|

|

Joined: Jul 2000

Posts: 4,588 Likes: 20

1000 Post Club

|

1000 Post Club

Joined: Jul 2000

Posts: 4,588 Likes: 20 |

If it only has 28K on it I wouldn't worry about adjusting it.

Larry/Twisted6 [oooooo]  Adding CFM adds boost   God doesn't like ugly.

|

|

|

|

|

Joined: Aug 2014

Posts: 821

Major Contributor

|

OP

Major Contributor

Joined: Aug 2014

Posts: 821 |

If it only has 28K on it I wouldn't worry about adjusting it. I drove it from MD to NC and back over the last 4 days for our 10 year anniversary and the trans worked flawlessly so I'd agree with that. 1,000 miles in 4 days. 300+ for three full days of great driving and 1 day of boating, partying, and eating. The trip started off in Frederick, MD, went down rt 340 to Skyline drive, drove the whole 100 miles of Skyline, stopped at a winery at the end (Veritas: I'd highly recommend it! Excellent wine. Bring lots of money) and continued on to Roanoke to spend the night. From there we headed over to Sneads Ferry, NC (on the ocean near the NC and SC border) where we shacked up with some friends. Sunday morning we left and headed up 95 to DC and back home to Frederick. Burning oil, though. Ran through a quart every fill up. Glad I had the oil pressure gauge and temp gauge now. Car never over heated and ran pretty well. Still fighting an off-idle stumble and had to change squirters from my #28 to my #35 when I went from 5,000 ft to sea level. I couldn't find a #32 anywhere but that seems to be the correct one for the car. It's on my to-do list now. I doubt the car has 30k miles on it now. Oil pressure was only reading 20 psi while running down the highway and 10 at idle (but that might be due to the gauge or how it was routed: mechanical gauge). She pulls very hard all the way to the speed limit (and a fair bit beyond...). I brought every tool imaginable for the trip and didn't need any of them. I'd call that success! I'll upload a few pics in a bit. Didn't take any gratuitous engine shots because it's covered in pollen. The engine bay is dirtier than it's ever been since I've owned it! That will be fixed this weekend. Idle is a bit rough still. Almost like it has a cam. It might for all I know. Any way to tell without pulling the engine apart? In the end it was a fun trip with no break downs, she drove well, tracked straight, got attention everywhere and really hummed along on the highway like a modern car. Thanks to everyone for their advice on the board. All of it helped make the car fun and reliable. Now I get to spend the summer keeping it clean, taking it for cruises with the kids, and collecting a few trophies from local car shows. Should be a great summer!

Last edited by gbauer; 04/13/15 09:59 AM.

|

|

|

|

|

Joined: Aug 2014

Posts: 821

Major Contributor

|

OP

Major Contributor

Joined: Aug 2014

Posts: 821 |

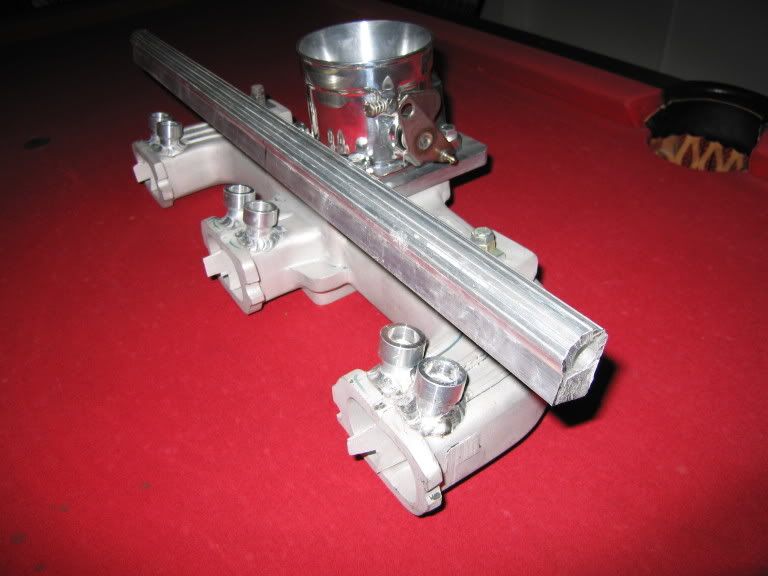

Pics:  My personal favorite pic:

Last edited by gbauer; 04/13/15 02:22 PM.

|

|

|

|

|

Joined: Aug 2014

Posts: 821

Major Contributor

|

OP

Major Contributor

Joined: Aug 2014

Posts: 821 |

Drove it on Sunday a bit. Idling rough now. I think I need to recheck my valve lash. Things loosened up on the long drive a bit and I'm starting to question my valves. Just a gut feeling.

I'm also going to try to fine tune the carb. Getting out the old vacuum gauge to adjust the idle mixture screws then rechecking timing (about a degree too advanced right now), idle speed, lowering the cold fast idle setting (too high now), and messing with the power pump cam. Also going to check the intake/exhaust bolts for snugness.

First, though, is the valve lash. I'll back each one off until they make noise then tighten 1/2 turn.

Running her hard for so long might have opened up some partially clogged oil passages, etc.

At idle I'm only reading 10psi for the oil pressure. I wonder if I need to bleed the pressure sensor line. It's on my to-do list as well. As the line naturally bleeds off a bit I'm noticing my reading has gone up about 5 psi at speed. I think the air bubbles in the line are causing it to read a little low.

Still have that off-idle stumble when I mash the gas. I can't floor it off the line but rather have to go half throttle until she's moving then floor it. Going to check float levels as well. I thought it was right but she's acting like there isn't enough gas when I floor it for a split second. Probably more to do with the accelerator pump arm adjustment.

At wide open the secondary seems to be opening as it should and I have lots of power. No problem there. Just a slight clack so I think the timing is just a tad advanced. Might need to do something about the vacuum advance. Advice there?

Soon it'll be time to just let it ride until next winter. Then it'll be a mild cam, lumps, clean up the head, new valves, new valve guides, inspect the lower end and cruise to Ohio for a little get together with you guys. Maybe EFI if funds allow. Definitely a new trans with more than 2 gears.

The following winter will be turbo time and rear end work to take it.

FInal goal is 400 hp at the rear wheels.

|

|

|

|

|

Joined: Jan 2015

Posts: 376

Contributor

|

Contributor

Joined: Jan 2015

Posts: 376 |

My old 292 in my 66 reads 5 pounds at idle and 20 pounds at 2500 rpm cruising around...even with 15-40!

|

|

|

|

|

Joined: Aug 2014

Posts: 821

Major Contributor

|

OP

Major Contributor

Joined: Aug 2014

Posts: 821 |

Thanks. Makes me feel a bit better about that... I go from my Camaro to my 2009 CTS and go from 10 lbs to 50 lbs at idle. Kinda raised an eyebrow.

|

|

|

|

|

Joined: Apr 2004

Posts: 3,566 Likes: 37

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,566 Likes: 37 |

The air in the oil pressure line will not cause a low reading. It all gets compressed with the same amount of pressure.

I like to adjust the valves with the engine off. Your engine has OEM lifters. They need more turns in than new style lifters. I believe it is 1- 1 1/4 for OEM lifter.

Put engine on TDC #1 and adjust both intake/ exhaust. Feel the pushrod by lifting up and down. When play is gone, give it the required turns.

Then turn engine 1/3 of a turn and repeat process on the next cylinder in firing order.

Repeat till done. Only 2 revs of engine.

Put some thicker oil in your engine. You really will need about 30 to be sufficient. On your stock engine.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Aug 2014

Posts: 821

Major Contributor

|

OP

Major Contributor

Joined: Aug 2014

Posts: 821 |

The air in the oil pressure line will not cause a low reading. It all gets compressed with the same amount of pressure.

I like to adjust the valves with the engine off. Your engine has OEM lifters. They need more turns in than new style lifters. I believe it is 1- 1 1/4 for OEM lifter.

Put engine on TDC #1 and adjust both intake/ exhaust. Feel the pushrod by lifting up and down. When play is gone, give it the required turns.

Then turn engine 1/3 of a turn and repeat process on the next cylinder in firing order.

Repeat till done. Only 2 revs of engine.

Put some thicker oil in your engine. You really will need about 30 to be sufficient. On your stock engine. I usually run 10W-30 or -40 in it. She burns a bit so I sometimes will have to suck it up at a gas station and put in what they have. I try not to do that, though. Dumb thought: the filter on the valve cover: do they get fouled often? Would that cause a rough idle? Mine has about 3,000 miles on it. I doubt it's the problem but thought I'd ask anyway since two weekends ago there was a TON of pollen down in NC when I was down there. It didn't idle rough until I got it back home. Is it better to adjust the lifters while running or like you describe? I've done it while running but never tried it your way.

Last edited by gbauer; 04/20/15 05:18 PM.

|

|

|

|

|

Joined: Apr 2004

Posts: 3,566 Likes: 37

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,566 Likes: 37 |

I always do it my way, that is why I recomended it. It does help to take the plugs out and mark the balancer at 120degree locations.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Jan 2015

Posts: 376

Contributor

|

Contributor

Joined: Jan 2015

Posts: 376 |

I've always done it running after the engine is at operating temp....loosen until they clack and tighten until there's no clacking at the rocker. Sometimes if you have noisy lifters it makes things harder but I've gotten used to it. In the morning mine clack like crazy but after its run for a few minutes all gets fairly quiet. I've never had to adjust hydraulic lifters with the engine off...only solid. But as Tom said...it is better and easy on your engine, but imop as long as your slow and you don't tighten of loosen to fast with the engine running all should be fine. Either way...have fun. lol

|

|

|

|

|

Joined: Aug 2014

Posts: 821

Major Contributor

|

OP

Major Contributor

Joined: Aug 2014

Posts: 821 |

Didn't screw with it too much this weekend. I've been wrenching on it too much lately and had to take a break.

That said I did get into the carb a bit. Pulled out the vacuum gauge and re-set the idle air screws. Switched the vac advance and trans vac lines so the vac advance is on manifold vac and trans is up top near the horn. Seems to run better and shifts a bit harder again. Re-checked timing: Roughly 6 degrees at idle. I had a slight detonation under load before at higher RPM's but that seems to have gone away after doing the above. Lowered the idle a bit too.

Still not perfect but much better.

I'm going to avoid working on it too much this summer. Next winter will be a mild cam and head work as discussed above.

Didn't pull the valve cover. It took forever to get it to seal up right and I'd rather wait to go down that road again until I pull the head.

We drove it a bit and though I didn't calculate gas mileage it seems to be doing very well.

Last edited by gbauer; 04/27/15 09:18 AM.

|

|

|

|

|

Joined: Aug 2014

Posts: 821

Major Contributor

|

OP

Major Contributor

Joined: Aug 2014

Posts: 821 |

Found my problem: the little BB in the accelerator pump fell out along with the bar. No wonder it was rich!

Silky smooth now.

|

|

|

|

|

Joined: Aug 2014

Posts: 821

Major Contributor

|

OP

Major Contributor

Joined: Aug 2014

Posts: 821 |

Carb is done (well I do need to drop 1 jet size but she's really close and that'll take just about 30 minutes including pulling and re-installing the carb...). Now it's time to fine tune the distributor. I'm only about 6 degrees advanced at idle. When I'm cruising along and give it about 3/4 throttle I get pinging. I don't have a tach but I'd guess it to be about 2,500 to 3,500 RPM's when it happens. If I floor it the pinging goes away. Also getting some dieseling when it's hot. Basically I think I'm getting too much vac advance. How would I fix that? If I can bring the vac advance down a bit I can increase initial advance a couple points and smooth things out some. I have one of these: http://www.ebay.com/itm/New-Chevy-Inline...e5a&vxp=mtr(not the best, I know...) Thoughts? I've never done this or even seen it done so a little hand holding would be appreciated.

|

|

|

|

|

Joined: Aug 2014

Posts: 821

Major Contributor

|

OP

Major Contributor

Joined: Aug 2014

Posts: 821 |

Also: Time to start talking about a little head work/cam job for next winter... I can definitely tell that's my next job on it. She needs a bit more breath to get up and go.

I want to do all the research now so I know what I want later.

End goal: Turbo charged 250, efi, 350hp+, streetable machine, maybe bottle as well. A nice cruiser with some punch.

Next winter: Head and cam.

I know I want lumps. I also want a mild cam. Back and forth on upping the compression and/or valves. Might opt to skip both with a turbo on the horizon. Other option might be to get a second head done for N/A and later sell it when I go forced induction. I'd think with the head and langdon headers I can at least offset the cost of the SPA turbo manifold.

(this summer is going to be spent enjoying the car, not working on it)

Last edited by gbauer; 05/04/15 11:41 AM.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

[quote=gbauerI'm only about 6 degrees advanced at idle. When I'm cruising along and give it about 3/4 throttle I get pinging. I don't have a tach but I'd guess it to be about 2,500 to 3,500 RPM's when it happens. If I floor it the pinging goes away. Also getting some dieseling when it's hot. Basically I think I'm getting too much vac advance. How would I fix that? (not the best, I know...) Thoughts? I've never done this or even seen it done so a little hand holding would be appreciated. [/quote] You can install an adjustable vacuum can if yours did not come with one. https://www.google.com/search?q=adjustab...mp;ved=0CFkQsAQQuestion, what octane fuel are you using? If it is 87 or less, I do not think the engine was designed to run on low octane we have nowadays. What was the lowest octane available in 1968? You can swap where your vacuum advance hose is hooked up. Port vacuum or direct vacuum, just to try it out. Dieseling, throttle blades open too far, idle too high? What RPM does the engine idle at in gear & out of gear? MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Aug 2014

Posts: 821

Major Contributor

|

OP

Major Contributor

Joined: Aug 2014

Posts: 821 |

Don't have a tach but I can hook up my external. I can probably lower it some but not a whole lot without potentially stalling the motor when it's in gear at a stoplight.

Running 87. I can try going up.

I've moved the vac advance from the metered to the intake port. I can go back. I prefer it on the intake, though, because the trans shifts better on the metered port. I can always add a T if needed.

What should it idle at in gear and out?

|

|

|

|

|

Joined: Aug 2014

Posts: 821

Major Contributor

|

OP

Major Contributor

Joined: Aug 2014

Posts: 821 |

I just did some interwebbing on adjusting the vac advance. Seems simple enough. I probably only need to back it out 1 turn from what I've read. Mine is the adjustable type. I just never new how to do it.

|

|

|

|

|

Joined: Aug 2014

Posts: 821

Major Contributor

|

OP

Major Contributor

Joined: Aug 2014

Posts: 821 |

Adjusted the vac advance and lowered the idle a bit. No more dieseling. No more pinging.

That said it's still a tad rich. Tonight's work is dropping the Jets down a size. After that I might need to go up to a 32 squirter. I'm at a 28 now. It's still a tad rough at idle particularly after flooring it and letting off fast. I think gas is pooling in the intake causing the rough idle. Intake has plenty of heat. It's too much fuel.

....and I know, I know... O2 sensor... maybe next week if the wife let's me open the wallet. that said she might say no because it's running so well now she won't think it's necessary until after we buy a new house.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

....and I know, I know... O2 sensor... maybe next week if the wife let's me open the wallet. that said she might say no because it's running so well now she won't think it's necessary until after we buy a new house. It is pretty easy to get it. By stating the Wide band reader will get it to run perfectly & save $$$ by having the A/F ratios correct, will save on gas usage. Simple , right?  By adjusting the vacuum can, did you make sure you did not completely take out it's ability to get a vacuum signal? MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Aug 2014

Posts: 821

Major Contributor

|

OP

Major Contributor

Joined: Aug 2014

Posts: 821 |

it's still advancing, just not so much. I haven't actually. Hecker the timing yet.

|

|

|

|

|

Joined: Jan 2015

Posts: 376

Contributor

|

Contributor

Joined: Jan 2015

Posts: 376 |

Whats your timing without vacuum?

|

|

|

|

|

Joined: Aug 2014

Posts: 821

Major Contributor

|

OP

Major Contributor

Joined: Aug 2014

Posts: 821 |

Whats your timing without vacuum? 8 degrees. I tried a bit of mid grade gas and magically it's no longer pinging. Seems to have a bit more umph behind it too. Looks like I just upgraded to 89+ octane... I think I'm done for the summer now. I'll get back to the fun stuff this fall with it. Probably just buy one of Tom's heads already done up, get some new rods, a cam (Tom might just get a big order out of me) and slap that in. Probably upgrade the trans to a TH350 or 400 at that time as well. Looked into going 700r4 or even a 4L80 but both seem like overkill for a weekend cruiser. If budget permits I'll probably also do EFI next winter. ...all in preparation for this thread being moved one subforum down... Hopefully for next year's little shindig in Ohio I'll be pretty close to maxed out for a naturally aspirated 250 without crazy stuff on the head or intake. Then next time we all get together I'll be up around 400 hp at the rear round thingies. Lots of work before I get there! Once the head is done and I can enjoy it for a summer as-is the following winter will involve new pistons, rods, and the snail with the stuff involved with that. Intercooler (probably no water or meth injection: street car), bigger exhaust, etc. I want to keep the little 250 badge on the car and pass big blocks at the track. As is I walk my buddy's stock 327. I'm going for bigger fish next.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

[quote= Probably upgrade the trans to a TH350 or 400 at that time as well. Looked into going 700r4 or even a 4L80 but both seem like overkill for a weekend cruiser. Intercooler (probably no water or meth injection: street car), bigger exhaust, etc. I want to keep the little 250 badge on the car and pass big blocks at the track. As is I walk my buddy's stock 327. I'm going for bigger fish next. [/quote] TH400 trans is a bit of over kill for a 6 cyl also.

The trans that drops in w/out needing to change the driveshaft or trans mount, a 200R4.

The 4L80E & 700R4 both require swapping driveshaft & cross members.

Having OD makes for freeway runs much more enjoyable. Plus better acceleration ,(better gearing) , having better gearing is like adding HP/torque to your engine. All positives , just cost, not so positive.

Meth or water injection is exactly what you use on a street car, when turbo charging, it just makes sense to use, because you are not going to be filling up on race gas for a street car.

Meth or water injection is just like race gas performance while running pump gas.

Even if you are not racing, it just makes sense to inject water just to reduce the chance of detonation.

A couple of friends use this system http://www.alcohol-injection.com/en/19-universal, they do not race, just daily drivers.

Gives then peace of mind plus there cars do not detonate anymore after their installs.

One has it on a 2001 Pontiac GTP, supercharged, other 2004 Jetta turbo.

Both are very happy they installed it & glad they did install it.

AS far as my methanol system I use, best thing ever I installed, made the biggest improvement over any other modification I installed.

Not to mention, it does not detonate anymore.

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Aug 2014

Posts: 821

Major Contributor

|

OP

Major Contributor

Joined: Aug 2014

Posts: 821 |

I thought the 200r4 required a different crossmember. If not then that's what I'll look for.

How often do you have to fill up the water injection system? I always assumed that you had to fill it often. If not then I agree for $400 it's worth it.

Any recomendations on the efi system? Fast is nice but it's also nice and pricey.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

From what I remember, the 200R4 is a straight drop in trans that can replace your factory installed PG, short tail shaft TH350, 3 speed Saginaw, 4 speed Muncie transmissions. You reuse the same driveshaft & cross member. As far as refilling the water injection tank, that depends on how much you are injecting, what size tank you have, how often you are into boost etc. I use a standard size GM overflow tank, holds, 2 QTS approx? I need to refill after 4 or so 1/4 mile passes, but I am also injecting a lot of methanol, so much it changes the A/F ratio. You can run a small jet as to just use for chilling the intake air temps & not really use that much. 1/2 gallon tank, refill once a week? EFI systems out now are self learning, really works good & for the guy just get into EFI, would be a wise choice, but they are about $2500 or so. Megasquirt is about the cheapest, but not the easiest, you need to know the basics & then some. My friend is a dealer for SDS that is what I am going to be using. http://www.sdsefi.com/MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Jul 2000

Posts: 4,588 Likes: 20

1000 Post Club

|

1000 Post Club

Joined: Jul 2000

Posts: 4,588 Likes: 20 |

How much is that set-up From what I remember, the 200R4 is a straight drop in trans that can replace your factory installed PG, short tail shaft TH350, 3 speed Saginaw, 4 speed Muncie transmissions. You reuse the same driveshaft & cross member. As far as refilling the water injection tank, that depends on how much you are injecting, what size tank you have, how often you are into boost etc. I use a standard size GM overflow tank, holds, 2 QTS approx? I need to refill after 4 or so 1/4 mile passes, but I am also injecting a lot of methanol, so much it changes the A/F ratio. You can run a small jet as to just use for chilling the intake air temps & not really use that much. 1/2 gallon tank, refill once a week? EFI systems out now are self learning, really works good & for the guy just get into EFI, would be a wise choice, but they are about $2500 or so. Megasquirt is about the cheapest, but not the easiest, you need to know the basics & then some. My friend is a dealer for SDS that is what I am going to be using. http://www.sdsefi.com/MBHD

Larry/Twisted6 [oooooo]  Adding CFM adds boost   God doesn't like ugly.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

How much is that set-up Are you asking about the SDS system or a 200R4? I can ask my friend for what a basic SDS system cost now. Probably about $1000-1400 dollar range, as a guess. All the tuning done on hand held unit, no need for laptop to boot up, take up space, inconvenience. It's right there in the palm of your hand. The newer units can data log from what my friend told me. MBHD From what I remember, the 200R4 is a straight drop in trans that can replace your factory installed PG, short tail shaft TH350, 3 speed Saginaw, 4 speed Muncie transmissions. You reuse the same driveshaft & cross member. As far as refilling the water injection tank, that depends on how much you are injecting, what size tank you have, how often you are into boost etc. I use a standard size GM overflow tank, holds, 2 QTS approx? I need to refill after 4 or so 1/4 mile passes, but I am also injecting a lot of methanol, so much it changes the A/F ratio. You can run a small jet as to just use for chilling the intake air temps & not really use that much. 1/2 gallon tank, refill once a week? EFI systems out now are self learning, really works good & for the guy just get into EFI, would be a wise choice, but they are about $2500 or so. Megasquirt is about the cheapest, but not the easiest, you need to know the basics & then some. My friend is a dealer for SDS that is what I am going to be using. http://www.sdsefi.com/MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Aug 2014

Posts: 821

Major Contributor

|

OP

Major Contributor

Joined: Aug 2014

Posts: 821 |

Sounds like a good deal. Where are the injectors installed and do you need a separate throttle body?

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

Here is my Clifford intake with injector bungs. The angle is not the best. I just want to get this thing running so was not too concerned with the proper angle.  Yes on a separate throttle body.  The other is a intake manifold I made for a 12 port head.  MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Aug 2014

Posts: 821

Major Contributor

|

OP

Major Contributor

Joined: Aug 2014

Posts: 821 |

On the Clifford it looks like you put in weirs between the injectors. Was that necessary?

I may hold off on FI until after I can see some systems in person next summer in Ohio. Looks nice and neat though. That said I can get an EFI system like this for free from a friend who wants to help build the engine up a bit. I showed his little red car on page 1 or 2 of this thread. He suggested doing exactly what you did but after talking with Langdon I was talked out of it. If I hadn't been I'd probably have a set up like your second pick on my car right now (except the runners would be flat so I could fit a spinning thingy below them at a later date which is approaching pretty quickly).

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

With the Clifford, I installed a divider plate to trying to improve fuel/air distribution & possibly increase port velocity.

Port velocity is low with the Clifford intake manifold.

What EFI system can you get free?

" I showed his little red car on page 1 or 2 of this thread. He suggested doing exactly what you did but after talking with Langdon I was talked out of it. "

Not sure what you mean by that statement?

Talked you out of doing what exactly?

My 12 port manifold sits pretty close to even with the cyl head.

The intake ports are at a 45 degree angle.

On the Siamese port head I would put runners pointing up a bit to give you more room for that spinning thing below.

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Aug 2014

Posts: 821

Major Contributor

|

OP

Major Contributor

Joined: Aug 2014

Posts: 821 |

It's a cobbled together system with an early megasquirt controller.

Langdon said GM tried to get efi systems to work with injectors on the 250's in Mexico towards the end of their run and couldn't get it. He described them doing exactly what you did. The problem was something to do with swirl. He said they couldn't get the system to not run lean. I suggested the weirs you have in yours and he said they helped but never completely stopped it. Maybe they didn't protrude far enough in and weren't using lumps so the air/fuel was swirling behind the head stud boss? Just a thought.

He also said that in N/A applications the weirs would essentially cut the flow to the individual cylinders in half. With a forced system, though, that shouldn't be as much of a concern I wouldn't think.

I'm not sure how they tested it. Probably something way above what we're able to do. I doubt they just hooked up an O2 sensor or read the plugs but you never know.

Tom and I talked for a good hour about the build. His headers were the first performance part I put on the engine. Really nice pieces that seem to flow very well. Since the intake and carb I can tell the only things holding it back (n/a) are the cam and head but she's still quite a bit faster than stock.

All that aside I wondered about the new systems and their ability to better control things. The GM testing was done in the 1980's and technology has improved just a little bit since then...

Last edited by gbauer; 05/15/15 12:55 PM.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

The fuel distribution would be better if you completely divide the Siamese ports.

Tlowe has done it to his Elky, Turbo6 has done it.

There are draw backs to doing this though. It makes the intake port window too small and really restricts the airflow by a large amount.

Turbo6 had to increase the boost pressure by (IIRC) 5-10 PSI just to get the same amount of power output as an undivided intake port.

Positive side, more even fuel distribution, smother idle, better mileage possibly.

I do not think it is a swirl effect problem, more of a problem of cylinder scavenging, or?

Head boss's were already removed on their heads, no swirl around a head boss action going on, just an adherent design flaw of Siamese port heads.

Lump port would not change this problem either.

I do not plan on making a lot of power with my used 250 turbo engine, so I do not plan on dividing the intake ports for now anyways, because I know how much a divider absolutely kills cyl head flow.

Some EFI systems are made to tune individual cylinders, but if you still have a Siamese port head, you will still have uneven fuel distribution problems.

GM might have stopped testing on the EFI Siamese port head in the 80's, maybe that's why they switched to the 12 port head on the newer 250 engine made until 1997.

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Aug 2014

Posts: 821

Major Contributor

|

OP

Major Contributor

Joined: Aug 2014

Posts: 821 |

Would it be worth the money to go to a 12 port head? If I went there what would I be looking at power wise?

I might consider doing it next spring depending on what happens ($$) when I sell my current house and move.

It'd be nice to hit 300+ hp N/A and worry about the spinny thingie down the road a year or more further.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

What 12 port head are you asking about? The Brazilian head? If that one, no not really worth it, that head does not flow all that well, but it is a 12 port. The castings seem to be thin & tend to crack @ a certain HP level. MBHD Would it be worth the money to go to a 12 port head? If I went there what would I be looking at power wise?

I might consider doing it next spring depending on what happens ($$) when I sell my current house and move.

It'd be nice to hit 300+ hp N/A and worry about the spinny thingie down the road a year or more further.

12 port SDS EFI

|

|

|

|

|

Joined: Aug 2014

Posts: 821

Major Contributor

|

OP

Major Contributor

Joined: Aug 2014

Posts: 821 |

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

That all depends on what you are wanting to get out of your 6. If you want the best cyl head available, Sissell's is the one to get. He has manifolds etc, to complement most all your needs. http://sissellautomotive.com/12%20port.htm#Accessory:32Anchor http://sissellautomotive.com/index.htmThere are other things to consider though. No brackets are made to bolt onto the cyl head. No power steering, A/C, smog pump, etc, you would have to make your own. IIRC, Turbo6 calculated Douglas' Chevy Opala 250 6 w/Sissell head was making between 1000- 1200 HP N/A, 250 engine, Mike Kirby built a very, very mild 250 engine with his 12 port head, was in a magazine & made 320 HP. MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Jul 2000

Posts: 4,588 Likes: 20

1000 Post Club

|

1000 Post Club

Joined: Jul 2000

Posts: 4,588 Likes: 20 |

I know the older Kirby head was worth 2hp per cubic inch, at the vary least Depending on the build.

Larry/Twisted6 [oooooo]  Adding CFM adds boost   God doesn't like ugly.

|

|

|

|

|

Joined: Aug 2014

Posts: 821

Major Contributor

|

OP

Major Contributor

Joined: Aug 2014

Posts: 821 |

Well now I just gotta get that Powerball and I'm good to go!

In all seriousness approximately what would I be looking at for the head and intake manifold? How about the lower end? Cam? Pistons? I'll make the brackets with a buddy who would definitely be up for this kind of insanity. That'll just be the cost of some billet aluminum and our time in the shop (well I also have to provide the beer and he doesn't like the cheap stuff... might be cheaper if I start brewing my own...).

Just a rough budget estimate. Are we talking 3k? 5k?

It'd be nice to be big-block fast in a streetable six.

...and, of course, I'd need to work on the rear end, trans, rear suspension... Project creep.

Would 10k cover the whole thing?

Thinking out loud again: We'd probably make our own intake so we can use a modern electric throttle body and an EFI system.

Make that 12k.

OK so here's the wish list:

Sissle head: $?

EFI system with electronic throttle body (and new go-peddle): $1,500

Fab up brackets and intake: $250 in materials

used 700r4 and bits to mount it: $750

Ferd 9" Rear, modified: $1200-ish if I do a lot of the grunt work

Rear suspension work to take the abuse: $2000

Bottom end stuff and machine shop block work: $2,500

Cam and rollers: $700

Projected project creep based on knowing myself too well: $3000

$9,400 plus the head.

What am I missing?

....or a turbo for $3,000 + rear + trans + cam + headwork for a total under 6k.

I think I know what my wife is going to say.

Last edited by gbauer; 05/19/15 09:58 AM.

|

|

|

|

|

Joined: Sep 2004

Posts: 5,840 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,840 Likes: 1 |

About $4400 for head, manifold, valve cover, thermostat housing. Unless prices has changed?

He had a modern throttle body manifold for sale.

As for the rest, prices can vary all over the place.

Mike has , rods, (pistons, designed for his 12 port head), cams, & more, most all you need for your 6 build.

MBHD

12 port SDS EFI

|

|

|

|

0 members (),

125

guests, and

27

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

|