Curious to see what the serious interest would be in a 4bbl carb intake for the 4200.

The magic number is about 15.....

I would have some intrest. Something that comes to mind is something along the lines of the Mopar slant 6 long tube low profile intake. I know the 4200 is a wide engine and this would be a issue on some cars. In my case I have a wide bay...J

Randy, which design were you thinking of, single or dual 4V?

IIRC you posted a rendering for each.

I was thinking single 4bbl.

On another note I went to visit an retired pattern maker tonight who has done several intake manifold patterns recently for antique stuff but knows what he is doing - Boeing still calls on him for work.

So the design, tooling and casting talent to get the job done are in place IF and only IF the demand is present.

Until the design is done I cannot get a cost on the tooling nor an estimated cost on the casting.

Being a low run part it will be more than an off the shelf manifold where the tooling and design cost have been absorbed over 100's of parts.

Over to you folks if you want to make this happen. So not to drag this out forever, does Feb. 6 sound like an reasonable have your answer in date? If you know folks who like the engine, always want one but are not computer/EFI folks - get on the phone and call them. I know some inliner's don't use computers at all. If you know folks on other forums that don't come in here - get hold of them or cross post a link.

Marc

Marc, you could become an advertiser in the 12 Port News for your 4.2 stuff. That would help you reach that segment of Inliner members that don't participate on the forum at all. Just a thought....

Marc, you could become an advertiser in the 12 Port News for your 4.2 stuff. That would help you reach that segment of Inliner members that don't participate on the forum at all. Just a thought....

Something to consider.

I suppose making it with an interchangeable top would be cost prohibitive? That way you could have tops for 1x4-2x4 3x2 blower whatever you wanted. Some of the Hogan race manifolds have that feature but you do pay for them.

Harry,

To cast the part with a removable top is not so hard. A couple of knock on problems come up:

1) what to do with plenum (s)?

2) what cross section does the "log" part need to have to accommadate the variable position plenum?

3) end applicaiton - bigger volume tends to kill low end torque.

So Harry's question prompts what carbs and how many do folks want - at the end of the day we need a common answer OR if someone wants to buck up for the design & tooling they can have what they want.

So carb type:

1 x 4bbl

2 x 2bbl

3 x 1 bbl

3 x 2 bll?

300 views and only 1 comment on which carb to use.

I'd make a removal-able top and leave it blank for the buyer. Then I'd also make a stack-able spacer for between top and bottom, to vary plenum size.

Larry

I'd make a removal-able top and leave it blank for the buyer. Then I'd also make a stack-able spacer for between top and bottom, to vary plenum size.

Larry

Larry,

Trying to get a concept for this...

For a 4bbl the plenum has to be about the same size as the bolt pattern. How to make a removable top that fits a 4bbl and keeps the plenum/runner (think a 250 manifold) at a reasonable size so if someone wanted 3 x 2 bbl the log part is not huge all the way across the length of the manifold.

If you have an idea mind sketching something up?

1 x 4bbl not so hard

or

multiple 2 bbl's not so hard

both together ???????????

I agree, not easy to do. A 1×4 needs different runner lengths and entries to avoid mixture distribution problems with 3 & 4, a 3×2 needs them alike.

I can sketch something up, but I need more input.

I know of the mixture problem on 3&4, is there a solution, runner length 3&4(?).

To further explain,"For a 4bbl the plenum has to be about the same size as the bolt pattern", not true. I'm looking at both the Clifford and Offy, and the "bolt pattern" is outside the plenum. The runners on the Clifford are about 3" x 1.5" and the plenum is 3.75" wide, the Offy is smaller. The runner/plenum(?) need to be as wide as the outside distance on the 2bbl throttle plates, and not as high as the Clifford. I only have a Rochester 2 Jet to measure and that's 3.5", this is also width of the 4bbl slots on the Clifford. This width would on have to be maintained for the length mount 3x2 or some distance minus runner length for 1&2, and 5&6. This would also be the measurements with width added for fastening to the manifold. Additional width where required for mounting cab(s). The top plate could be .375-.5 thick aluminum plate, and the manifold would have be machined to accommodate. A spacer could be made by just cutting out a top plate to the inside of the runner. There are several(?) problems so far, a right angle at the top of the runner for it's length, and the 4bbl plenum.. Add a spacer under the 4bbl(?). The Qjet folks would definitely need to use and adapter.

IIRC the runner needs to be some multiple of the optimum length. The runners on 1&2, 5&6, on the Offy and Clifford are about 4-5 times longer than the 3&4 runner. The Clifford runner starts to narrow at 2-3 times the length 3&4. I'm thinking that runners 1&2, 5&6 only need to be 2-3 times the length 3&4.

One size never fits all, but this should be flexible to accommodate most.

Larry

A couple of notes and an idea...

Each intake port on the 4200 is very close in size to the combined intake port size on the 250/292.

What if the intake looked like this one? The tooling is a lot easier to make. Leave the top off the casting and folks can make there own top plate from flat AL plate. Nothing that a jigsaw and drill press would not handle.

intake The runners length could be made longer.

That looks good to me.

I would provide the top with just the holes and screws to hold it to the manifold. That eliminates any question of it fitting the manifold from the buyer. You may also have to add some width to mounting a 4bbl.

Larry

Like to get a bit more feedback before settling on this layout.

Now the next issue is to find 20 people who want one.

Until there is enough interest and money committed not much sense in starting the design work. I've asked another inliner to see if they can act as treasurer for the initial buy.

Ball park costs per unit:

castings $150-200

tooling $150-175 (3000 - 3500 tooling)

machining $125

Call it $500 as a round number in qty 20.

For reference a Hogan sheetmetal intake runs $2000+

First of all, I'm committed to my 292 for the forseeable future. Second, in my estimation, these engines are seldom going to be exposed, these are typically going into drivers, racers and runners, right? Typically not into a T-bucket or a street roddish type car. This is my read on the market. So I would go with a single 4bbl intake. Cheaper & easier for the end user (don't have to buy 3 carbs or sync them) and I don't believe you give up that much power to the multiple carb intakes for the ultimate power seekers, and with a power adder it would be preferred to be single carb anyhow. IMHO you have to shoot for the "performer rpm" market, not the "victor jr./victor ram" market to sell 20 of these.

First of all, I'm committed to my 292 for the forseeable future. Second, in my estimation, these engines are seldom going to be exposed, these are typically going into drivers, racers and runners, right? Typically not into a T-bucket or a street roddish type car. This is my read on the market. So I would go with a single 4bbl intake. Cheaper & easier for the end user (don't have to buy 3 carbs or sync them) and I don't believe you give up that much power to the multiple carb intakes for the ultimate power seekers, and with a power adder it would be preferred to be single carb anyhow. IMHO you have to shoot for the "performer rpm" market, not the "victor jr./victor ram" market to sell 20 of these.

Good feedback

More the better.

Have you guys seen Steve's Ford?

roadster roadster2

Dunno.

An inliner looks so much better with multiple carbs. I've built many multi-carb units and would not want to tackle a single 4V intake because it is more work to get right with likely less payback in performance than multi carbs.

For a WOW factor gimmee multi carbs.

I agree with Frenchtown. The "Wow" factor with a multi-carb setup is cool looking.

I have a 3-Deuce setup which has been pretty much a no problem setup. It's a warmed over 292 with a Offy 3x1 intake with 2bbl adapters and 3 Holley/Webers. The carbs are progressive carbs which mean you can adjust each carb separately and run straight linkage. Set it and forget basically. I fiddled with the jets intially as it was running way too rich. After a few calls to Tom Langdon @ Stovebolt, I settled with #48's in the primaries and #53's in the secondary. I have the secondaries to come in when I floor it. Gas mileage is decent if you don't floor it all the time. I did experiment with disconnecting the front and rear carb's secondary linkage to see if it would make a difference. No noticable difference in start up, cruising or idleling. A noticeable increace in mileage as it increased 2-3 MPG!

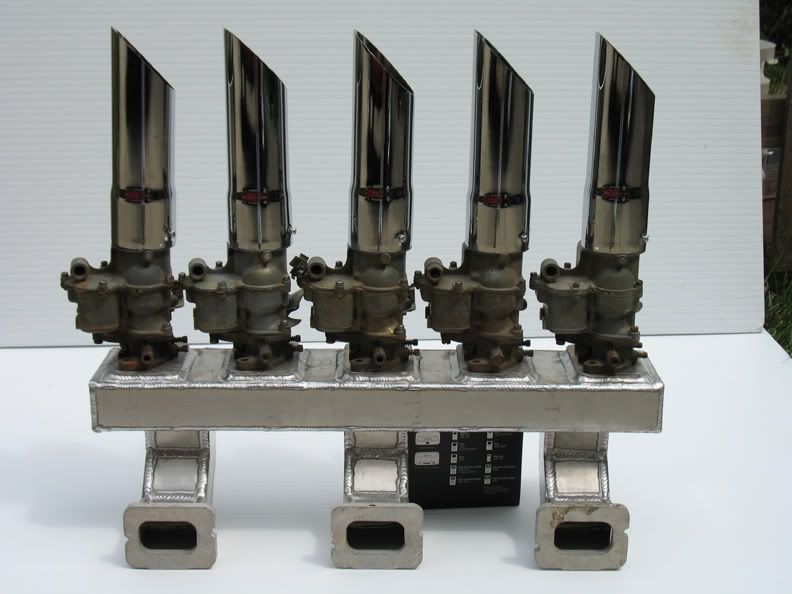

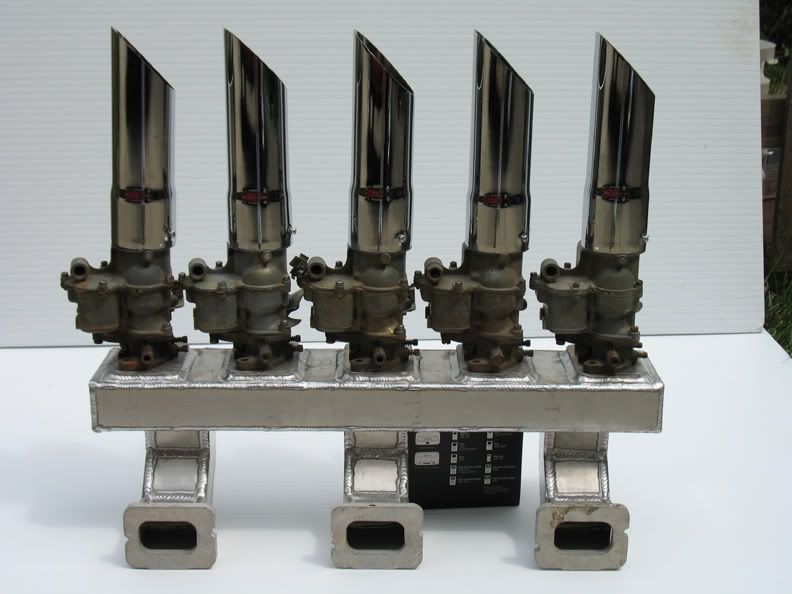

The phots below is the manifold I designed a few years ago. It was water jet cut and Tig welded and designed for my 292. Talk about a "Wow" factor!

I never ran it as one of buddies saw it before I was able to try it and just had to have it. I was planning on blocking number 2 & 4 off with hidden plates so it could be streetable. Running 5 Strombergs 94's on a six banger would have been interesting!

RapRap

I think I would be tempted to build something like this:

That way people could add whatever type of carbs they like; [1]4V, [2] 2Vs, [3] 2Vs, [3] 1Vs, injection...

I really like that manifold! did you build it? Nice versitilty!

Rap

I think I would be tempted to build something like this:

That way people could add whatever type of carbs they like; [1]4V, [2] 2Vs, [3] 2Vs, [3] 1Vs, injection...

If we did something like this design it'll make the patterns more involved possibly with some added cost. The design is doable.

A couple of things to consider:

hood height

manifold width

AND

We still need numbers to make this a "go". So its upto you folks to decide if this is a part the inliners want to have available. I can't afford to take on the tooling cost myself, but will donate my time to do the design work.

The plenum on the sheetmetal/EFI base manifold shown above doesn't seem to have too deep of a plenum, so are you saying that is pushing the limit of useable hood space, and will you be able to make a manifold that has adequate plenum volume for the 4200. Do you have any height and width dimensions to observe that you know of to accomodate most possible applications. Obviously trucks shouldn't be a problem, but low hood lined cars can be where the most problems will occur, I would think.

I'm open to all ideas. The plenum on a 250/292 manifold isn't much deeper than what is shown.

We do need to start putting some constraints down as far as manifold width and height though.

so start putting your height and width constants down at the end of the day it'll have to get boiled down to a number everyone that want a part can live with - not nessecarily what they ideally want or it'll never get there.

Guess this attempt is dead.

If the input starts flowing I still have some time to get at this, however, the closer we get to spring up here the less time I have.

What about the stubs you had cast for your intake?

Are those feasable to manufacture?

I have no idea if there would be interest though.

To keep the manifold height low - most likely an issue for most installs and to allow "easy" fab. I sketched up one possible layout.

In final form the intake would be close to 11" wide from head flange to outside of the intake.

[url=

flat 4200 intake[/url]

The runner paths for 1,2,3&4 are shown 5&6 would mirror 1&2 .

To get more equal runner length is harder on the 4200 - 6 ports and the port cross section is 90% of the combined port of the 250 engine. This head layout really screams for a dual carb setup to get the runners closer to the same length.

Dual carb version - 12.75" wide

[url=

Comments on the above to layouts welcomed.

A more complete view of the 2nd one...

[url=

dual[/url]

The model requires more work to complete - but close enough for discussion... The removable top carb mounting plate (not shown) could be left blank to accept different carb types

One week and nary a comment.

You may as well include provisions for side draft carbs too.

Yep could do that. They would have to be pretty big side drafts though.

I can see the 2x4 using 2 x 390 cfm or 2 x 500 cfm carbs. Remember the 4200 head flow quite well.

Thought this would have generated more interest than it has. The biggest issue folks here have (after the looks) is the EFI.

This gets rid of the fuel side.

If you are willing to run side drafts you could run a pair of big bore DCOE Webbers (IIRC 50+ mm are available).

Of course if you are running side draft Webbers it seems a waste to run a plenum, but that's me.

flat 4200 intake[/url]

flat 4200 intake[/url]