|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

X2,

Summit is a great place to buy parts.

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

got the engine back today. Power washed everything. Blew it off and sprayed wd40 in all the oil passages and exposed metal surfaces. Got the crank installed today. All main bearing clearances are between .0007"-.0010". Honing the cylinders tomorrow to install the new pistons. Rings are gapped slightly over stock for higher heat of the turbo. Should have the engine back together probably by the end of the weekend. Car is all stripped down and ready for a motor. Should be back together by next week

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

Honing the cylinders after installing the crank?

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

Glad it's coming together.

What end gap with the rings did you end up with?

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

Main bearing clearance is way too tight for a performance build. Also like panic said, block should be honed not only before crank is installed, but before the block is washed and cleaned.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

Took the crank out. Honed each cylinder. Cleaned everything and reinstalled the crank. Installed all the pistons. Went to tighten the rod bolts. Torqued them all to 35ft/lbs and then to 45ft/lbs. Broke a bolt on the fourth bolt at 45ft/lbs. Going to buy a set of ARP rod bolts now.

Anyone know where to find the oil pump gasket? Or should I just clean and use silicone gasket or what?

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

When you install new rod bolts you resize the rods @ the same time.Have the machine shop install your rod bolts & resize the rods. The oil pump gasket is just paper thin. Not real sure if it is needed, but you can use Hylomar as a gasket. http://www.amazon.com/Permatex-85249-Hylomar-Universal-Dressing/dp/B0018PSATYhttp://www.youtube.com/watch?v=yXiVZIBoHL0I have been using it for years on aircraft jet engines & when I was road racing motorcycles & used it on 2 stroke engines. Gas, two stroke oil & engine oil does not effect it. Great stuff! MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

Torqued them all to 35ft/lbs and then to 45ft/lbs. Broke a bolt on the fourth bolt at 45ft/lbs. 250 rods only torque to 35 ft.lbs, there only 11/32" not 3/8". Why did you think they torqued to 45 ft.lbs.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

I looked up the reason why people need to resize rods with ARP studs and it's because the increased pressure from chromoly bolts slightly changes the shape of the end which can lead to slightly increased bearing wear. However people replace the bolts with ARP studs without resizing them with success. I'm out of options and money and I have to have this engine running in 2 weeks.

250 rods only torque to 35 ft.lbs, there only 11/32" not 3/8". Why did you think they torqued to 45 ft.lbs.

That's what the chilton's book said. I guess it lied

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

I took a engine rebuilding class in college & the instructor said any time you change the rod bolts you need to resize the rods. http://www.yellowbullet.com/forum/showthread.php?t=326615Just another forum. MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

Snowman, i've resized 1000's of rods and the main reason they have to be resized when replacing the bolts(not just ARP, but any brand) is because the rods become distorted when you push the old bolts out and put the new bolts in. I've tried every trick in the book to try to find shortcuts around this when customers have had a tight budget, and it literally cannot be done without consequences. Also upgrading to an ARP requires them to torque a little more than the stock bolts which also makes the housing bores smaller and also out of round. Your on your way quickly to a 3rd rebuild and you haven't even gotten the second one done yet. My advice is stop immediately and walk away until you can do it correctly!

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

I looked up the reason why people need to resize rods with ARP studs and it's because the increased pressure from chromoly bolts slightly changes the shape of the end which can lead to slightly increased bearing wear. However people replace the bolts with ARP studs without resizing them with success. I'm out of options and money and I have to have this engine running in 2 weeks.

250 rods only torque to 35 ft.lbs, there only 11/32" not 3/8". Why did you think they torqued to 45 ft.lbs.

That's what the chilton's book said. I guess it lied 292 rods torque to 45 ft.lbs., but the 194-250 rods only torque to 35 ft. lbs.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: May 2009

Posts: 493

Contributor

|

Contributor

Joined: May 2009

Posts: 493 |

the rods become distorted when you push the old bolts out and put the new bolts in. I've tried every trick in the book to try to find shortcuts around this when customers have had a tight budget, and it literally cannot be done without consequences. Agree. Best plan is a proper reconditioning with new bolts for the reasons you state. However, I have installed new bolts without resizing on more than one occasion without failure. I do not recommend this but it can be done. Not good practice especially if you are going to run hard. Snowman- I have twisted off 11/32 rod bolts too. I may have seen the same erroneous spec! After that experience I ALWAYS replace factory rod bolts.

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

I'm concerned with the remaining life in the bolts that didn't break...

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

well I ordered the ARP bolts. I don't have the time to take everything back apart or the money to get the rods resized. I'm just going to have to hope and pray. I'm going to replace all the bolts anyway so I'm not concerned with the other bolts.

What should I torque them to?

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

It will tell you on the package when you get them. They recommend stretch instead of torque, just read the paperwork when it comes.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

Well I got the new ARP studs installed. Got the crank in, got the rods connected, got the oil pump in. Got the harmonic balancer on. Got the timing cover on. Got the head on and cam/valvetrain in. Got the manifolds on. Still got some stuff to do and a gasket or two to get.

At this point, I'm just hoping it'll turn over and survive the break-in period... The whole rotating assembly is really hard to turn and I don't know if that's just because there's a whole valvetrain to turn and that they're all fresh, unoiled bearings.

I'll probably finish it out within the next few days and let ya'll know how it works out.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

You mentioned earlier last week you only had .0007 or so main bearing clearance. That is way too tight. To give you an idea of how little clearance that actually is, take a human hair and split it into 5 equal thicknesses, then take one of those split pieces and split it in half again.....Also, putting studs in the block will make the main housing bores close up even tighter than when you checked it and only had .0007" clearance, so you may have close to no clearance at all right now, thats why its so tight. You also mentioned "unoiled" bearings, did you install them dry....

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

I think he is referring to the ARP rod bolts as studs? Sounds like the bearings are dry, .0007 is too tight, I am sure it's hard to turn the crank as it should with that tight clearance, no oil & what is the crank run-out?  MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

I think he is referring to the ARP rod bolts as studs? Sounds like the bearings are dry, .0007 is too tight, I am sure it's hard to turn the crank as it should with that tight clearance, no oil & what is the crank run-out?  MBHD For me to hear that is like someone scratching their fingernails across a chalkboard!

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: May 2010

Posts: 134

Contributor

|

Contributor

Joined: May 2010

Posts: 134 |

How did you come up with this 7tenth figure? Don't try to start it with those numbers. If your a decimal off then it's way to loose. Better check it again.

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

I used stock main bolts. I only replaced the rod bolts with ARP bolts and nuts.

I'm not special y'all. I used craptons of assembly lube on every moving part of the engine when I assembled it. main bearings, rod bearings, cam, lifters... I meant that the bearings hadn't had a full revolution and the oil pump wasn't primed so it didn't have an actual film of oil in any of the bearings. Just assembly lube.

I plastiguaged the main bearings. All of the plastigauge were right at or slightly longer than the .0010" mark. I also managed to not clean of earlier assembly lube before I checked the clearance so I'm assuming that the film of assembly lube also made it read a tighter clearance than it actually was.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

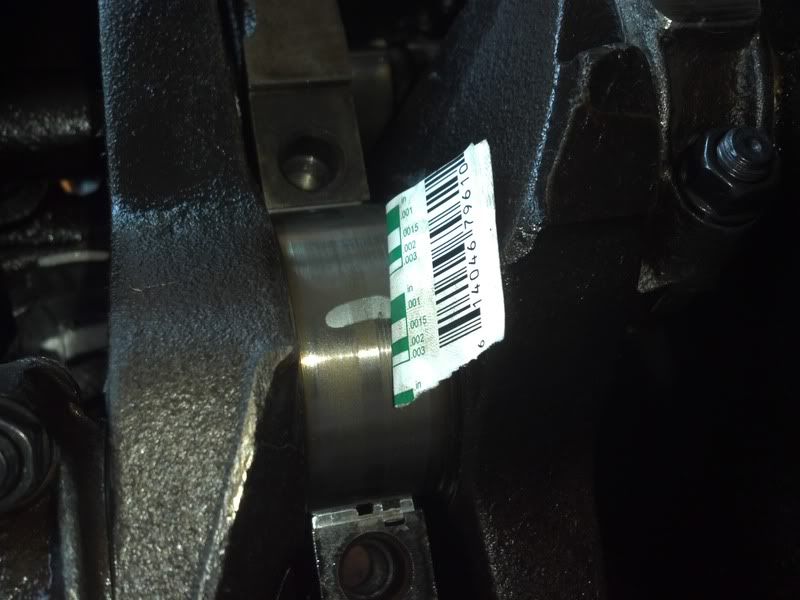

This is what all of the bearings looked like. Redid the plastigauge without the oil and it's actually about .0011"

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

Your clearances are still way too tight,if you doubled that you would be at the minimum safe clearance to be.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

Well why on earth would a stock crank with stock size bearings have such

Incorrect tolerances

Last edited by snowman4839; 07/29/12 10:57 PM.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

There probably spot on if you were building a "stock" engine, but when building a performance engine you have to observe different machining techniques and components to adjust the bearing clearances where they need to be, thats where the term "blueprinting" comes into play. If your intention is to build a hot performance engine, you need to seek out a machine shop that is familiar with how to do this so they can perform the necessary tasks and provide you with the necessary components to help you achieve your goal. Your probably not even using a high performance grade or race type bearing set, and thats one of the key elements that often gets overlooked when doing a performance build.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

OP

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

snowman4839,

curious as to what is your max RPM you can turn your engine to ( making power ) w/your stock camshaft & 10-15 psi of boost pressure?

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

Well I'm rebuilding this to stock. The engine ran fine when it was stock with the turbo. The big weak link was the stock fuel system. I'm just askin if the engine will run at 11/10000" clearance in the main bearings.

It'll probably be 10psi and I wasn't expecting much past stock. Probably 4800rpm at the most. Stock max hp is at 4200rpm and id imagine the turbo would let it breath a little higher

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

Having 10 psi no longer makes it stock! It might have stock type components, but it needs to be prepped like a race engine because of the HP level you are now expecting to have which is double or more of what is was stock. Your just not understanding that you are way beyond being able to use cast pistons like in your first build, and other stock type parts and clearances, that turbo changes everything.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

I just want it to run. I don't expect this to be a bulletproof engine. I just need a running stock engine in it that happens to have a turbo on it.

I just need to know if it will run at 11 or 12/10000" clearance

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

I just need to know if it will run at 11 or 12/10000" clearance Not for long!

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

I just need to know if it will run at 11 or 12/10000" clearance Not for long! Meaning for 5 seconds on the first start or a few thousand miles after some abuse from the turbo?

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

I'd saying starting and idling will be fine, but you could count the abuse time in seconds not miles as you stated! If your going to build a stock engine....fine, if your going to build a performance engine, thats fine too, but you've convinced yourself its a stock engine that just happens to have a turbo on it, and the two aren't compatible with the methods you are trying to use. What kind of bearing clearances did you have on the rods?

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

Well is there a different set of bearings I can buy that will have a larger clearance? I don't have the time or money for machine work

I just still don't understand why a stock crank with stock replacement bearings would have such incorrect clearances.

Last edited by snowman4839; 07/31/12 03:22 PM.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: May 2010

Posts: 134

Contributor

|

Contributor

Joined: May 2010

Posts: 134 |

After looking at the picture of your plasigage again it's hard to tell but it looks like the plasigage is narrower then the .001 mark which would mean the clearence is greater then .001. Is this correct or am I looking at it at a weird angle. It looks closer to .0015 from my angle. Which would be fine.

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

He doesn't have the plastigage paper lined up with the plastigage on the journal, but you can tell its right at .001!

Snowman, there are many things that can be causing your issue, all of which are well beyond your ability to check or correct by yourself. You need to take the crank to a machine shop and have the journals mic'ed and let the machinist tell you if it needs to be reground. You have to realize if its never been reground before, it can easily be out of round by over .001, and you could likely be measuring the clearances on the areas of the journals that are the larger diameters with less wear on them. Also, the main housing bores in the block could also have tightened up, which is common on engines that are as old as this one and have never been rebuilt or align honed before(other than from the factory), all of these things are normal and are often the main stumbling block for guys like you that try to rebuild them without having the block or crank checked out before hand. There are so many variables that are just beyond your current knowledge of understanding that makes it hard for you to see the big picture. The bearings you have could also be the problem, they are man-made and not beyond being defective, but until you start eliminating other things that are common repair items related to engine building such as the housing bores or crank journals, you are spinning your wheels and can end up throwing good money out the window if you don't make sure the block is in good shape before you begin sinking money into parts.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

Is taking the crank out and getting 10/10000" polished off a reasonable solution assuming the crank is still concentric? That would put each clearance anywhere in the 20/10000" to 25/10000" range

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Mar 2010

Posts: 630

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 630 |

Well since I don't have the money to machine this motor correctly, I found a 1980s 250 with the integrated head. Can I bolt my 60s head on an 80s block so I can use my reliable carb and manifold setup?

Is there any differences in the later motors besides the head/manifold setup?

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Jul 2000

Posts: 4,588 Likes: 20

1000 Post Club

|

1000 Post Club

Joined: Jul 2000

Posts: 4,588 Likes: 20 |

Larry/Twisted6 [oooooo]  Adding CFM adds boost   God doesn't like ugly.

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

X2, cylinder head will interchange will no problem!

Class III CNC Machinist/Programmer

|

|

|

|

0 members (),

125

guests, and

27

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

|