and the rods and pistons are in also. Still waiting on the camshaft. Ready to put in the stainless steel "O" rings in the block. I have sent the head to the machine shop to have larger valves installed.

Any chance it will be ready for Bonneville this year?

That was not the plan. I will run what's in the Stude this year, hoping to get into the 2 club with the twin turbo charged BBC. Then I will install the GMC.

Gary, made a nice "new engine" check out pass at El Mirage this weekend running the rear gear I'm planning on using to use at Speed Week. Saw no reason to have the normal El Mirage gear for one pass.

A pleasant surprise showed up when my son and 2 grandsons came down to pick me up and said we are going to impounds. I broke the 1997 record by 1/2 mph. Deliberatly had it rich not to hurt it; plugs said that too. The boys said they thought I was going to take it easy, I told them I did. Friends who were watching at about the one mile said I shifted it smooth and easy and it never missed a beat. Saving overdrive for Bonneville.

My last ride for a while. The son is taking over and his oldest (15) will be in the seat in about a year and a half. Nice to go out on top.

See you in Wendover....JD

JD, that's great news, how much rpm do you run the GMC. Did you lean it out a tad for your backup run? See you in a little over 3 weeks.

One run is all that's needed at El Mirage. Since it was a little fat, it started getting lazy near 5400 so I shifted there. Came back to about the same for high gear. JD

Donnie Johansen is bringing the camshaft for the GMC to the salt flats. The machine shop is reworking the head with bigger valves.

Just heard from Donnie Johansen last Friday, "the GMC reground cam is in the mail". After I get the problems solved with the Merlin Big Block Chevy I can get back to work on the GMC.

My experience with DJ is, he grinds a good cam, but it takes him a while.

God's Peace to you.

d

Inliner #1450

Got the camshaft from Donnie Johansen last week, it's looks great. It clears the aluminum rods by about 1/8". I installed the timing gears, timing cover, ATI Super Damper, and the oil pan. Now I can get to work on the head.

I just traded my Garret GTP38 turbo (7.3 L Ford Diesel) for a Holset HSSuper 40, supposed to be better for performance.

A drag racing friend of mine came out yesterday to install the stainless steel O rings in the block. Got the head back from the machine shop last week, now I can put on the head using the copper gasket and ARP head studs, then I can measure and order push rods. Been a long project but I have other projects for other people to do and besides I am in no hurry to finish the GMC.

Gary,

Glad your making progress on the Jimmy. I ordered my pistons today and my unground cam is on the way to me. I think I'll have Dema Elgin grind it for me. Are you going to dyno your engine?

Ron

Ron, I am not planning on dynoing the engine because of the turbo installation. I will probably run it on a chassis dyno like we did with the big block Chev. Have you purchased a transmission adapter yet?

I just ordered pushrods today from Manton. They are 3/8" dia. x .095" wall thickness x 10-3/4" long. The next thing to purchase is the trans adapter and flywheel.

Gary,

I mailed a blank cam, 12 used and 12 new lifters to Dema Elgin this morning for him to grind. He's also testing the lifters for hardness and checking for the radius on the contact surface. I was very impressed with him after talking to him about my cam requirements.

Ron

Ron, let me know how that comes out. I met Mr. Merrit from Humansville that other evening, he is coming back this afternoon. I loaned him the pattern for the copper intake/exhaust gasket. He is going to loan me his aluminum adapter plate so I can make a pattern of it. I got the pushrods from Manton last week, they look great. The engine is all but done. You need to come down this was some time, I'll take you for a ride in the Studebaker, it has a passenger seat with a seat belt.

Roy Merrit is a hell of a nice guy with lots of drag racing experience and a fantastic memory. We have his GMC block at the shop and awaiting pistons from JE. He and I are building almost the same engine. I finally had to use 308 inch Hudson rods and modify the hell out of them to get a decent piston in our engines. I'm still trying to get my money back from Howards but I'm not holding my breath.

I'll take you up on the visit. What's a good day to come down?

By the way, you can email me direct at "goldenri@aol.com".

Ron

I bought an SFI approved flywheel for a big block Chevrolet, welded up the dowel pin hole and had the center machined out to the diameter of the GMC and the 6 holes drilled to fit the GMC. Now I can work on the adapter plate.

GH and Ron, What are the updates on these engines? It would be handy to get all the info for these in one spot. What a resource and time saver. Vendors of gaskets, pistons, rods, cams, lifters, pushrods, rockers, etc. Interchanges for flywheels, dampeners, valves, springs would be great.

Ron did you get your ride?

GH, Is the Jimmy in the Stude?

What trannys were you adapting?

Thanks, Beater

Beater of the Pack, my GMC is completed as far as I can go before it goes into a car. I have offered my 53 Stude up for sale. I am planning on building a new car for the GMC 6. Copper head gasket from Horsepower Engineering, pistons from Venolia, rods from Howards, cam reground from Donnie Johansen, stock lifters resurfaced, pushrods from Manton, stock rockerarms, ATI super dampner, SBC valves and springs, big block chev flywheel reworked. All balanced with Cloyes timing set that is not marked correctly for the GMC, you have to degree the cam and remark it.

GH, Thanks! I'm in the process of planning a 302 build to run at Bonneville. It will be in a GMC pickup, the most time & $$$ friendly for me at this time. I like Studes too My son drives a

'54.

Beater,

321" GMC (+0.125")Block is filled with HardBloc to water outlet.

308 Hudson rod (8.115" C-C)

0.880" Pontiac pins, 84 grams lighter than GMC.

JE 11.5:1 piston (400 grams lighter than GMC)

Stock main brgs.

CR90P rod brgs ( 1940-1950"s Chrysler)

2.02/1.60 SB Chevy valves

#983 cylinder head, ported. 264 cfm @ 0.600" lift

Dema Elgin did the cam based on everything else in the engine.

I wouldn't consider anyone else grinding a cam for this engine. Pulls like a freight train above 3500 rpm.

Aluminum roller rockers we made. (1.85:1 ratio on a 1.00" shaft)

I saved 1.25 POUNDS per cylinder with the piston/pin/rod.

Bearings look good after 20 pulls on the dyno and 6 runs down the strip.

Smith Brothers Pushrods, Bend, Oregon. 5/16, 0.125" wall. Beautiful work and delivered on THE day promised.

My partners and I threw together a set of zoomie headers for the car so we could make the nostalgia race. That hurt the low-end TQ. This winter I plan to get the engine back on the dyno and build a 4x1 header and a better intake manifold.

Hope this helps.

Ron (Goldenri@aol.com)

Ron, thanks for taking time to post this! It is exactly the kind of information I need. You and Gary have helped a lot. Man 1.25 lbs. Per cylinder. I'd sure like to see/hear it make a pass! how far do you take it above that 3500 rpms? I'm going back through old posts looking for info and sorting piles and drawers of parts to see what I need. Thanks again, Tom

Gary, I found the same problem on some Cloyes gears for the 300 Ford. The advance and retard keyways were marked incorrectly.

Tom,

Glad to help. We redline the engine @ 6000 just to be safe. With the piston/rod/pin weight reduction and Fluidampr I think the crank will be safe at that rpm. By the way, a SB Chevy Fluidampr bolts on without any modification.

Panic,

I'll look for some pictures of the combustion chamber.

8.115" is the stock 308 Hudson rod C_C and the CB-90P bearing fits the rod without modification. You will have to turn the GMC rod journal to the Hudson size and narrow the rod to fit the GMC rod journal. The small end of the rod will usually hone to a Pontiac pin. I had to get Pontiac pins that were 0.884' (0.004 oversize) because I screwed up one of the rods and honed it too much.(asleep at the wheel).

If you port the head you need to get the intake valve lift above 0.600" to make the best power. In that case I'd talk to Dema Elgin to get the best cam.

Hope this helps guys.

Ron

Thanks Ron, Where else would racers share hard learned "secrets" with guys that might turn up in the next lane? With me it's all for fun. I gave up being famous a while back! Right now I just want to make a serious pass on the salt. Then I'll get Pissy!

1.94 intakes from a 235 Glide head can be made to work. Also 2.02 or larger can also be made to work from a SBC.

Bill Fisher recommended 1 15/16" intake and 1 11/16" exhaust valves in all 4 styles of GMC heads. That's 1.9375 & 1.6875. There were no SBCs back then so I don't know if he would have used the 2.0 valves.

Im speaking of today's technology. Im going to flow my GMC head with the 2.02's and even 2.05's to see what the max is that can be achieved. Plus, adding "lumps" to both the 235 and GMC head will help im sure.

I'm with ya'! I'm really interested to see what the lumps do.

Yeah, the siamese exhaust is fair, but the single port is pretty bad! There are several companies that have the common SBC valves with a blank stem so you can cut your grooves if you choose to. Im also going to test a 5/16" stem and 7mm just to see what the airflow advantage is for these heads. Its pretty substancial on SBC race stuff, and with these heads, any extra you can get, is that much more than you had. Overkill maybe, but thats the point of this exercise, to take these heads where no man has gone before....

The GMC valves have a 0 degree angle relative to the deck. The Chevy head has the exhaust valve angled, but not canted. I dont have the Chevy head handy to check the angle of it right now, but I can if you need it. I have already plotted all the valve centerlines on the GMC head, and the intake and exhaust ports and bolt holes so I can make header flanges and intake flanges for sheetmetal intakes...

Probably will have to be custom made.As you mentioned there isn't really anything close to working or even modified. Since I have CNC capability,and could design something pretty quickly with my CAM software, I was going to buy some cheap roller rockers just to rob the roller tips and axles, and pushrod cups out of, and at some point make the shaft stands and shaft similar to what Ron did with his GMC.....at some point in my spare time(ha ha)!

I love this! I don't understand it, but I love it!

Once again I'll get a little sappy and say what a great thing it is to be privy to these discussions and to have guys take time to educate those of us who need it. I literally grew up in the "garages" my dad worked in and the parts houses and automotive machine shops where he had free run of all resources. Also my uncles service stations and wrecking yard. I know a lot about some things but there are HUGE holes in between knowledge pockets! This is like looking over Wayne Horning's shoulder while he's talking to California Bill. Well for me it is! This is exactly why I joined Inliners. Thank you to all who are posting here and sharing your hard won expertise!

I am going to make a rocker stand similar to what Jesel makes,and eliminate the factory type shaft. You could either drill and tap the plate for rocker studs or use a more modern shaft mount rocker like they offer as well. You can block off the oil port in the head, and use conventional oil-thru-pushrods to get the oil to the rockers. Of course you will also have to have oil-thru-lifters to do this. That is also an area I am looking into, boring the existing lifter bores to use modern SBC type lifters(roller)and hyd. and flat tappet as well. BHJ makes a lifter-tru plate to correct the lifter bores for the SBC's, I've used it many times, and am considering making one to do this for the Stovebolts and GMC's. That would open up many more doors of opportunity for cam choices, as well as provide a more economical way to use a roller cam in these engines....

Lifter bore is the same as the early Chevy at just a tad under 1 inch, you could use the lifters out of a Keith Black hemi!. The hardest part is finding a rocker long enough to bridge the distance as they are longer than even a BBC or Ford. Arias and Jerry Weigt both make roller rockers.

Its common to install brass bushings into the bores after you correct the lifter bore centers with the BHJ fixture. So you have the option of make it accept any lifter size that you want to. The purpose is to provide a commonly available inexpensive roller lifter to help offset the added expense in other areas of the roller setup! Where would you find an application specific roller lifter for a 235/261? Isky can make a set for a Flathead Ford for $600,the Stovebolts and GMC's would fall into that same price category as well. A SBC is 1/2 that much or less! You can find them used all day on Ebay for $100-$150 bucks. You cant even find Stovebolt ones at all. So it definately provides a new venue for them to explore, and hopefully raise the HP potential for them....

Just preference mostly. Most anything with Hemi attached to it also carries many more $$$$$, Chevy stuff is more common used if someone prefers that route, but the size itself is insignificant, its the open door to apply this technology to these engines that is being overlooked. It is the route I personally am going to use,and if others choose a different approach for their needs or tastes, then they can take it.There are many lifter size possibilities that can be used, I just prefer the SBC/BBC size.

I think there is some HP gains by straightening the lifter holes. As I mentioned in another thread when I put my mule motor on my friends spintron, I was shocked by all the movement in the valve train. The end rocker wobbled and their was almost a 2% deflection. Thats why I built a girdle for the rockers, basically the bottom half of my valve cover. For all out racing applications valve terrain stability among other things is key.

I think before we are through, we will have uncovered many things people didn't think was possible with these engines! I have always thought that a more rigid platform for the rockers would be a benefit. I think if you made a plate to bolt to the existing rocker stand bosses, you could also make a similar pedestal mount shaft rocker like Jesel offers, or install a conventional rocker stud setup and put a stud girdle on it if you still need more support for deflection. It would have to be an improvement, especially if increased spring pressures are used in performance cams, and even with rollers like we are discussing...

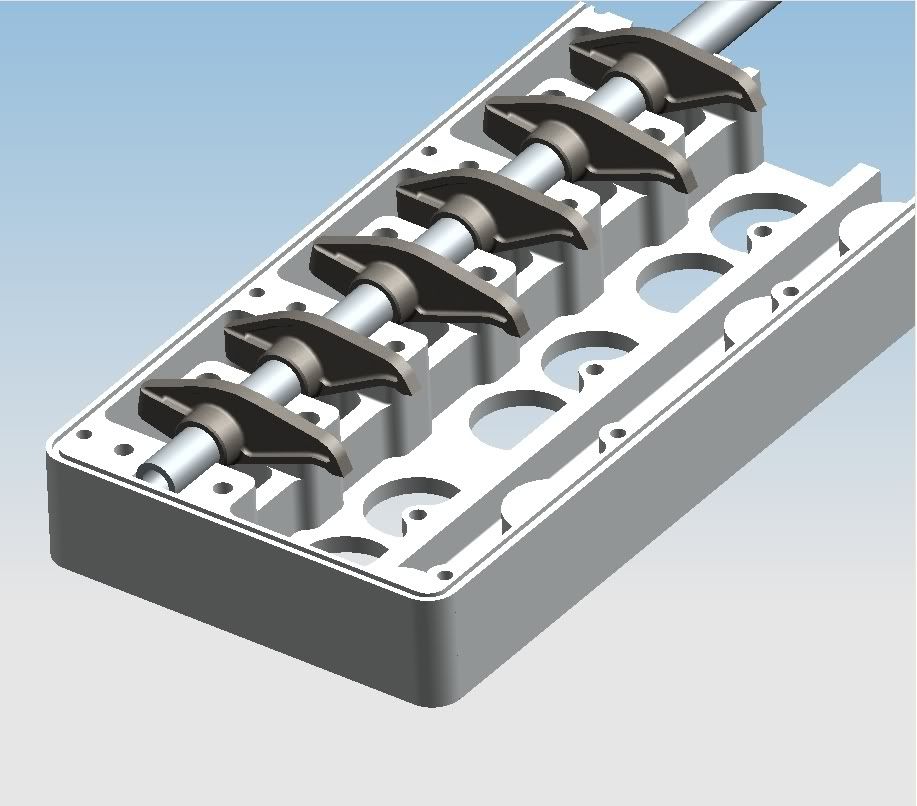

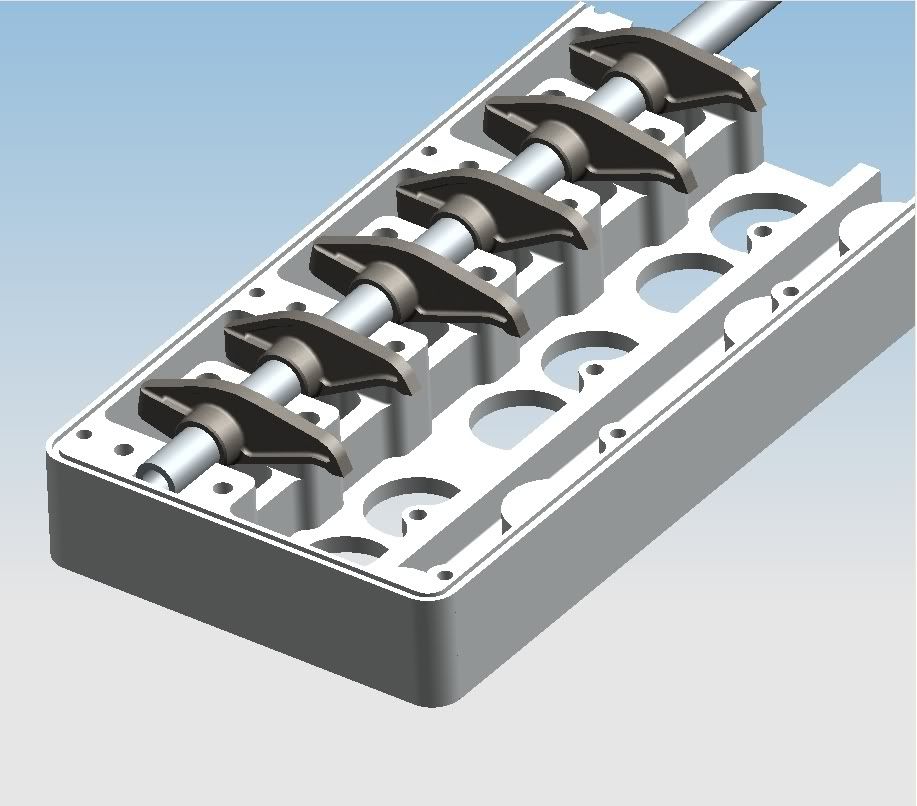

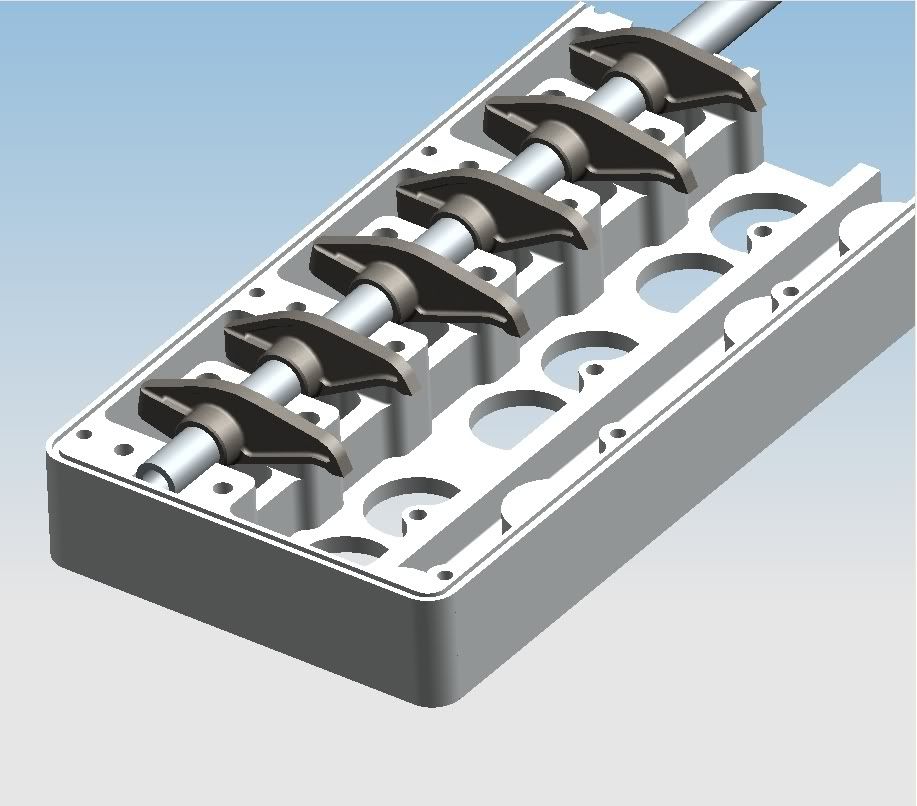

This is what I did for my rockers and girdle. After running the design through a FEA program the rocker came out looking very similar to the Del West Style thats in NASCAR. The shaft is also smaller than a stock GMC. A lot of work on a spintron went into this.

I'm confused:

"boring the existing lifter bores to use modern SBC type lifters" (smaller than .842") vs.

"just a tad under 1 inch, you could use the lifters out of a Keith Black hemi" (.904")

I thought the .901" was a standard Chrysler size (B-RB, some Hemis) I'm not sure about the A-LA, but the Magnum small blocks (5.2/5.9, 4.7 probably, but don't know if it's the same diameter) were suposedly roller equipped. Anyone know their lifter diameter?

This is what I did for my rockers and girdle. After running the design through a FEA program the rocker came out looking very similar to the Del West Style thats in NASCAR. The shaft is also smaller than a stock GMC. A lot of work on a spintron went into this.

Thats a nice looking set-up! I would say that is plenty ridgid enough. What ratio rocker did you end up using!

The stock 235 lifter size is around .990! Most of the time when you correct the lifter bores in a SBC with the BHJ Lifter-Tru plate, you obviously go to a larger diameter to correct the angles and centerlines of the lifter bores.Then you install brass bushings into the oversized bores to retain the SBC .842 lifter size. Also using a .875 Ford lifter in a SBC is also a popular mod as well.You will need to bore to over 1"(depending on bushing OD), and then bush it back to .904. Compare a set of new SBC roller lifters to a new set of Chrysler roller lifters! Chevy is still less expensive. It still opens the door to make any number of lifter size selections you choose.

I've seen a block (alloy SBC) with those bushings. Would there be enough metal around the lifter boss to move it that much?

I ask as I figure you would have to go with a billet cam core or one that's been hard faced. I don't know which would be cheaper. As there isn't a large market for the billets and you would likely want a larger base circle (with a commensurate larger core diameter to stiffen the cam) a custom billet could be made to bring the lobe directly under the tappet. As the flat tappet lobes are offset from the center of the lifter bore some to facilitate tappet rotation (or at least it looks like it).

That would reduce the need to offset the bores as far.

Would you want to use a vertical link style roller tappet, or the kind with the rivets in it to engage a raceway (keyway, pilot groove, ???)? The riveted ones are somewhat more expensive (from what I've seen) but you wouldn't need custom link bars for them (not sure it that's a big enough PITA to care about when you're that far in).

Stock Chrysler Hemi's use a .904 lifter. Keith Black and many others use a 1 inch lifter, so do some Fords (I think).

GMC 302 Lifter bore = .9905 - .9915

Lifter diameter = .989 - .990

clearance = .004

There is a link here at Inliners that will take you to the Classic Truck site where all this is listed.

http://www.oldgmctrucks.com/page0311.html

I just took a quick look at my Jimmy block and it looks entirely possible. It will be close next to the main bearing web but will fit. Another idea would be to use 1 inch .125 wall aluminum tubing to make your lifter bushings. It is a good bearing material (like VW cases) and is much cheaper. Maybe a chamfer up top to hold oil next to the lifter. What about the push rod tips?

Well, a stock Jimmy pushrod is 12 and 13/16ths inches long and the head has a .550 inch hole for it to pass through. One would have to be very careful to use a cam that will match the lifter material as Jimmy's used both steel and cast iron cams throughout the years. Tom Langdon at Stovebolt would be a good person to ask. Personally, I'm sticking to the 1 inch roller lifters on my work bench and with Jesel style rockers. Good luck

Reason for my question:

There is an intermediate step (not "green", and no longer favored as an advantage) that has been used for 75 years - the mushroom tappet.

The maximum velocity a flat tappet can reach (which determines how much valve open area you can fit into a specified duration) is roughly proportionate to the tappet's contact surface length:

Maximum velocity per degree Of rotation = (tappet diameter - .040Ē)/114.6so the .904" and .875" are favored over the .842" for V8 because they allow hotter profiles.

For many V8s this has limits because the tappets are so close together, but it appears that the stovebolt & GMC spacing is more generous.

There is no complex machining, because the gallery appears fairly open and only clearance to permit the upper (non-critical) surface of the "foot" to rise farther.

The cam can be any cam that works as to material (no steel, billet, etc.), but the grinds can be far more aggressive, especially the "split" between nominal IVC vs. effective (.050") IVC (which balances compression bleed-down against inertia fill), and nominal EVO vs. effective EVO (which balances pumping loss against duty cycle %).

How about the tappet price?

Just use the VW Type I (air-cooled opposed 4) 31mm (1.22", over 24% more area than a .990" stock tappet) mushroom, still made new & cheap by EMPI, by bushing the tappet opening down to .748" (19mm). The tappet still rotates as normal with the tapered lobe.

No linkage, no tie bars.

I myself, had completely forgotten about the mushroom tappets as an inexpensive alternative,good thinking! Someone that didn't want the expense of trying to use a roller setup, might explore that possibility.

The VW tappets are an interesting option, I see your picture is of the high perf ones with the direct lobe oiling (nice holes

).

I would still expect the cam core needs to be bigger (to stifen it) if you are building a race engine, as that's what I keep hearing / reading. Stands to reason as long as it is.

This is a cutaway of a 302 GMC head. It doesn't look like their is too much material.

I was surprised that the 983 casting I used on our 321 was thinner than I would have believed. I opened up the intake runner to the size of the alignment ring and broke thru on one of the head bolts. I had to install a sleeve in the head bolt hole to seal the runner.

I also machined a hole in the block so I could measure the thickness of the cylinder wall before we bored the block. It was about the same thickness as a 350 SB Chevy (0.200"). I thought these old engines had a lot more material in them than that. To be safe I filled the block to the bottom of the front water outlet with Hardbloc before it was bored.

Ron

It does make you wonder. I can pick up a 302 block. I can't do that to a Ford flathead.

Actually, that is the main focus of another thread that is currently underway in the Engine section entitled "261 Chevy 848 porting"! I will have before and after flowbench results showing how this technology applied to these earlier heads not only improves the flow capabilities tremendously, but when done in conjunction with modern porting techniques will take the 235/261 and GMC's to a much higher plateau than they have ever gone before.

Hey Panic!! I'm enjoying this. Keep it coming. 1 OL REDNECK I.I.#113

Its been known for many years by those that are in the profession of head porting and other areas, that surfaces with an airplane wing edge, that is blunted or ellipsed, creates much less turbulence than a sharp leading edge does in terms of airflow. That mistake is also many times done with knife-edging crankshafts. When a sharp leading edge is ground on the edge of the counterweights. Crower was one of the first to change to the "airplane" wing technology for their crankshafts leading edge almost 20 years ago. For years, people were taking the term literally when speaking of knife-edging, and finally discovered it created almost as much turbulence as the flat edge of the crank did before it was ground on. Sissell/Kirby was and is the leader in siamese port development,also creating the "lump" port technology for the 250' and 292's. Brian and Glen Self are very close behind, and still currently dominate most racing bodies that involve those engines!

How consistent are these castings from port to port and head to head?

Since those heads weigh so much, you would think there would be more metal in them in some of those areas. I agree about the engineers for some of those crank companies too, I guess they figure its been working for them, so why change it....go figure!

Thanks, there is a lot of useful information there. A great deal is coming together here!

Panic....I've looked at a ton of GMC heads and own more than most guys. In my opinion your cut away appear to be one of an exhaust port. My reason is the divider and a shadowed area behind it and the left edge appears to bet retangular in shape and not circular. The valve area is very small and the chamber appears to be one of the last small port ones made with the shrouded intate and exhaust. Hey I could be wrong and often times I am. JD

Yeah, even the 983 head im doing looks a look larger in that area also, must be an early non-302 head. If its the same head as in his other illustrations with the combustion chamber example with the colored rings, its definately not a 302 head. The 302 actually has a pretty good chamber shape and design, similar to the SBC only larger.

Oh,so those pics aren't from something you have personally done yourself then.

I posted the original cutaway picture. Its of the exhaust of a GMC 302 head. I needed a bad head to cut up before modifying my NOS head and Buffalo gave me the bad 302 head at Bonneville a few years ago. If I can find the intake cutaway I will post it.

I found the intake port cutaway. This was cut through the middle of the intake runner. I was trying to see how much wall their was before hitting water.

So, with the small port heads is there more wall or more water? I'm betting on water!

Speaking of cams, as I recall Jim Hedrick had come up with a cam design for these motors. I heard his car run once and at idle it sounded terrible. But when he was on the gas it sounded like a monster. Maybe CNC-Dude can chime in on this.

Often wondered if any of Vizard's work would translate to these engines.

I dont think Jim ever experimented with different specs on lobes for the siamese ports and non-siamese ports on the same cam. The life expectancy of those engines was so short, that track time was at a real premium. Jim worked very closely with Mark Heffington,former owner and pres. of Cam Dynamics on developing the cam profiles for the 292's. He ended up using some Pro Stock lobe profiles in those engines. Which at that time was insane by many peoples standards for a 6 cylinder. Most of the fastest records and passes were made with valve lifts of over .900 lift. And that was back in the late 1970's and early 80's when Jim finally hit upon the right cam #'s.And they remained the same from then on.Cams in modern Comp Eliminator SBC's are that big today.The strange sound he was referring to was a "churping" sound the engines made when idling. He always thought it was a combo of the huge Pro Stock grinds on the lobes and the possible reversion of the exhaust and "lump" porting. It never was found to be on any other engines that they did for other people, and those two things were the only differences,cam profile and head. I only know of Cotton's engine ever being on a dyno twice....ever. I saw the second and last time it was. I think kinda' along the same lines as panic,in that those types of different specs would be more apparent on the Minis as opposed to the larger bores and different engine parameters of a larger engine. But, that is also an area that could be researched and proven or put to rest. I know of Winston Cup teams doing that to some of their engines to compensate for "good ports"/"bad ports" on some of their R&D programs, and only found tiny gains in that area(2-3HP typically).So many new things are coming about with the 235's and GMC's with the roller billets I will soon be making for each of them, and now being able to supply a camgrinder with actual cylinder head flow #'s and data, that is now so critical for the best cam selection. That data has never been provided for either engine except for the special few that have the capability to do so. I have spoken to a cam grinder that has expressed interest in taking that flow data and optimizing some grinds for me in developing the billets I will be providing. He also thought that applying the "lump"port concept to these early engines was the most innovative idea he had heard in a long time,and was really willing to work with me and others in this area. I think that before long we will see some spectacular advances done with these engines,especially in the cam and head category....

The 292 roller lobes would be way too radical for either the 235 or GMC. My cam grinder is going to evaluate his lobe library to see what could be used based on the head flow specs and compression and the normal data needed to select an optimum lobe profile. Plus, the 292 heads are much more capable of better airflow than the earlier heads by far. Even though they share many commonalities and are both siamese style engines, I suspect the overall lifts and durations in comparison will be much lower for the 235/GMC's,unless a 12 port head is used that can significantly boost the airflow #'s. I will be getting some 8620 2"bar stock this week to begin roughing in a couple of roller blanks so I can be on "GO" when I reach that point. Making the rockers wont be that much of a challenge, especially with the CAM software I have available and the equipment to machine them with coupled with my experience in this field. The hardest part will be to acquire the pushrod cups and roller tips and pins for the rockers, most cam companies like Crane and Comp wont sell you those pieces individually, because they dont want anyone to make rocker arms but themselves.

I may be able to get a set of BBC roller rockers for parts. They were offered to me for my 292 project but he'll never know!

Ok, put them up for a rainy day,im sure they will come in handy!

Guys,

I built a complete roller rocker assy with stands and a 1.0" shaft, rifle drilled for oiling. The ratio is 1.85:1. After 20 pulls on the dyno the valve lash didn't move.

If someone will explain how I post pictures I'll show what I built.

By the way, I talked to Vizard about headers for the GMC and he didn't think his experience with the 4 cylinder would apply to the inline 6 engines with siamese ports.

Ron

Ron, Here is where I learned to post links to pictures. What you learn there works here.

LINK Or maybe this is better.

LINK

you admit it is photoshopped after you cant identify the head

This is so cool, always appreciate the rude personal comments.

Fixed all that offensive stuff for you.

Whats rude about pointing our that you didnt know what cylinder head you displayed? It didnt add anything pertinent to the discussion as you could not identify it - someone else did.

Nothing rude about that. sorry if you found it offensive

Re: You can block off the oil port in the head, and use conventional oil-thru-pushrods to get the oil to the rockers

I'm not sure whether that's best. It saves some plumbing, no lines to fracture. However: it takes pressure from the tappet gallery, yes?

I didn't think the GMC had pressure to the tappets, only the 1954-* Chevy?

If I missed that (and there is pressure) you still have leaks and pressure loss at ever transfer: gallery to tappet, tappet to pushrod ball, pushrod ball to rocker end, rocker body to rocker shaft. I don't know how much is lost, or whether there's a front to rear bias (last tappet from the gallery feed gets lower), but any dirt it picks up will stop the pushrod oiling.

Using a single line to a distribution point allows adjustment to the volume/pressure without taking the motor down (blue rocker? more oil).

Re: cams

Paraphrasing Vizard, the siamese port layout means that there is a maximum practical duration before the exhaust valve of 1 cylinder is open during the intake stroke of the opposite cylinder on those that have both intake and exhaust shared (#2-5), causing the vacuum to be satisfied by exhaust pressure rather than fill the cylinder from the intake manifold. Unlike the usual high overlap problem, this doesn't decay to harmless at higher speed.

Panic,

I agree, and I haven't found a header arrangement that will work on our GMC since the siamese exhaust pulses are 240 degrees apart and my cam is bigger than that. I do know the zoomie headers are hurting the low-mid range TQ.

Ron

Ron,

Have you tried changing the firing order....using a custom ground cam naturally!

Ouch: that's a new crank!!

Just swapping the events on some cylinders can be done with just the cam, but it won't change the number of degrees of split between paired cylinders.

I've been wrestling with the firing order, paired cylinder thing (my head hurts).

That explains why the Mini can use a header: the cyinder pairing has 360 separation.

What pairing of exhaust pipes have you tried?

I suspect that the zoomies are either:

1. too big, and you're getting reversion because of low vel in the primary, and it's backing up into the port

2. the length is creating a wave that arrives at a bad moment and stifles something else

As Smith suggests: the easiest, most trouble-free exhaust system is 8" stubs. No wave can arrive late enough to affect anything, no backpressure, no length at all (they can differ if you have chassis clearance probs). Probs: sounds like gunfire, flames under the hood. Even this can be fixed (as you'll see on really old racers), the stubs empty into a very large can - as long as the cam area immediately inside the stub entrance is 10X the stub area there's no collector effect. If the pipes are 1.75" OD (1.652" ID based on 18 ga.) the area is 2.14", so if the can is at least 5" in all directions from the stub it's the same as exiting in free air (except for the noise, heat, flames). You only need a single exhaust, any size will do, and pointed per rules (down and back).

Ron, just use what JD has done and all will be well. It's not that big of a deal! A 4 into one W/merge style collector is the best overall header system out there. The small losses we have because of the siamese intake and exhaust ports will be more than offset and the gains well worth it. An ounce of reality is worth a pound of theory.

http://www.landracing.com/forum/index.php/topic,4169.0.html

Thanks guys for the info on the Jimmy header. I considered Smith's suggestion on the short stacks (<8") and I also considered dumping directly into the large collection box.

However, from all the engines I've had on the dyno (conventional engines...not this geek) I've seen large TQ gains below peak TQ, and usually a 1-1.5 percent increase in peak HP, with a 4 into 1 header. On one 406 SBC I verified a 96 lb.ft. increase in TQ @ 4500 RPM when I extended the collector to 18 inches.

I'm satisfied (???) with the HP & TQ (346 & 347) but the thing is a complets dog below about 3500 RPM.

I've decided to build an adjustable 4-1, 1 3/4 x 40" with a 3 or 3.5" collector. If that doesn't work I'll try something else.

Thanks, Ron

Even though your piston and rod combo was a nice swap, I think you left a lot on the table as far as torque goes by going with such a long rod length to stroke ratio for such a relatively low RPM engine. I know your goal was to get an extremely lightweight piston out of the deal.

cnc,

what do you mean by "i think you left alot on the table"? i did not take it as anything bad. just want to know what is wrong with his 8" or so rod and a light piston. tom

No,it definately wasn't meant in any kind of derogatory or diminishing way.Explaining how longer rods kill low end torque is difficult, in that it envolves a lot of physics and technical terms and mumbo jumbo. It mostly has to do with how it changes the dwelling of the piston at both ends of it stroke TDC and BDC.And engines are really pretty sensitive to even small changes in their R/L.The only way to try is to compare an engine that you could relate to. Take a 292 with its 4.12 stroke and 6.76 long rod. Now take that same 292 and put a 7.500 rod in it. The engines are built and prepped indentically in every way, except for rod length.As you begin to push the rod length of a given engine upward, and increase its R/L ratio, you also push the torque curve upward as well. You also create a narrower torque band. In the short rod engine as the piston approaches TDC and BDC, you can graph with a degree wheel and dial indicator various points of rotation relative to piston location in the cylinder, as it approaches and passes these TDC and BDC points. Now if you do the same with the long rod engine, and compare the same degree wheel locations relative to the piston as the short rod engine. You will see that with the the long rod engine, the piston slows down or dwells longer as it approaches and passes those TDC and BDC points. That loss of inertia also causes a loss of torque.(Hope this isn't boring) Low RPM engines(up to 7000)seem to have more usable HP and torque with relatively low R/L ratios, around 1.5 to 1.6,provide good low RPM grunt. Ratios in the 1.7 to 1.8 range are mostly used by engines that have a considerably higher peak RPM(up to about 9000)a Winston Cup Chevy engine has 1.81 with a 6.350"rod and 3.500 stroke, and the loss of the torque down low in the RPM is insignificant in these engines. Even though the GMC has a pretty high ratio already, 1.7 ratio, changing a 350 from a 5.7 to a 6 inch rod makes a huge noticeable change in its low end characteristics, and you only are changing the ratio from 1.64 to 1.72. Now, saying all that, to say this, changing his ratio from 1.7 to 2.0, is a very large jump for an engine that probably has a peak of maybe 6500 or so.He made some very good dyno #'s to say the least, but I think he gave up a lot of torque by making that big of a change in rod length, and since HP is also a by product of it, he really would have seen some much higher HP and torque #'s with a stock length rod. The good thing about HP is that it doesn't know if you have a fly weight piston or a 10 lb. piston, it makes the same either way....

I think Ron used that rod length because a Jimmy engine , from the deck to the centerline of the main bearings is a little over 11.25 inches. A 10 pound piston is a little hard on the rods at 7 grand.

I agree, im also sure the SBC pistons he used were much cheaper, than an application specific GMC piston. And again, im not saying he was wrong to use this combo, just making an analysis on the subject of how R/L affects the characteristics of an engines performance.

I wonder if anyone has done back to back dyno runs changing only the rod length and piston pin height. I think that is the only way to tell what is true and what is theory.

Well it isn't theory, it can be seen on any dyno with any engine, and has been for many years. That is one of the determining factors in engine development programs that I have been involved with in the many realms of racing i've experienced. There are many benefits of increasing the R/L ratio, but the decrease in torque in the low side of the engines power band is a trade off. You just have to determine if it will benefit your needs, and not affect your performance characteristics you are seeking. He might have 1000 more RPM of usable power band on the low side of his range to gain back, and on a engine makes its peaks around 5500(I think thats what his dyno results stated), that is a pretty big lose to consider. He mentioned it was dead below 3500 RPM, so he has a relatively slim power band, if he gained another 700-1000 below 3500, his results could be much different. It would be nice to do a back to back comparison, its probably not cost effective unfortunately.

I agree that the 8.125" rod hurt my low end TQ but felt the longer rod and reduced compression distance would allow me to drasticly reduce the piston, rod and pin weight and make life a lot easier on the crank. By the way, the piston is a custom JE with a 50cc dome. I couldn't find an OEM piston with enough dome to get the compression I wanted. With this combination I saved more than 1.25 pounds per piston/rod/pin.

Another factor is our rules that require a bias ply tire with a maximum tread width of 6 inches. Traction off the line is a problem and tire spin in first gear is excessive, but taking off in second bogs the engine. I wish the rules allowed an automatic tranny. Some of the guys are running automatics and can control wheel spin much better. Their also a few tenths quicker even though our car miles per hour much better.

I'm going to try the 4x1 header and I think it will pick up the TQ quite a bit.

Thanks for the comments, Ron

The reason I say that is because despite all the talk, I have never seen actual dyno runs to support any meaningful horsepower/torque differences. Here's an article to contemplate.

http://www.iskycams.com/techtips.php#2005 I'm not trying to be argumentative here, I just would like to see how much we are talking about.

I've never personally dynoed an engine with different rod ratios. From the tests I've seen the HP & TQ numbers are VERY close, typically <1 percent difference. I'm sure there are specific applications where different rod ratios would be worth the effort. However, on the GMC the piston/rod/pin weight savings over shadowed all else. There are so many other areas to address with this engine that rod ratio is a very low priority.

The distributor gear and cam gear were destroyed the last trip down the strip. So I build an external oil pump (BB Chrysler) and distributor drive thats driven off the front of the engine with a Gilmer belt. I fired the engine and set the timing and everything looks good...no leaks and 60 psi of oil pressure. If I knew how to post pictures on here I'd show what it looks like. If someone will let me send them the pictures they can post them.

That is if anyone's interested.

Ron

Pics would always be great, I dont know how to post them either, as i've had several 292 race engine pics I thought would be good to share....

Ron, I've got the pictures you sent me, give me a bit, I'll post them.

Gottum

I can't seem to find the pics of the rods though.

I remember one that had the stock rod & piston laid out next to the 'new' rod and piston, but I as yet haven't found it in my stuff.

Here

I for one would be very interested. I just happen to have that very pump assembly on my bench right now!

guy's,

ron sent me these pics of the oil/ distributor system for his kickin jimmy.

all you have to do is sign up with imageshack and install their free software. upload your images and then it is copy and pasting after that. i always send the thumbnail version so people with slow internet do not have problems. tom

I'd like to see more pictures of Ron's racer!

the decrease in torque in the low side of the engines power band

What do you think causes this?

Well naturally the more aggressive the profile is on the camshaft contributes to it. But making a change of over 1" inch in length to the connecting rods might have had some part in it as well.....ya think!

The mechanical engineers that have worked with the Winston Cup engine builders i've worked with, have explained it to me in terms that still border on a thesis level. Many times if they cant dazzle you with brilliance, they will baffle you with BS! Sometimes you would get an actual answer to a question, other times they would do that, usually meaning, you don't need to know! First, their main focus is on making the most HP and torque in the engines operating RPM range, usually between 7500-9000 RPM on Super Speedway motors, and around 6500-8500 on Short track engines. So what the engine does below that range, doesn't really concern them that much. They have done so much R&D in the R/L, that they have done exhaustive dyno and cam testing for all possible rod lengths(starting with 6.125" and going to 6.350" with rods made for lengths every .050 in between)and stroke combos. All that with no definintive answer as to why the loss of torque really occurs,other than it does, and they can prove it does. But that loss doesn't affect them, because it happens much lower in the RPM range than concerns them. Im sure that with the same R&D and dyno time that they spend with their engine programs, Ron could probably recoup what was lost, but he would have to know what he lost to begin with, and establish a baseline to compare.

Panic,

The pump is internally vented to the suction side and I figured if the pump could supply steady pressure to a BB Chrysler at RPM, it surely can handle my little GMC at 6000 RPM.

I agree about the scoop....but, my partners aren't gearheads and just wanted it to look pretty. The mirror finish is handy for them to comb their hair. I didn't have a vote on that since I'm bald.

Actually the whole car is a sort of compromise since there are 5 partners on the car. Kinda like someone once stated......the camel is really a horse designed by a committee. Overall, I'm very satisfied with all the partners contribution to the project.

Changes will be made as necessary when (IF) someone goes faster than we do.

Ron

That's gonna take some doin'.

I thought the Ramchargers were combating an oil starvation issue abbove 5000 RPM (and winding it a fair ways past that) when they came out with their bigger pickup tube? Or was I mis informed?