|

|

Joined: Apr 2004

Posts: 3,566 Likes: 37

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,566 Likes: 37 |

Looking good in the pics.

Couple comments.

To lower the turbo air intake temps, remove the air cleaner , insert a tube and move the air cleaner to the fender well behind headlights.

If you use a high pressure EFI fuel pump, the pressure reduction required will cause excessive heat in the pump and pumped fuel. Use a low pressure pump.

If possible, get a intercooler and get it plumbed in. It will make a world of difference.

You will have to pull the engine to access oil pan.

Keep up the good work. Tom

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

I removed my oil pan by removing the motor mount bolts (the 2 long ones) , lifting the engine as high as possible & put wooden blocks inbetween the motor mount halves, one side @ a time, I did not have a engine hoist when I did this.

Pan came right out & that is when I installed a standard volume oil pump to replace the HP HV pump.

Intercooler, methanol injection will do wonders.

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

I'm pretty confident that I understand what meth and an intercooler do.

Methanol, when injected, raises octane of the charge and absorbs heat in the cylinder which allows for cooler temps.

Water when mixed with meth has the same type of heat absorption without the benefit of octane boost.

Intercooling cools off the compressed air charge because it gets hot when compressed. This gives the charge a cooler starting temperature in the cylinder.

^^^That's what I've gathered from what I've read.

You are understanding what they can do,,, but my main point for you to get them is so you CAN run more initial timing, you CAN run 14 degrees initial or more & you CAN go a lot faster if you install these items alone, then go tune it all in & then you CAN smoke those V-8 thingys.  You stated it made crazy power & it spooled fast when running 14 degrees initial timing correct?, basically speaking you were very much impressed I believe?? Well, if you get the carb stuff sorted out, you add the intercooler it will improve you power all around, but more important, it will GREATLY reduce the chance of detonation.Add a methanol injection kit, same thing as above,,, BUT even more so, more power, even more least likely to detonate & will make greater power everywhere in the power band.MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

Ok. so I ended up pulling the engine today after school. It wasn't that bad at all. maybe 3 hours getting it out with my friend. But now I can get to the oil pan and fix all of that return business. I'm also going to take the chance to reseal everything correctly so I don't get vacuum/boost/exhaust leaks, replace the head gasket, and the rear main seal.

Tom - I have been planning on doing that but instead removing a high-beam light and sticking my air filter right in that hole so that it will constantly have cool air blowing on it.

Can you recommend a fuel pump for me? I know that MBHD recommended the 2 holley black and blue pumps but they just barely have enough pressure to support 14psi. I was hoping for something like an even 20psi because that the most boost I'd ever try to run probably. (MBHD please make some more recommendations too). But that Aeromotive regulator seemed fine but are there any other cheaper alternatives?!?

I really want to get an intercooler but I only have so much money :-( My to-get list goes...

1)Fuel pump and reg

2)MSD box

3)Intercooler

4)Meth Injection

Hank - I understand that an intercooler would boost power by giving more power by a denser charge. But why would meth increase power? It seems like meth is a safety device more than a power-adder. Because with the amount of advance you'd have with an intercooler, it seems like any more advance would start to diminish the return? I hope that made some sense?

Also, if I added a meth injection kit, would I need to resize my power valves? Would I need to add less gas because it's adding the meth? SO like if I tune my car like it is now and drill the PVCR to where it's dead on, will a meth injection kit throw that off?

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Dec 2005

Posts: 452

Contributor

|

Contributor

Joined: Dec 2005

Posts: 452 |

Snowman,

First get the carb setup right so it will idle good with smaller jets, 2.5 power valve, then drill pvcr to make up for the smaller jets, may need a 50cc pump since you only have one, brown cam, bigger squirters. Should idle and respond good.

With a stock head at 15 psi you could make 400 HP but not with a stock pump and lines. 3/8 min. best 1/2 with a return to tank. you need about 32-36 gl/hr @ 22psi (6-8 psi plus 15psi turbo) most pumps are rated at free flow if you try to make pressure the flow go's away. A holley blue will not work, call any pump co. and tell them what you are doing (400+ HP and 15 # boost).

Ign. May need coil upgrade, new wires a must, NGK 6-7 heat range, 30-34* total timing, if ign. is weak a smaller plug gap will help .020.

I do not think you need an intercooler or water injection now just run racing gas when at high boost until you get everything right, it will be much easier and safer for now.

You are proving to all of us what I always thought, that a stock engine can take and make 400HP.

Turbos are easy on the bottom end, just need good pistons.

Harry

PS If you have only one o2 sensor you are taking an average of all 6 cyl and some may be rich and others lean so when everything is running good take it on the hwy. drive it for a few miles, then make a pass and read the plugs to see if they are the same, 400 HP is were you may have a problem with distribition.

Last edited by Turbo-6; 11/02/11 09:36 AM.

Turbo-6

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

With methanol injection, it will allow you to run even more timing, which will give you more power. It would be almost like running race gas on pump gas,plus waaaay less spendy than actually buying race gas, & with this bad economy plus you not haveing extra $$$ to buy race gas,, it just makes sense to go w/the more affordable way for now.. As far as having to rejet & adjust the carb to use methanol injection? Yes, you will most likely need to do so. Shoot for 10.5-11.0 A/F ratio when injecting methanol. I was so surprized how much faster my Syclone ran when I switched to a better methanol injection system. The top end power is where I noticed it the most (it improved everywhere also.), plus it allowed me to run 24 psi on pump 91 octane fuel. It really is that incredible.You are only going to be able to advance your timing so much when you add an intercooler, when you also add a methanol injection on top of your intercooler, you will be able to run more agressive timing curve & more total timing, that will equal more power. I would like to think I somewhat steered you in the right direction on parts to get & when I said for you to go turbocharged when others were telling you to just go natuarally aspirated for now,get a .96 A/R turbine housing, cast pistons won't work etc, etc, etc. Basically saying, I dont just try & give you all this hype about turbos are the way to go for no good reason, you are seeing the reasons first hand & are getting rewarded for your hard work. That little 6 you got going is a stock engine w/bolt-on parts, just think what it will run when you get it all tuned & running correctly w/the good supporting parts.1)Fuel pump and reg 2)MSD box 3)Intercooler 4)Meth Injection And later on, how good a purpose built turbo inline would run.  When running a methanol injection system, you can have it so it just basically super chills your intake temps & does not add too much meth,,( your A/F ratio should not change too much, requiring rejetting,modding the PVCR,etc) or you can have it so it can add a lot more fuel super chill your intake temps & add more octane it will throw off your A/F ratio when using a lot of methanol, but engines have run still really good when running 9.8-10.0 A/F ratio on pump gas also, it is really easy to adjust. My Syclone still ran great when the A/F ratio was 10.0 (when I first started messing the the meth injection kit) I eventually leaned it out & my engine seemed to like 10.5 -10.8 A/F ratio, all on pump 91 octane. Running a lot of meth & adding a lot of timing will give you the most power, but it will also be on the edge of living & blowing up, meaning, if it fails (the meth injection) & you are running a lot of boost & a lot of timing,, the engine will be destroyed very quickly. You can run the meth system, inbetween just adding a little or adding a lot also. All depends on your goals. I think I am the only advocate of running methanol injection here it seems,,,but like I told you before, it is really worth your trouble to use it. I know I cannot afford to use race gas in my Syclone to drive it on the street, thats why methanol makes so much sense to me to use it. Cost less, but like I said, it is more risky if something fails or jet nozzle gets plugged, etc.  I told Tlowe years ago to put a methanol injection kit on his Elky, but no bite.  If you are going to change your head gasket,basically cleaning & scraping your head & block surfaces & slapping one on,, use the Felpro 1025 head gasket. http://www.ebay.com/itm/Fel-Pro-Performa...=item4cfadcfc39http://www.summitracing.com/parts/FEL-1025/I'll look for a better pump, I did not know you are planning on running 20 psi. As far as a cheaper fuel regulator, hard to say to find a cheaper less $ one, but I'll look. MBHD BTW, when I advise using methanol I mean using 100% methanol, no water. It's been proven time & time again on dyno runs & track runs, you will make more power running 100% methanol. Only drawback, you cannot see methanol burn (in case of a fire) & it is more of a fire hazard than mixing methanol & water. Methanol kits have come a long way in the last few years. Systems years ago, used a weak windshield wiper pump or simular, low pressure low volume 10 psi or so. Pumps now go as high as 250 psi, that equals better vaporiztion, no droplets. I had an old Edlebrock NOS VINTAGE EDELBROCK 9356 VARA JECTION WATER INJECTION water injection system, years ago, 15 -20 years ago, had a weak windshield pump motor & a nozzle that you would drill your air cleaner lid & install a nozzle, very crude system that realy did not do much but add droplets down your carb, I guess it cleaned the chambers & piston tops @ most. Not too much adjustable, & the newer meth systems have better fuel curves throughout the entire rpm range. Much more accurate fuel metering. http://www.google.com/imgres?imgurl=http...9QEwAA&dur=3648http://www.google.com/imgres?imgurl=http...9QEwCw&dur=1749

Hank - I understand that an intercooler would boost power by giving more power by a denser charge. But why would meth increase power? It seems like meth is a safety device more than a power-adder. Because with the amount of advance you'd have with an intercooler, it seems like any more advance would start to diminish the return? I hope that made some sense?

Also, if I added a meth injection kit, would I need to resize my power valves? Would I need to add less gas because it's adding the meth? SO like if I tune my car like it is now and drill the PVCR to where it's dead on, will a meth injection kit throw that off?

12 port SDS EFI

|

|

|

|

|

Joined: Dec 2005

Posts: 452

Contributor

|

Contributor

Joined: Dec 2005

Posts: 452 |

Snowman,

You don't need to run Q16 or expensive fuel, 110 octane is $6.00 a gal here, and It's only to get your car safely in tune then go to reg. pump gas. I tried a water/meth. injection 15 years ago and for my buck it's not worth it.

I tend to go for max. all the time, just as you started with 6 psi then felt the power of 15 and don't want to go back.

On a fuel system don't go cheap it's the most important part, or turn down the boost ! Holley has a new pump 12-700 that looks good.

Harry

Turbo-6

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

Alrighty then. I disassembled my engine today. I haven't taken off the timing cover or removed the rotating assembly but I had a question to ask first. Can I just power wash the block while it's disassembled to clean it up? Would the water evaporate out of the block or would that mess everything up by getting water mixed with the leftover oil and end up where it shouldn't be?

I'm going to put in new:

-Rear main seal

-Head gasket

-Oil pan gasket

-Flywheel

-Pushrod cover gasket

-Timing cover gasket

-Oil pan (So I can do the oil return correctly)

and reassemble it.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Dec 2005

Posts: 452

Contributor

|

Contributor

Joined: Dec 2005

Posts: 452 |

Snowman,

To clean your block you need to disassemble it completely,cam,rod & pistons,crank,check bearings, wash block with power washer, blow dry with compressed air, everything else wash in solvent and blow dry.

This would be a good time to install a good piston, a flat top TRW stock replacement V8 piston.

Harry

Turbo-6

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

Darn. Aw well. I can't really afford to put in a flat top piston right now. 1 reason is cost, I really just need to get it running. and 2nd, I can't really afford to raise the compression any higher. Then I'd REALLY need race fuel all the time.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

I'm going to put in new: -Head gasket Get the Felpro 1025 HG

"While your in there"

Surface cyl head .040 or more.

-flwheel ,new flywheel? get a steel one, not cast iron.Use a 153 tooth one that is a bit lighter than stock. IIRC, stock flywheel weighs 32-35 lbs?[/b] New pressure plate? get a 3000-3200 lbs diaphram type. You are probably going to burn up the clutch more w/the new found power & the stock low lb diaphram pressure plate is pretty weak lb wise. I know I had the standard 3 speed trans factory in my Camaro. BTW, did you pull the cylinder head off?

If so,,, did you happen to look @ the tops of the pistons?

Post some pics of the pistons when you get a chance?Thanks MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

I'm not an expert or anything but the pistons look darn near new. My friend noticed something odd though. The 4 rear pistons have 3 circles on them and the other 2 in the front don't. What's with that? Also. I looked at the Felpro 1025 on summit you linked me to and it has a completely different bore size. It's like 4.125" or something. My stock bore size is 3.875". I doubt it would work with .3" difference on each of the bores. Do I really need to resurface the head? I didn't plan on adding much to it really but replacing a few important gaskets and cleaning it and painting. Wouldn't that also raise the compression some? Yes a new flywheel. My original stock one has spider cracks on it. Why would I need a steel flywheel? What benefit does it have? Because it's like an extra $100 that I don't really have right now for a steel one. Why would I need a new pressure plate? I replaced it with a stock type one about 4000 miles ago and it still looks great. I never felt it slip under full boost. So I don't see how it would burn up the clutch. I have to take out the crankshaft to replace the rear main seal right? I need to because I had quite a bit of oil slung around in the bellhousing. I also had a bit of a brain fart with disassembly. I got 4 of the lifters mixed up and I THINK I know where they came from but I'm not sure. What would happen if those 4 lifters did get mixed up and got put in the wrong spot? Also, would it be a big deal to take out the crank, pistons, and rods? Don't I just need to make sure that I put the bearings and caps in the same place and get a piston ring compressor to put the pistons back in? Then torque everything to spec? Isn't that about it to reassemble the rotating assembly?    A lot of carbon buildup in the heads from running rich

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Dec 2005

Posts: 452

Contributor

|

Contributor

Joined: Dec 2005

Posts: 452 |

Snowman, Mixing up lifters could make them go flat, but since your on a budget I would take my best guess.

Your engine looks so clean I would do as you said and just change the seal if you haven't done this before talk to some one that has and be very careful.

Harry

Turbo-6

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

Well what do you mean they could go flat? How likely is it that would happen? Could I just buy 4 new lifters as a fresh start so that new wear patterns could be made since lifters aren't that expensive?

Why should I be so careful changing the rear seal? I thought it was a simple, take it out, put in a new one. What is there to be cautious about?

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

[quote=snowman4839]I'm not an expert or anything but the pistons look darn near new. My friend noticed something odd though. The 4 rear pistons have 3 circles on them and the other 2 in the front don't. What's with that?

Maybe they have been changed?

Also. I looked at the Felpro 1025 on summit you linked me to and it has a completely different bore size. It's like 4.125" or something. My stock bore size is 3.875". I doubt it would work with .3" difference on each of the bores.

As far as I know, it is the only readily available HG that has a stainless fire ring made to take abuse of turbocharging & blower etc that does not cost an arm & a leg. Like a MLS COMETIC HG w/a cost of $177 dollars & needs a special smooth sealing surfaces. They require surface finishes to be 50 RA or finer and flat within .002”.

Yes it has a 4.125" bore, I am not thrilled about that either but it works & I have used them on my 250's, w/no problems

Since the bore is that much bigger, that is part of the reason I suggested for you to mill your cylinder head to get back some of the compresssion lost by the bigger HG bore.

Do I really need to resurface the head? I didn't plan on adding much to it really but replacing a few important gaskets and cleaning it and painting. Wouldn't that also raise the compression some?

Yes a new flywheel. My original stock one has spider cracks on it. Why would I need a steel flywheel? What benefit does it have? Because it's like an extra $100 that I don't really have right now for a steel one.

I just got done turning the brake rotors on my truck, it had spder cracks also, but after the rotors were turned/cut, the cracks were machined out. (sorta simular)

The steel flywheel does not usually explode like what your cast iron flywheel could possibly do., It's just safer, that's all, & a SFI steel bellhousing, dont want you to maybe get injured, if something lets go, & some tracks might require you to run these special safety equipment?

Usually, when you get your flywheel resurfaced, the cracks will be removed when it gets cut (as long as the cracks are not too deep)

Why would I need a new pressure plate? I replaced it with a stock type one about 4000 miles ago and it still looks great. I never felt it slip under full boost. So I don't see how it would burn up the clutch.

I would think the cracks your flywheel has is caused from slipping, unless you are just slidding the clutch so much you are burning up the clutch & heating up the flywheel?

Maybe not , but that's my thinking. The stock 6 cyl pressure plate is pretty weak IMO, & if you are going through the trouble of these other changes, you might want to consider an upgraded pressure plate w/more gripping power.

I have to take out the crankshaft to replace the rear main seal right? I need to because I had quite a bit of oil slung around in the bellhousing.

I also had a bit of a brain fart with disassembly. I got 4 of the lifters mixed up and I THINK I know where they came from but I'm not sure. What would happen if those 4 lifters did get mixed up and got put in the wrong spot?

Also, would it be a big deal to take out the crank, pistons, and rods? Don't I just need to make sure that I put the bearings and caps in the same place and get a piston ring compressor to put the pistons back in? Then torque everything to spec? Isn't that about it to reassemble the rotating assembly?

[/b]You might be able to change out the rear main seal by just removing the main cap & push out the old seal & slid in the new seal, just the same way the old seal came out.

You can install the rear main seal in backwards. So , make sure which way it goes.

On the lifters,,, need to change the 4 you are not sure about w/new lifters.

[b]MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

Snowman,

now that you got it all apart, how about some pics of your downpipe ,wastegate plumbing, exhaust system etc.

Thanks for the pics BTW.

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Dec 2005

Posts: 452

Contributor

|

Contributor

Joined: Dec 2005

Posts: 452 |

Yea, you can just replace the 4 lifters but be sure to break them in same as a new camshaft. If you have the newer main seal with out the "feet" you could loosen all the mains and remove the main cap and push the seal out, besure you lube the seal edge with oil and use loctite #518 flange sealant were the steel main cap meets the iron part of the block.

Harry

PS I just thought the "feet" are on the cap of the early engines

so should work on anyone.

Last edited by Turbo-6; 11/09/11 08:21 PM.

Turbo-6

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

Would this be a good pump? http://www.summitracing.com/parts/CRT-P4601HP/100gph and 18psi and has 3/8" fitting

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: May 2009

Posts: 493

Contributor

|

Contributor

Joined: May 2009

Posts: 493 |

I've run mixed up lifters successfully once on a small block a long time ago. Got lucky. I don't recommend.

Your odds are probably better with four new lifters rather than four used ones on the wrong lobes. It's a gamble either way.

|

|

|

|

|

Joined: Dec 2005

Posts: 452

Contributor

|

Contributor

Joined: Dec 2005

Posts: 452 |

Snowman, as to the fuel pump, you need to know the flow at the max pressure that you need.

6-8 psi plus boost, ie. 8+15psi boost = 23 psi min. at this pressure the pump needs to flow the amount of fuel you need for the HP you are going to make.

Harry

Last edited by Turbo-6; 11/21/11 01:09 PM.

Turbo-6

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

well jeeze. I can't pick one that'll work to save my life! Can someone show me one that'll work? I'm hoping it'll be in the $100-$250 range. I mean again, could I use a higher pressure pump so I don't have to worry about fuel pressure in the future and just use that aeromotive regulator to keep it in carb-safe levels? Like http://www.summitracing.com/parts/MAA-4060FI/?rtype=10 ? The only concern I have with that is it only does about 60gph. But according to Hangar18, that pump should be fine for up to 600hp. EDIT: Actually can I use this regulator instead of the aeromotive?. It uses 3/8" lines like the pump, it has 1:1 boost/vacuum pressure, has base pressure adjustable from 3-12psi (I need like 4 or 5psi?) and it's a return style. Isn't that exactly what I need? It would also look good because it's the same brand as the pump (because looks are what I'm really concerned with at this point ~sarcasm~) and it's like $60 less than the aeromotive but does the same thing.

Last edited by snowman4839; 11/22/11 05:51 AM.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Apr 2004

Posts: 3,566 Likes: 37

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,566 Likes: 37 |

Something like this will work. It may be more than your budget for now. http://www.summitracing.com/parts/CMB-03-0062/As stated by Turbo6, you could possibly need 20 PSI of fuel pressure if throwing 15 Lbs of boost.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

well again though, why couldn't I get a high pressure fuel pump and just set the regulator to carb levels. Then I'd have it in carb levels, not have to worry about not having enough pressure, and it'd still rise 1:1 with the boost. Wouldn't those 2 Mallory parts work?

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

You should have 5 psi fuel pressure or so above boost pressure.

A pump designed for EFI is not going to work for you.

MBHD

I know there are guys running a lot of boost & blowing through carbs, I just have not asked them what pump they use.

And if I found out what pump they use,, snowman, you are not going to like that price either.

12 port SDS EFI

|

|

|

|

|

Joined: Apr 2004

Posts: 3,566 Likes: 37

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,566 Likes: 37 |

As I stated in earlier posts. Using high pressure pump (42 psi) and regulating it down will cause fuel heating. This is not a good thing.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

That kit has a pump that only produces 14psi. So that means I could only run like 6 pounds of boost (total - base = boost so 14 - 8) before I start to drain the bowls again.

Last edited by snowman4839; 11/22/11 11:53 PM.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Apr 2004

Posts: 3,566 Likes: 37

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,566 Likes: 37 |

I only looked at the 1st summit page describing the combination. You are correct, you get the idea, so go and find one.

8 PSI is a bit much to run on a holley for full time use. It would be better to run 5-6 PSI of fuel, less chance of the needle and seat not sealing

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Dec 2005

Posts: 452

Contributor

|

Contributor

Joined: Dec 2005

Posts: 452 |

Snowman,

You can run an EFI pump if you want. But the stock style has to be in the tank to run cool.

Out side pumps still use fuel to cool them but don't need to be in the tank. they are rather expensive.

I use an SX enginering pump, they are 3 miles from my shop and help me anytime I need any help. They were one of the first to make these pumps which are from the aircraft industry. The guy that started Aeromotive worked for SX but then started on his own and has one of the best systems.

We just built a small flathead v8 motor with two small turbos for a street rod it has a EFI pump in the tank and a regulator that looks like an old time blue holley but is boost referenced and has a return line to keep the fuel cool, and 2 two barrel carbs, from C & S Specialties the place that makes blow through Aerosol Billet carbs. This setup is to make 350-400HP. My 3 carbs were built by these guys they are very sharp on anything, especialy carbs. (candsspecialies.com) Phone 1-636-723-4996

Call Mallory - Aeromotive - C&S or anyone and talk to them tell them you want to run 15psi boost and make about 400HP with a carb. But talk to someone about the complete system, don't just buy anything.

Harry

Last edited by Turbo-6; 11/23/11 12:00 AM.

Turbo-6

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

12 port SDS EFI

|

|

|

|

|

Joined: Dec 2005

Posts: 452

Contributor

|

Contributor

Joined: Dec 2005

Posts: 452 |

Is a chevy V8 mech. pump the same as a chevy inline ?

I thought the "race pumps" were only for chevy V8s, they are realy a neat design.

Harry

Turbo-6

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

Not sure, that's why I stated this in a previous post.

"Maybe you can adapt one of these to work? "

I thought the bolt pattern is the same. Yes, no?

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Dec 2005

Posts: 452

Contributor

|

Contributor

Joined: Dec 2005

Posts: 452 |

MBHD, Sorry I did't catch the adapt part, but yes the bolt pattern is the same. does anyone know the length of the rocker arm on an inline six between the face of the pump at the gasket surface to the end of the arm were it rides on the cam ?

A chevy V8 uses a push rod but an inline 6 just rides on the cam, right?

Very good idea!

Harry

Turbo-6

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

Harry,

did you get your new cylinder head yet?

Whats the latest going on w/your ride?

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Dec 2005

Posts: 452

Contributor

|

Contributor

Joined: Dec 2005

Posts: 452 |

Have not received the 12 port head yet, Mike said Dec.

Our track has been closed this past year ( Gateway Raceway )

it is to reopen 2012, can't wait.

Harry

Turbo-6

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

Well right now, I'm trying to work out getting a racepumps pump and regulator to work for me. I need to call them tomorrow and see whether the SB or BB pump will work. From the pictures, the SB pump looks more similar to mine. The only concern I have right now is the fact that they seem to have a reputation of loosing prime and vapor locking. Not good for a daily driver. But again, I'll just talk to them and see what I should do.

If I were to get a turbo valvetrain, would I need to replace the whole thing? Or could i just use a new turbo cam and keep the original rockers/lifters/pushrods/timing gears? Because I might have enough money left over after the holidays for a cam (like ~$150)

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

If you get a new turbo cam, you will need new lifters also.

Did you change out the rear main seal?

Engine is still out of car?

If you do get a turbo cam it will give you more HP for sure.

The stock cam just kills any potential for higher HP.

But it also allows for the turbo to spool-up pretty quick.

What cam specs are you looking to get?

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

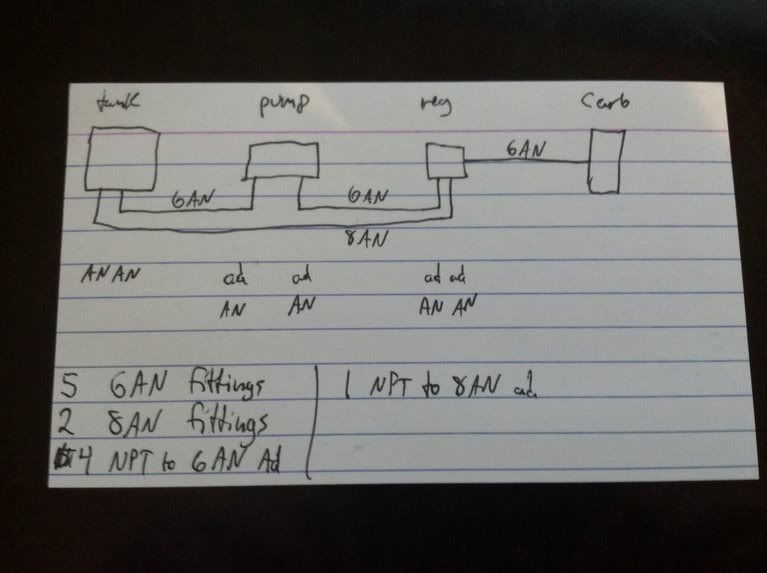

Well I guess it makes sense that I have to get new lifters for the wear patterns but would i need to get new pushrods or rockers? Yes, the engine is still out. The valvetrain, head, pushrod covers, and valve covers are on so basically everything is on besides the manifolds. Right now I'm just getting it cleaned up for paint and it'll probably be back together by the end of the week and in the car within a week. I didn't change the rear main seal, I think it was just the rear part of the oil pan gasket actually so I just didn't mess with any of that jazz and just replaced the oil pan gasket. I didn't touch any of the rotating assembly. I really have no idea what type of cam specs to get. I was either going to call Lunati or Comp and just get their recommendation. Or... get one of yall to send me a grind sheet for a known turbo cam that works well that I can send to them. So if ya'll have a grind sheet, please send me one. How much would it delay the spool? Because I'm absolutely in love with how it spools right now. I mean 15psi by 2800? That's perfect. I don't want it coming in at like 4000+?!? Also now that I have this turbo and all that on, how high can i rev it and not blow it up? I mean stock redline is like 4600 or something? Doesn't it start to float valves or something once you get up past 5000rpm? Also how high can I keep it at cruise? I mean can I let it cruise at like 3500 or 4000rpm and not break anything? I STILL CAN"T FIND A FUEL PUMP THAT'LL WORK FOR ME!!!!!! I talked to racepumps through email and they insist that their SBC pump will not work on an I6 even though I'm almost sure they're the same. I'm at a loss of what to do. The closest thing I found was that mallory http://www.summitracing.com/parts/MAA-4060FI/ and that mallory regulator http://www.summitracing.com/parts/MAA-4309/ . I know you said so but I don't see fuel heating being a problem using these from what I've read. I mean I've looked around and there are people using aeromotive A1000s with their carb blow through applications. That's like a 100gph pump at 90PSI!!! I mean if it works fine for blow through with TWICE the pressure as that mallory pump, I don't see any problems with half the pressure. The only way I could understand it causing fuel heating problems is if it was a dead-head regulator but since it's constantly being circulated, doesn't that eliminate that problem? Also how would I need to modify my fuel tank for this? How would I put the 6AN fitting on it for the 3/8 feed line? EDIT: Yeah this is exactly what I thought. This thread specifically says you can use a EFI pump with a carb regulator at carb pressures as long as the carb regulator is return style. He specifically mentions using an A1000 (90PSI!) with an aeromotive CARB regulator for his blow through setup. If you care to read it, here is the thread. 2ND EDIT: This is the layout. I forgot the inline filter between the tank and pump on the 6AN line. Ad means NPT to AN adapter since the pump and regulator use NPT. basically 6AN between everything except an 8AN return form the reg to the tank. As it turns out, AN stuff is expensive (duh), are there any noticeably cheaper alternatives to hook this stuff together?

Last edited by snowman4839; 11/29/11 08:16 AM.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

Come to think of it, instead of modifying my fuel tank, can I just install a fuel cell in my trunk and run all of the fuel pump stuff from that? And just leave the mech. fuel pump and lines on there and then just T in the electric fuel pump into the line to the carb? Also I'd have to put one way valves into the plumbing so they won't pump into each other. So basically have two separate fuel systems but be able to switch the electric one on and off for using the turbo?

It seems that'd be very convenient because I could just put premium (or race fuel!) in the fuel cell and then just run off of 87 all the other time which is what the mech fuel pump would be drawing from. That's because once I turn on the electric fuel pump, it'd overpower the mech. fuel pump supplying only fuel from the fuel cell since the base pressure from the electric pump's regulator (5-7psi) is greater than the mech. fuel pump (~3psi) so it'd drive the mech pump's 87 back up to the one-way valve. Then I could run off of the fuel cell and have all of my fun and then just switch the electric pump off, it'd cut all the extra electric pump's pressure off (and stop using the premium fuel), the one way would prevent the mech, fuel pump from pumping into the cell, then the mech could take over for daily driving and just burn 87. Is that not a fantastic idea??????????????

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: May 2010

Posts: 134

Contributor

|

Contributor

Joined: May 2010

Posts: 134 |

I think your trying to make it to complicated. Use size 8 as your feed and you could drop down to size 6 as your return. Feed with the bigger line return whats left with the smaller line. I would not try to include the mechanical with the electric. To many ways to go lean. Keep it simple.

|

|

|

|

0 members (),

125

guests, and

27

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

|