|

|

Joined: Aug 2011

Posts: 48

Active BB Member

|

OP

Active BB Member

Joined: Aug 2011

Posts: 48 |

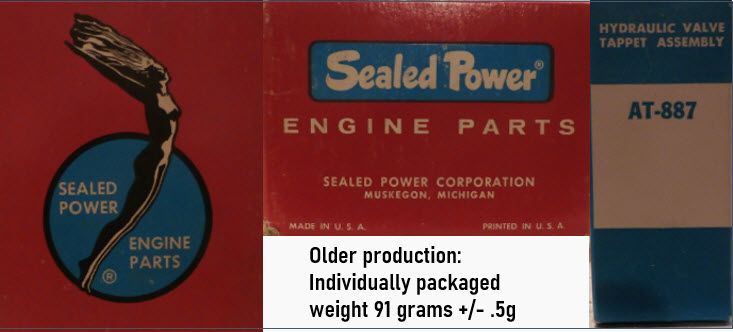

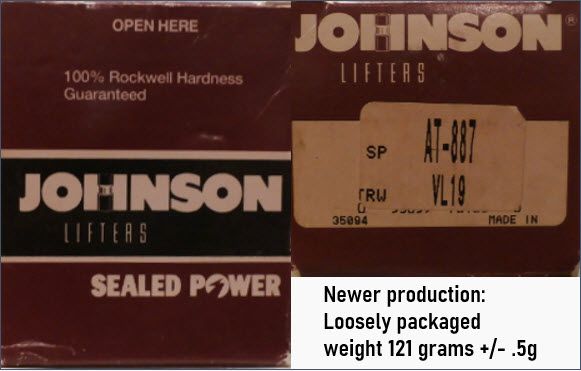

Well crap, I should have bought those! Ordered lifters from Amazon. Maybe not the typical place but they had hylift Johnson's for a decent price. I am curious to hear your feedback when your shipment arrives and the lifters are in hand. I spent some time back in '15 looking into this topic: Inliner's Engines Posting I found the new production lifters extremely heavy compared to stock and NOS after-market. The added weight seems counter productive to controlling the valves as RPM increases. Personally, I would go for NOS after-market. They still show up regularly: Ebay Sealed Power AT-887 lifters.

|

|

|

|

|

Joined: Aug 2011

Posts: 48

Active BB Member

|

OP

Active BB Member

Joined: Aug 2011

Posts: 48 |

Stock 49, after reading the lifter thread the set of lifters out of the original 248 are your "unknown" style in addition to 8 of the lifters I just pulled from the cast cam 302.

Last edited by Hillbilly; 02/12/20 10:21 AM.

|

|

|

|

|

Joined: Apr 2003

Posts: 1,541 Likes: 16

1000 Post Club

|

1000 Post Club

Joined: Apr 2003

Posts: 1,541 Likes: 16 |

Stock 49, after reading the lifter thread the set of lifters out of the original 248 are your "unknowwn" style in addition to 8 of the lifters I just pulled from the cast cam 302. The 'unknown' set from my post were pulled from my '49 216 and were running on a steel camshaft - suggesting chilled iron construction. They are not worn suggesting cam-lobe and lifter face are compatible. The absence of holes (top or sides) is most curious. No idea who manufactured them or when . . .

|

|

|

|

|

Joined: Aug 2011

Posts: 48

Active BB Member

|

OP

Active BB Member

Joined: Aug 2011

Posts: 48 |

Mine were used but we're sitting on the new ISKY LDB cam ground on a forged steel core. I believe the previous builder planned to run them "as is" but the engine was never fired. Old valve tip grinders can flat face a lifter but you must go to a a special place to get the radius-ed face found on new lifters. I will save the Isky cam and "unknown" lifters for a possible future budget build.

Last edited by Hillbilly; 02/12/20 10:23 AM.

|

|

|

|

|

Joined: Aug 2011

Posts: 48

Active BB Member

|

OP

Active BB Member

Joined: Aug 2011

Posts: 48 |

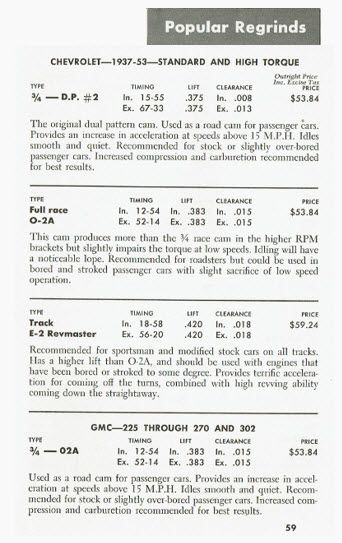

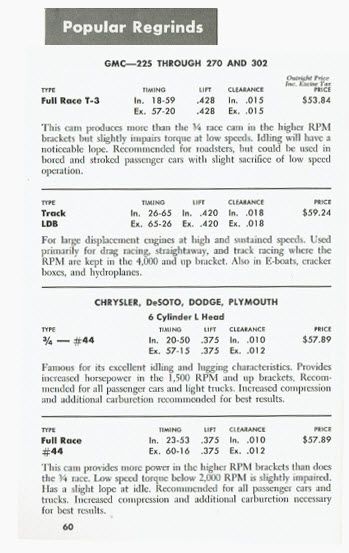

I was looking this over again and remembered. If you add the timing numbers together then add an additional 180 you will get the advertised duration for the cams. So the old LDB was a 271 duration cam. I had the ISKY cam run on a cam Dr. and it shows the @.050 duration to be 198.3 intake and 210.1 exhaust with .345 intake lift and .377 exhaust so it doesn't match this catalog. I wonder if the grind is custom or if the LDB changed over time. The Isky LBD has a lot less duration and lift than would be common now so I need to pull the forged steel cam from my spare 248 at the farm for a core to regrind at Bullet racing cams. Hi Hillbilly . . . nice find. To bad about the pond in the oil pan :-(. I see from the thread over on HAMB that you're looking for specs on that Isky regrind. I have the 1956 catalog. Chevy and GMC cams are found on page 59 and 60:    Unfortunately, back then there was nothing but advertised (valve event) durations - so there is no telling what the .020/.050 specs are for modern comparisons. Another thing interesting about these old catalogs is the breath taking prices. $59 was a ton of money in '56 - adjusted for inflation that is well north a $500 in today's money! regards, stock49

Last edited by Hillbilly; 02/12/20 10:51 AM.

|

|

|

|

|

Joined: Aug 2011

Posts: 48

Active BB Member

|

OP

Active BB Member

Joined: Aug 2011

Posts: 48 |

The CFM calculation (CFM = D × RPM × VE ÷ 3,456) is not divided by the number of carburetors for IR. 375 CFM total is not 125 CFM for each of three.

For reasons too lengthy to explain, three individual carburetors for an L6 can, and should, be much larger than three carburetors on a common manifold.

Except for the fabrication, the Weber DGV 32/36 is an excellent choice for IR. Other choices include Rochester 2G, SU HD6, Stromberg 175CD. Panic, the problem I see with 2gs and possibly some of the others is tuning power valve opening. 2gs Use a wound spring that has to be over come by vac. The hillbilly way to tune the is clip the spring and I have done it with success on a single 2g on a 350 but using that method for tuning to closely match 3 on a IR manifold makes me nervous. In fact in looking the tuned spring is the problem with 228/28 Zenith's and the Stromberg BXOV. I believe that is part of the reason 97s are so popular is the plunger for the accelerator pump opens the power valve. 94s open with a valve like a standard 4150/2300 so it could be tuned closely on vac. The 2 Stromberg Bxov-2s I have are a matched pair for a dual single bbl set up but for a 500 cubic inch fire truck engine. It is doubtful the power circuits will match my needs and having various springs wound with the coil count, length and K I need will be a bit of a challenge. 94s are readily available, the Jets are common and the power valves are available but they certainly aren't 4 times bigger than the cfm needed for a pair of cylinders. We flowed a zenith 228 11 with a 30mm Venturi at 1.5" of HG at about 120 cfm dry and a 94 at 150 cfm dry. Not sure what a 1-7/32 Stromberg will flow but it does have a bigger Venturi(30.95mm) so it may flow about 6% more.

Last edited by Hillbilly; 02/12/20 10:32 AM.

|

|

|

|

|

Joined: Aug 2011

Posts: 48

Active BB Member

|

OP

Active BB Member

Joined: Aug 2011

Posts: 48 |

Canceled the Amazon order and ordered the NOS lifters

|

|

|

|

|

Joined: Aug 2011

Posts: 48

Active BB Member

|

OP

Active BB Member

Joined: Aug 2011

Posts: 48 |

My plaster piston mold was soaking up the alcohol so my dome measurement was off. Coated it in a thin layer of rtv after paint didn't work. They came out to 60 cc. When I get my crank ground I will be able to mock it up but it looks like 9.5-10 to one will be easily possible.

|

|

|

|

|

Joined: Aug 2011

Posts: 48

Active BB Member

|

OP

Active BB Member

Joined: Aug 2011

Posts: 48 |

Does anyone have real world compression limit for pump gas? I know there are lots of variables but it would be interesting to hear what everyone is running.

|

|

|

|

|

Joined: Apr 2003

Posts: 1,541 Likes: 16

1000 Post Club

|

1000 Post Club

Joined: Apr 2003

Posts: 1,541 Likes: 16 |

There are a a lot of variables here - but typically pump gas tops out in the 11 or 12:1 range.

The basic guideline I have seen (based on static C/R) is 200psi cylinder pressure requires 93 octane. If you go up or down by 5 psi you need 1 more/less octane number . . .

Being in Nebraska you have E85 at the pump so you can blend your own higher octane. :-)

|

|

|

|

|

Joined: Aug 2011

Posts: 48

Active BB Member

|

OP

Active BB Member

Joined: Aug 2011

Posts: 48 |

E85 is awesome stuff but not sure if I can get it on my trip to Bonneville.

|

|

|

|

|

Joined: Aug 2011

Posts: 48

Active BB Member

|

OP

Active BB Member

Joined: Aug 2011

Posts: 48 |

NOS sealed power lifters showed up today

|

|

|

|

|

Joined: Apr 2003

Posts: 1,541 Likes: 16

1000 Post Club

|

1000 Post Club

Joined: Apr 2003

Posts: 1,541 Likes: 16 |

NOS sealed power lifters showed up today Got a triple-beam balance? Curious about the weight. Also, anything on the packaging that dates them?

|

|

|

|

|

Joined: Aug 2011

Posts: 48

Active BB Member

|

OP

Active BB Member

Joined: Aug 2011

Posts: 48 |

I have a oz scale and they came in a box that smells like an root celler.

|

|

|

|

|

Joined: Aug 2011

Posts: 48

Active BB Member

|

OP

Active BB Member

Joined: Aug 2011

Posts: 48 |

The all weigh 90-92 grams.

|

|

|

|

|

Joined: Apr 2003

Posts: 1,541 Likes: 16

1000 Post Club

|

1000 Post Club

Joined: Apr 2003

Posts: 1,541 Likes: 16 |

The all weigh 90-92 grams. That suggests an older production run. I have yet to be able to put dates on these parts - the packaging is not dated. And why they get heavier overtime is also a mystery . . . My research suggests that alot of the NOS parts out there may have come from just a handful of factories before production moved overseas. Apparently, there was a concentration of lifter production in and around Muskegon Mich. This may have included some OEM work for GM as this company history page about Johnson alludes (when Olds switched from flat-heads to OHV in '49): HyLift Johnson This was certainly a watershed moment for Olds - but as we all know Buick, Chevy and GMC were well ahead in this arena. For my own build - I was never able to snag a full set. I got half a box of 12 of the older production. These were individually packed:  I used those on the intake lobes. And I found 1 full and 2 partial boxes of some newer production - 4 packs - with lifters loose in the box with card-board dividers so they don't rub against each other:  Giving me 10 to choose from. I used the 6 closest in weight on the exhaust lobes. Leaving me with 4 in hand if anyone is scrounging . . . For me the most interesting part about this topic is what appears to have been dozens of different specifications for what ultimately is summarized overtime as a single interchangeable part. The dimensional differences being minor. In my 06 Weatherly Index the Dana Clevite part number 213-1661 is obsolete and the earlier part number 213-1603 has 28 cross-references including both of the Sealed Power part numbers AT708 and AT887, as well as, all of the GM part numbers 839263 (Chevrolet 216), 2194006 (GMC I6) , 3660438(Chevrolet 235), and 3836342 (I6 Corvette). Which makes no sense because of the change in materials from forged steel to cast iron we know the Corvette part is incompatible with the others.

|

|

|

|

|

Joined: Aug 2011

Posts: 48

Active BB Member

|

OP

Active BB Member

Joined: Aug 2011

Posts: 48 |

Sleeve put in cylinder one, freeze plugs installed, block short filled with block filler, cc'ed the hand ground head. Pics on the HAMB

|

|

|

|

|

Joined: Oct 2007

Posts: 5,042 Likes: 51

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,042 Likes: 51 |

You are really moving on this!

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Aug 2011

Posts: 48

Active BB Member

|

OP

Active BB Member

Joined: Aug 2011

Posts: 48 |

|

|

|

|

|

Joined: Apr 2003

Posts: 1,541 Likes: 16

1000 Post Club

|

1000 Post Club

Joined: Apr 2003

Posts: 1,541 Likes: 16 |

Your project is moving faster then most . . . it's quite a thread over on HAMB.

I am curious to learn more about your cooling plans with a partially filled block. With less coolant capacity in the block the thermostat is going to cycle more frequently demanding more from the radiator. Are you going to run an oil-cooler?

|

|

|

|

|

Joined: Aug 2011

Posts: 48

Active BB Member

|

OP

Active BB Member

Joined: Aug 2011

Posts: 48 |

I plan to run a stock 3/4 Radiator. I will probably only run a restrictor instead of a thermostat unless it runs way to cool. Minimal cooling happens in the lower part of the cylinder. No plans for an oil cooler. I trust my machinest. He has done short fills before on the street. It may shorten oil life but it will get changed well before it is damaged by heat.

Last edited by Hillbilly; 02/16/20 12:16 AM.

|

|

|

|

|

Joined: Aug 2011

Posts: 48

Active BB Member

|

OP

Active BB Member

Joined: Aug 2011

Posts: 48 |

There is honestly more oil to coolant contact in the head and lifter area than there is in the bottom of the cylinders.

|

|

|

|

|

Joined: Apr 2003

Posts: 1,541 Likes: 16

1000 Post Club

|

1000 Post Club

Joined: Apr 2003

Posts: 1,541 Likes: 16 |

I plan to run a stock 3/4 Radiator. I will probably only run a restrictor instead of a thermostat unless it runs way to cool. If it turns out that you need a partial continuous flow to avoid the thermostat cycling too quickly a small hose by-pass loop (like on the BBC) or a couple of small holes in the thermostat flange should do the trick. Its counter intuitive but an engine without a thermostat will not run cooler. The coolant needs to spend time in the radiator in order for heat to dissipate. There is honestly more oil to coolant contact in the head and lifter area than there is in the bottom of the cylinders. This is true. And the concentration of heat up top is what causes the thermostat to open. But when it does open the coolant in the radiator (if it has spent enough time there) will be significantly cooler then what is in the bottom of the block. This sets up a convention effect wherein the incoming coolant falls into the bottom of the block and the pump is moving the hottest fluids out through the thermostat until it closes. I personally have no experience with partially filled blocks - but it eliminates this convection zone and reduces the amount of coolant in the system. I would expect to have to compensate for this in some way.

|

|

|

|

|

Joined: Aug 2011

Posts: 48

Active BB Member

|

OP

Active BB Member

Joined: Aug 2011

Posts: 48 |

in an open loop system like a plant where water flows to a cooling tower I believe residence time is truly a factor. In a a closed loop like an engine the internal restrictions of the engine and radiator slow the coolant flow satisfactorily.

|

|

|

|

|

Joined: Aug 2011

Posts: 48

Active BB Member

|

OP

Active BB Member

Joined: Aug 2011

Posts: 48 |

You are absolutely correct the cooling area of the radiator controls how hot an engine gets, the thermostat just slows the flow till up to temperature.

|

|

|

|

|

Joined: Aug 2011

Posts: 48

Active BB Member

|

OP

Active BB Member

Joined: Aug 2011

Posts: 48 |

But I likely will use a 160 thermostat.

|

|

|

|

|

Joined: Apr 2003

Posts: 1,541 Likes: 16

1000 Post Club

|

1000 Post Club

Joined: Apr 2003

Posts: 1,541 Likes: 16 |

But I likely will use a 160 thermostat. And where will the sub 160 degree coolant come from to close it? It can be hard to get one's head around - counter intuitive. Installing too low a thermostat tends to set up a continuous flow - the result is all of the coolant in the system slowing rising in average temperature to a point where the temperature in the radiator is the same as what is in the block. In start and stop low speed traffic - perhaps no problem. On the freeway cruising at 70mpg the temp gauge will go up up up . . . as heat is not dissipated. I would expect to run a hotter thermostat. A heater core with no shutoff would add a second loop and more capacity.

|

|

|

|

|

Joined: Aug 2011

Posts: 48

Active BB Member

|

OP

Active BB Member

Joined: Aug 2011

Posts: 48 |

I don't believe you need residence time in a closed system.

I have experience with high horsepower and cooling systems. There may be a system that requires a thermostat to cool the system but I haven't found one. My experience is if the engine gets hot you have poor air flow through the radiator, limited radiator cooling area or a engine fault like a head gasket forcing gas into the cooling system creating a air lock or a boundary layer of air.

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

The closed thermostat is what creates the pressure to raise the local boiling point near the exhaust valve seats and spark plugs.

|

|

|

|

|

Joined: Aug 2011

Posts: 48

Active BB Member

|

OP

Active BB Member

Joined: Aug 2011

Posts: 48 |

So you are suggesting that the throttling of the water pump is the sole source for system pressure? Not the pressure created by superheating the water?

A system has a equilibrium temperature that changes based on the ambient temperature and the heat output of the engine. The thermostat allow the temperature of the system to be higher and warm.up faster than the equilibrium temperature when the equilibrium temperature is lower than the desired system temperature. This temperature may need to be raised to help remove condensation from the oil, allow heat in the passenger compartment, allow for more consistant temperature for fuel system tuning for Max mpg. If the radiator is undersized, lacks air flow, high ambient temperature or the engine load is much higher than design, the system will "overheat". Some systems may need this throttling in flow but I do not believe the system is in a constant state of starting and stopping and that a thermostat bypass is used for anything up more than allowing min pump flow to prevent cavitation during start up, and thermostat holes also allow egressed air to escape at start up.

BUT, I will also say that if you have good experience doing things your way and are happy with the results you should keep doing that. I appreciate the lifter help and all of the conversations around inline engines and vintage hot rodding. I am surprised by the people who think the only vintage hot rod engine is a flat head.

Thanks

John

|

|

|

|

|

Joined: Apr 2003

Posts: 1,541 Likes: 16

1000 Post Club

|

1000 Post Club

Joined: Apr 2003

Posts: 1,541 Likes: 16 |

I don't recall flatheads being discussed in the thread . . . I must have missed that.

My questions/comments stem from a general curiosity on your build and how you intend to overcome potential issues that result from modifications.

IMHO there are 4 reasons for a by-pass loop including:

-promotion of even and rapid warmup

-preventing water pump cavitation

-avoiding hotspots from developing in certain areas (as panic points out)

-or worse creating steam pockets near those hotspots

On my heavily modified stovebolt the by-pass loop runs through the intake manifold water jacket - serving two purposes at once.

Keep us posted on the progress. At the rate your going it should be running soon.

|

|

|

|

|

Joined: Aug 2011

Posts: 48

Active BB Member

|

OP

Active BB Member

Joined: Aug 2011

Posts: 48 |

Sorry, Flatheads are the general discussion in the local shop whenever someone sees my hot rod engine.

I plan to convert my nicson to water heater.

|

|

|

|

|

Joined: Aug 2011

Posts: 48

Active BB Member

|

OP

Active BB Member

Joined: Aug 2011

Posts: 48 |

And do I appreciate the comments and help.

Not sure how long till it runs, lots left to do. Still need to mock it up to determine deck height for compression. Head still needs valves and guides then proper springs and run on the flow bench. Need custom pushrods, have to get the pan, oil pump, damper and flywheel from my old 248 in the farm. Need to drill the crank and flywheel for 4 additional bolts. Balance the rotating assembly. Drill the block for full filter oiling and bend up 1/2 tubing and mount a filter housing.

Rebuild the pair of Stromberg BXOV-2s, build linkage, plumb the fuel system and block oiling system. Still stuck on what belt system to use. Not sure if I should go to 3/8 or stay with what I have.

|

|

|

|

0 members (),

83

guests, and

42

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

|