|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

I understand that it would be slightly more complicated but would it work? It would actually be a lot better for me because I wouldn't need to run premium all the time.

How would I have more opportunities to go lean? I would just need to make sure that the pump is on before I start getting on it.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Jul 2009

Posts: 55

Active BB Member

|

Active BB Member

Joined: Jul 2009

Posts: 55 |

My system is along the lines of your thinking.

I have not istalled it yet but here it is.

I have one custom fuel cell for all of my fuel (most likely racing fuel)

i then come off of the cell with two -10AN fuel lines both feed through inline Peterson fuel filters. one line goes to a Aeromotive 11203 SS fuel pump for daily driving under normal pressure. The other -10an line goes to a Aeromotive 11202 A2000 pump for strip use. Both of the lines have a one way check valve and feed into a y fitting and then a -10 AN on to the regulator.

From the regulator on i have -8AN lines to the carb with a return line back to the fuel cell.

I would show pictures but i have not installed it yet, i have all the parts though.

I understand what your trying to accomplish, you may want some check valves here or there if you want to keep the mechanical pump.

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

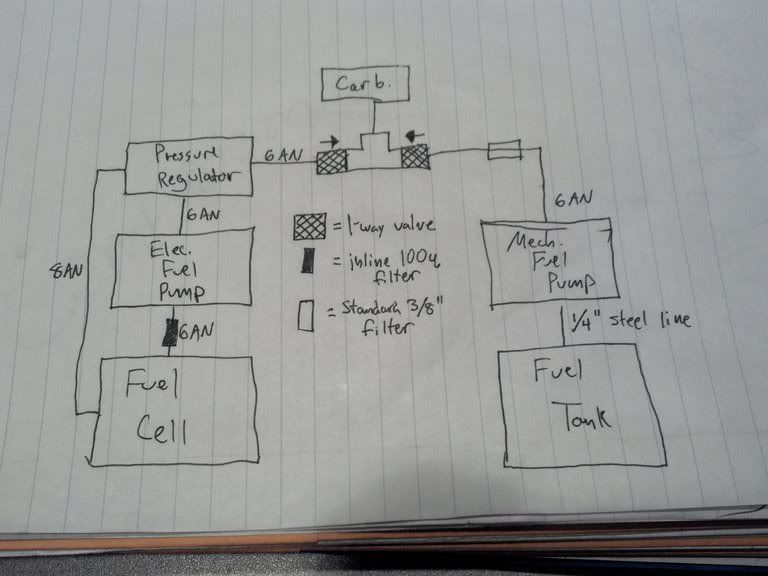

Well here is the diagram. The only problem I can see here is if the mechanical fuel pump would somehow break if it doesn't have anywhere to push the fuel since the electric fuel pump will be stopping it at the one way valve

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

Just would like to say, if you are going to run 87 octane fuel you definately should get an intercooler set-up on there.

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: May 2010

Posts: 134

Contributor

|

Contributor

Joined: May 2010

Posts: 134 |

So if I'm understanding you correctly you want to do your street driving with low octane gas through a 1/4" steel line. Then if you want to step on it you'll flip a switch to activate and electric pump and good gas. For one thing I don't think 1/4" fuel line is big enough also you'd better hook up a boost pressure switch to activate the electric pump or you'll run out of fuel real fast if you forget to flip the switch when you go to pass someone. Good luck.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

Yeh, we already told him the 5/16 factory fuel line needs to be replaced.

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

Ok so the way it'd work is...

For daily driving,

I keep the electric pump off, the mechanical pump is pumping 87 at 3-4psi through it's one way valve to the carb. It can't go back into the electric side of the system because the electric side has a one way valve too. So this way I can run 87 for normal driving.

For fun driving,

I flip the electric pump on right before I want to step on it, it pressurizes the fuel system with 93 (or race fuel) because I can set the regulator higher than pressure the mech. pump puts out. So if I set the regulator to 6psi and the mech. pump only produces 3psi, the electric pump will force the mech. pump's 87 back up to the one way valve on the mech. pump side and keep any of the 87 from getting into the line since the mech. pump can't create enough pressure to overcome the electric pump's base pressure.

SOOO... that way the electric pump will fill the fuel circuit with 93 when it's on and it will create too much pressure to let the 87 flow past its one-way-valve. That will allow me to choose when I want to run the more expensive fuel but will also allow me to get REALLY expensive fuel (i.e.) race gas because I won't actually be burning it all the time.

MBHD: That's the whole point, I won't *really* be running 87. Just for light acceleration and cruising. When I want to get on it, I basically switch the electric pump on which will overpower the 87 with 93 because of the pressure difference of the mech pump (3psi) and the regulator base pressure (5-7psi) and then I can run off of the 93 for as long as I want.

Look at my diagram. I'm going to run 6AN fuel lines through everything which is the equivalent of 3/8" line. I've read that should be good up to like 375hp which is where I'll probably top out this engine. But I'm more doing this because that's the size of the inlet and outlet size on the pump and regulator. Also once I get up to the 1/2"/8AN pumps, they start at like $300 for the cheap ones.

Do ya'll have any comments on using that pump and regulator? I did my research and I'm 90% confident they'll do what I need them to do but I'd still like your "blessing" if at all possible haha.

EDIT: So is the line from the mech. pump to the carb 5/16"? So what size fitting would I need to find to adapt it to AN? Would it be a 5/16 to AN or would it be slightly larger like 3/8 to AN? because I'm trying to find an adapter for the outlet of the mech. pump to AN but they don't make ANYTHING for 5/16" to 6AN. It's either 1/4" or 3/8" to 6AN.

Last edited by snowman4839; 11/30/11 08:40 AM.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: May 2009

Posts: 493

Contributor

|

Contributor

Joined: May 2009

Posts: 493 |

If you want to run 87 then you should build it to run 87 and not fool around with dual fuel systems.

More hardware means more things to go wrong like fuel leaks for example. More weight to haul around, more parts to buy.

|

|

|

|

|

Joined: May 2010

Posts: 134

Contributor

|

Contributor

Joined: May 2010

Posts: 134 |

Exactly what he said. Keep it simple. Les things to go goofy.

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

There is going to be more to swapping back and forth based on fuel grades than just flipping a switch. I doubt you'll even have the same timing setting on the 87 octane tune-up as you would the higher grade, and probably not even the same jetting. Like Stroker said, pick 87 octane or premium grade, not both! You definately need a 3/8" fuel line from the tank to carb which ever fuel you choose to be on the safe side.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

I understand it would be more work and be a little complicated BUT it would actually cost more to do the fuel tank modification because I'd have to get a new fuel tank ($180 + shipping) and modify the outlet line size as well as pay for high octane all the time. I just need to know if there's anything wrong with how it'd work.

Why would there be more to swapping fuel grades? I could set the timing pretty far advanced when I'm on 87 but just not get into boost because that's where it'd knock. It won't knock on idle/cruise on 87. As for jetting, it won't be a huge deal if it runs a little lean or rich while at cruise or idle as long as it's not WAYYY off.

When I want to get on it, I switch on the 93 pump and it'd suppress detonation for when I get into boost.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

This is what you do, as I always told you this is what you should do. Get methanol injection, http://mysite.verizon.net/res11pgkr/vehicles/customkit.html http://www.ebay.com/itm/Alkycontrol-Meth...=item335618a9f1 you can be real thrifty & run 87 octane all the time, no need for two tanks,2 pumps, check valves extra lines & so on & so on. Quote from Julio

Can I run the boost I currently run with race gas using alcohol injection?

Yes, though the timing used may be less. Some vehicles like my own, run more boost on AI than can on race gas, though I run more timing on race gas than AI. My own example, I can run 24 PSI on race gas, but any higher, will produce detonation(KR) due to incoming air temps being so high. Due to an inefficient intercooler. On alcohol Iíve blown past 30 PSI boost and gone faster than I ever have using race gas. Based on my own combination of components used.Get that pump you wanted to get , @ least step up to a 3/8 fuel line from inside the tank up to the front. You still need to run a return line into the fuel tank. You do not need a new fuel tank to install a 3/8 or bigger line inside. Look here to get some ideas: http://www.novas.net/forums/showthread.php?t=327&highlight=sending+unitI am pretty sure you can buy a factory style in tank pick-up that is 3/8" size & even bigger. Look for Chevelle in tank pick ups assy's. Example: http://www.ebay.com/itm/1968-1969-1970-C...=item4cf51c729dIIRC, Companys make factory style fuel pick up assys w/a 1/2" hose if you want one. Need to research online. I am not sure if that regulator will only give you 5 or so psi, I did not read the specs., You definately need a fuel pressure reg that will dial down the fuel pressure to 5 or so psi, that is boost referenced. Snowman,,Read up on this: http://mysite.verizon.net/res11pgkr/faq/acfaqs.htmlMBHD

12 port SDS EFI

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

I UNDERSTAND that I should be using alcohol eventually if I want to make a lot of power.

HOWEVER... I still need to get enough fuel to the engine regardless. Having said that, I need the pump, regulator, 6AN lines, fittings, and about 85% I'm talking about anyway. The only thing we're arguing over is where the fuel is coming from and some plumbing. I think it would be better for me to run it this way because I can burn expensive fuel when I want to and cheap fuel when I need to. the price difference isn't that big between our two ideas so why would there be any reason not to do it if I can save on fuel and it wouldn't cost much extra? Again is there any reason why it wouldn't work?

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Feb 2010

Posts: 136

Contributor

|

Contributor

Joined: Feb 2010

Posts: 136 |

This dual fuel system, seems crazy. Stick to a single, simple system. Much less of everything, including problems. My boost referenced mechanical pump is doing great, no fuel starve, no lean. Simple and effective.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

Snowman, you do not need to have a goal of making a lot of power by using a methanol injection system. I am suggesting for you to run cheap gas all the time (like you mostly want to in order to save some $$$$), 87 octane & you can go with higher boost w/87 octane & using a methanol injection system. Not exactly sure what octane you would get by using 87 octane & a meth kit installed, but it will be more octane than running straight 91 octane for sure. After you install a intercooler system & meth injection system, I can see you running 15 psi of boost pressure pretty easy, & you said your car was crazy fast when boosting to 15 psi, correct? I think you should keep your fuel system as simple as possible. It is a neat idea of what you are thinking about doing & people have done dual fuel systems w/success. Believe me when I say you will be more than happy the way your car will run on 87 octane , intercooler installed & a meth kit. Have I steered you wrong so-far? Also, I high light my words to you on my posts because I think you do not go to the links I post or sometimes actually read my posts. You dont have to, just thought you want some input. I just mean for you to pay attention if you like.  If I was shouting, they would all be caps. MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

Well I'm probably going to go with my dual fuel system route for now because even it doesn't work at all, I'll have everything I need to get the one-tank system to work. I'd just have extra fuel cell, one-way valve, and some fittings. Then we all get to be happy, and if my idea doesn't work, you can rub it in my face haha (but I can still get it working right with the one-tank system).

After I get the fuel system worked out, then it'll be onto an intercooler, turbo cam, and meth injection (probably in that order).

I always pay attention but sometimes I'm just stubborn

Come to think of it, can I mix meth with the 93 in the fuel cell? Would that have any positive effect or would that eat my fuel line and seals?

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

Goodluck with it.

make sure to have the appropriate saftey requirements when you install a fuel cell in the truck, otherwise the race tracks probably will not let you race.

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

Well I got it running. I ended up having to reseal the carb to manifold because I had a pretty bad vacuum leak and it would barely idle. Now it idles nice and smooth but I can't get anything tuned. Everything is lean all the time.

The idle mix screws respond well and I can get it to idle right at 14.0 AFR. But I have very bad lean stumble anywhere off idle. I changed the jets from 73s to 70s and then the lean stumble became very apparent. Then I changed the squirter size from 25 to 28 and it helped a little. I have a orange pump cam on position #1 if that helps. Any ideas? I'm probably going to end up playing with jet sizes over the break.

I just don't get why it would go from running really rich with large jets to running really lean and having lean stumble with slightly smaller jets.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

Well I just swapped out the jets for 74s and now it just runs rich but still has the bad stumble. The only thing I can think of now is the squirter size. I mean what else would cause this?

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

Try a larger squirter, 31's or larger to help w/the stumble. You still might have a vacuum leak somewhere.Have the engine idle & spray starting fluid at the carb base gasket & intake to cyl head gasket & all around the carb for other possible leaks,( it's very flamable so be very careful & done you it on a really hot exhast manifold, try the starting fluid spray when the engine is cold, just to be a bit safer. With the engine idleing ,if the engine RPM goes higher when you spray starter fluid @ the areas mentioned, that means there is a vacuum leak where you are spraying the starter fluid. What did you end up doing s far as your fuel system? Going w/a fuel cell & stock gas tank? Increasing the feed line from the gast tank to the front? IMO, it is really a big waste of time to run cheap 87 octane fuel in your stock tank & run a completely different fuel cell & lines just to run 91 octane. You will get better results & higher octane & be able to run more boost when running the 87 octane & injecting methanol.(I think I already stated something simular before?) If you wanted to raise your octane for the 87 octane in your fuel tank, put in some Xylene, or of course Torco http://torcoracefuel.net/pro-accelerator.html octane booster. If you have a LOWES or Home Depot near you, they should sell Xylene so you can pick it up locally. FORMULA 2 Xylene R+M/2...117 Cost...$2.75/gal Mixtures with 92 Octane Premium 10%...94.5 Octane 20%...97.0 Octane 30%...99.5 Octane Notes: Similar to Toulene. 12-16 ounces will only raise octane 2-3 *points*, I.e. from 92 to 92.3. Usually mixed with Toulene and advertised as *race formula*. http://www.gnttype.org/techarea/misc/octanebooster.html MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

Well I just ordered a 33 and it should be here by like wednesday. I just don't get why it would run so badly now when it ran fine before the rebuild with the 25 pump shot. I highly doubt it's a vacuum leak because I know I got the carb/manifold leak sealed up because of how much better it idles. I'm also pulling more vacuum now than I was before the rebuild (17-18psi of vac before and 23psi+ of vac now).

I'm still working out the fuel system for now. Trying to get money and parts organized and whatnot.

I'm still going to try the fuel cell idea.

I AM GOING TO EVENTUALLY GET METH INJECTION but again, I have a lot of other stuff to get first... (intercooler, ignition box, fuel system, turbo cam and valvetrain, etc.........)

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Jan 2010

Posts: 493

Contributor

|

Contributor

Joined: Jan 2010

Posts: 493 |

23 in. of vacuum is a bunch! certainly no vacuum leak. does adjusting the idle screws affect the idle? if not, look for an idle circuit obstruction (dirt). are the throttle butterflies nearly closed at idle- if the throttle is open too much at idle you could be losing the function of the idle and off-idle circuit. How is the vacuum advance hooked up, manifold vacuum or to some point above butterflies? Maybe due to a backfire the power valve diaphram is busted (naah-excellent manifold vacuum), actually I've never seen that high of vacuum readings at idle with any cam, all my stock experiances have been under 20 inches. Not to into Holleys but just some thoughts-does it pop back thru the carb- or just stumble?

Oops, you said it do respond to idle screws, It seems to my old school pre-smog experiance that 14:1 is pretty lean for an crude idle circuit. This was something considered a bit lean even at cruise conditions in the 50's/early 60's. Try riching up the idle to say somewhere in themid to lower 13's and see if it helps. Lean idle mixtures required 195 degree thermostats, reduced timing, heated air to the AIRHORN. Look at your stock air cleaner/ exhaust manifold, it had a "stove" providing hot air to the carb because those carbs were jetted so lean from the factory. You cant expect an aftermarket carb to perform as well as the original setup did from death valley to pikes peak and mountain iron to Arizona - the original was custombuilt by the factory to handle all the above situations and every thing in between. The only gripe is that it was too small for the hotrodder. Everything is a compromise. And then came smog controls- in 1974 chevrolet even "loosened" the torque converters to help their "stumble" problems. I think richen up the ilde.

Last edited by preacher-no choir; 12/12/11 04:22 AM.

|

|

|

|

|

Joined: May 2010

Posts: 134

Contributor

|

Contributor

Joined: May 2010

Posts: 134 |

I would guess if you added up the total costs of two fuel systems over the cost of a home made water methanol injection system it would be a wash. The water/meth system would be much safer and provide more power when you need it and still run low grade fuel up to a point. To me it seems like two fuel systems are asking for a melt down. Just forget to flip the switch once under full boost.

|

|

|

|

|

Joined: Apr 2004

Posts: 3,566 Likes: 37

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,566 Likes: 37 |

23 inch's of vacuum is great.

My engine likes 12.75- 13 AFR at idle. and with 24 degrees timing at idle. These engines have poor chamber design.

I also like to keep things simple for the fuel system.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

Yeah sorry about that. It wasn't 23psi of vacuum. Turns out my vac/boost gauge reads vacuum in inches of Hg and reads boost in psi. Weird but I guess it makes sense.

So I get about 22-24" of vac depending on the position of the moon but it idles well and holds rpm well but it still has a problem changing rpm and I know it's the accelerator pump now because I did a simple test with my dad. He watched the A/F gauge and I gave it full throttle and used a squirt bottle to squirt in extra gas and he said the A/F ratio never went above 15 (it's 13 at idle) when I did that so now I know I just need the extra gas which hopefully the 33 squirter will do for me.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

This even has a BOV for $205,hard to beat this price I would think. Christmas is coming soon ;-) http://www.ebay.com/itm/CXRacing-UNIVERS...=item43a9e297bbI like these intercoolers better, just because of the 3" core. http://www.ebay.com/itm/31X12X3-Universa...=item439a1dfbc6http://www.ebay.com/itm/31-x11-5-x3-FMIC...=item3a52cca082It is not a bar & plate design, but it's lighter & I.I.R.C., the tube & fin design are more efficient. Just a reminder, this is not high quality kit, the hoses are not a 4 ply (should not be a problem though)the clamps are a bit cheesy,(but they work)bar & plate design are more durable,(but heavier) the tubes are desent & have rolled beads on the ends( so the hoses dont blow off) The BOV is cheap ,but they seem to work OK, I have something simular on my Syclone. When your accelerating the A/F ratio should be a lot richer than 15:1, probably closer to 11:0 -12:1 A/F ratio as a rough estimate when you enitially stab the throttle "quote: I'm also pulling more vacuum now than I was before the rebuild" What did you actually rebuild, was it when when you pulled the engine? Still waiting on pics of the engine installed w/all the pipeing/plumbing ,BOV,carb bonnet,, etc. ThanksPosting pics helps others out here that are considering turboing there rides. MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Jan 2010

Posts: 493

Contributor

|

Contributor

Joined: Jan 2010

Posts: 493 |

Does it have 13:1 or does it have 14:1 at idle?

Is your leg broken or is it not? We can only diagnose what you write us in reading. The bigger the number the leaner the condition, 13: 1 is not too bad where 14 is bad and probably needs a computer to make the car live with that much leanness at idle-certainly some heated air to the carb. How quickly do these sensors react? On these cars where smog is a not a concern , you can always err on the rich side without a problem.

The primary function of an accellerator pump is to add additional gas when the throttle is opened suddenly-when there is'nt enough gas momentarily being drawn out of the float bowl (sudden lack of vacuum due to throttle blades being popped open). I think in this situation, the acellerator pump will be used as a crutch to cover up a faulty (dirty or clogged) off-idle or transision passages which are used to ease the fuel into the main metering circuits.

That is what they were designed for, and this is what you dont have. I feel something is preventing fuel passage thru them, loosely and commonly termed dirt. Obviously the main circuit is clear as you have no prob holding say 3000 rpm, and no prob holding say 600 rpm- so no trash in the idle circuit, but a big stumble(does it pop thru the carb?) when you try to take off. What happens if you ease into throttle vs. jumping into it? Jumping into it need the pump for help, easing into it need an operating transition circuit. What is your timing at idle? and do you have an operating vacuum advance?

"Back in the old days" when today's folks chuckle and think things were not pertinate to today's probs, a guy who was working with the same problems on his 270 hp two-four bbl '57 chevy and trying to check it out would have singed eyebrows from leaning over the carb (a bump on the back of his head from the hood)and a burnt spot on his hood all from staring down a backfiring carb (or two). Be careful looking down a loaded gun or carb. Very lean mixtures go "pop" thru the carbs.

Last edited by preacher-no choir; 12/13/11 09:57 AM.

|

|

|

|

|

Joined: Jan 2010

Posts: 493

Contributor

|

Contributor

Joined: Jan 2010

Posts: 493 |

Maybe it aint dirt-maybe a meetering plate gasket installed upside down or backwards preventing flow of gasoline thru the meetering plate (hollys have them kind of stuff (never see it onna rochester-hah)

This thought furnished by statement of "why did it do so good before rebuild" (of carb?-or motor).

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

snowman4839,

saw the videos, nice.

It appears there is a huge lean stumble in your video, need to richen up the accelerator circuit.

I was wondering if you ever hooked up your boost reference line from the mechanical pump to the intake manifold?

If so,, do it help any?

When you installed the 1025 head gasket, did you mill the head any? if not, you lost a bit of compression from your already low compression.

On your 4 speed trans, what is the first gear ratio?

I am wondering if you will be able to use your column shift w/the 4 spd?

Even if you can get it to work,,, I am really thinking it will not shift as good as a floor mounted shifter, less flex in the linkage rods as compared to the column shift linkage.

Basically saying, it will slow down your shifting ability running a columm shifter.

I noticed the up pipe to the turbo, it seems to have steps/mismatch from the 2.5" pipe to the T4 flange.

From my findings, having such a severe mismatch/steps of the pipe to T4 flange, this will cause the turbo to spool slower & actually cause it to make less boost pressure down low, when the turbo is finally spooled up, the turbo will make the boost pressure, but it will be slower to spool up quickly & get into boost sooner.

Basically saying, if there is anything you can do to smooth out the transition of the 2.5" pipe to the T4 flange it will help a bunch.

Hope the squirter helps out, I would think it will.

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

snowman4839,

saw the videos, nice.

It appears there is a huge lean stumble in your video, need to richen up the accelerator circuit.

By richen the circuit, I'm assuming you mean get a bigger squirter?

I was wondering if you ever hooked up your boost reference line from the mechanical pump to the intake manifold?

If so,, do it help any?

Well the deal is I did at first when I was running 15psi and it still ran out of gas pretty quickly. I don't have it hooked up now because the jbweld sealing the fitting to the housing of the pump kept cracking and it wouldn't hold pressure. So I just said forget it and that's why I'm working on the electric pump setup now.

When you installed the 1025 head gasket, did you mill the head any? if not, you lost a bit of compression from your already low compression.

No I didn't, but it seems to run fine. I mean how much could I have really lost? like a tenth of a point?

On your 4 speed trans, what is the first gear ratio?

It's a 3.11 first gear whereas the three speed i had was a 2.84 first gear

I am wondering if you will be able to use your column shift w/the 4 spd?

Even if you can get it to work,,, I am really thinking it will not shift as good as a floor mounted shifter, less flex in the linkage rods as compared to the column shift linkage.

I've driven it some and it shifts very nicely and I can shift pretty damn fast. My 1st to 2nd is extremely quick and my 2nd to 3rd is a little slower since I have to switch the forks but I've gotten good at that since it used to be my first to 2nd with the 3 speed

Basically saying, it will slow down your shifting ability running a columm shifter.

I noticed the up pipe to the turbo, it seems to have steps/mismatch from the 2.5" pipe to the T4 flange.

From my findings, having such a severe mismatch/steps of the pipe to T4 flange, this will cause the turbo to spool slower & actually cause it to make less boost pressure down low, when the turbo is finally spooled up, the turbo will make the boost pressure, but it will be slower to spool up quickly & get into boost sooner.

Basically saying, if there is anything you can do to smooth out the transition of the 2.5" pipe to the T4 flange it will help a bunch.

I know the pipe isn't ideal but it works and I did do a bit of work hammering the pipe into the shape of the flange. Eventually I'm going to get someone to make a single pipie (no weld line in between bends) and do good TIG welds around the flanges but for now that's what I got

Hope the squirter helps out, I would think it will.

I certainly hope so. I can't think of what else would fix it.

MBHD I also ended up taking my carb off for a minute today and blowing compressed air into all of the holes and especially the transition slots. When I ran it after that, it seemed to help a little bit but I still have a bad lean stumble. What are you guys running on your holleys? Tom - what'd setup did you have on that holley 500 you did the turbo dyno on. Boucher - what jets/squirter/PV/etc. are you running?

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

[quote=snowman4839 By richen the circuit, I'm assuming you mean get a bigger squirter?YesWell the deal is I did at first when I was running 15psi and it still ran out of gas pretty quickly. I don't have it hooked up now because the jbweld sealing the fitting to the housing of the pump kept cracking and it wouldn't hold pressure. So I just said forget it and that's why I'm working on the electric pump setup now.You can still drill & tap the hole for a 1/8th inch NPT fitting.Examples:

http://www.mcmaster.com/param/asp/PSearc...MMainWidth=1402

http://www.ebay.com/itm/Performance-Stai...=item564771503bWhat are you guys running on your holleys? Tom - what'd setup did you have on that holley 500 you did the turbo dyno on. I would not try & copy there jet or squirter sizes, one was for a dyno,Boucher is running a 350 CFM 2bbl carb Boucher - what jets/squirter/PV/etc. are you running? [/quote]

12 port SDS EFI

|

|

|

|

|

Joined: Jan 2010

Posts: 493

Contributor

|

Contributor

Joined: Jan 2010

Posts: 493 |

cant watch, got dial-up, would have to shave twice waiting for it to download.

Look up somewhere how carbs work especially holleys, learn it yourself, its the best way, the physics is all the same, just the methods of control differs between the various carb makers.

You can see everybody has an opinion, just like o/ds and axle ratios-anyone with a keyboard can be/is a Goodwrench. Look at how Ford starters work after you twist the key compared to how GM does it. Bottom line they all spin the flywheel.

Saw just first 5 or 6 seconds, is it true it was idling at 1000 (+) rpm and at that point you are seeing the 23 inches of vacuum?

Your butterfly maybe positioned open enough to be idling on a good part of its transistion circuit (slot) thereby using up what is normally used for transistioning to the main metering circuit.

Ideally your idle would be maybe 600 rpm resulting with maybe only 19" vacuum (more normal reading), the throttle butterfly would be positioned just at or slighty below the transistion slot or passageway just waiting for the blade to open and allow manifold vacuum to be exposed to this slot so that this additional fuel passage way can spring into action providing, no, ALLOWING extra fuel to carry out its intended duty. If You choose to have this high of an idle and are using up the transition passage, then YES, you will need more acelleration pump shot to overcome (remember crutch) this man made stumble. (does it run on after you turn off the key?)

A stock cammed engine should not need a 1000 rpm idle if the carb is set correctly. Check out the Idle circuit section of a good carb book and look at where the butterfly is positioned-say maybe- the Doug Roe Rochester book. (dig-dig). These things were put in carb to improve drivability. Just wait till it gets really cold-what a bear!

You have a good text book problem, with many guesses offered as to why its there. This is an excellant challange to learn what is the prob. Once you get a good handle on carbs and really understand how they work, then fi/efi and how computers make them work will be a snap.

|

|

|

|

|

Joined: Feb 2010

Posts: 136

Contributor

|

Contributor

Joined: Feb 2010

Posts: 136 |

MBHD[/quote]

What are you guys running on your holleys? Tom - what'd setup did you have on that holley 500 you did the turbo dyno on. Boucher - what jets/squirter/PV/etc. are you running? [/quote]

I am running: Carb jets 61 with a 8.5 Power Valve, #28 shooter and White accelerator pump cam in position #2.

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

MBHD - I'm just not going to worry about boost referencing that pump since I'm going to get the electric setup in a couple of weeks.

Preacher - Believe me. I've read the crap out of how carbs work. I've gone into detail about how each system works. I understand what does what. I knew that having too much of the transition slot exposed would cause problems with stumbles which why I went out today and lowered the idle and richened it a little on the idle circuit to see if that would help the bog and that it was at about 750rpm and it still has the bad stumble.

It doesn't run-on after I turn it off. Between the 3 carbs I've had on this engine (monojet, holley 390, and this holley 500), this carb has done the best not to run on. The monojet would run on a lot. The holley 390 would occasionally and you could tell it wanted to. This holley 500 just stops right how it should.

I even took out the idle screws and blew WD40 and compressed air to clear out the passages and the transition slot. It barely helped if at all.

Boucher - That's exactly what I needed to know. I've been wondering what type of shooter you'd use on a 350 and if you're running a 28 shooter on a 350cfm and I'm running a 25 shooter on a 500cfm, that could be a big problem. The switch to the 28 I had helped some but I have a 33 shooter coming so hopefully that'll help.

Also can you remind me what was causing your bad bog? I remember you have videos of it and you fixed it but I don't remember what the problem was.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Feb 2010

Posts: 136

Contributor

|

Contributor

Joined: Feb 2010

Posts: 136 |

Also can you remind me what was causing your bad bog? I remember you have videos of it and you fixed it but I don't remember what the problem was.

My bog was associated with having too much fuel. Mine would act very similar to your when you roll slowly into it. But when I punched it, it would pour black smoke out exhaust and AFR would go to 10. I had to from a 31 shooter to a 28 and also my pump shot was too much on the accelerator pump. When looking at the whole picture, I believe this was caused by having my PCVR's drilled out a little too big from the start. (.078") If I were to do it over again, I would tune with a stock PCVR size, then adjust ONLY from WOT. Good Luck, you are close. Remember to do one adjustment at a time. Also, the adjustments are sensitive.

|

|

|

|

|

Joined: Jan 2010

Posts: 493

Contributor

|

Contributor

Joined: Jan 2010

Posts: 493 |

is your butterfly uncivering thr transition port at idle. did you slow down the idle by moving the butterfly, or by messing with the mixture screws?

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

Boucher - so the 31 to 28 was a pretty big switch?

Preacher - They're uncovered just a hair. I moved the butterfly to slow down the idle and then I richened it up with the mix screws just to give it a little more gas in hopes of helping with the lean stumble.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

snowman4839,

one other thing I noticed on your vids, the newly welded pipe fitting you installed into you oil pan, what type of threads are on the fitting & on the "B" nut AN hose fitting (the blue one) does that have an angle seating area, like a 37 degree flare?

Just wondering.

Also, what RPM does the factory say to have the engine idle at? 650-700 RPM? I can remember, it's been too long.

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Feb 2010

Posts: 136

Contributor

|

Contributor

Joined: Feb 2010

Posts: 136 |

Boucher - so the 31 to 28 was a pretty big switch?

It was enough for me. I believe they are in increments of 3. One step at a time for me.

|

|

|

|

0 members (),

125

guests, and

27

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

|