|

|

Joined: Apr 2006

Posts: 831

Major Contributor

|

OP

Major Contributor

Joined: Apr 2006

Posts: 831 |

Is it possible and/or has anyone installed a Pontiac OHC on a 292?, looking at the seperated intake ports for EFI.

'45 Ford PU

66 Valiant wagon, leaning tower of power.

79 Chevy C10 w/250

02 PT Cruiser Convertable

|

|

|

|

|

Joined: May 2009

Posts: 493

Contributor

|

Contributor

Joined: May 2009

Posts: 493 |

Put a 292 crank into a Pontiac OHC engine would be way easier.

292 crank clearanced and ground to 2.00 crankpins destroked or not, 6 inch rods, and a set of custom pistons. No camshaft clearance issues like the pushrod engine. Might need some valve clearance notches on the pistons, I'm not sure about that. Everything else stock Pontiac.

I know that wasn't the question. Do you want to create a rocker arm and pushrod setup on the OHC head? Or actually run the overhead camshaft? Either seems a lot more work to fit on a 292 block.

Last edited by strokersix; 11/15/11 05:41 PM.

|

|

|

|

|

Joined: Apr 2011

Posts: 40

Active BB Member

|

Active BB Member

Joined: Apr 2011

Posts: 40 |

Why not look into the Brazilian produced multi-port head? From what Ihave heard there is one and it is now becoming popular (albeit pricey) and it will give some good verified results.

Normbc9

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

I think he is looking more at the "cool factor" than anything. Having an OHC 292 would be pretty neat.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Apr 2006

Posts: 831

Major Contributor

|

OP

Major Contributor

Joined: Apr 2006

Posts: 831 |

What I'm actually looking for is a divided intake port so the TPI injectors on a Clifford intake can be fired into their respective cylinders only. My other choices are possibly more expensive like bolt in or welded in port dividers or even more expensive a Brazillian hed. Both the 292 & 230 are 3.875 bores so there shouldn't be any valve shrouding, and now that you mention it an OHC 292 would be pretty neat.

'45 Ford PU

66 Valiant wagon, leaning tower of power.

79 Chevy C10 w/250

02 PT Cruiser Convertable

|

|

|

|

|

Joined: Oct 2007

Posts: 411

Contributor

|

Contributor

Joined: Oct 2007

Posts: 411 |

Brazillian head ? i didnt know there was such a critter for the 292 that has divided ports for the intake. i,d like to see a picture of that.......

I BELIEVE IN " JOHN 3:16 "

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

I'm pretty sure that adapting a Sprint head to a 292 (or other common Gen-3 block) is going to be rough going.

The other way (modify the 292 crank to get an acceptable rod length) is much easier, but not as large. The Sprint deck height is IIRC 9.15 like the Chevy. Using even a 5.7" rod (not enough for this stroke) the 4.12" arm means the piston is only 1.39" compression distance (for zero deck) and the piston for a 6" rod is an ashtray at 1.09". Dropping the stroke to 2.0" journal takes off about .095" (the pin difference, less .005" for clean-up).

What I don't know is, how far off are the head bolts, water, etc. between Sprint and Chevy?

Do you see where I'm going...

|

|

|

|

|

Joined: Oct 2000

Posts: 368

Contributor

|

Contributor

Joined: Oct 2000

Posts: 368 |

Several years ago I had a article, I think it was by John Thawley, about putting a 292 crank in a 250 for sprint car racing. It had all the technical info, pistons, rods, clearancing, and even how a cast crank was preferable to a forged crank for longevity. It's probably somewhere in my archives, but ??

Tim

Tim Tenold

I.I.#498

|

|

|

|

|

Joined: Apr 2006

Posts: 831

Major Contributor

|

OP

Major Contributor

Joined: Apr 2006

Posts: 831 |

The head bolts and water passages are close, the problems to use the OHC head on a Chev block is I'll have build some way of driving the belt, a belt tensioning system, , a fuel pump drive, oil pump drive, distributor drive, oil holes in the right place to supply the head and cam, drainback holes to get the oil back to the pan. Maybe leaving a stock cam in the block will solve the oil pump, fuel pump and distributor drive problems. The tensioner and drive may be adaptable from the Sprint engine.

Last edited by jalopy45 #4899; 11/20/11 09:31 PM. Reason: fut fingas

'45 Ford PU

66 Valiant wagon, leaning tower of power.

79 Chevy C10 w/250

02 PT Cruiser Convertable

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

What I was thinking is to give up the cam drive entirely, and just use the head casting by adapting pushrods and rockers to it.

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

The head bolts and water passages are close, the problems to use the OHC head on a Chev block is I'll have build some way of driving the belt, a belt tensioning system, , a fuel pump drive, oil pump drive, distributor drive, oil holes in the right place to supply the head and cam, drainback holes to get the oil back to the pan. Maybe leaving a stock cam in the block will solve the oil pump, fuel pump and distributor drive problems. The tensioner and drive may be adaptable from the Sprint engine.

Yep, it would definately present some challenges. Also a longer cam drive belt too. Can't be any harder than welding 2 SBC heads together and fabbing all the items together to make that hybrid head mod work.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Mar 2007

Posts: 8

Active BB Member

|

Active BB Member

Joined: Mar 2007

Posts: 8 |

I will have a go at getting some photos of the patterns from the cross flow, 12 port 194 - 292 head I am doing. The patternmaker is making good progress.

There is a way to go yet regarding cutting the first castings up and checking for wall thickness and core shift etc.

The head uses regular BB rockers and valves in a row,round intake

ports,exhaust between pushrods,custom length pushrods,spark plugs on intake side,standard rocker cover or fit the old style,

chambers are performance SB shape with volume to suit application.

|

|

|

|

|

Joined: Jul 2004

Posts: 365

Contributor

|

Contributor

Joined: Jul 2004

Posts: 365 |

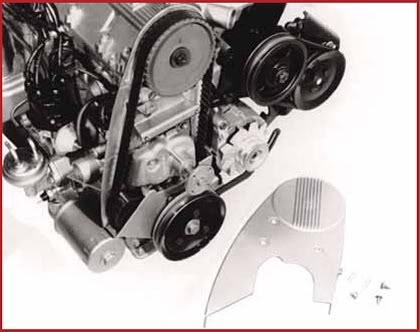

Why not use the front pulley from the Pontiac to drive the timing belt? The distributor, oil pump/filter and fuel pump all drive off an accessory unit. If the head is close, it maybe very viable.

|

|

|

|

|

Joined: Apr 2006

Posts: 831

Major Contributor

|

OP

Major Contributor

Joined: Apr 2006

Posts: 831 |

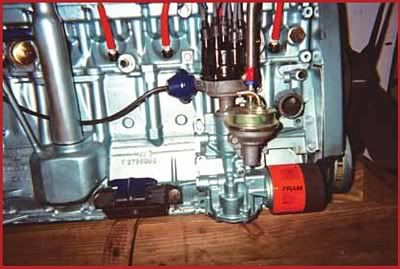

The front pulley and water pump will work, the tensioner/accessory drive wil probably have to be replace with a new design as the original ones had slots to slide up and down and held down with bolts into the block. ,  ,

'45 Ford PU

66 Valiant wagon, leaning tower of power.

79 Chevy C10 w/250

02 PT Cruiser Convertable

|

|

|

|

|

Joined: Jul 2000

Posts: 4,585 Likes: 19

1000 Post Club

|

1000 Post Club

Joined: Jul 2000

Posts: 4,585 Likes: 19 |

Why not use the front pulley from the Pontiac to drive the timing belt? The distributor, oil pump/filter and fuel pump all drive off an accessory unit. If the head is close, it maybe very viable. Why not for get the dist and go with coil on fire with a crank trigger.You can also think about a belt drive oil pump.If going to do all that other work to swap the head?

Larry/Twisted6 [oooooo]  Adding CFM adds boost   God doesn't like ugly.

|

|

|

|

|

Joined: Jul 2004

Posts: 365

Contributor

|

Contributor

Joined: Jul 2004

Posts: 365 |

Another option would be to block the oil lifter galley, then you could use the stock cam for all the accessories. All you would need is a belt tensioner.

|

|

|

|

|

Joined: Apr 2006

Posts: 831

Major Contributor

|

OP

Major Contributor

Joined: Apr 2006

Posts: 831 |

That would be the most logical way to run the oil pump, distributor and fuel pump, from the photo's and drawings I've been looking at, an oil return line may need to be installed from the rear of the head. I've called about a couple of complete engines for sale on craigslist but they were both small carb units. It looks like it's cheaper to buy the complete engine ($250-$500) than a head ($600).

'45 Ford PU

66 Valiant wagon, leaning tower of power.

79 Chevy C10 w/250

02 PT Cruiser Convertable

|

|

|

|

0 members (),

154

guests, and

49

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

|