|

|

Joined: Apr 2004

Posts: 3,555 Likes: 34

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2004

Posts: 3,555 Likes: 34 |

Keep your fingers crossed. A newly designed cross flow head for the 250-292 Chevy motor is in the works.

It is being developed in New Zealand by a daring individual. Intake will be on driver side and exhaust on the passenger side. Intake flows will be around 250, not sure on the exh. A custom intake will need to be made, same for the exhaust.

Individual intake ports are used. The chambers will also be of a modern quench type design.

The head is in the final stages and should be cast soon.

Just putting this out to see what interest there is.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

It sounds interesting. I guess as with everything interest will depend on price. We could save on shipping by having some of the multitude of Kiwis who go to Bonneville bring them along.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

They actually will only be available through US distributors that you will buy from, so the shipping will be rolled into the cost from them. As soon as they do come available, the R&D will begin to see what, if anything needs to be tweaked before they are released to the public. Should be interesting to finally have a 21st century cylinder head for these engines.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Aug 2009

Posts: 52

Active BB Member

|

Active BB Member

Joined: Aug 2009

Posts: 52 |

|

|

|

|

|

Joined: May 2000

Posts: 1,464

1000 Post Club

|

1000 Post Club

Joined: May 2000

Posts: 1,464 |

Two suggestions (based onmy own experience w/ prototype crossflow heads):  Make the head such that a simple adapter plate can be used to mount existing U-flow manifolds so the user will not have to obtain another manifold. Same with exhaust side. Make the head so it can be machined to flow A LOT more than 250 intake.

FORD 300 inline six - THE BEST KEPT SECRET IN DRAG RACING!

|

|

|

|

|

Joined: May 2010

Posts: 134

Contributor

|

Contributor

Joined: May 2010

Posts: 134 |

Will these new heads be iron or aluminum? With the low cost of sbc aluminum heads available why isn't the hybrid head more popular? Seems like reasonably straight forward deal other than plugging the block water holes. I am baseing this on Leo's build only.

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

This new head will be aluminum. Several reasons why the hybrid head isn't more popular is most racers have no interest in it, plus you don't end up with any better of a head than if you built a true brazed lump port head or a Kirby 12 port head. Also, you weaken the block too much by changing the bolt pattern to the head by redrilling into sections that don't have bolt bosses cast into the blocks deck surface. The later LS style V8 head would probably be a better choice because it comes much closer to using the existing bolt holes in the block than the early V8 heads do. Its also easier to make the head fit the block instead of trying to make the block fit the head. By the time your done, you just have too much money spent on doing a hybrid head compared to buying a head that already fits the block that doesn't require altering the block or head. I think the hybrid head was more of a "because he could" kinda' thing instead and just being different than thinking it actually was providing any real gains over other options that are available, and I think others see it as that and haven't tried to do it for themselves.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Sep 2004

Posts: 5,839 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,839 Likes: 1 |

That sounds interesting, finally another aftermarket cyl head that sounds to be better than a siamesed head.

If it only flows 250 CFM @ 28 inches, that is not much better than a lump port siamesed head? although they will be individual ports, that's a plus.

The Ford aluminum aftermarket inline six head flows better than stock but it's not cross flow & you do not need to make your exhaust manifold? A stock one or header can be used?

What's the price of the Ford head,, $1800, I think that is a good price for an aftermarket cyl head.

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Apr 2004

Posts: 3,555 Likes: 34

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2004

Posts: 3,555 Likes: 34 |

I was wrong about the flow. Initial testing shows 270 on intake and 200 on exh. With more to be had with details.

Using flanges to bolt a intake or exh will be light years ahead of clamping the parts on.

This would also be a cleaner head to bolt a turbo onto.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

Yeah its 270 CFM right out of the box, unported. So it has a lot of room to grow and can accomodate the needs of the more serious performance enthusiast looking to go to the next level.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

The stock Gen-3 L6 cam lobes for the siamese ports are: E I I E E I I E E I I E Is the new head the same, or will it require a billet cam? What makes this interesting is that the Chrysler Australia "hemi" L6 motor has the same bore pitch as the Chevy (4.40"). If the valve positions for separate ports are: E I E I E I E I E I E I the Chrysler's Weber, etc. manifold would be an easy adaptation, they might even make the intake side match the Chrysler completely to avoid the problem entirely. But - a new cam would be $$$. Here's a 4 bbl. Chrysler manifold

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

The costs of having the firing order changed on the new camshaft is not much more than the cost of an off the shelf camshaft. They might tack on a few extra bucks to call it a custom grind, but they all start out as round lobe blanks, and at they point can be made to accomodate any needs. A cam that has already be ground for one firing order cannot be reground for another firing order however. No need for billet unless you just wanted to use a roller cam.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

they all start out as round lobe blanks

We disagree.

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

I guess it depends on who is making the blank. All the ones I have ever seen are all of the round lobe, unfinished variety. I'll post a pic I have done lately for a customer. Who are you meaning by "we", you've been here long enough to know that no one every agrees with you.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Jun 2011

Posts: 56

Active BB Member

|

Active BB Member

Joined: Jun 2011

Posts: 56 |

Keep your fingers crossed. A newly designed cross flow head for the 250-292 Chevy motor is in the works.

It is being developed in New Zealand by a daring individual. Intake will be on driver side and exhaust on the passenger side. Intake flows will be around 250, not sure on the exh. A custom intake will need to be made, same for the exhaust.

Individual intake ports are used. The chambers will also be of a modern quench type design.

The head is in the final stages and should be cast soon.

Just putting this out to see what interest there is. I'm REAL interested! I am willing to buy a bare machined head as I want to do some valve train mods anyway.

Gearhead's Quickchange Exchange

"My Rear End is Louder Than Yours"

|

|

|

|

|

Joined: Jul 2012

Posts: 12

Active BB Member

|

Active BB Member

Joined: Jul 2012

Posts: 12 |

any word on this new head yet

norm roll

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

Work is still being completed on the patterns at this time. It was discussed to try and have a few raw castings made by the end of this year, so we'll see how close they make the deadline.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Jun 2011

Posts: 56

Active BB Member

|

Active BB Member

Joined: Jun 2011

Posts: 56 |

Gearhead's Quickchange Exchange

"My Rear End is Louder Than Yours"

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

Looking to have some raw castings before the end of the year. Got a few emails in the last few weeks stating its still on schedule for that. So we'll see.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Jun 2011

Posts: 56

Active BB Member

|

Active BB Member

Joined: Jun 2011

Posts: 56 |

Do we have a ball park price?

Gearhead's Quickchange Exchange

"My Rear End is Louder Than Yours"

|

|

|

|

|

Joined: Sep 2004

Posts: 5,839 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,839 Likes: 1 |

Minimun $2000 ish will be my guess.

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Apr 2004

Posts: 3,555 Likes: 34

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2004

Posts: 3,555 Likes: 34 |

Hard telling. I would hope it to be less than that. Plenty of variables, casting, shipping, machining ect.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Sep 2011

Posts: 210

Contributor

|

Contributor

Joined: Sep 2011

Posts: 210 |

Gotta love those Aussies. They do sick stuff with 6 cyls!

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

There aren't any Aussie's that have anything to do with this head, where did you get that idea.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: May 2000

Posts: 1,464

1000 Post Club

|

1000 Post Club

Joined: May 2000

Posts: 1,464 |

There aren't any Aussie's that have anything to do with this head, where did you get that idea. No... but they do have other brands of very high tech crossflow heads in Australia. Aussies in general do not view inline sixes as red-headed stepchildren as do many American consumers.

Last edited by THE FRENCHTOWN FLYER; 11/28/12 08:37 PM.

FORD 300 inline six - THE BEST KEPT SECRET IN DRAG RACING!

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

No... but they do have other brands of very high tech crossflow heads in Australia. Aussies in general do not view inline sixes as red-headed stepchildren as do many American consumers. [/quote] The Flyer speaks the truth here. Even in our own ranks are those who view the inline engine as a cute quaint leftover from another time. Tell that to the import tweekers whose turboed 4 cylinder inlines are the street racing terrors of the 21st century. Then look at what was offered in Australia in inline performance while we were drooling over cubic inches. We have to reverse engineer our inlines.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Apr 2006

Posts: 831

Major Contributor

|

Major Contributor

Joined: Apr 2006

Posts: 831 |

I'm waiting to see what intake and exhaust options are going to available for this new head. Them down under boys have engines that were designed for utilatarian use rather than speed like early Amercan engines, they have their share of V8's but the inline motors have the majority.

'45 Ford PU

66 Valiant wagon, leaning tower of power.

79 Chevy C10 w/250

02 PT Cruiser Convertable

|

|

|

|

|

Joined: Nov 2004

Posts: 178

Contributor

|

Contributor

Joined: Nov 2004

Posts: 178 |

I believe this Toyota Inline Six has done pretty well on US soil. What do you think? https://www.youtube.com/watch?v=sTaPp9vLYe0Anyway, after a long period away from my 250 Chevy, I´m now coming back slowly. Good to know that new heads are been thinked and, even better, about to be produced. There is a myth here in Brazil that someone at Sissel was casting the 12ports again. I still havent see any arround. But I´m just curious to see this new kiwi head!

250 and 261

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

You don't need a cross-flow head, either. The Nissan 240/260/280Z (RB26, etc. motors) do very nicely with 12 ports on 1 side.

|

|

|

|

|

Joined: Apr 2006

Posts: 831

Major Contributor

|

Major Contributor

Joined: Apr 2006

Posts: 831 |

There is a new 12 port head for the 6's and an 8 port for the 4's about to make a splash on the inline market real soon including intakes and are not Sissel's.

'45 Ford PU

66 Valiant wagon, leaning tower of power.

79 Chevy C10 w/250

02 PT Cruiser Convertable

|

|

|

|

|

Joined: Apr 2006

Posts: 831

Major Contributor

|

Major Contributor

Joined: Apr 2006

Posts: 831 |

There is a new 12 port head for the 6's and an 8 port for the 4's about to make a splash on the inline market real soon including intakes and are not Sissel's.

'45 Ford PU

66 Valiant wagon, leaning tower of power.

79 Chevy C10 w/250

02 PT Cruiser Convertable

|

|

|

|

|

Joined: Jun 2011

Posts: 56

Active BB Member

|

Active BB Member

Joined: Jun 2011

Posts: 56 |

Quit teasin'! Who? When? How much? This will definetly have an influence on my build.

Gearhead's Quickchange Exchange

"My Rear End is Louder Than Yours"

|

|

|

|

|

Joined: Apr 2006

Posts: 831

Major Contributor

|

Major Contributor

Joined: Apr 2006

Posts: 831 |

I'll leave it up to the manufacturer to do an official release but if you liked the Duggan and Deppe parts for the 6's and 4's, you're going to like this stuff. My guess is by the first of the year, possibly Christmas. I'm also hoping to see the new crossflow head by then as well, this will be an interesting year for inliners.

'45 Ford PU

66 Valiant wagon, leaning tower of power.

79 Chevy C10 w/250

02 PT Cruiser Convertable

|

|

|

|

|

Joined: Aug 2012

Posts: 166

Contributor

|

Contributor

Joined: Aug 2012

Posts: 166 |

So is this going to be a street able head or is this primarily for racing applications?

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

The 12 Port head will be available in both a solid race version and also a water jacketed version for street and racing as well. Along with it will be a mechanical fuel injection intake manifold and a single 4 BBL intake. A finned valve cover and also a 2 pc. timing cover and one piece timing cover w/fuel pump drive mounting are also available.

An 8 Port aluminum cylinder head for the 4 cylinder little brother of the 250/292 is also available along with an aluminum race block.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: May 2000

Posts: 1,464

1000 Post Club

|

1000 Post Club

Joined: May 2000

Posts: 1,464 |

Now we all need a 4.250 bore siamesed block.

FORD 300 inline six - THE BEST KEPT SECRET IN DRAG RACING!

|

|

|

|

|

Joined: Sep 2004

Posts: 5,839 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,839 Likes: 1 |

I'd be happy w/a 4.125" bore to take advantage of a larger valved better flowing cyl head.

To me no reason to go that big unless you just want a bigger engine, & that's cool also.

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Jun 2011

Posts: 56

Active BB Member

|

Active BB Member

Joined: Jun 2011

Posts: 56 |

Now we all need a 4.250 bore siamesed block. And a 5" Crank!!

Gearhead's Quickchange Exchange

"My Rear End is Louder Than Yours"

|

|

|

|

|

Joined: Jun 2011

Posts: 56

Active BB Member

|

Active BB Member

Joined: Jun 2011

Posts: 56 |

tlowe,

Now that Scott has come out of the closet, so to speak, would you care to share more on the crossflow head?

Gearhead's Quickchange Exchange

"My Rear End is Louder Than Yours"

|

|

|

|

|

Joined: Apr 2004

Posts: 3,555 Likes: 34

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2004

Posts: 3,555 Likes: 34 |

I've been out of the closet a long time. Just came out of the correct side.

Progress is still being made on the 12 port cross flow head. A slight water jacket addition had to be made. Hopefully the 1 st castings will be coming out soon!

It's hard to imagine a cleaner design like this did not come out long ago. A turbo system will have it perfect. Hot exhaust on one side, clean, cool fuel and intake on the other.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Jun 2011

Posts: 56

Active BB Member

|

Active BB Member

Joined: Jun 2011

Posts: 56 |

I can hardly wait. Will be saving up for the big debut.

Gearhead's Quickchange Exchange

"My Rear End is Louder Than Yours"

|

|

|

|

|

Joined: Jun 2011

Posts: 56

Active BB Member

|

Active BB Member

Joined: Jun 2011

Posts: 56 |

Gearhead's Quickchange Exchange

"My Rear End is Louder Than Yours"

|

|

|

|

|

Joined: Apr 2004

Posts: 3,555 Likes: 34

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2004

Posts: 3,555 Likes: 34 |

I hope to hear something soon.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

Got an email from him several weeks ago regarding something else, but no update on the crossflow head from him.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Apr 2004

Posts: 3,555 Likes: 34

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2004

Posts: 3,555 Likes: 34 |

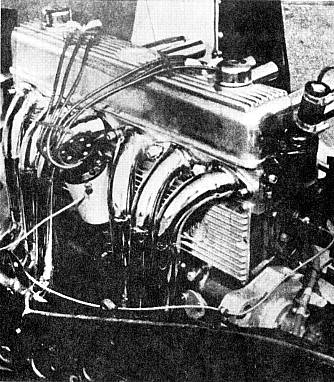

Progress as promised. Some pics of the new head. Remember, this is a raw casting, no machine work is done to it yet. It is also the first one made. Many refinements need to be done to get good consistent castings. Next will be making a jig / jigs for machining. What do you think? Intake ports are the round ones and are on drivers side. Sparkplugs are also on driverside. Exhaust ports are on passenger side and allow for multiple bolt patterns. You might also note the kidney shaped combustion chambers. Should be a fun one to turbo with the intake and exhaust being seperate.

Last edited by tlowe #1716; 05/19/13 01:22 AM. Reason: Beaters fault

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Jan 2012

Posts: 65

Active BB Member

|

Active BB Member

Joined: Jan 2012

Posts: 65 |

Wow, looks/sounds promissing for sure.

|

|

|

|

|

Joined: Jun 2007

Posts: 1,411

1000 Post Club

|

1000 Post Club

Joined: Jun 2007

Posts: 1,411 |

Looks darned good for as cast, even better for being the first one out of the tooling.

My, what a steep learning curve. Erik II#5155

|

|

|

|

|

Joined: Aug 2003

Posts: 1,905

1000 Post Club

|

1000 Post Club

Joined: Aug 2003

Posts: 1,905 |

The intakes look like they would flow good already!

Drew

Mid-Atlantic Chapter

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

That looks good. What is the chamber size? What valves will it use? What rockers?

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Apr 2004

Posts: 3,555 Likes: 34

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2004

Posts: 3,555 Likes: 34 |

Beater,

I am not sure on the chamber size. 1.94/ 1.6 valves. Standard pedestal mount Chevy 6 rocker arms.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Sep 2004

Posts: 5,839 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,839 Likes: 1 |

Round ports are much easier to deal with when making headers & intake manifolds. Square ports are a pain to make runners for. This guys paid big bucks to have runners made for his intake ports. post #111 & newer. http://www.theturboforums.com/threads/353498-Aussie-t51r-feed-202ci-holden-6/page5 $1800 for just the runners. MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

Hotrodding is as expensive as you make it!

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: May 2000

Posts: 1,464

1000 Post Club

|

1000 Post Club

Joined: May 2000

Posts: 1,464 |

.

Square ports are a pain to make runners for.

This guys paid big bucks to have runners made for his intake ports. MBHD ...Or you could just hammer some out over a chunk of wood:

FORD 300 inline six - THE BEST KEPT SECRET IN DRAG RACING!

|

|

|

|

|

Joined: Apr 2004

Posts: 3,555 Likes: 34

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2004

Posts: 3,555 Likes: 34 |

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

That's great! I am always impressed with people who actually do stuff.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Aug 2013

Posts: 5

Active BB Member

|

Active BB Member

Joined: Aug 2013

Posts: 5 |

I'm very interested in this head. I hope it works out. Looks pretty good so far.

|

|

|

|

|

Joined: May 2000

Posts: 1,464

1000 Post Club

|

1000 Post Club

Joined: May 2000

Posts: 1,464 |

That is very interesting. My first impressions:

I like the shape of the combustion chambers - it reflects current thinking and should burn fast and not need a (large) piston dome.

I like the placement of the exhaust runners but don't think round is necessarily the best shape.

I wonder why the intake port opening is so low on the casting. It looks like there is real estate to move it upward and minimize the effects of a tight short side floor radius. (see my photo above)

It also looks like you have the option to make the valve train either stud-mount rockers or shaft-mount rockers. I like that insofar as I have become a convert to the benefits of shaft-mount.

Symmetrically opposite paired cylinders can be problematic.

I realize you are quite far along in the casting process. I'm just brainstorming some thoughts which no doubt you have addressed. Good luck with this project.

FORD 300 inline six - THE BEST KEPT SECRET IN DRAG RACING!

|

|

|

|

|

Joined: Apr 2004

Posts: 3,555 Likes: 34

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2004

Posts: 3,555 Likes: 34 |

Frenchtown,

I had to think about your answers/ questions a bit.

You are looking at the ports wrong. The intakes are round and the exhaust are rectangular.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: May 2000

Posts: 1,464

1000 Post Club

|

1000 Post Club

Joined: May 2000

Posts: 1,464 |

Hey Tom, You're right - I did think the round ports were exhausts and the rectangular were intakes. The rectangular ones just looked so much larger than the round ones so I assumed they were the intakes. It looks like a fun project.

FORD 300 inline six - THE BEST KEPT SECRET IN DRAG RACING!

|

|

|

|

|

Joined: Jul 2013

Posts: 12

Active BB Member

|

Active BB Member

Joined: Jul 2013

Posts: 12 |

If these are produced and can be had for somewhere around the $1,800 range then I will definitely be interested in having one.

|

|

|

|

|

Joined: Jul 2014

Posts: 1

Newcomer

|

Newcomer

Joined: Jul 2014

Posts: 1 |

Hi - I'm new and just came across this. Did anyone actually ever get one of these and run it?

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

I think life just got in the way. I talked to him a few months ago about something unrelated and the head was never mentioned. This has been an ongoing project for close to 4 years or so, and sometimes you just hit a wall or lose interest.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Mar 2007

Posts: 8

Active BB Member

|

Active BB Member

Joined: Mar 2007

Posts: 8 |

The cross flow head is still work in progress and is more a hobby than commercial, hence my priorities are to my family and business (try manufacturing competing against China).

I have seen things on the first casting that have required a rethink as to ease of casting etc.

During the last month an intake pattern has been done for triple side drafts that could take any log style manifold bolted on as well.There is a cast exhaust pattern almost finished,three into one style.

Here in New Zealand there are not so many foundries to choose from capable of casting a head but saying that I like a challenge!

Alistair

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

Alistair, I sent you an email earlier today if you could respond. Thanks

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Jun 2011

Posts: 56

Active BB Member

|

Active BB Member

Joined: Jun 2011

Posts: 56 |

Gearhead's Quickchange Exchange

"My Rear End is Louder Than Yours"

|

|

|

|

|

Joined: Aug 2015

Posts: 13

Active BB Member

|

Active BB Member

Joined: Aug 2015

Posts: 13 |

I know it's been almost a year since the last post, but I figured this thread (more specifically, this product) deserves a bump. I'd love to see these go on sale, and might even be able to buy one on top of that.

|

|

|

|

|

Joined: May 2000

Posts: 1,464

1000 Post Club

|

1000 Post Club

Joined: May 2000

Posts: 1,464 |

If these are produced and can be had for somewhere around the $1,800 range then I will definitely be interested in having one. It would be a bargain if it could be marketed at twice that price.

FORD 300 inline six - THE BEST KEPT SECRET IN DRAG RACING!

|

|

|

|

|

Joined: Jun 2015

Posts: 13

Active BB Member

|

Active BB Member

Joined: Jun 2015

Posts: 13 |

I would be interested in this head being in Australia. As for Ford Australia made an Alloy Cross flow headed 250 from 81 to 93 . And CHI make an Alloy head for the Chrysler 265 Hemi.

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

I think he ran out of ambition.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Apr 2004

Posts: 3,555 Likes: 34

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2004

Posts: 3,555 Likes: 34 |

I think he ran out of ambition. Not the case. The first casting was cut up and examined. Realizing there were areas that need more work. The pattern was changed and then the second casting was poured. This casting was also cut up for examination. A third has been cast and is getting prepared for machining. This is expensive to do. The pattern work, casting cost all add up. The machining costs will also add up. Be patient, the project is moving forward.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

There are lots of folks around who talk about 12 port cross flow head production that seem to run out of something. "Ambition" is as good of a word as any.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Aug 2015

Posts: 13

Active BB Member

|

Active BB Member

Joined: Aug 2015

Posts: 13 |

Thanks for the update Tom! I am going to file this away for long term. Hopefully our truck will be ready for it by the time y'all start selling it.

|

|

|

|

|

Joined: Apr 2004

Posts: 3,555 Likes: 34

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2004

Posts: 3,555 Likes: 34 |

Keep in mind. This is not my project. Am simply passing on the info I know.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Apr 2004

Posts: 3,555 Likes: 34

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2004

Posts: 3,555 Likes: 34 |

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Jul 2000

Posts: 4,585 Likes: 19

1000 Post Club

|

1000 Post Club

Joined: Jul 2000

Posts: 4,585 Likes: 19 |

That is one Ugly looking head. But main Question is What does it flow? How big are the valves and How big of a valve will it take? Also that rear Pipe Looks vary close to the starter So I can see a heat issue there.

Larry/Twisted6 [oooooo]  Adding CFM adds boost   God doesn't like ugly.

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

The second distributer is a tall one. Another special part? The first headers would fix that.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

I bet the timing would be fun to set on that one with the headers hot.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Aug 2014

Posts: 821

Major Contributor

|

Major Contributor

Joined: Aug 2014

Posts: 821 |

I bet the timing would be fun to set on that one with the headers hot.  Not to mention the routing of the plug wires... I can understand why they went with the exhaust on that side but it does pose a few challenges. On the other side would have been tough for any kick-down linkages or throttle cable routing. Kinda damned if you do sort of thing. That said a turbo set-up with this would be really nice!

Last edited by gbauer; 10/16/15 10:56 AM.

|

|

|

|

|

Joined: Aug 2009

Posts: 52

Active BB Member

|

Active BB Member

Joined: Aug 2009

Posts: 52 |

When will the heads be ready?

|

|

|

|

|

Joined: May 2000

Posts: 1,464

1000 Post Club

|

1000 Post Club

Joined: May 2000

Posts: 1,464 |

Here's a simple solution to the distributor: a right angle drive using two Boston HLK101Y bevel gears. Now ANY distributor (or mag) could be used. Works for mine.  Also note the intake manifold adapter - it allows for the use of ANY aftermarket or production intake by changing the stud locations to stock production dimensions.

Last edited by THE FRENCHTOWN FLYER; 11/10/15 11:06 AM.

FORD 300 inline six - THE BEST KEPT SECRET IN DRAG RACING!

|

|

|

|

|

Joined: Apr 2004

Posts: 3,555 Likes: 34

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2004

Posts: 3,555 Likes: 34 |

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Aug 2014

Posts: 821

Major Contributor

|

Major Contributor

Joined: Aug 2014

Posts: 821 |

are you setting this up to take individual injectors for EFI? Looks like it with the bosses on the intake runners.

|

|

|

|

|

Joined: May 2000

Posts: 1,464

1000 Post Club

|

1000 Post Club

Joined: May 2000

Posts: 1,464 |

Injectors are best aimed at the base of the intake valves. Those boss locations may work better for vacuum taps - or nitrous injection.

FORD 300 inline six - THE BEST KEPT SECRET IN DRAG RACING!

|

|

|

|

|

Joined: Nov 2004

Posts: 420

Contributor

|

Contributor

Joined: Nov 2004

Posts: 420 |

Be nice if injector tubes were like the 360 Outlaw Sprint Cars were and reach all the way down the port to the base of the intake valve...They remove the hose and screw out the injector and pull it out of the port. It is about 10 inches long.

Last edited by SCRAPIRON, #4711; 03/23/17 04:58 PM.

Jerry Davis II#4711

ol Smokey said "one test is worth a thousand expert opinions."

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

Just remember that the person undertaking this project is not very knowledgeable about the dynamics or mechanics of cylinder head design or airflow. And is only doing it to basically check off a box on his bucket list, and is really only a labor of love for him. So it is what it is, and has a long way to go to even be tested, much less proven. So don't expect it to be a contender by any means even against a lump port head.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Apr 2004

Posts: 3,555 Likes: 34

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2004

Posts: 3,555 Likes: 34 |

Just remember that the person undertaking this project is not very knowledgeable about the dynamics or mechanics of cylinder head design or airflow. And is only doing it to basically check off a box on his bucket list, and is really only a labor of love for him. So it is what it is, and has a long way to go to even be tested, much less proven. So don't expect it to be a contender by any means even against a lump port head. The head project is not mine. Not sure why you would make such a comment about someones work and passion. He may comment, but I will say he has gone to great lengths to make this a great head. It is pretty exciting that someone is trying to develop a new meat and potato product for this engine in this day and age.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Nov 2004

Posts: 420

Contributor

|

Contributor

Joined: Nov 2004

Posts: 420 |

I wish i was a expert with millions to play with.. being i am NOT "I got to dance with who brung me" I just WISH someone who WAS, would think out of the box...Be a trend setter not a trend follower. Some how make them wider,taller and get those port straighter. See i told you i wasn't a expert but a pretty good day dreamer...!!

Jerry Davis II#4711

ol Smokey said "one test is worth a thousand expert opinions."

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

I know its not your project, Alistair contacted me originally for design consultation and input and told me that his goal was strictly to do it because he always wanted too, and had no background in how to make one really, and no real expectation it would be anything other than a "one off" or very low quantity type of product. Not knocking him at all, just informing those that questioned the bosses on the intake and that they don't align with their thinking and experience in these matters. He is just a simple guy that has a goal, but isn't an engineer or designer with those types of skill sets, and it was never his goal to make something to be on the same level with Brodix or Dart or even Sissell. I think everyone else's expectations are higher than his.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Mar 2007

Posts: 8

Active BB Member

|

Active BB Member

Joined: Mar 2007

Posts: 8 |

The bosses are for vacuum tapping or any bracket, NOT injection.

The same pattern is used for all three, simplicity is best.

I made my own flow bench from scratch to understand what was required,so the condescending remarks Scott about the simple guy without the skill set for this is uncalled-for, get off your high horse.

I spoke to you originally about the viability of selling a head not design consultation as you call it.

Where are the positive remarks that would have been plentiful when I joined Inliners International many years ago.

The Kiwi "can do" approach suits me best.

Alistair Parker

|

|

|

|

|

Joined: Nov 2012

Posts: 551

Major Contributor

|

Major Contributor

Joined: Nov 2012

Posts: 551 |

Josh

72 gmc lwb air ride 5 speed (soon) turbo 292 II# 6102

|

|

|

|

|

Joined: Nov 2012

Posts: 551

Major Contributor

|

Major Contributor

Joined: Nov 2012

Posts: 551 |

I think it looks slicker than snot I am also building my own intake I am not sure how well it will work but it's a lot of fun!

Now you took it to a whole nother leve . Keep it going it's looking good

Josh

72 gmc lwb air ride 5 speed (soon) turbo 292 II# 6102

|

|

|

|

|

Joined: Aug 2014

Posts: 821

Major Contributor

|

Major Contributor

Joined: Aug 2014

Posts: 821 |

With the individual intake ports a port injection system might be something to play with down the road. I'd guess it would be easier to one-off fab one out of steel rather than cast it.

Regardless I've recently sold my inline but I like to see people trying new stuff.

...and I was really starting to hate my carb...

Good luck!

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

Sorry if you feel my comments were condescending by referring to you as "simple", meaning average like most of us including me, they weren't meant to be. Just giving an explanation to previous comments and not meant to downplay your efforts or abilities. Its been a long time since this project got started and many are anxious to see results and a working prototype in action. Good luck, you've at least gotten a head or two cast and machined it appears. And the "can do" approach has gotten you this far so keep plugging away at it.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Jul 2000

Posts: 4,585 Likes: 19

1000 Post Club

|

1000 Post Club

Joined: Jul 2000

Posts: 4,585 Likes: 19 |

Well this head be able to run water?

Larry/Twisted6 [oooooo]  Adding CFM adds boost   God doesn't like ugly.

|

|

|

|

|

Joined: Mar 2007

Posts: 8

Active BB Member

|

Active BB Member

Joined: Mar 2007

Posts: 8 |

Yes will run water.

Just a little background. 80% of the pattern making time is in the water jacket cores and figuring it out,what a mission. I was not comfortable with the water flow around the plugs down the intake side so I put a water gallery in that widens the head at that point.

Dissecting a typical Japanese cylinder head (masters of casting) shows very thin wall castings that take little space but a slight core shift in the common limited run, jobbing foundry means leakage before or after machining. Porosity in castings is not such an issue these days but saying that the head has extra holes in the casting for venting that get plugged.

I made the intake ports very thick for extreme metal removal !

Going cross flow on such a narrow block things get crowded if you want to keep the pushrods in the original position.

Many aftermarket aluminium V8 heads have surprisingly little water jacketing on the intake side I discovered.

Alistair

|

|

|

|

|

Joined: Jul 2000

Posts: 4,585 Likes: 19

1000 Post Club

|

1000 Post Club

Joined: Jul 2000

Posts: 4,585 Likes: 19 |

Nice Job on it so far anyway. Have you had a chance to run any flow #s On it yet? And What size valves will it be able to handle?

Larry/Twisted6 [oooooo]  Adding CFM adds boost   God doesn't like ugly.

|

|

|

|

|

Joined: Mar 2007

Posts: 8

Active BB Member

|

Active BB Member

Joined: Mar 2007

Posts: 8 |

When I flowed the plastic pattern, 180 cfm on the exhaust and 270 on the intake with 1.6 and 1.94 valves, 2.02 fits no problem. The difficulty was getting a good seat in the pattern. I haven't flowed a cast head yet as the first two were cut up to check all over the casting for consistent thickness. I moved the valves so the big pushrods do not touch the side of the block but they are still at the original centers.

|

|

|

|

|

Joined: Oct 2009

Posts: 471 Likes: 9

Contributor

|

Contributor

Joined: Oct 2009

Posts: 471 Likes: 9 |

|

|

|

|

|

Joined: Apr 2003

Posts: 1,537 Likes: 15

1000 Post Club

|

1000 Post Club

Joined: Apr 2003

Posts: 1,537 Likes: 15 |

The Kiwi "can do" approach suits me best.

I am a big fan of doers . . . and triple Webers! Not to mention the perseverance to stick with one's vision even when the realization takes time. To cut up your prototypes in order to tick and tie the details on the casting internals is proof enough for this inliner that you are serious about getting this right. Are you really going to try to fit a dizzy to the hot side of the engine? Some of the earlier photos suggested so. Coil over plug with a crank trigger might prove easier - though hardly vintage . . . What car is this power plant destined for?

|

|

|

|

|

Joined: Mar 2007

Posts: 8

Active BB Member

|

Active BB Member

Joined: Mar 2007

Posts: 8 |

Thanks for the interest guys.I figure there is an insulation out there in this high tech space age thin enough to shroud and protect the distributor on the 250, the 292 is easier.The right angle drive idea is great on a truck but a Nova not good.

I do not think it necessary to go the crank trigger way at this stage.

When running on the test stand I will put a thermocouple on it to see what's happening.

This head with early valve cover and traditional carbs etc will look old school as per the Wayne head.

I had to slightly bulge the end of the metal valve cover to fit over the rockers, hardly noticeable, Tom will have it sorted with his cover.

Alistair

|

|

|

|

|

Joined: Apr 2003

Posts: 1,537 Likes: 15

1000 Post Club

|

1000 Post Club

Joined: Apr 2003

Posts: 1,537 Likes: 15 |

Ah yes that Wayne Horning look  now I am even a bigger fan of the build. With the dizzy hole so far forward I guess the header tubes can just sweep back . . . Will the outer perimeter of the head eventually be trimmed/slimmed once the internals are sorted?

|

|

|

|

|

Joined: Oct 2009

Posts: 471 Likes: 9

Contributor

|

Contributor

Joined: Oct 2009

Posts: 471 Likes: 9 |

|

|

|

|

|

Joined: Dec 2017

Posts: 17

Active BB Member

|

Active BB Member

Joined: Dec 2017

Posts: 17 |

|

|

|

|

|

Joined: Jan 2010

Posts: 349

Contributor

|

Contributor

Joined: Jan 2010

Posts: 349 |

Any update on this glorious project?

I am often heard saying “bit of kiwi ingenuity” having lived there!

|

|

|

|

|

Joined: Sep 2017

Posts: 209 Likes: 2

Contributor

|

Contributor

Joined: Sep 2017

Posts: 209 Likes: 2 |

Any chance they will be making a blower manifold?

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

I would guess that they didn't anticipate enough sales volume to warrant the R&D.

|

|

|

|

|

Joined: Sep 2017

Posts: 209 Likes: 2

Contributor

|

Contributor

Joined: Sep 2017

Posts: 209 Likes: 2 |

I don't have a distributor. I will need an intake for a 4-71 blower, any takers? Will stainless header flanges be available?

Last edited by mick53; 12/10/18 03:14 AM.

|

|

|

|

|

Joined: Sep 2017

Posts: 209 Likes: 2

Contributor

|

Contributor

Joined: Sep 2017

Posts: 209 Likes: 2 |

It would be nice to find someone that is building a stout 292 with a billet crank and maybe say 3 Roch, 2 bbl carbs. Crank fired ignition, external oil pump and a 4-71 blower. That would be a great test for it. I would put that guy at the top of my waiting list. Especially if it were being built by someone like Gaerte Racing Engines. Tom might know such a guy. It would be all the rage at SEMA in say a 53 1/2 ton with TKO 600 and Frankland quick change rear end. Just a thought.

|

|

|

|

|

Joined: Jan 2013

Posts: 80

Active BB Member

|

Active BB Member

Joined: Jan 2013

Posts: 80 |

Any updates from Mr. Alistair?

|

|

|

|

1 members (stock49),

276

guests, and

27

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

|