|

|

Joined: Apr 2003

Posts: 1,537 Likes: 15

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2003

Posts: 1,537 Likes: 15 |

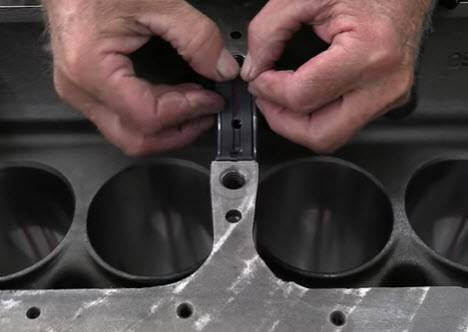

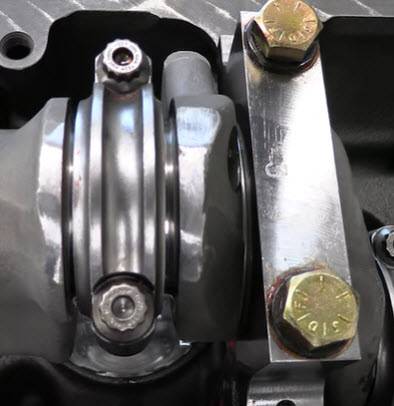

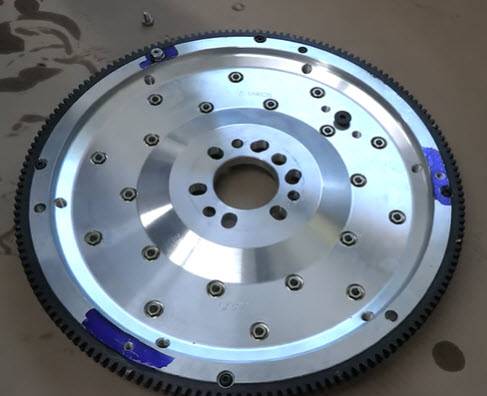

The folks over at Horsepower Monster have posted a video of an incredible 261 build.  The dyno numbers are mind boggling for a 4 main cap crank.  The center caps have been replaced with custom steel billet bits with a wider stance on the block:   The crank has been turned down to LS bearing specifications (to reduce surface area) and LS bearings are riding piggy-back on stock bearing shells:  The custom pistons that are riding on H-beam rods are pin guided:    The ignition timing is fully electronic with no distributor and hence no oil pump. The pan has been plumbed for a dry sump. The fuel pump mounting boss has been repurposed for a cam position sensor:   Timing is driven from a bell house adapter fitted crank sensor:  tracking three flying magnets on an aluminum flywheel:  The coil packs are tucked underneath the intake so they disappear once the engine is installed:  Custom exhaust manifolds were cast in stout proportions to hold the turbos firmly:

|

|

|

|

|

Joined: Apr 2003

Posts: 1,537 Likes: 15

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2003

Posts: 1,537 Likes: 15 |

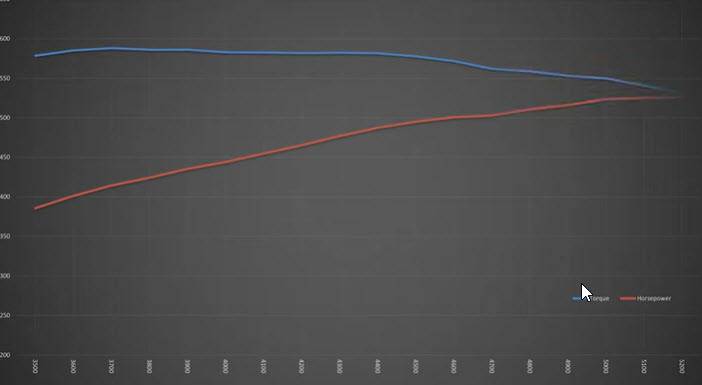

The valve train is roller bearings everywhere! From the camshaft journals to the lifters and the rocker arms:    All fitted to a reproduction Wayne crossflow head:  Still more custom castings are found on the intake side of the engine. The adapters serve two purposes – one to mate the Borla throttle bodies to the head – two to provide balance runners between the ports for a MAF sensor. Everything is o-ringed for a tight seal:   The next casting creates an intake box to receive air from the twin turbos with trumpet flared openings into the throttle bodies.   Absolutely gorgeous. The layout for the build is designed to fit under the hood of a late fifties Suburban:     The initial dyno results are in excess of 580 pound feet of torque and 525 horse power. An eye popping result. The trace shows no reason to rev this engine  Like all Stovebolts, peak torque shows up early and the HP curve shows diminishing returns for added RPM. The engineering and workmanship in this build had me saying wow so many times during the video I lost count . . . The video can be found here on YouTube

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

WOW! I think if I walked int a shop and saw it I might not recognize it right off. What a cool package. The whole build just goes beyond what I thought I knew. Seeing new tech applied to old engines is really exciting. Thanks for posting this.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Oct 2015

Posts: 10

Active BB Member

|

Active BB Member

Joined: Oct 2015

Posts: 10 |

|

|

|

|

|

Joined: Oct 2009

Posts: 471 Likes: 9

Contributor

|

Contributor

Joined: Oct 2009

Posts: 471 Likes: 9 |

I would love to have the brains and experience that some have for this kind of work. Without getting into the money it took for the build, which is really terrific, I really am facinated with the line boring and piggy backing of the bearings. I also wonder whether its possible to revisit the rod and piston issue with these motors, i.e., can a different stronger lighter rod be used and if so, can a lighter stronger piston be matched up to get better compression then stock 261 pistons (without having to go to custom designed pistons), for all of us backyard builders.

Last edited by mdonohue05; 10/25/21 10:32 AM.

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

The Wayne chamber appears to be open, with no quench surface. I assume the piston shown is close to zero deck at TDC.

This means the engine will have lower compression than the stock 261.

The 261 head's large chamber volume is partially contained in the exhaust pocket. Without a custom piston there is no way to get a compression dome.

|

|

|

|

|

Joined: Apr 2003

Posts: 1,537 Likes: 15

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2003

Posts: 1,537 Likes: 15 |

The Wayne chamber appears to be open, with no quench surface. I assume the piston shown is close to zero deck at TDC.

This means the engine will have lower compression than the stock 261.

The 261 head's large chamber volume is partially contained in the exhaust pocket. Without a custom piston there is no way to get a compression dome. With pop-off valves tuned for 10 pounds of boost wouldn't a tight quench area lead to detonation on pump gas? Seems they built it with a lower static compression by design.

|

|

|

|

|

Joined: Aug 2003

Posts: 353

Contributor

|

Contributor

Joined: Aug 2003

Posts: 353 |

"The crank has been turned down to LS bearing specifications (to reduce surface area) and LS bearings are riding piggy-back on stock bearing shells"

I think I understand what's going on with this engine build except for the bearings.

This sounds to me like an LS bearing mounted inside the OEM shell.

Is this correct?

How do you keep it in place?

Wouldn't this be more prone to spinning a bearing?

Maybe I'm missing something?

Pete

64 Chevelle

61 C30 Panel truck

|

|

|

|

|

Joined: Apr 2003

Posts: 1,537 Likes: 15

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2003

Posts: 1,537 Likes: 15 |

"The crank has been turned down to LS bearing specifications (to reduce surface area) and LS bearings are riding piggy-back on stock bearing shells"

I think I understand what's going on with this engine build except for the bearings.

This sounds to me like an LS bearing mounted inside the OEM shell.

Is this correct?

How do you keep it in place?

Wouldn't this be more prone to spinning a bearing?

Maybe I'm missing something?

They don't spend a long time discussing this detail. But the builder states that "by getting the crush just right" there is no chance of a spinning a bearing. This suggests to me that 'tangs' in LS bearing are biting into the stock bearing shell material when the crank is torqued down. I am not sure if LS bearings are staked - but if the stake lined up one the stock bearing shells that would be another way to prevent the LS shell from moving.

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

The Wayne head was not chosen for this ($50,000? more?) project because its a great design, but because you can buy one (to adapt or make one from scratch: add $$$$$$$$$$$). Yes, it's an improvement over the existing.

No one would consider using that chamber design today, it was obsolete in 1949.

There's just not enough sales volume to make a modern bolt-on stovebolt head, like superimpose the LS design onto the 261 block.

|

|

|

|

|

Joined: May 2009

Posts: 493

Contributor

|

Contributor

Joined: May 2009

Posts: 493 |

I like this engine build!

Is that a stock crankshaft forging?

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

|

|

|

|

|

Joined: Jul 2000

Posts: 4,585 Likes: 19

1000 Post Club

|

1000 Post Club

Joined: Jul 2000

Posts: 4,585 Likes: 19 |

That is one bear of a build.

Larry/Twisted6 [oooooo]  Adding CFM adds boost   God doesn't like ugly.

|

|

|

|

|

Joined: Sep 2017

Posts: 86

Active BB Member

|

Active BB Member

Joined: Sep 2017

Posts: 86 |

And HP was still rising.

Better safe than sorry.

Regards,

Rick

Inliners #6543

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

There were so few original parts used that it's hard to say what's safe.

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

It reminds me of an article I read a several years ago about the last guy who was flat track racing a Norton. The only original engine parts were the inner cases.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Oct 2021

Posts: 4

Newcomer

|

Newcomer

Joined: Oct 2021

Posts: 4 |

It is an incredible build, but I'm sure it also had an incredible budget!

|

|

|

|

|