I'm finally pushing ahead with this install. I am pulling the 194 this weekend, so if I want to drive the car again, I'll have to get the 292 in there.

I'll post updates to this thread as I get things done as well as update my website:

1963 Chevy II Nova 292 Conversion There are a few challenges to overcome to getting a 292 into an early Nova (a few have told me not to try). Here are a few threads on inliners that have helped me overcome the Chevy II specific issues as well as some others:

Oil Pan Clearance Oil Pickup Support Valve Cover Fitment Hood Clearance

You need to get one of these motor mount adaptors.

It is steel and will allow bolting of a V8 standard motor ( rubber) to it and the bolt to a V8 bracket on your subframe in the standard V8 location.

Available from:

Davidson Performance Fabrication

> location: Lavaca, AR

> phone:479-221-8557

> website:davidsonperformancefabrication.com

> email: bddave@pinncom.com

>

I will get pic's. Tom

You need to get one of these motor mount adaptors.

I will get pic's. Tom

Thanks Tom. I have a plate that I was planning on using, but I'm interested in seeing what else is out there.

I made some good progress last night. I had a couple of people come over to help me take the hood off. When we were done with that, one of them said 'Let's pull the engine.' Everything was already unbolted so it went quickly.

After pulling the 194 out, I'm thinking that I want to remove the core support before putting the 292 in. There isn't much room in that engine bay!

I am so watching this...good luck mate!!

-Sam.

I made some progress yesterday:

•removed core support

•removed wiper motor

•dropped items off for sandblasting: core support, hood hinges, battery tray, engine mounts

I also prepped part of the engine bay and got some paint on it to see how much imperfections will show up with the semi-gloss paint. I will need to spend more time sanding!

engine bay

I prepped my 65 Nova Coupe much the same way.

You might want to pull the steering gear out of the way too, if you have not done so.

Don't stop now, once that BIg Six lands in there you will be a proud as a new Daddy.

James

I prepped my 65 Nova Coupe much the same way.

You might want to pull the steering gear out of the way too, if you have not done so.

Don't stop now, once that BIg Six lands in there you will be a proud as a new Daddy.

James

I've thought about doing that. Just trying to figure out how meticulous I want to be on the engine bay stuff. I've repainted/resanded a couple of times already b/c I haven't been happy with the result.

I really want to have this thing back on the road by May 2nd.

Here are pics of 2 different 292 adaptors that he makes. The steel one is cheaper. All you need to do is bolt a V8 rubber motor mount to it and then to a V8 frame support. The V8 frame supports and motor mounts are much stronger than 6 cyl ones. For the drivers side use a inline bracket from a 63-70 pickup. Than a V8 mount will also fit on that side. Tom

Thanks Tom. Any idea on what the cost is for those?

made some more progress over the last few days:

http://63chevyii.com/the_build/2010/january.htmI was hoping to get the 292 in the engine bay yesterday to see if my passenger side mount will work, but then realized that I need to get some flexplate bolts. The engine was previously bolted up the a sm465.

Do you have any pics of where its still hitting the pan.

Do you have any pics of where its still hitting the pan.

At first it was hitting right above the draining bolt. You can see some intial pics in this gallery:

63ChevyII Pics I banged that section in, and the rubbing pt moved further out. The more I dimpled it, the further out the rubbing moved. I beat it in far enough that I now have a 1/4 - 1/2" tear for most of the width of the oil pan. I will take some pics tonight when I get home.

there are a couple of vids in this directory. Let me know if you have problems view and I can upload a different format.

oil pan interference vids The tape is where I've been thinking of cutting the pan.

Wow,looks like you need to just cut out a complete section for it to fit correctly.

Relocate a drain plug somewhere else.

On Twisted6's Nova, I believe he mods a 250 pan to fit the early Novas,the 292 pan is larger in many areas,hence the problem you are having.Or is it a 250 pan in the vids?

MBHD

Wow,looks like you need to just cut out a complete section for it to fit correctly.

Relocate a drain plug somewhere else.

On Twisted6's Nova, I believe he mods a 250 pan to fit the early Novas,the 292 pan is larger in many areas,hence the problem you are having.Or is it a 250 pan in the vids?

MBHD

it's a 250 pan.

if I use this pan, I will put the plug on the back of the oil pan.

Looking at the 292 block, I don't think there is a good spot to redrill it to use a nova oil pan.

So I either have to mount the dipstick on the outside of the block, or made some major mods to the oil pan. My welding skills are marginal at best, so this is going to be tough.

The center link seems to be fine, but the tie rod ends are hitting now. How much more does the steering wheel need to turn before it hits the bump stops on the spindles. Check out the Moroso website and look at their V8 Chevy II oil pans. They has some good dimensions to go by for reference on the notches in their pans you can go by.

I like your vids. Sorry about the dilema.

By the time you finish cutting that pan out to clear the steering, not much oil sump and reservoir is going to be left.

I vote for using the chevyII pan and mount the dipstick on the pan. Be sure to brace the tube.

Let's see pics of the pass side mount. Tom

The center link seems to be fine, but the tie rod ends are hitting now. How much more does the steering wheel need to turn before it hits the bump stops on the spindles. Check out the Moroso website and look at their V8 Chevy II oil pans. They has some good dimensions to go by for reference on the notches in thier pans you can go by.

cool - I'll check that out. It is hitting in the center still. I'll get another vid. I'll take a look at the bump stops too.

I like your vids. Sorry about the dilema.

By the time you finish cutting that pan out to clear the steering, not much oil sump and reservoir is going to be left.

I vote for using the chevyII pan and mount the dipstick on the pan. Be sure to brace the tube.

Let's see pics of the pass side mount. Tom

Thanks. I figured vids were better than pics.

I'm thinking the same thing on the external dipstick. Also seems to be the easiest thing to do also.

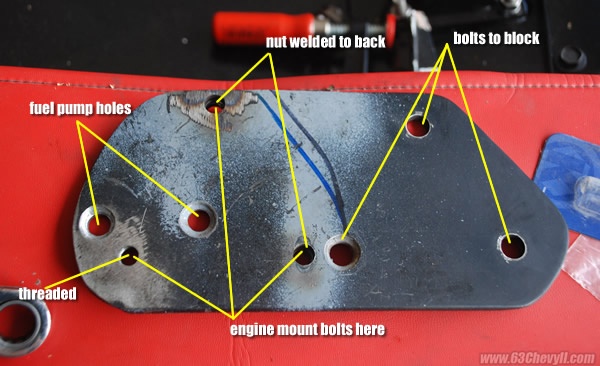

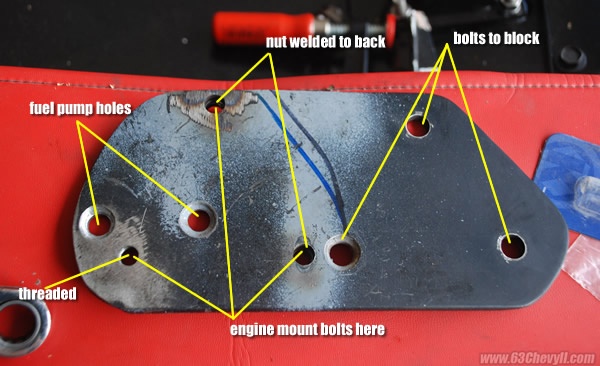

Here's the passenger mount - it isn't pretty but I think it will work. Another person made the plate and drilled 5/8 holes that are there. They gave up on their 292 install and gave the plate to me.

Note the diff in height between the holes that mount to the block and the holes that the engine mount bolts to. If I were to do it over, I'd leave more material around the top hole, as well as the fuel pump furthest to the left. I've traced the plate so that I decide to make another, it should be easier.

When I pulled the engine out to pull the oil pan and put the flexplate on, I'll clean up the plate and paint it.

I didn't come up with the idea for this plate. I got the idea from T. Griffith and have passed it on to a few others over the last couple of years:

T. Griffith's Chevelle

I like your vids. Sorry about the dilema.

here another video I made. It has nothing to do with my 292 install, but it should be more interesting:

SoCal Nova PCH North Cruise

SoCal Nova PCH North Cruise

Vid is great. It's great to see beautifully restored cars, but I really love to see the car's that look like daily drivers. Especially seeing kids drivin' them.

The center link seems to be fine, but the tie rod ends are hitting now.

In the videos above, if you watch the middle of the pan, above the oil pan drain and center link, you can see the pan flexing.

Ok, I see it now. If you look at the Moroso site, they give dimensions from the pan rail down, and from the rear of the pan forward for the Chevy II pans. You can see how close you are to meeting those #'s with your pan, and it might tell you how much more you need to go.

thanks. this should help:

Compared to most of the 292 installs I have seen, your videos show the motor is sitting an inch or two high. On my 63 with stock spindles I needed to "dimple" the rear sump pan at the curve above the drain plug and the drain plug was below the tie rod. On my 66 with dropped spindles we used a Chevy II pan and had no clearance issues are all.

If it were me, I would re-confirm all of the engine and trans mount measurements and angles are good. If you have access to a stock Chevy II that still has a six in it, check the pan rail height to the subframe and compare it to your 292 install. If everything checks out, think about going to a Chevy II pan and pick-up instead of building a custom unit.

The work you have done looks great. Before you start making major mods that others have not needed to do in a similar situation, sit back for a little while and look at your installation. Hopefully you will not find anything, but the one thing you do not want to do is start making wholesale mods and find out one minor miscalculation caused a major domino affect.

I have stock height spindles also. drop coils shouldn't affect the steering to oil pan clearance, should they?

On your 66, what did you do regarding the oil dipstick placement?

Last night I was wondering if the engine was too far forward in the engine bay and if that's why the interference is so bad. I don't know how this is possible though - the engine is bolted to the tranny, which is bolted to the tranny crossmember. The engine is bolted to engine mounts, which are sitting where they need to be on the frame. I can take some pics of how everything is sitting in there tonight and see if I can email some people that have L6's in their novas to see if they can take some measurements for me.

If you have access to a stock Chevy II that still has a six in it, check the pan rail height to the subframe and compare it to your 292 install.

Would measuring from the crossmember up to the pan rail be a good comparison?

I do not remember which trans you are using, but if you are using a PG, TH350, 4spd or 3spd and the stock trans crossmember the engine is in the correct location front to back. On both of mine the stock Chevy II subframe mount, rubber mount and engine mount were reused from the 194s. The right side on the 66 used the stock motor mount with the top hole redrilled. A gusseted plate was welded to the motor mount and it mounted to the rubber mount in the stock location. The 63 uses the same set-up on the left and the right side uses the stock right side motormount and rubber mount with a new mount welded to the subframes. In both cases the engine and trans were installed with the trans and left side bolted in and the right mounts set once everything was level. One thing we tried was a generic GM urethane trans mount.

It was supposed to fit, but ended up being too tall and messed up all of the angles.

On the rear sump pan, just used the stock hole in the block and the dipstick tube I believe is an original as it has a bracket that mounts to the center bolt of the rear push rod cover. The center sump pan had a triangle shaped piece with the dipstick tube welded to the side of the pan.

I am using a PG right now. I disconnected the engine and tranny last night unbolted the tranny from the tranny crossmember and made sure the tranny was slid back as far as it could. I may have moved it 1/8"-1/4". The edge of the tranny pan is sitting right at the edge of the crossmember. If I push the tranny back any further, the pan will be above the crossmember and the tranny bolts won't go in.

I was also going to have them measure from the cross member to the front of their oil pans. (i'll post pics to show what I mean).

I am concerned with the angle of the engine. Measuring front to back and across the carb plate, the front is lower than the back. I am wondering how much of this is due to the rake of the car, since I have shorter tires up front. If I raise the front of the engine to where the carb plate is level front to back, the holes on the engine mounts do not line up with the holes in the frame mount perches (not sure is this is the correct term). I had two other guys measure the distance from their crossmembers up to the pan rail and I believe we're all within an 1/8" of each other. So maybe the back of the engine is sitting high?

From what I am seeing, it seems that the engine is in the right spot, but things just aren't adding up. I must be missing something really simple.

I was also going to have them measure from the cross member to the front of their oil pans. (i'll post pics to show what I mean).

If I compare this to others, I should be able to confirm that the engine is sitting back far enough in the engine bay.

This is how the engine sits when it settles in. If I take a left to right measurement of it across the top of the head, it is very close to level.

Passenger side:

Drivers side:

This is where the tranny sat before I tried to move it back. I will get an update picture:

As you can see, there isn't much room to go back further.

How much more does the steering wheel need to turn before it hits the bump stops on the spindles.

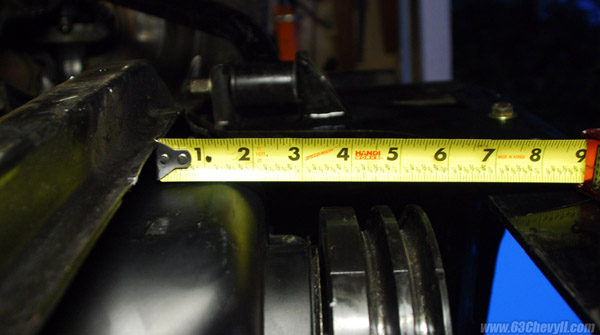

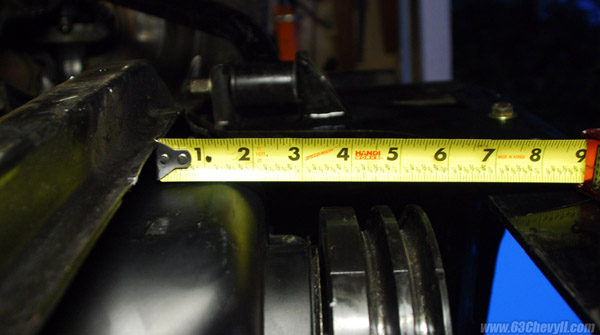

bumps stops - is that the flat area pictured here?

if so, I have about 1.25 inches to go.

You can see how close you are to meeting those #'s with your pan, and it might tell you how much more you need to go.

I was pretty close eyeballing it. I had marked out an area that I thought I'd need to cut out and using the morose numbers, I was close. The green tape shows what would need to be removed according to moroso:

at the top edge of the green tape, you can see some blue sharpie ink on the pan peeking out from behind the tape. That's the area that I had marked out to remove.

anyone have any thoughts on my last couple of posts?

Lyndon, from your video you posted of you moving the steering wheel back and forth, you could tell you were real lose to having enough clearance with the center link and tie rod ends. Maybe you could make some cardboard templates to use as a guide around the tie rods and center link so you can make sure you "nail it" on this next go round. Keep us posted on your results.

I was thinking of doing that. I had thoughts of cutting away part of the pan while the engine is in the bay, but I don't know how I'd go about doing that without getting metal shavings/dust all over the internals.

I prob just have to pull the engine. pull the pan off. mock up with cardboard. then reinstall engine with cardboard attached to oil pan.

There might be away too literally chisel out the pan. You would lose about a 1/4 inch of material. If you have an air chisel (hammer)they come with a bit that looks like chisel, but has slot in it, at the end of the slot is hook that points down. It will peel 1/4 inch slot in sheet metal. I love it for exhaust pipe that doesn't want to come apart.

Larry

I'm not the best resource here, but if it comes down to you pulling your engine again, would it be possible to cut the offending piece out, and weld in a piece of pipe that's cut in half length ways? Thats what I have planned on doing when the time comes for me.

Nonetheless, great job and good luck! The air chisel looks like it should work well.

I can't help on why the clearance is tight, or any part of the car.

However, from personal pan clearance experience (Chrysler 440 in 1971 Duster) I can tell you that when you think you have enough clearance, you don't, and when you hit the brakes hard the engine shifts forward quite a bit.

Add extra room, or you'll have to do it again.

I can tell you that when you think you have enough clearance, you don't, and when you hit the brakes hard the engine shifts forward quite a bit.

Add extra room, or you'll have to do it again.

Thanks for the tip!

I pulled the engine out Sunday afternoon. I had a hard time getting in there with the chisel, although it was a great idea.

I notched that pan 1/2" less than what the moroso site called for b/c I was afraid of the notch interfering with the pickup. I formed and tacked a piece of 16 gauge sheet metal in there and put the engine back in the car.

It is really close to clearing everything now. It seems that the only thing that is hitting is the castle nut on the tie rod end on the passenger side.

I think I'll notch is as much as I can without it hitting the pickup. This will have to wait until after May 8th, as the inlaws are arriving from NH on Wednesday. I'll be on the road May 4 - May 8. Hopefully I'll be motivated and excited about working on this when I get back.

just got back from vacation. I've spent some time though practicing welding on sheet metal with the flux core welder I have.

I'm planning pulling the engine tonight and working on the oil pan over the next couple of days. Two of the biggest events of the year for my 'car club' are on the 22nd and 29th of this month. I'm going to be disappointed if I miss both of them.

Keep us posted on your progress.

got home at 5pm last night from work. Worked on car from 5:30 to 12:30am, when I ran out of welder wire. I got the engine out and spent lots of time working of the oil pan. I have a couple of leaks to plug and have to move the drain plug to the back of the oil pan.

With a little luck, I'll finish up the welding on the oil pan put a thin coat of jb weld over the seams tonight, then sand and paint the pan tomorrow.

Tomorrow, I also hope to install the new fuel lines, work on the radiator mounts.

Fri plans - put oil pan & flexplate on and install engine, hopefully for the last time.

Best of luck man, I'm really excited to see your car with a 292 in it. Fluxcore can be a pain, but it sure gets the job done.

Anything else you have to do to finsih the install, besides the oil pan and install the engine?

Hope to see pics and vids!

-Sam.

ton more actually. Even with as hard as I'm working now, I'll be lucky to finish by June 1st.

hey 63chevyII have u 2 tried use exhaust pipe 4 the center link clearance issue? when i put a v8 in my 67 i looked at the moroso

pans 4 the novas using there mesurements, i used 3" pipe then put in vice and squeezed down 2 2.5" so it was now oval shaped, cut of what i did not need, added a s10 4.3 4x4 bottom 1/2 of pan 2 create a deep sump with the pump pick up 2 the stock pump.

lasted 4 yrs with no problems. made 2 others also. now i 2 am doing the same thing 2 my 67 using a 66 shell 2 do my mock up in

as i have a 3 sheeve balancer. i have modified the r. side mount so when i put it in this weekend, i want 2 c what i can do 2 make it look factory. pics will follow poss by mon. i have a pic on old pc at home where i saw one on ebay where a 63 had a 292 with somewhat decent pic of the right mount. the rad so is the other issue as i mite cut some core support and move rad outward some (not doing the elec fan thing) it's a race car. functionality be for bling. no hood latch as i use hood pins.

ok pics r up. ask away (have not done oil pan yet)

http://s42.photobucket.com/home/6pac2go

Thats what I meant - glad I'm not alone with using a piece of pipe to section into the pan.

Can't wait to see both of your guys' pics. My install will rest alot on the success of 63chevyII's install, and how he likes the big six in his car.

Keep at 'er1

-Sam.

I ending up wrapping a piece of 16 gauge steel around a 2.5 inch pipe.

Hey guys,,I've been looking to do this with a 65,,,can I go back to the beginning for a couple questions,, I know the passenger side mount has to change, but I thought the driver standard inline mount matched the 292,,?? did I see on here a mount that mounted to the block then had an arm that reached forward to the inline 6 perch/nub,,instead of the full v-8 change,,?

The oil pan,,, can I not use the standard chevy11 pan I have now,,, my engine right now is a 1974,, my machine shop made a jig to drill a dipstick hole into the pad on the earlier block, worked great, then I epoxied the rear original hole,,I figured I would do the same to the 292,, or is that pad not there,,,I haven't even been able to find a big six in my area to look at,,,

the left side mount's will still stay the same, the right side is what comes into question as most use the fab style (help me here 63chevyII & others) on the right side that relocates the mount back to the original location but u sacrafice the mech fuel pump, so then a elec pump comes in 2 play. as far as the use of the original pan yes! u can use it but where 2 put the dipstick (ha ha no pun inteaded) is up 2 the user. in the past on later blocks i have put them in the pan using the big block piece from the pan weld or braze in and also have done the drill bit style in the original location. now as for my style of right side mount, i had an old rusted frame that i cut the frame piece off of, the block mount was opened up so that it would clear the block and mount flush and in my pics as i laid the eng/trans combo in the holes all lined up just need now to pull it all out and put in race car weld up fame part then just somewhat down hill from there. also pay close attion 2 the balancer clearance issue between rad/pump pully/fan and such. i have at least 1/2- 3/4 space in all places. questions? keep asking i'm sure other's will answer also.

well i have the engine at work 2 day and will b changing the pan and p/up and some of the gaskets and paint it. would like 2 put in the race car this weekend but will c.

progress is really slow, but I am getting a few things done.

I am at the point were I pretty much have questions on everything I do.

Vince has been a huge help and when he's not

racing his fuel altered or working, he's out here helping me.

Progress -

pics may -june

hey 63, i'm with ya on the slo thing. put it in last week friday and took home on sat. now just get it 2 my buddies house 2 weld.

1 set back was a locked up left caliper

hey 63 did u use a 230/250 type damper cause i'm still gona use the 292 3 sheeve type. also another problem is the stock 292 alt bracket. i have only 1 and it's 1/4 shorter then the small block 6's. as i have mounted the small 6 alt bracket and the pulleys no line up unless i use a double pulley. the the end damper sheeve lines up with the outter sheeve alt pulley, so i will use the stock small 6 bracket 2 use only a single pulley

hey 63 did u use a 230/250 type damper

I believe you're not supposed to use a STD-LD damper on a 292.

I am using a 2 groove 292 pulley. It's the one where the pulleys are close to the outer edges and there's a half inch between the pulleys. I just sent it back yesterday to have them move it out 1/8" on the hub so that everything lines up.

I am using a BBC pulley on the waterpump and the alternator brackets from STD-LD (the 194 that was in there previously).

ok on the pulley (yours) its just i'm was going by what they said about smoothness (vibe) by using the bigger damper along with the bigger flexplate.

when I get the damper back, will take some pics of the alignment with the BBC waterpump pulley and alternator (which I had converted to a 100 amp, 1 Wire).

hey 63 how's the rad situation going? i've got mine all welded up (frame mount), water pump b here tomorrow. have old on now for mock up. I'm tring not 2 modify the core support for rad because i do not won't 2 go the elec fan route

ordering two 8" electric fans today probably. Plan to start fabricating a shroud this weekend.

well i worked on a core support 4 the 3core rad w/a 6 blade

custom fan (thin blade) w/plenty room at rad/fan/bottom pulley

made some support brackets 2day have 2 wait till i get them welded in and some final tweeking

Progress has been slow...

I have a 2 core crosswflow aluminum universal rad from summit. I also bought some nice brackets for mounting (http://home.earthlink.net/~2drcdan/id1.html). Another guy with an L6 has used this radiator and mounts with a mechanical fan with no problems. Problem is, he was using a 250 and from what I can tell, the waterpump snout on my 292 sticks out further. I'm guessing it sticks out further so the the fan can clear the larger harmonic balancer. There is no way I can use a mechanical fan with this radiator. There isn't even enough room in there for two 10" electrical fans, so I bought two 8" fans (rated at 2200cfm each, IIRC). I was planning on making a shroud for the fans and upon further inspection, it looks as though I will need to bolt everything up to the core support (rad, shroud, fans), then put the core support in the car. Which means, if the radiator or fans need to come out in the future, I'll need to pull the grill and everything else out. I'd like to avoid this if possible.

If possible, I'd like to buy a HD L6 Nova radiator and use a mechanical fan. I know the HD L6 Rad will give me more clearance, but not sure if it will be enough for a mechanical fan. I'm a little upset since I already bought the aluminum radiator and can't return it.

This is the HD radiator:

my original is like this one (notice the wide brackets):

Vince

Vince convinced me that I should just install the 700R4 while we have everything apart. This of course means spending more money and more time off the road for the Nova. I better just do it now though, b/c with the hassle the 292 install has been, I may never want to take it off the road again

I pulled the powerglide out and got the 700R4 bolted up to the 292 in about 45 mins. Then I spent an hour

trying to get the crossmember bolted up to the car. Since the 700R4 is larger, I think it may be hitting somewhere in the trans tunnel. The transmission mount that I bought is supposed to be 62-67 nova specific and drop the transmission down so that it doesn't hit the tunnel. I will give it another try tonight.

so tonight I bolted the engine hoist up to the engine to pull the engine and tranny forward to try to figure out my crossmember problem.

Turns out the crossmember hits the floor before it is high enough to bolt to the car. CPP has a 30 day return policy. I've had the crossmember since March. I'm hoping they'll let me return or exchange it.

I had same rad/fan problems on my 65 chevy2,,,my rad looked like the original type,,, got it from us radiator,,it was a super cool 3 core,,,what I found with 250 water pump and a 1/4" alum spacer(the savior) from march pulleys,,(it wasn't cheap,,,)put the spacer about 1" away from the core,then the fan and bolts,,anything less the blades smacked the damper,,2 grooves,,the original 1 groove cleared, the fan was another concern, I got a nylon flex to fit but the big one hit the tranny fittings and the small one too small,no flex fan fit all the arcs on the blades hit the damper, and steel ones with no flex didn't work either the front tips of the blades are out farther than the center hub,,it was way to close to the tanks for comfort,I found a universal steel at autozone that was flat across the face and fit,, I picked the larger to get side to side on the rad, but it did not allow use of the tranny fitting,, even with the tightest 90 I could find,,,

I think I will be able to use a mechanical fan with the HD L6 radiator and the 2 groove balancer I have. It is going to be close, but I won't know for sure until I test fit everything.

After poking around on a few websites, I figured out that the tranny crossmember is actually made by Bowtie Overdrives. Here is an email I got from them:

WE MANUFACTURE IT .. YOU CAN SEND IT TO US SO WE CAN CHECK IT OUT ON THE JIG OR SEND IT BACK TO CPP AND GET ANOTHER ONE .. POSSIBLE IT MOVED DURING WELD PROCESS.. NON OF THE X MEMBERS WE SELL EXCLUDE ANY EXHUAST MODS IF YOU HAD PRE EXISTING EXHAUST..

Hopefully CPP will take it back, if not though, it looks like BTO will.

We, put a 700 R4 in my Bro's 67 ChevyII and I made the rear xmember. Used 1.5 x 3" tubing. Bent a wire to fit from side to side and then cut/ welded the tubing as needed. Took 2 hrs.

On my car (65 Elcamino) , There was not room for mech fan, used 3 fans positioned around the nose of WP. They have had no problem keeping up. My bro also uses 1 large elec fan on his II. works great.

It's been a frustrating few days.

I traded in the tubular style crossmember for a sheet metal style one.

The crossmember bolted up fine, but when I add the tranny mount, the transmission hits the tranny tunnel in three places.

The direct fit/replacement radiator I got doesn't actually just bolt in. I will have to drill some holes in the core support to mount it. Not that big of a deal, but a little frustrating when you pay extra for the 'direct fit' aspect.

To top it off, I got asked if my car could be used in an HP commercial that is probably being filmed as I type this. These jobs usually pay pretty well from what I hear...

oh well, vent over

mmmmmm, that's the same flat style member I used in my 65,,,no problems at all,,where is it hitting,,I'll look at mine when I get home and check back,,

Looks good ,sounds good.

Looks like you can fit a SPA turbo exhaust mainfold in there & a turbo.

Nice work.

What happened here

http://s42.photobucket.com/albums/e320/6pac2go/?action=view¤t=2day008.jpg&newest=1Fan cought on something?

MBHD

ya the fan brackets i was using broke 2yrs ago w/the old 6

mite know it was friday the 13th! but its fixed a still holds water and temp 165-180 w/a 160 stat

Atleast you have a schedule! Keep up the good work. Maybe you will get to drive it before the snow fly's. Oh wait, you probably don't get snow.

Looking at your site ( very nice), do not see any write up details on the 292. Carb, cam, exh , intake ect. Just more fun reading. Tom

Atleast you have a schedule! Keep up the good work. Maybe you will get to drive it before the snow fly's. Oh wait, you probably don't get snow.

Looking at your site ( very nice), do not see any write up details on the 292. Carb, cam, exh , intake ect. Just more fun reading. Tom

Thanks Tom. I do some freelance web design when I have the time or need the $ for my car.

I plan on doing more detailed writeups on the car once I get it up and running. I'm taking lots of pictures along the way, so I'll have plenty of material to work with when the time comes.

Made some progress on the nova over the last couple of weeks, mostly related to heater box, trunk, and fan cleanup and refinishing.

pics here:

63ChevyII.com Pics, 07.25.10 - 08.14.10 I was hoping to get the flexplate and torque converter installed today, but hit a bit of a snag. The 292 flexplate I bought a few months ago and 700R4 torque converter patterns don't match up. Looks like I will be drilling the old 194 flexplate for the alignent dowels, unless I can figure something else out.

Nice work!

Those fixed 4 bladed fans suck/push a lot of air!

MBHD

Nice work!

Those fixed 4 bladed fans suck/push a lot of air!

MBHD

Thanks - next time I think I'll take the heater to the sandblaster/power coating shop... that was a ton of work.

. Oh wait, you probably don't get snow.

believe it or not, we actually do occasionally:

03.13.10 - 1963 Chevy II sNOwVA

Nice work!

Those fixed 4 bladed fans suck/push a lot of air!

MBHD

regarding the fan, I'm glad I was able to find it. I had a hard time finding one that would work with the 292 water pump. From what I can tell, some of the 292 water pumps only have one bolt pattern, which matches the SBC/BBC pattern. The 194 pumps I have have dual patterns, one which is smaller that the SBC/BBC pattern. Most of the fans I have have the smaller pattern and won't work with the 292.

I found two fans that will work with the 292 - a 4 blade off of a 3rd gen nova and a 6 blade from a what I believe was a 60's dodge. I am hoping the 4 blade pulls enough air b/c it has more clearance that the 6 blade. Both are really close and I have a friend coming over to see if he thinks I have enough clearance.

Fan patterns:

The "small" pattern was also used on the Mouse (SBC). So it was on both the I6 and the SBC. I don't know what year they switched over to the later big pattern, maybe the same year they switched from the Rochester B carb to Satan's Carb (the Monojet:).

The "Small" pattern is also the same as the Ford fan, I have used 4-blade Ford fans on the 250 and 292, with the right water pump there is enough clearance to the rad. I did have to space the fan out maybe 1/4" to clear the double-pulley 292 damper.

Fan patterns:

The "small" pattern was also used on the Mouse (SBC). So it was on both the I6 and the SBC. I don't know what year they switched over to the later big pattern, maybe the same year they switched from the Rochester B carb to Satan's Carb (the Monojet:).

The "Small" pattern is also the same as the Ford fan, I have used 4-blade Ford fans on the 250 and 292, with the right water pump there is enough clearance to the rad. I did have to space the fan out maybe 1/4" to clear the double-pulley 292 damper.

that's is good info to have. thanks!

I added a few more details to my webpage:

http://63chevyii.com/the_build/2010/august.htm

I was hoping to install the torque converter and flexplate yesterday with the engine in the car. I spent about 3 hours messing with it, until I decided to pull both the tranny and engine again. Turns out the flexplate bolts are hitting the torque converter, due to the reinforcement plate/taller profile heads on the ARP flexplate bolts I'm using. I'm going to try removing the reinforcement plate tonight to see if that will give me enough clearance.

I hope I don't have to go with the original flywheel bolts - I have no idea where they are!

hey 63 i used grade 8 bolts and external serated lock washers 4 mine

DO not use washers on your flywheel/flex plate to the crank.APR crank bolt kits will tell you right in their paper work NO washers.

If your building any type of high rpm motor(another words higher then a stock motor would rpm) The harmaonics on these motors will flatten out the star washers and Now You flywheel/flex plate will be come lose!

well i took my 67 w/the 292 in it 2 the track friday night

test/tune at M.I.R.

1st run

rt. .218

et. 16.16

mph 80.92

2nd run

rt. .122

et 16.10

mph 81.29

3rd run

rt. .143

et 15.99

mph 81.67

4th run

rt. .083

et 15.81

mph 82.74

5th run

rt. .271

et 15.83

mph 82.61

what ya think?

Not bad,not bad.

What are your 60' times?

What is done to the 292?

Rear gear ratio,sticky tires,(I'd guess no)

Weight of Nova.

Auto, manual?

Details,details

MBHD

6pac2go,

I'm also curious about your setup.

My best guess at it from playing with my Gonkulator computer is that your car is slightly light (2900 w/driver down the track?), basically stock 292 with the 2.5" exhaust manifold, wide open, and maybe a 2bbl carb on top? I don't recognize the intake, what is it? Trans, either 4spd or Turbo350, I couldn't tell from the movie, 3.08 or 3.55 gears depending on the trans.

About a 2.20 60ft time is my calculation, 10.01 at 67.8 1/8 mile.

Want to hear more about your car! cool interior!

well i took my 67 w/the 292 in it 2 the track friday night

test/tune at M.I.R.

1st run

rt. .218

et. 16.16

mph 80.92

2nd run

rt. .122

et 16.10

mph 81.29

3rd run

rt. .143

et 15.99

mph 81.67

4th run

rt. .083

et 15.81

mph 82.74

5th run

rt. .271

et 15.83

mph 82.61

what ya think?

the eng is stock, 292 exhaust 2.5, dual outlet flow faster,

intake is homemade of big block header pipes w/a v shaped plenum w/a divider plate in the center, 2gc carb w/#61 holley jets, th350, shift kit, vega torque vertor,3.08 gears (8.5)but w/the 205-75-14's it drops the ratio 2 a 3.00. shift at 4500 but i did take it 2 5000 a couple times and stilled pulled hard, thru the traps about 4200-4400. the 60' time's u geuss r about right, tires are set at 45psi front-rears 30psi, traction bars, 90-10's front, stock rear (shocks) camaro seat, chevette shifter, also ran no air filter, stall at about 1500-1800 rpm's, water temp never over 170

intake is homemade of big block header pipes w/a v shaped plenum w/a divider plate in the center, 2gc carb

Details?

Pictures?

Awesome sounding 292 that you have Mr 6pac2Go

Link does not work for me.

MBHD

when u click link it comes up w/back or home. click home then click here

MIRDrag - Test and Tune (MIROCK) • 10/1/2010

then cars, 1st page sec row black 67 w/white wheels

(sorry bout all the stuff 2 go thru just 2 c it)

went 2 track again friday the 8th

1st pass

rt .112

mph 83.65

et 15.73

2nd

rt .025

mph 83.75

et 15.66

3rd rt .143

mph 83.68

et 15.66

4th

rt .192

mph 83.41

et 15.83 ( valve floated, went up 2 5k)

5th rt .086

mph 83.50

et 15.70

i nomally shift at 4700-4800 and it seems 2 like it there.

took off air filter and muffler vs the 1st time i took it 2 the track. should have other pics by wed.

6pac

Those are some more great times.

That is about what my Gonkulator computer showed, a gain of about .15 sec and 1mph+ or so on unhooking the muffler. That air cleaner looks pretty big, I doubt if any of the gain was from taking that off.

I calculate your engine at

Torq 258 at 2700

Powr 172 at 4200

Seeing the car in the 15.60s at 83+ shows what you can do with a light car, a good setup, and no accessories to rob power. Now I am extra anxious to get my 292 in my own car.

new pic, front end lift (no not off the ground) hope this link works.

http://public.fotki.com/Samm601/maryland...g-14.html#media

I fired it up last weekend and got it running, but in order for it to idle on it's own, I had to turn the distributor so that the timing is really retarded (maybe as much as 30 degrees, at least according to the timing mark).

I had someone help me find TDC and mark the balancer. Is it possible that when I put the distributor in it was off by a tooth or two? If so, which way do I need to turn it, counter clockwise?

Is it possible that when I put the distributor in it was off by a tooth or two? If so, which way do I need to turn it, counter clockwise?

Depends on if you were 1 or 2 teeth advanced or 1 to 2 teeth retarded.

You can install your distributer anywhere,any tooth you want,it really does not make a difference,just need to have room for the vacuum canister to move w/out hitting the engine/lifter cover.

Sounds like your TDC mark is incorrect,I'd suggest to find the true TDC again.

MBHD

I haven't been on here much since June or so. At the beginning of June a friend convinced me (after a month of trying) hike Mt. Whitney on Aug 22nd. Mt. Whitney is quite an undertaking for someone that is out of shape, so until last week, most of my free time was spent training for the hike (

pics here).

The car was pretty close to being on the road in June, but I was also feeling burnt out and got to the point where I needed some help troubleshooting things.

Vince (http://www.mayedamotorsports.com/) came by a couple of times over the last 3 weeks or so to give me a hand and to check over my work. Sunday I was able to drive the '63 for the first time in about 16 months. I still need to get the exhaust done and there are still a few small things to take care of. I'm very excited though to have it back on the road:

pics/vid here

I hit a bit a bit of a snag (or maybe I should say my fan did).

Pulling into the driveway the other night the 4 bladed mechanical fan I was using barely kissed the bottom lip of the radiator. Unfortunately, it was enough to get it to leak. I dropped the radiator off to be repaired ($20) and installed an 18" flex fan. I have about a 1" of clearance now, but have yet to run it in hot weather to see if it will cool sufficiently.

On another note, the radiator guy told me that the radiator leaked b/c it was put together poorly and that it shouldn't have leaked with that amount of contact.

I believe it hit due to some chassis flex (inclined driveway) and decelerating at the same time. I checked the motor mounts and they had loosened up some, but I don't think this alone wouldn acct for the problem.

If your having that much chassis flex you might need to consider some frame connectors in the near future.

There was only about 1/8 - 1/4 of an inch between the lip that was hit and the fan. Frame connectors are probably a good idea though...

Even if you go with the Bolt-in connectors and not the weld-ins.You'll be happy you did,And wounder why you had not done it before.If you end up flexing the body to much you may not get the doors to open OR close. You can also make your own from 2x2 box and some angel. Not hard to make and you may? save a few bucks over buying premade.

Here are some updated

pics and a

video

Can see pics but not the video. The link on your site to youtube is not correct ( it is just a youtube link).

Nice work on the car!

Now can see the video! Looks like one happy pooch.

Now that you have driven it and probably broke it in. How does the 292 perform compared to the previous engine? Mileage? Maybe review your specs.