|

|

Joined: Aug 2013

Posts: 78

Active BB Member

|

OP

Active BB Member

Joined: Aug 2013

Posts: 78 |

Good morning all! I decided to go ahead and make a separate thread for my 250 build (some might remember I started this back in 2014 but had to pause for a few years). I'm now retired from the Navy and even though life hasn't slowed down much, I do have more time to wrench on the old things I like!

Thankfully I was able to hold on too many of the parts I already purchased for the engine; just not the truck......but I picked up a real gem recently so I'm back at it!

So what I have now is:

1. 250 shortblock with 83k on it that needs a rebuild

2. 194 non integrated head I purchased from Mr HotRod6

3. Clifford Intake, Shorty Headers, and single Weber 2 barrel carb/air cleaner

4. Davis Speed Equipment Alt/pwr steering/AC brackets as I plan to run all systems

5. Fel Pro engine gasket set

6. AC Delco Starter

7. Tuff Stuff alternator/power steering pump

8. Misc hoses/clamps etc.

I think the next logical step is to start building the shortblock. Although I'm still taking things apart on the truck, that's ok because it will take me a bit of time to purchase all the parts I'd like to run in the engine so that works out just fine.

Down the road I'd like to run some form of boost so forged pistons and connecting rods are on my wish list along with ARP main studs. I'll need some time to find a good machine shop in my area as well.

Right now it looks like Scat 6" H-Beam rods are readily available from a few different sources but I'll need to find a source for pistons. I see alot of SBC/BBC/LS slugs but not much in the way of inline 6.

Also need to figure out the camshaft profile as well.

Plenty of details to keep me busy for the the foreseeable future! Looking forward to FINALLY moving forward on this engine build!!

|

|

|

|

|

Joined: Feb 2014

Posts: 505

Major Contributor

|

Major Contributor

Joined: Feb 2014

Posts: 505 |

Finances caused me to pause my project too. Hoping to pick it back up in the next year. Right now just keeping it running and doing the cheap and laborious fixes on it.

Have the 194 head combustion chambers been worked on or stock CCs and valve shrouding?

|

|

|

|

|

Joined: Aug 2013

Posts: 78

Active BB Member

|

OP

Active BB Member

Joined: Aug 2013

Posts: 78 |

Finances caused me to pause my project too. Hoping to pick it back up in the next year. Right now just keeping it running and doing the cheap and laborious fixes on it.

Have the 194 head combustion chambers been worked on or stock CCs and valve shrouding? Funny how and when the curve balls come! Everything is stock on the 194 head for now anyway; Larry/aka Twisted6 gave me some advice a few years back on what to do to the head to get some solid performance out of it. So my plan is to follow his advice when the time comes to work on it.

|

|

|

|

|

Joined: Aug 2013

Posts: 78

Active BB Member

|

OP

Active BB Member

Joined: Aug 2013

Posts: 78 |

Question: who offers a 6.2 rod and forged piston for the 250?

|

|

|

|

|

Joined: Aug 2013

Posts: 78

Active BB Member

|

OP

Active BB Member

Joined: Aug 2013

Posts: 78 |

I suppose I should state my power level goals. Due to NOT being independently wealthy I'll be doing this build in roughly 2 stages, maybe 3.

Stage 1 is a dependable daily driver type. So utilizing the Clifford intake/exhaust parts. I'll be running the Weber 2 barrel for initial break-in and driving until I save enough for Stage 2; a turbo system and associated induction system/components. Going to run a modified STS type setup, hopefully with an air to air intercooler.

When it's all said and done I'd like 400rwhp. Nothing earth shattering but that's a good number in a 2wd pickem-up-truck!

Shortblock and head are the keys to making this work. I want to build the motor such that I don't have to go back in and redo anything; if I can help it anyway.

Looks like the Scat 6" rods are fairly easy to track down but a nice flat top forged piston is a little tougher.

The two companies I know of that offer a piston are 12bolt.com and Sissell, both about $600 +/-

Problem is most overbores I see are 40 and 60 over. How much bore wear do these motors typically see? I was always told to take what you need to get the bore prepped correctly and save a little for another rebuild. On previous engines I've had to take .005 and .020 to get the cylinders prepped; but those were on engines where forged pistons were more readily available.

Anyway, just trying to get my list of parts and associated costs together for the rebuild so I can present the numbers to mama! haha!

take care!

Last edited by moregrip; 07/20/17 08:53 AM.

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

Question: who offers a 6.2 rod and forged piston for the 250? Most all connecting rod companies offer them as a custom part, but also at a custom price. 5.700" and 6.00" are the norm for the 250 engines for off the shelf, modest pricing rods. As for piston sizes, you will rarely find a 250 or 292 that will clean up at .030" over, and i've seen many that had a couple of cylinders that wouldn't even clean up at .060". The front 2 cylinders are the worst ones typically. So find a block and get it rough bored first to verify it will clean up at an acceptable bore size before buying pistons. You seemed surprised at the cost of pistons, many people expect that building a 6 cylinder is somewhat cheaper than a V8 because there are 2 less cylinders. Its often considerably more and even with less HP than you'd get with a V8 unfortunately. So don't let cost hinder you.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Aug 2013

Posts: 78

Active BB Member

|

OP

Active BB Member

Joined: Aug 2013

Posts: 78 |

Question: who offers a 6.2 rod and forged piston for the 250? Most all connecting rod companies offer them as a custom part, but also at a custom price. 5.700" and 6.00" are the norm for the 250 engines for off the shelf, modest pricing rods. As for piston sizes, you will rarely find a 250 or 292 that will clean up at .030" over, and i've seen many that had a couple of cylinders that wouldn't even clean up at .060". The front 2 cylinders are the worst ones typically. So find a block and get it rough bored first to verify it will clean up at an acceptable bore size before buying pistons. You seemed surprised at the cost of pistons, many people expect that building a 6 cylinder is somewhat cheaper than a V8 because there are 2 less cylinders. Its often considerably more and even with less HP than you'd get with a V8 unfortunately. So don't let cost hinder you. Hey thanks for the reply CNC Dude; not really shocked by the price just kicking myself for not buying a set of forged 307 pistons when I had the chance a few years back! I suppose the offset benefit is a modern ring package and floating pins. I didn't realize these blocks took so much to clean up; I'll definitely take your advice and see what it will take to clean mine up before I purchase pistons though. I will be going with the 6" rod mainly because they are stock items and more reasonable cost wise. Looks like I'll need 12-15lbs of boost to get my desired 400rwhp, so I'm looking at an ARP short stud and/or bolt option for the 3 bolt in lumps; will be using ARP head studs everywhere else and a MLS type gasket for a good seal.

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

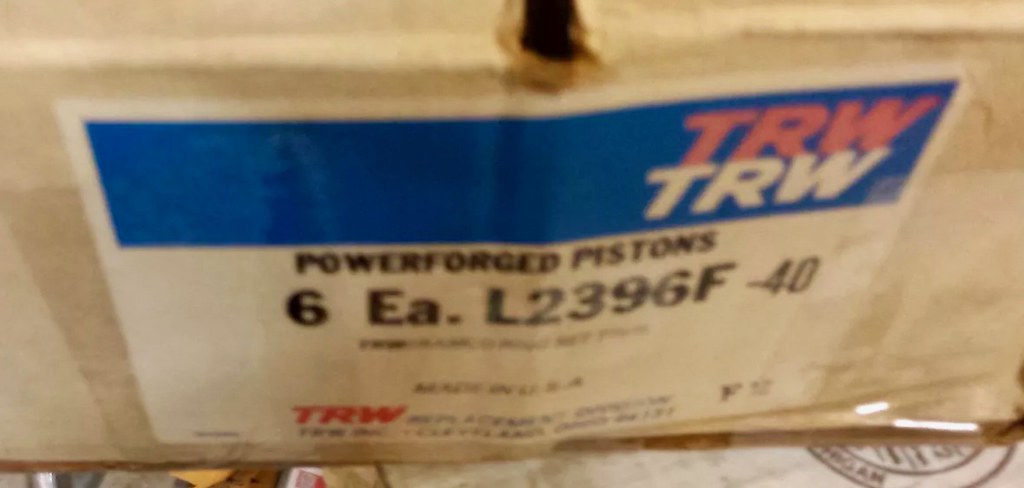

Question: who offers a 6.2 rod and forged piston for the 250? Most all connecting rod companies offer them as a custom part, but also at a custom price. 5.700" and 6.00" are the norm for the 250 engines for off the shelf, modest pricing rods. As for piston sizes, you will rarely find a 250 or 292 that will clean up at .030" over, and i've seen many that had a couple of cylinders that wouldn't even clean up at .060". The front 2 cylinders are the worst ones typically. So find a block and get it rough bored first to verify it will clean up at an acceptable bore size before buying pistons. You seemed surprised at the cost of pistons, many people expect that building a 6 cylinder is somewhat cheaper than a V8 because there are 2 less cylinders. Its often considerably more and even with less HP than you'd get with a V8 unfortunately. So don't let cost hinder you. not really shocked by the price just kicking myself for not buying a set of forged 307 pistons when I had the chance a few years back! Not all forged pistons are created equal. For the expected boost level you are seeking, you need a very premium quality piston forging, and TRW doesn't offer that in the 307 style pistons. You need a true forced induction aluminum alloy and specific piston die to create a piston forging that can withstand the constant cylinder pressures of 12-15 psi. The TRW's will only last for the short term, but soon fall victim to being subjected to use it wasn't designed or intended for. For forced induction, you need a 2618 grade alloy piston. You can also get other custom features to ensure longer piston life with a custom piston that you won't get with an "off the shelf" piston like the TRW. Even companies that manufacture MLS head gaskets only rank it in the middle of the pack for sealing ability for forced induction compared to copper gaskets and o-ringing, which they highly recommend for that type of usage. Plus, MLS gaskets require some more specific machine work that makes them less forgiving if these procedures aren't followed also. And not all machine shops are capable of performing these tasks, so make sure your machine shop has experience with them and knows how to follow and perform these tasks because the gasket company many not honor any warranty issues if the block and head aren't prepped correctly.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: May 2000

Posts: 1,464

1000 Post Club

|

1000 Post Club

Joined: May 2000

Posts: 1,464 |

My block machinist told me a MLS like a Cometic reqiures a mirror-like finish on both the deck and head surfaces.

FORD 300 inline six - THE BEST KEPT SECRET IN DRAG RACING!

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

Yes, they have a minimum allowable surface finish and minimum flatness requirement. So every time the head is removed, those things have to be maintained or sealing will suffer.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Aug 2013

Posts: 78

Active BB Member

|

OP

Active BB Member

Joined: Aug 2013

Posts: 78 |

Question: who offers a 6.2 rod and forged piston for the 250? Most all connecting rod companies offer them as a custom part, but also at a custom price. 5.700" and 6.00" are the norm for the 250 engines for off the shelf, modest pricing rods. As for piston sizes, you will rarely find a 250 or 292 that will clean up at .030" over, and i've seen many that had a couple of cylinders that wouldn't even clean up at .060". The front 2 cylinders are the worst ones typically. So find a block and get it rough bored first to verify it will clean up at an acceptable bore size before buying pistons. You seemed surprised at the cost of pistons, many people expect that building a 6 cylinder is somewhat cheaper than a V8 because there are 2 less cylinders. Its often considerably more and even with less HP than you'd get with a V8 unfortunately. So don't let cost hinder you. not really shocked by the price just kicking myself for not buying a set of forged 307 pistons when I had the chance a few years back! Not all forged pistons are created equal. For the expected boost level you are seeking, you need a very premium quality piston forging, and TRW doesn't offer that in the 307 style pistons. You need a true forced induction aluminum alloy and specific piston die to create a piston forging that can withstand the constant cylinder pressures of 12-15 psi. The TRW's will only last for the short term, but soon fall victim to being subjected to use it wasn't designed or intended for. For forced induction, you need a 2618 grade alloy piston. You can also get other custom features to ensure longer piston life with a custom piston that you won't get with an "off the shelf" piston like the TRW. Even companies that manufacture MLS head gaskets only rank it in the middle of the pack for sealing ability for forced induction compared to copper gaskets and o-ringing, which they highly recommend for that type of usage. Plus, MLS gaskets require some more specific machine work that makes them less forgiving if these procedures aren't followed also. And not all machine shops are capable of performing these tasks, so make sure your machine shop has experience with them and knows how to follow and perform these tasks because the gasket company many not honor any warranty issues if the block and head aren't prepped correctly. Blessing in disguise on the pistons!! I am familiar with the surface finish needed for MLS gaskets, I think we went with an RA 80 for my LS motor build back in 2005, and I believe the ideal range is RA 60-100? But it's been a while!

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

I'm moving farther and farther away from the inlines myself and getting back to my grass roots in racing and the LS stuff is where I spend much of my time now. And the MLS stuff is pretty good for them at the moment.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Aug 2013

Posts: 78

Active BB Member

|

OP

Active BB Member

Joined: Aug 2013

Posts: 78 |

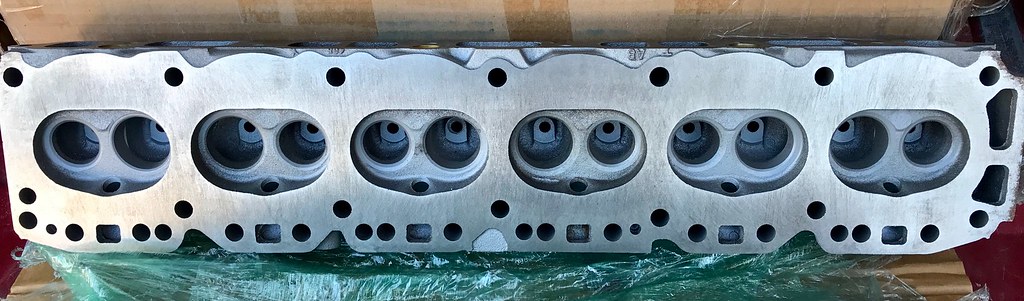

Couple more details to complete the build: inline 6 head cleaned up and ready for more work:  not here yet, but, on their way, NOS 250 inline 6 forged pistons!

|

|

|

|

0 members (),

148

guests, and

20

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

|