|

|

Joined: Jun 2005

Posts: 590

Major Contributor

|

OP

Major Contributor

Joined: Jun 2005

Posts: 590 |

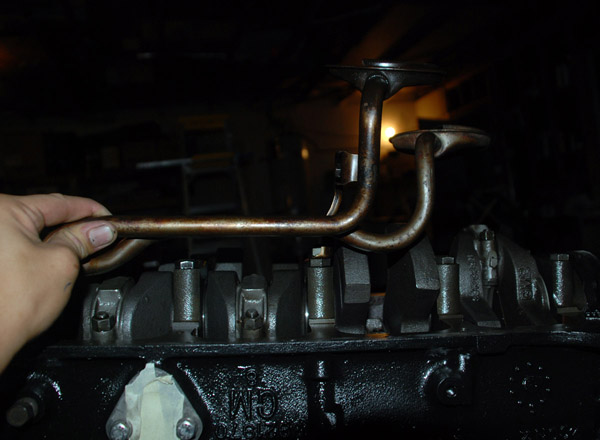

Did the 250 have a support for the oil pickup? I know that the 292 did, but it won't work with the 250 oil pickup.   For those that don't know, I'm installing a 292 in a 63 Nova and need to use a rear sump oil pan.

Last edited by 63ChevyII; 08/26/09 03:51 AM.

|

|

|

|

|

Joined: Jul 2000

Posts: 1,613

1000 Post Club

|

1000 Post Club

Joined: Jul 2000

Posts: 1,613 |

Yes, the one I have had a support.

I.I. #3174

|

|

|

|

|

Joined: Apr 2004

Posts: 3,566 Likes: 37

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,566 Likes: 37 |

i have had to modify one to fit. used the 230/250 one to modify. tom

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Jun 2005

Posts: 590

Major Contributor

|

OP

Major Contributor

Joined: Jun 2005

Posts: 590 |

hmm... Someone gave me the pickup and pan, but I don't think the support was in the box. I probably won't be able to order on online will I?

Last edited by 63ChevyII; 08/26/09 02:14 PM.

|

|

|

|

|

Joined: Apr 2004

Posts: 3,566 Likes: 37

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,566 Likes: 37 |

no new ones that i know of. find a used one. get the stud too. or just get a stud and make the clamp. one tip for you that i have learned with the 292. make sure to double check clearances with the crankshaft. it will clear, even with a car pan. tom

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Jun 2005

Posts: 590

Major Contributor

|

OP

Major Contributor

Joined: Jun 2005

Posts: 590 |

Thanks for the help.

I have a friend that is going to look through some stuff to see if he has one. Does anyone have picture of one that I can send him?

|

|

|

|

|

Joined: Jan 2007

Posts: 20

Active BB Member

|

Active BB Member

Joined: Jan 2007

Posts: 20 |

Lyndon,

I saw the picture and I will look for that part. Are you in a big hurry for it? If not, I could look for it on Saturday.

Later,

Sgt. Steve

|

|

|

|

|

Joined: Jun 2005

Posts: 590

Major Contributor

|

OP

Major Contributor

Joined: Jun 2005

Posts: 590 |

Lyndon,

I saw the picture and I will look for that part. Are you in a big hurry for it? If not, I could look for it on Saturday.

Later,

Sgt. Steve Hey Steve. I don't want you to make a special trip for it, but the sooner I can get it the better. I was supposed to bring the engine down to Vince's last Sunday, but I'm still trying to finish some stuff up. He's helping me with the mini-subframe kit install, disc brakes, rear end and engine.

|

|

|

|

|

Joined: Jan 2007

Posts: 20

Active BB Member

|

Active BB Member

Joined: Jan 2007

Posts: 20 |

This is all for your 63? You sold your 65 didn't you?

|

|

|

|

|

Joined: Jun 2005

Posts: 590

Major Contributor

|

OP

Major Contributor

Joined: Jun 2005

Posts: 590 |

This is all for your 63? You sold your 65 didn't you? Yup - it's for the 63. I sold my 65 Nova, 66 C-10 and 70 C-10...

|

|

|

|

|

Joined: Jun 2005

Posts: 590

Major Contributor

|

OP

Major Contributor

Joined: Jun 2005

Posts: 590 |

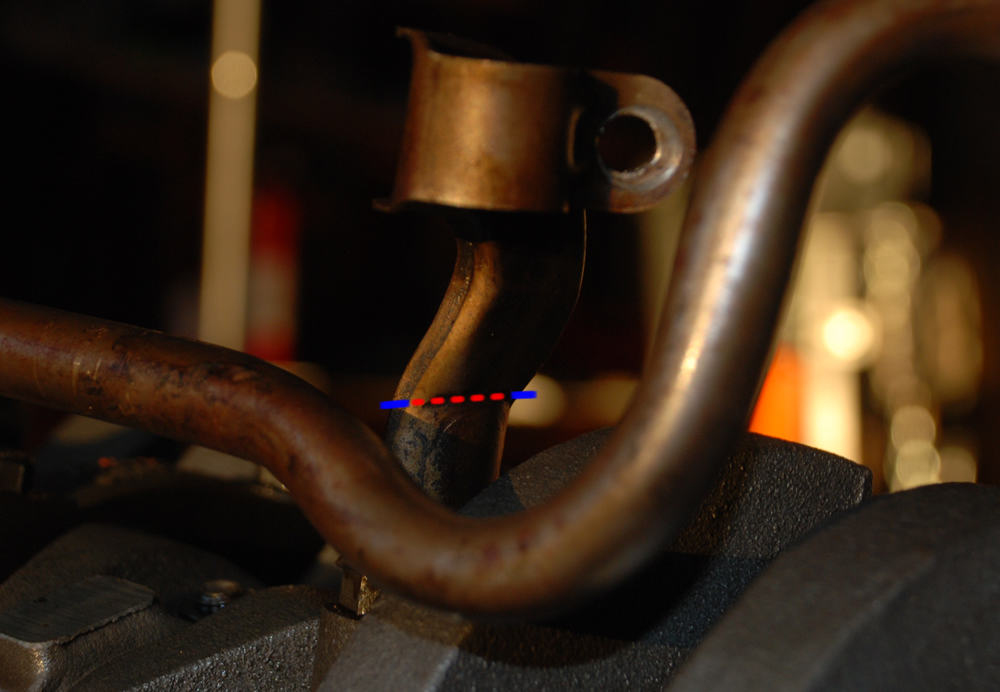

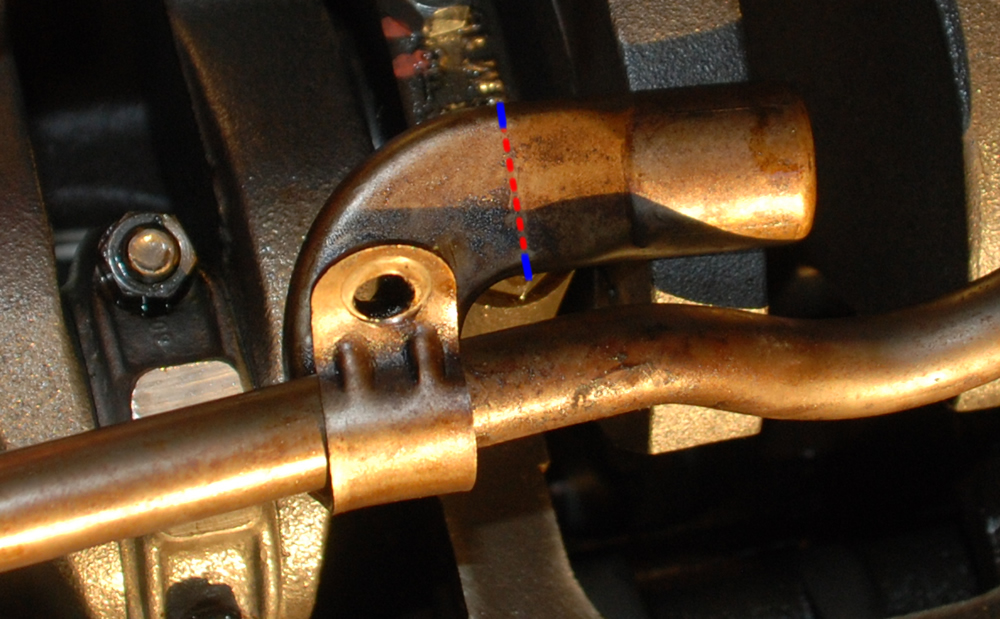

I spent some time looking at the support tonight. I don't see why I shouldn't just cut the edges (edges are curled for support) and bend the support towards the front of the engine. I hope this illustrates what I mean - this is the support bolted down where it is supposed to be. I'd cut on the blue and bend at the red, then tack weld on the corners:  Here's a view with the support clipped to the pickup. If I bent it 90 degrees on the red line, it should bolt up where is it supposed to:  what do you guys think?

Last edited by 63ChevyII; 08/27/09 12:11 AM.

|

|

|

|

|

Joined: Jun 2005

Posts: 590

Major Contributor

|

OP

Major Contributor

Joined: Jun 2005

Posts: 590 |

I was able to find a pickup for a 250. Can I just move the stud to where it would work with the support and move the bolt to where the stud was?

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

Lyndon, it will be fine to do that, just loosen both bolts on each cap to do this, and not just the one bolt you need to take out.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Jun 2005

Posts: 590

Major Contributor

|

OP

Major Contributor

Joined: Jun 2005

Posts: 590 |

Thanks - When I put them back on, what do they need to be torqued to?

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

Most general shop manuals will say 65-70 ft. lbs. usually.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Jun 2005

Posts: 590

Major Contributor

|

OP

Major Contributor

Joined: Jun 2005

Posts: 590 |

how much clearance do I need between the crank and oil pickup support. After some grinding on the support, this is what I have:

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

As long as you have at least a 1/16" of an inch clearance from all rotating parts you will be fine. Also make sure the pickup depth is the same as the original, and not higher or a lot lower than before.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Jun 2005

Posts: 590

Major Contributor

|

OP

Major Contributor

Joined: Jun 2005

Posts: 590 |

As long as you have at least a 1/16" of an inch clearance from all rotating parts you will be fine. Also make sure the pickup depth is the same as the original, and not higher or a lot lower than before. I think there's about 1/16 of an inch of clearance. I think I will grind more away though to be on the safe side.

|

|

|

|

|

Joined: Jun 2005

Posts: 590

Major Contributor

|

OP

Major Contributor

Joined: Jun 2005

Posts: 590 |

I was able to finish up the pickup support this weekend. I had to grind through the pickup support in one spot, then added some weld to the back of it to strengthen it back up. I will put up a detailed post later, but there are a few pics in this gallery: 04.13.10 - 04.18.10~ Progress pics

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

That should give you enough clearance.

Class III CNC Machinist/Programmer

|

|

|

|

0 members (),

125

guests, and

27

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

|