|

|

Joined: Dec 2010

Posts: 535

Major Contributor

|

OP

Major Contributor

Joined: Dec 2010

Posts: 535 |

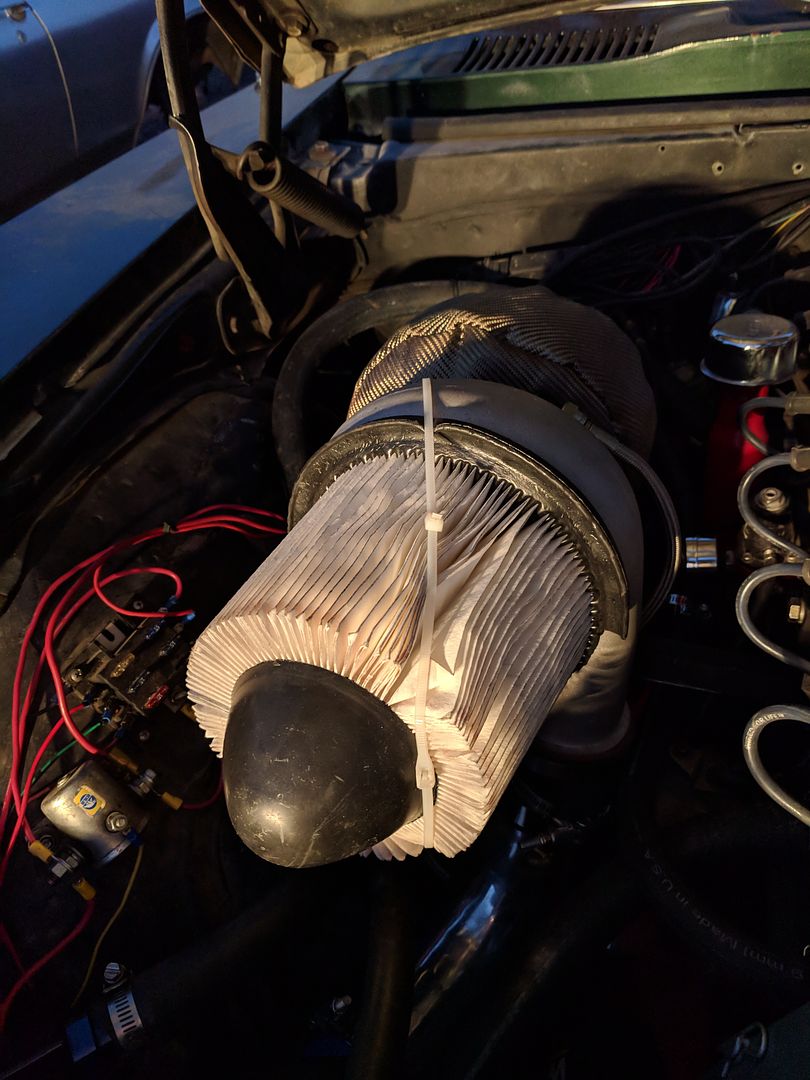

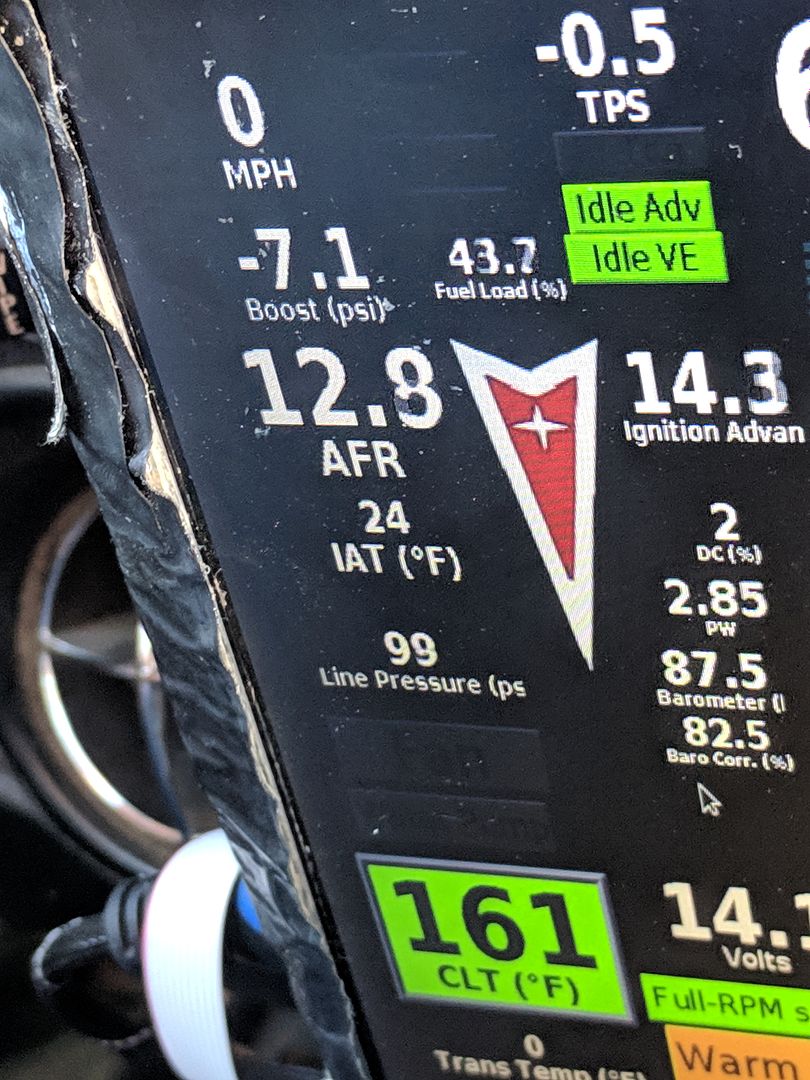

I've been busy. Time is getting short! In short, I've driven it to work two days in a row, had one hiccup and have made 4 psi of boost at half throttle at 2500 rpm, so I do not think I'll have a spooling problem. I was really excited to drive it to work yesterday, I stopped at a car wash on the way to work, washed the car, then about ten minutes later sitting in stop and go traffic (mostly stopped) I noticed the coolant temperature rising. Ordinarily it rises at a stop until 200ºF when I'd have the fan kick on then within 10 seconds it starts dropping. This time by 203ºF I knew something was amiss. The computer said the engine fan should be on, but it didn't seem like it, so I pulled into a Home Depot parking lot to check it out. Got out of the car and I couldn't hear the fan then right as I was reaching for the hood latch this happen!  Okay, it turned out that the heater hose popped off the radiator, and upon inspection I think the hose clamp was loose. All the steam is from the electric water pump still pumping hot water out, not necessarily from boiling over. The hose clamp was on the ground and I didn't have to loosen it at all to put it back on.  So I got 5 gallons of water from Home Depot and was on my way. I was running straight water anyways because tracks don't like glycol spills.  My poor just washed car   My Ford air filter was a casulty of the spill. It turned into mush (I took this picture about 30 minutes before steaming).  So I picked up some 4" couplers yesterday to put a proper filter on it. The tube is a scrap piece of exhaust tubing I had laying around. Tonight I'll cut one that will put the filter in the fender well for cooler air. Though so far, yesterday and today at anything over a few mph the intake air temperature sensor reads ambient temps. Which beats the +40ºF the stock manifold set always registered!  I'm still tuning on it. Every drive yesterday it was running really lean so I didn't want to push it. Driving to work this morning I finally had it giving me mid-10's AFR readings as it was getting into boost. Still have not gone over 65% throttle as part of the tuning process. But good to know it can start making boost below 3,000rpm. I currently have the stiffest single wastegate spring that came in the kit installed. I have the other springs on hand to adjust it as necessary. I want to keep the boost down to around 8psi until my good engine is together. The transmission is pretty good too! I'm still adjusting the shift points for when to be in and out of overdrive, but it'll bark the tires going into second gear with just a little extra throttle. I'll probably dial that down a little, but it's been fun yesterday and today. It runs smooth well into the 80mph's. I think the intake and headers have upped the naturally aspirated power, but its hard to tell since I also upped the gear ratio from 3.42 to 3.89 as well. I think I have enough fuel pump to get me to around 350 horsepower, maybe even 400 horsepower, which would be double what it was making before. Now to get the trailer sorted. I head out Tuesday!

|

|

|

|

|

Joined: Apr 2004

Posts: 3,566 Likes: 37

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,566 Likes: 37 |

Good to get those bugs worked out. You are very talented and full of energy. Wish we were in the same neighborhood. Could have lots of fun.

What EFI/ trans controller are you using?

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Dec 2010

Posts: 535

Major Contributor

|

OP

Major Contributor

Joined: Dec 2010

Posts: 535 |

It is a home built Megasquirt 3 with expander board for sequential EFI/spark and a Microsquirt transmission controller using a two wire CAN connection to the Megasquirt to get basic data (RPM, TPS, MAP, etc) to control shifting. Conversely the Megasquirt picks up the vehicle speed from the micro.

I have a CANegt unit on the shelf to wire in 6 EGT sensors, but ran out of time for that part of the project.

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

Does your MS allow spark retard input during shift? My Toyota A340E (4-speed OD) does, not sure how much but reduces traction loss, probably helps friction materials.

|

|

|

|

|

Joined: Dec 2010

Posts: 535

Major Contributor

|

OP

Major Contributor

Joined: Dec 2010

Posts: 535 |

It does. I currently have it pulling 5º NA and 8º in boost. I think I can pull up to 15º.

Horsepower wise, I'm not currently making enough to hurt the build setup for a turbo LS engine even if I didn't pull timing. The guy that built it built one for my friend that was running regular high 9's in a 3800lb car (he since went to a 4L80e running low 8's).

The real solution is to lower the line pressure at the specific load level its currently chirping the tire. Worse case I'll adjust line pressure by gear and knock it down a bit only for the 1-2 shift.

|

|

|

|

|

Joined: Dec 2010

Posts: 535

Major Contributor

|

OP

Major Contributor

Joined: Dec 2010

Posts: 535 |

The Final Count Down! Tied up a lot of little loose ends and now going on to packing.  A gratuitous engine shot.  I need to pick up two more clamps, but have moved the air filter into the fender.  I thought about just reading the speed off the display, which will always work in a pinch, but decided to step up to an actual speedometer/trip/odometer gauge. It's a Summit brand electric speedometer. I don't have the time to pull the dash to tuck the wires, but this will get me by for now. I'll get a black wrapping on the wires tomorrow. Supposedly will report 0-60 and quarter mile times. Uses 8,000 pulses per mile output from the Mega/Microsquirt.  I'm going to change the oil tomorrow and figured I'd check the level based on how much oil is added. Here is the level with 4 quarts. Figure about 1/2 quart is in the oil filter and another quart is running through the engine, with a stock 5 quart fill it it should be right under the baffle. Its like the engineers knew what they were doing...

|

|

|

|

|

Joined: Apr 2004

Posts: 3,566 Likes: 37

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,566 Likes: 37 |

Well, did you make it to drag week with the Poncho?

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Dec 2010

Posts: 535

Major Contributor

|

OP

Major Contributor

Joined: Dec 2010

Posts: 535 |

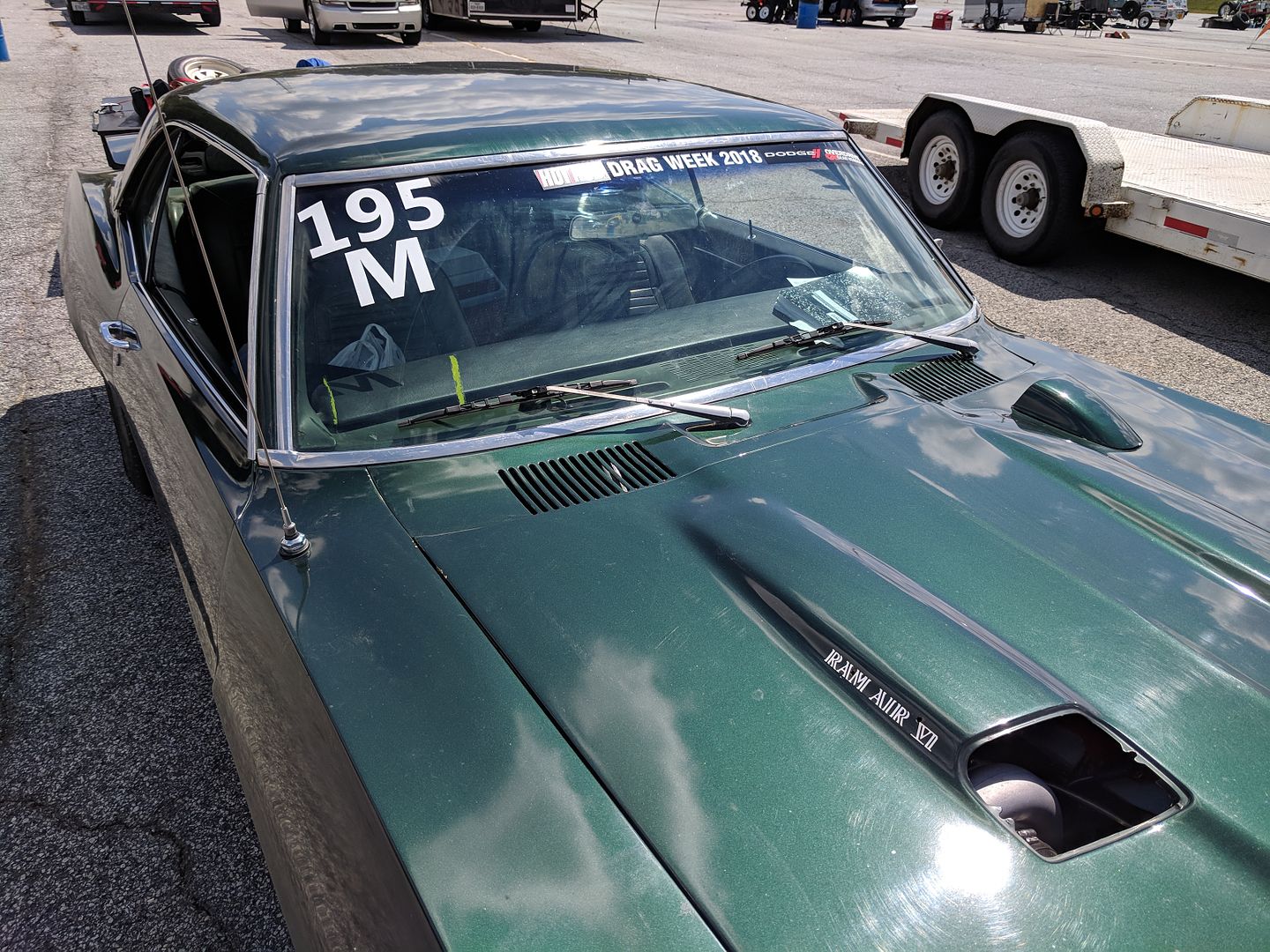

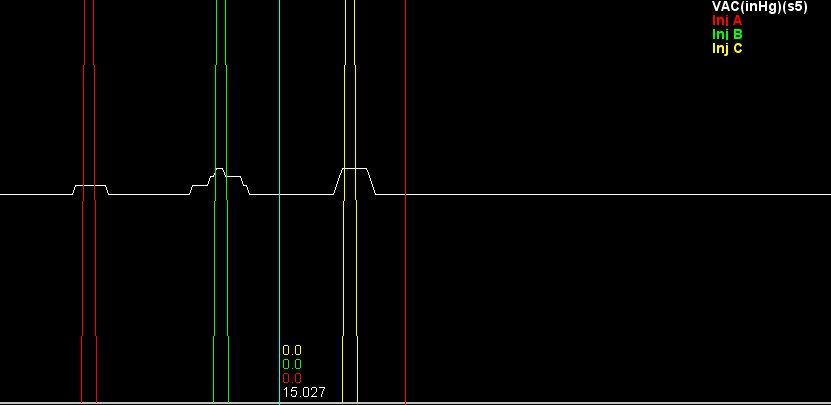

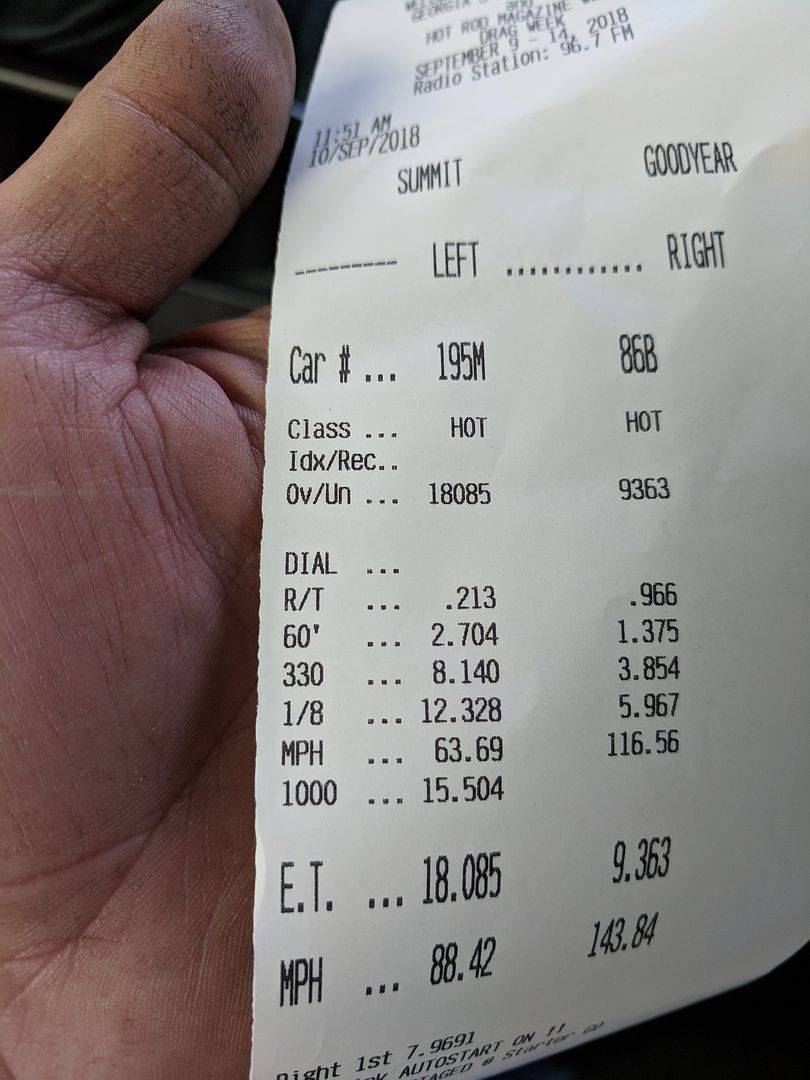

I did make it, survived the whole week. About 3300 miles of driving. Haven't made it home yet to decompress and post. The abbreviated version is I couldn't get it to 60ft worth a dang and would only spool up 5psi in 3rd gear giving me a dismal 15.1x at 93mph. With the 4.56 gears it had 1.8x 60ft's, with the 3.89 gears the best I could muster was 2.2x, even leaving at 2200rpm and 2psi of boost. I should have been able to crack into the 14's if I could get it to launch decently. NA the engine was making 175HP based on my last 1/4 mile runs, and this time around it averaged 240HP with 7.5psi in 1st and 2nd gear and 5psi in 3rd. I put a boost controller on it and it didn't seem to make a difference, so I'm sure there is not enough exhaust flow, which is not surprising. On the highway it makes 8+psi fairly quickly, just not in a 1/4 for a stop. It liked to rpm a bunch more, used to nose over at 5100rpm, now pulled clean to 5800rpm and may have wanted more but oil pressure was wobbly at the top of each gear. The engine consumed about a quart of oil every 200 miles, so it isn't the engine is not in the best of shape, though the oil pressure is good. It was a very popular engine. Lots of folks stopped by with a lot of interest.   https://www.youtube.com/watch?v=MuqDe1uCChE https://www.youtube.com/watch?v=MuqDe1uCChE

|

|

|

|

|

Joined: Apr 2004

Posts: 3,566 Likes: 37

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,566 Likes: 37 |

I had fun just checking on your progress each day. Bet you had a blast.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Dec 2010

Posts: 535

Major Contributor

|

OP

Major Contributor

Joined: Dec 2010

Posts: 535 |

|

|

|

|

|

Joined: Dec 2010

Posts: 535

Major Contributor

|

OP

Major Contributor

Joined: Dec 2010

Posts: 535 |

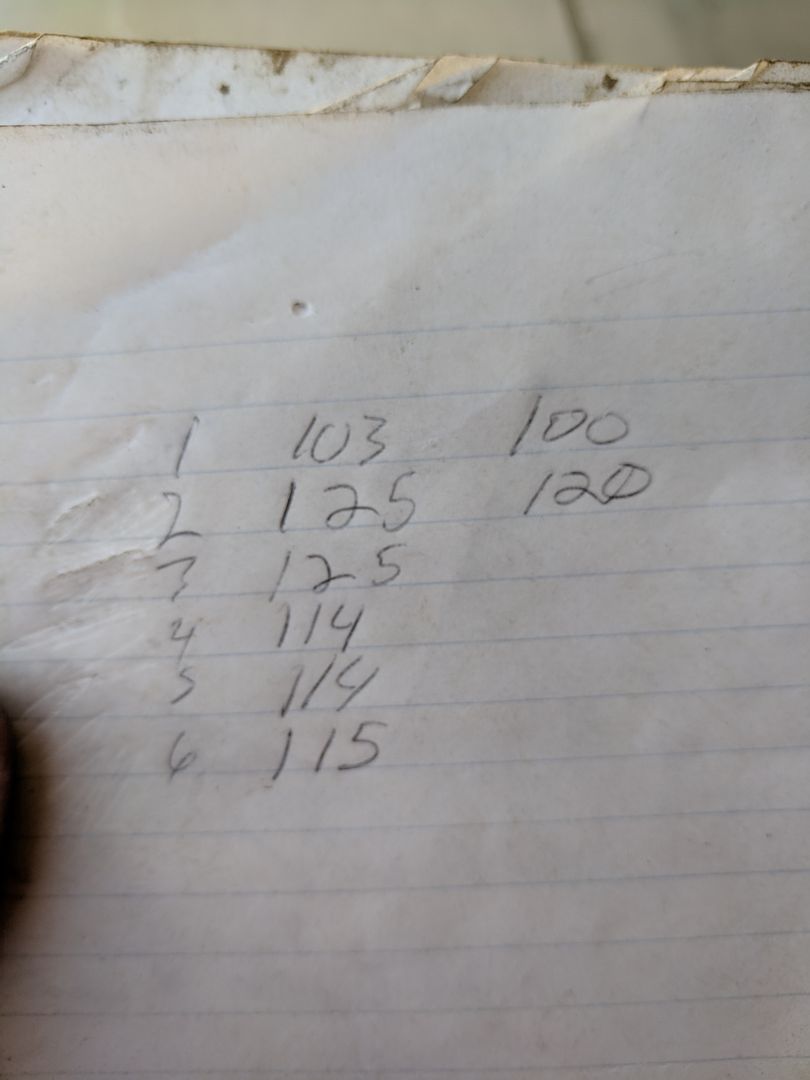

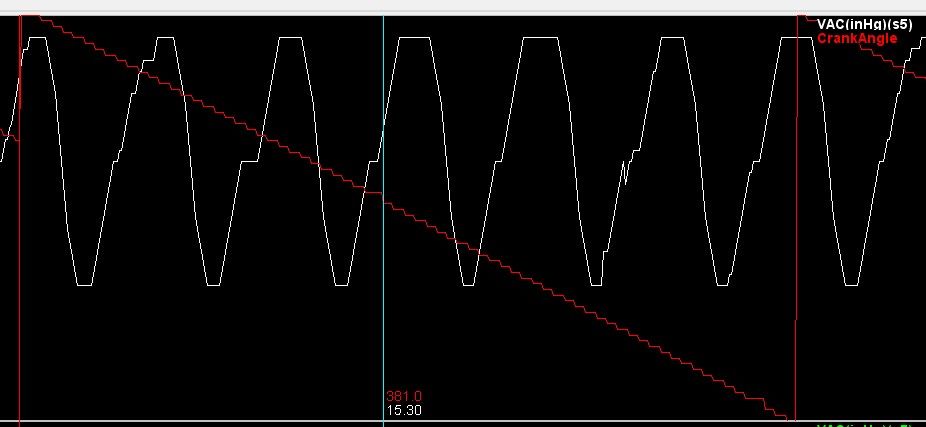

Some updates and recaps. The machine shop finished their work and I've brought it all home, but have not yet done anything with it. I've been driving it every now and again. Took it to a Cars and Coffee last week when the weather was nice. It was still pretty cold out in the morning but not to bad by noon.  Just a bit cold in the morning.  So the oil consumption and tail pipe smoking has gone up quite a bit so I did a compression test and it wasn't pretty. Last time I did a compression test a few years ago it was about 130psi across the board, and now it looks like 4 cylinders are low with one of them being very low. I ran out of time to re-test all the cylinders or try oil in the cylinders to see if it goes up.  With the Megasquirt I did a vacuum versus crank degree plot to see if anything obvious would pop up, like a few cylinders pulling less vacuum, but nothing definitive really showed up. The plot reads backwards, so right to left with the red line being crank degrees from 0 to 720, so each vacuum peak is a cylinder, from right side is 1-5-3-6-2-4, with the right side of the peaks being as the valve opens.  While I was their I checked my injector timing versus manifold vacuum. I had set injector timing based on a spreadsheet calculation I did, and it looks like it was pretty spot on at peak vacuum. This only really helps at idle and low rpm. My goal was to inject fuel at highest vacuum after the exhaust valve closes. This was based on PipeMax plots and cam timing.  So after doing this I started thinking about the oil consumption, and it seemed I was adding significant amounts of oil prior to even leaning on it with the turbo, aka it shouldn't have been the turbo that hurt it. Maybe the rings got stuck while it sat for a chunk of summer? So I put a bunch of Marvel Mystery oil in the cylinders the other day and need to crank the engine over with the plugs out and run it a bit to see if the rings free up. This assumes it's stuck rings AND that if they've been stuck for 4,000 miles it hasn't hurt the cylinder walls even worse. Either way, it's still getting a new engine. So a bit of a Drag Week re-cap. I've already mentioned it's soft launching, only making 5 psi in top gear for 93 mph, or approximately 240HP at race weight. Though that 240HP is 65HP more than the 175HP it was making the last time I was at the track, or a 37% increase (it's definitely noticable!). I will likely need to get a different turbo, which is not unexpected, but will wait until the new engine and cam are in to see how it acts. Now this will be kind of a photo dump of the drive out and week. Ready for the highway.  Crossed a huge part of the country at 80-85mph.  First stop of the trip, Elko, NV.  It had been running hot, which it shouldn't have been because the new radiator, but the big intercooler apparently was killing air flow through the radiator. So I made a stop at a parts store and raided their cardboard pile to make some baffles to force the air back through the radiator. It helped out quite a bit. So at some point I'll make tin versions.  Lots of open road. I didn't take any pictures of it, but leaving Elko my turbo oil feed line blew apart due to me accidently kinking it at some point. I used a nylon fuel like patch kit to fix it until I got to a friend's house in Nebraska to swap a new line on (that he happen to have). But this work put my schedule about a half day behind.   Then it blew the gasket on exhaust port #2 to create a nice torch mark and singe some wire harness wrap. I actually at the end of the day just took some muffler repair putty and jammed it in the hole to sit over night and it held a few days.  In Wyoming met up with another Drag Week'er to caravan out (yes the Honda).  Cruising along at 2,800rpm at 80-85, pulling the trailer. Driving out I kept the engine on the rich side as a pre-caution. By the end of the week I had it leaned out quite a bit.

Last edited by TheSilverBuick; 11/21/18 04:14 PM.

|

|

|

|

|

Joined: Dec 2010

Posts: 535

Major Contributor

|

OP

Major Contributor

Joined: Dec 2010

Posts: 535 |

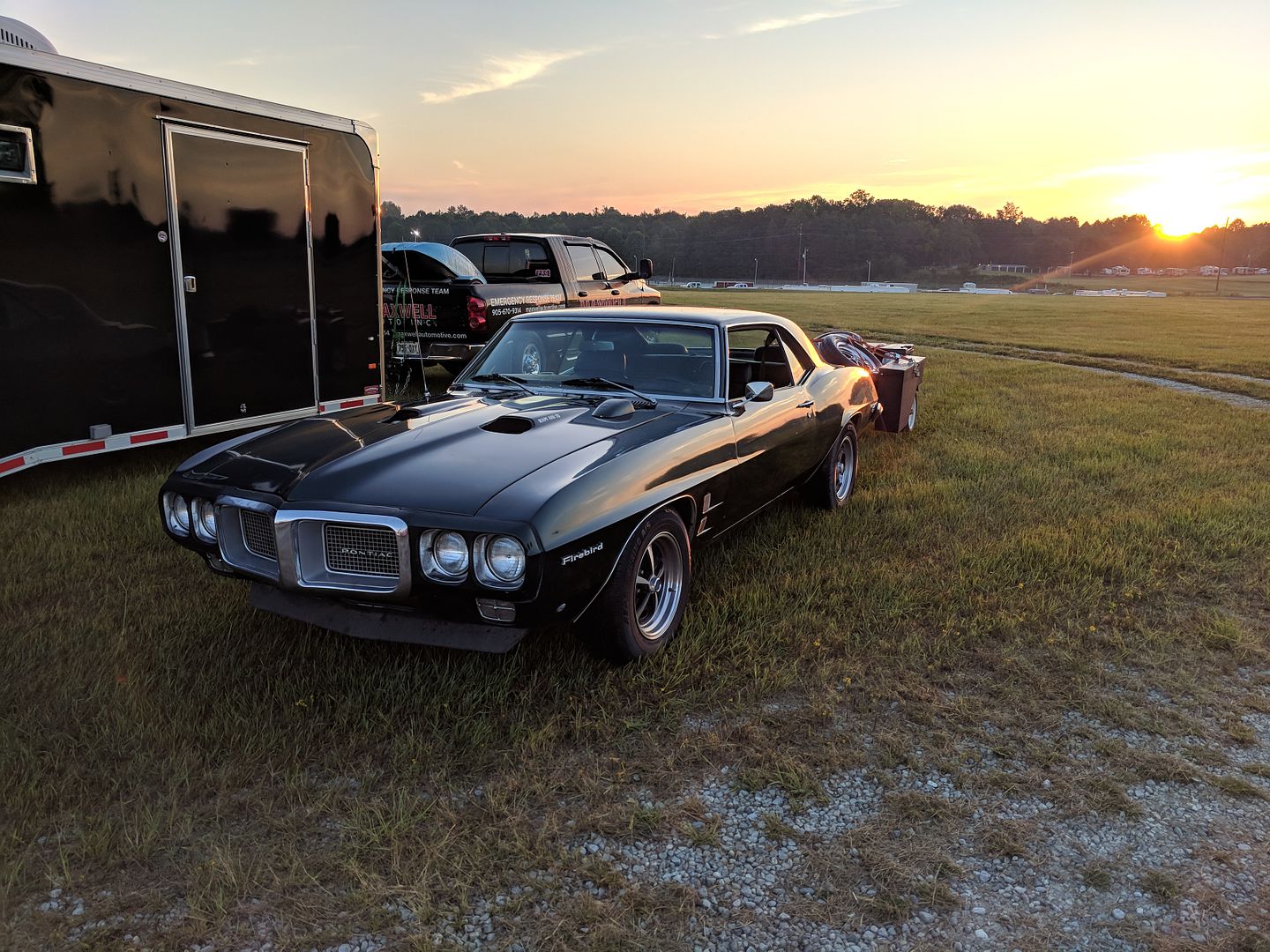

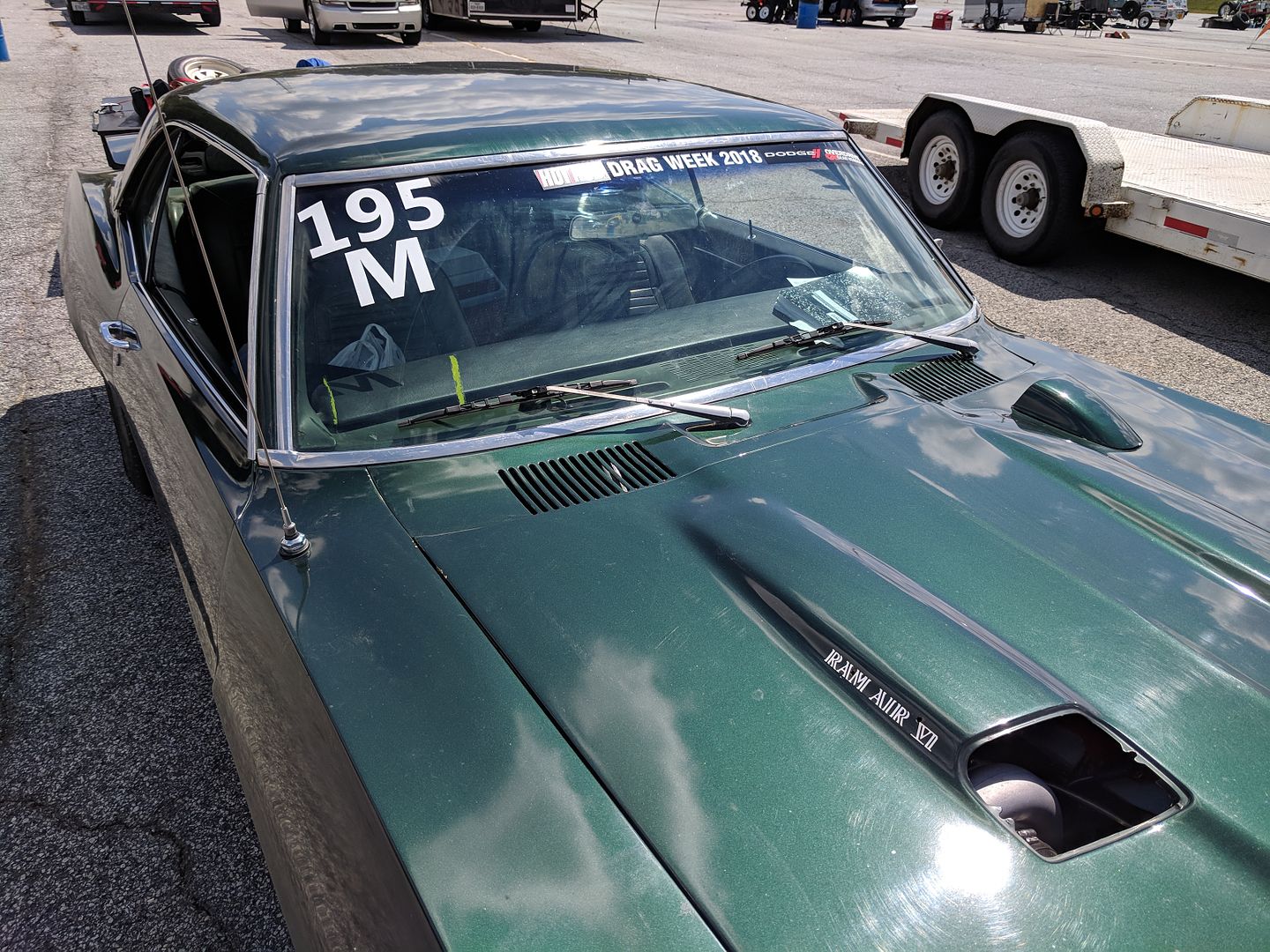

Then it scenery started turning greener and wetter.   Eventually stopped for dinner and wait for the rain to ease up.  The rain wasn't good for the card board box of my awning, but otherwise no real issues. Stocking up on another gallon of oil.  Then Friday driving out it blew the exhaust gasket on #1. So I did the responsible thing, pushed that piece back in place and put more muffler weld on it and waited about 30 minutes and hit the road trying to stay out of boost for a bit. The night before it had popped the previous patch, which I then re-patched.  Then Saturday around noon arrived in Commerce, GA! Registration was the next day so I figured now is a good time to changed out the intake/exhaust gasket. I had brought two spares.  I needed to trim the Clifford sourced gasket to the port match, as well as add the holes for the intake dowel pins. I brought a punch and chisel for this exact work. So lesson learned is this gasket material likely wants to be re-torqued a few times, something I had not done at all. So I spent the next three days re-torquing all the bolts each morning, after getting to the track in the morning, and again at night. The bolts I used were locking so they won't back out. So far it still appears to be holding.  Registration Day, waiting for registration to open.   Passed tech!  Day 1, in line!   And then I made a most comical mistake. Used to driving my Skylark with a 5-speed, I foot braked the car up on the line, let off the brake but muscle memory kept my foot hovering over the brake and when it was time to shift to 2nd gear I jammed on the brake like a clutch pedal as I grabbed 2nd gear! Eventually realizing my error finished the run dismally, though now I had the data I was looking for on shift rpm.  Afternoon rains came before I could make a second run. This was the only day that got rained out at the end.  So off on the road I went when the rain lightened up. First check point. For most the week I followed along Doc McIntire and the SeeRed Camaro. The weather slowed everyone down and he was running a half second off the pace he was hoping, but still won the pro-street NA class.

|

|

|

|

|

Joined: Dec 2010

Posts: 535

Major Contributor

|

OP

Major Contributor

Joined: Dec 2010

Posts: 535 |

|

|

|

|

|

Joined: Dec 2010

Posts: 535

Major Contributor

|

OP

Major Contributor

Joined: Dec 2010

Posts: 535 |

Day 5! Made it back to Atlanta Dragway!    I put a catch bottle on the outlet of my crankcase vacuum pump and it would pick up a bit of oil after a pass. This is even after the oil catch before the vacuum pump.  So then I got the idea to skip the vacuum pump altogether and open up the vent on the oil fill cap and see if the engine would do better with the crankcase fully vented to atmosphere versus just the 3/8th vacuum port, and it put a bit of oil out the vent into the catch bottle. This was not un-expected because my lash adjuster oil pressure regulator returns to the oil fill tube, so any gases going up the tube have a direct shot of oil entering the air stream.  It did okay, but oil pressure was a little wobbly at the end, so I thought I'd add a 1/2 quart of oil and then really wind up the rpms to see if I could crack into the 14's. But it wasn't meant to be. It nosed over very hard at the top end of 2nd, then a bunch of smoke coming out from under the hood, though oil pressure was still good. Turns out it nearly filled the oil catch bottle, then proceeded to oil down the engine bay. Called it the day and week. I finished Drag Week 2018 and the car still ran.    Then a friend of mine in Montana was rolling home with an empty trailer, so we loaded the car up on his trailer so I could fly home with my family.  Then in October I flew up to Montana and picked up the car to finish it's drive home.    Made it home!!  Now, I want to put the rear axle back in my Skylark and put the 8.5" back in. I've decided to buy some upgraded moser axles for the 8.5" and put in the 4.56 gears I have on the shelf. I figure the gears are good until I run about 108mph in the 1/4, depending how well the new engine and head breath. At which point I can decide if I want to go back to the 3.42 gears or buy a 9" rear end with a different ratio. At some point over the winter I'll get the other engine together.

|

|

|

|

|

Joined: Jul 2004

Posts: 239

Contributor

|

Contributor

Joined: Jul 2004

Posts: 239 |

Great trip! thanks for taking us along. This is a great thread.

|

|

|

|

|

Joined: Dec 2010

Posts: 535

Major Contributor

|

OP

Major Contributor

Joined: Dec 2010

Posts: 535 |

So Scott reached out to me for an update. A couple of things to update. The car is still together and running. I found that through out all of Drag Week the coil on cylinder #5 wasn't firing. Which would answer why it was having trouble spooling the turbo and having massive blow-by. Basically making 240Hp on 5 very rich cylinders. I found and fixed that and boy-howdy does it spool and go. It will start burning rubber at a rolling 40mph and 10psi. I wound it up to 20psi and 6100rpm a handful of times then the headgasket let go on the #5 cylinder, out the side. I suspect the thousands of miles, etc with #5 not firing may have started to push the gasket hydraulically. I had added a TON of fuel to the system to stop it from running lean, when in reality #5 was pumping straight air into the exhaust and the other poor cylinders were soaking in fuel. But I've changed the head gasket, and it runs but I haven't re-tuned it much (pulled some of the fuel out, but needs more). I fired it up last weekend and did a burn out just because. I still haven't finished assembling my good engine, with the forged rods and pistons, ported head, re-ground cam, etc. I want to take the car to a local chassis dyno to see what it's doing on all 6 cylinders at 10psi and 15psi. I suspect just under 400Hp at 15psi, but its just an estimate. It was making about 175Hp N/A at ~5,000rpm, so double that, maybe a little more. I'm also looking at changing out the intake that Scott made for one with a Webber carb unit modified for EFI and a boxed in plenum. Scotts is a good intake, but I think the longer intake runner length will be beneficial. The picture I have mocked up a box that is similar to the intake I have now, but will really have the throttle body moved further away from cylinder #1 and come in at a 45º angle. I'll weld bellmouths to each runner for smoother air entry. I think I'll be able to get my thermostat housing to fit with it as well and go to a conventional flow cooling. Get the water hoses away from the turbo. I'm probably ending my Photobucket subscription in January, so not sure what the pictures will do. I can't seem to get photos from my Google Photo's album to post directly hopefully the link works. https://photos.app.goo.gl/4rhtLq7sUqktzSCa8https://photos.app.goo.gl/isBJvCW5bKMJw5dT6Lets see if this album link works. I dropped a few photos in there showing the headgasket replacement, etc. https://photos.app.goo.gl/e9g5wmEKbKnXdeRR9As the car sits now, it has a 1969 Pontiac 250 with garbage cylinder walls, but new gaskets and bearings. A factory 4bbl cam, hand ported head by me, about 8.3:1 compression, a chinese GT45 turbo fed by homemade headers, twin-scrolled front three cylinders and rear three paired. 1.75" primary pipe to a t-4 flange and a 4" exhaust out the turbo to the rear axle then reduced to 3" over the axle. 3" intake tube from turbo, through 3" intercooler, to the intake. A 4L60e transmission and a 8.5" rear axle with 4.56 gears in it now. The EFI and transmission are controlled via a Megasquirt 3/3x. Bolt on crank trigger and a modified distributor as a cam sensor. $40 in junkyard LS coils and brackets for ignition and some mid-tier 80ph fuel injectors. As for the intake, I'll have to go digging for some pictures to show how it was finished for my use. The general work was the runners were a bit too narrow for the OHC so some plates were TIG'd to the runners to thicken them up. I assume that would not be an issue for the Chevy L6's. The injector ports were drilled, the throttle opening was widened to the size of throttle body I am using (45mm?) and a casting hole in the back of the plenum had a plate welded to it. The ports were opened up to match the porting on my head. There is a nice line of sight from the injector tip to the back of the valve. The downside for me was the fuel rail interferes with the thermostat housing. I'm not sure if this is an issue on the Chevy L6, I haven't looked. I could probably shorten the rail a little and make a custom thermostat housing, but I haven't given it that much thought.

|

|

|

|

|

Joined: Jul 2000

Posts: 4,588 Likes: 20

1000 Post Club

|

1000 Post Club

Joined: Jul 2000

Posts: 4,588 Likes: 20 |

You may want to look at the head and the block closely to make sure you didn't burn a grove in either. Because to me It almost looks like it may have??

Larry/Twisted6 [oooooo]  Adding CFM adds boost   God doesn't like ugly.

|

|

|

|

|

Joined: Dec 2010

Posts: 535

Major Contributor

|

OP

Major Contributor

Joined: Dec 2010

Posts: 535 |

No groove. There was PLENTY of fuel. Typically groves are burned in from going lean. It's been together all summer, its okay.

|

|

|

|

|

Joined: Jul 2000

Posts: 4,588 Likes: 20

1000 Post Club

|

1000 Post Club

Joined: Jul 2000

Posts: 4,588 Likes: 20 |

Larry/Twisted6 [oooooo]  Adding CFM adds boost   God doesn't like ugly.

|

|

|

|

|

Joined: Sep 2008

Posts: 3,673 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,673 Likes: 42 |

Thanks for the update Randal, there have been many anxious to see and hear results regarding the Marshall EFI intake. EFI is definitely the path that current and future hottrodding is headed. Your previous EFI projects with 6 cylinders has given hope to many seeking to go this route with their own projects.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Aug 2003

Posts: 353

Contributor

|

Contributor

Joined: Aug 2003

Posts: 353 |

I noticed in one of the photos from the Nov 2018 post you added a can of "Engine Restore" to the oil.

Did anything good or bad come from that?

I know what it did to my Chevy 250 and I wasn't amused.

Last edited by Chevelle292Wagon; 12/04/21 10:17 PM.

Pete

64 Chevelle

61 C30 Panel truck

|

|

|

|

|

Joined: Dec 2010

Posts: 535

Major Contributor

|

OP

Major Contributor

Joined: Dec 2010

Posts: 535 |

Knowing how bad the cylinder walls look and absurd amount of blowby that was happening, I wasn't too concerned about what the rebuild in a can would do. I didn't notice any change. Now as much oil as it consumed/leaked it was on the continual oil change method, lol

|

|

|

|

|

Joined: Aug 2003

Posts: 353

Contributor

|

Contributor

Joined: Aug 2003

Posts: 353 |

Hi, Yeah, I understand trying to wring a little more life out of an engine. What happened to my 250 Chevy was that the Engine Restore got into the rings and the rings then stuck down in the piston grooves. So, it went from 500-1,000 miles on a qt of oil to becoming a mosquito sprayer as soon as it started getting warmed up. The amount of oil smoke was startling, especially knowing how it had been running before I added that snake oil. Tried to flush it out a couple times but ended up getting new rings and bearings and doing a quick rebuild. So now I'm the brand anti-ambassador, I tell anyone to avoid that stuff when I hear it mentioned!  Knowing how bad the cylinder walls look and absurd amount of blowby that was happening, I wasn't too concerned about what the rebuild in a can would do. I didn't notice any change. Now as much oil as it consumed/leaked it was on the continual oil change method, lol

Last edited by Chevelle292Wagon; 12/07/21 11:04 PM. Reason: typo

Pete

64 Chevelle

61 C30 Panel truck

|

|

|

|

|

Joined: Dec 2010

Posts: 535

Major Contributor

|

OP

Major Contributor

Joined: Dec 2010

Posts: 535 |

Hilarious enough, the State of Nevada made me smog the car last year, and it passed no problem.

|

|

|

|

0 members (),

125

guests, and

27

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

|