|

|

Joined: Aug 2013

Posts: 78

Active BB Member

|

OP

Active BB Member

Joined: Aug 2013

Posts: 78 |

Reflecting: If I take all the input I've received based on individual experiences, what I've read/researched, expert input, and this discussion it appears results with the 194 head range from "down 45-50hp" to a "great performance head". My goal is to be on the right side of that equation if that makes sense! Thanks for the healthy discussion, I think I have enough data to formulate marching orders. I will post what I find out for your future review as well. And by all means please don't stop the discussion, more info is better than less (well, usually)  Lastly, what about my other choices? Are they sound in your eyes?

Last edited by moregrip; 02/25/14 09:02 PM.

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

Don't worry, this discussion has been going on for almost 50 years, it won't ever stop.  As far as the power the 194 head is down, let me say that the 45-50 HP i'm referring to is at the top of the ladder for an all out race engine, and the 10-15 HP mentioned is more at the stock and medium performance level of 150 HP and up.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Aug 2013

Posts: 78

Active BB Member

|

OP

Active BB Member

Joined: Aug 2013

Posts: 78 |

Last edited by moregrip; 02/25/14 10:35 PM.

|

|

|

|

|

Joined: Feb 2014

Posts: 505

Major Contributor

|

Major Contributor

Joined: Feb 2014

Posts: 505 |

Per-tee! Freshly painted blocks are always nice to look at. Is that chevy engine orange, it kinda looks red in the pics but it might just be the light? So you're using the stock dished pistons? Did you zero deck the block?

|

|

|

|

|

Joined: Aug 2013

Posts: 78

Active BB Member

|

OP

Active BB Member

Joined: Aug 2013

Posts: 78 |

here's a closeup of one of the cylinders:  and no I didn't leave the firewall unfinished   all work done with various wire wheels and fiber discs.

|

|

|

|

|

Joined: Aug 2013

Posts: 78

Active BB Member

|

OP

Active BB Member

Joined: Aug 2013

Posts: 78 |

Per-tee! Freshly painted blocks are always nice to look at. Is that chevy engine orange, it kinda looks red in the pics but it might just be the light? So you're using the stock dished pistons? Did you zero deck the block? that is my stock block in the chassis, just cleaned everything up a bit. Yes Chevy Orange (VHT brand). Stock pistons/no decking. All bolt holes chased and air blown dry.

Last edited by moregrip; 02/25/14 10:51 PM.

|

|

|

|

|

Joined: Feb 2014

Posts: 505

Major Contributor

|

Major Contributor

Joined: Feb 2014

Posts: 505 |

Oh, so you haven't rebuilt the short block. What is this engine in?

|

|

|

|

|

Joined: Aug 2013

Posts: 78

Active BB Member

|

OP

Active BB Member

Joined: Aug 2013

Posts: 78 |

Oh, so you haven't rebuilt the short block. What is this engine in? No rebuild, shortblock is used. It's a 250cid in a chevy C10 pickup.

|

|

|

|

|

Joined: Nov 2013

Posts: 482

Contributor

|

Contributor

Joined: Nov 2013

Posts: 482 |

Would you be kind enough to measure how far down the piston is at TDC? Jay 6155

|

|

|

|

|

Joined: Aug 2013

Posts: 78

Active BB Member

|

OP

Active BB Member

Joined: Aug 2013

Posts: 78 |

no problem at all......as soon as I get back home from TAD. I'm active duty military and the Navy is keeping me busy these days!

|

|

|

|

|

Joined: Feb 2014

Posts: 505

Major Contributor

|

Major Contributor

Joined: Feb 2014

Posts: 505 |

Just think of making the port window bigger.

If you can make the window bigger it should flow more.

I would not make the sides of the port bigger, I would grind down the bosses, if you are going to keep the bosses & not go w/lump ports.

....................

A great flowing head can be an absolute dog of an engine for driven daily driver. This great flowing head on a flow bench can look great on an engine dyno, but it could be a pig when actually installed into a car/truck or?

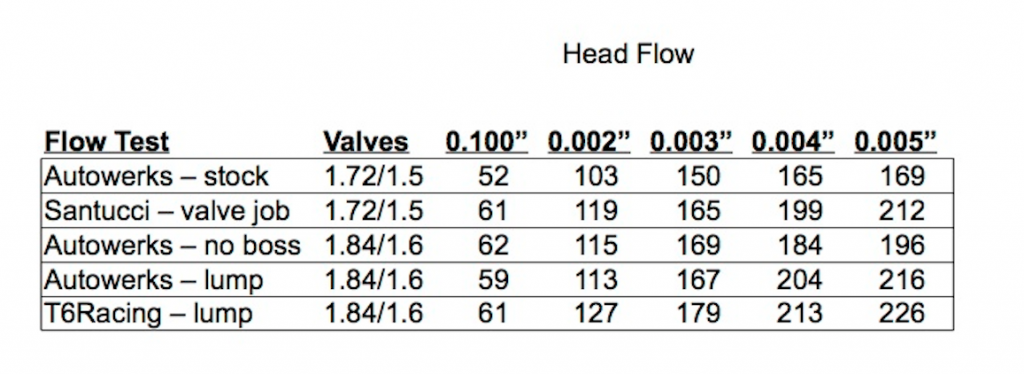

MBHD Yeah, a street engine or daily driver works in the sub-4500 rpm, and big ports are don't work well in that range. Big ports at low rpm have low velocity, while at high rpm the work very well. It's like breathing in through you nose, small port and air moves fast, while breathing the same amount of air through your mouth is a big port which slows the air speed down. A street engine wants velocity to make up for the low rpm of the engine and shorter lift of a street cam, so you don't want to remove anything unless it is tripping up flow in the throat. Keep the port as narrow as possible, this is why the SBC Vortec cylinder head works so well. I made this little chart based on the flow tests I've seen:  Now the Autowerks (from tlowe) numbers are directly comparable to each other, but the test from the Santucci book and the T6Racing are done on different flow benches, so their numbers are not directly comparable with the Autowerks. But as Santucci recommends in his book, the stock valves with a good valve job and a little port and bowl cleanup showed a lot of flow improvement over stock. While taking the bosses out actually made the flow worse over just the minor improvements. I'm not sure what improvement adding bigger valves would make with the bosses in place. But adding the lumps with bigger valves obviously improved flow even more, and with the material from the lump added back to the port it likely improves velocity over just the valve job (tlowe noted that there was no improvement from a lump with stock valves). The flow numbers suggest that lumps are optimal for a street engine, but if you're on a strict budget a valve job and basic cleanup is still a significant improvement over stock.

Last edited by Lifeguard; 02/26/14 01:10 AM.

|

|

|

|

|

Joined: Feb 2014

Posts: 505

Major Contributor

|

Major Contributor

Joined: Feb 2014

Posts: 505 |

Oh, so you haven't rebuilt the short block. What is this engine in? No rebuild, shortblock is used. It's a 250cid in a chevy C10 pickup. What year C10?

|

|

|

|

|

Joined: Aug 2013

Posts: 78

Active BB Member

|

OP

Active BB Member

Joined: Aug 2013

Posts: 78 |

Oh, so you haven't rebuilt the short block. What is this engine in? No rebuild, shortblock is used. It's a 250cid in a chevy C10 pickup. What year C10? Well it's a squarebody and in an effort to have a rust free truck it's part 73,77,and 87, lol

|

|

|

|

|

Joined: Jul 2000

Posts: 4,585 Likes: 19

1000 Post Club

|

1000 Post Club

Joined: Jul 2000

Posts: 4,585 Likes: 19 |

The stock valve only flows about 170cfm, with the lump it with flow just over 200cfm.

Larry/Twisted6 [oooooo]  Adding CFM adds boost   God doesn't like ugly.

|

|

|

|

|

Joined: Feb 2014

Posts: 505

Major Contributor

|

Major Contributor

Joined: Feb 2014

Posts: 505 |

The stock valve only flows about 170cfm, with the lump it with flow just over 200cfm. On the Autowerks site tlowe said that there was no change in running a lump with stock valves, you need to enlarge to at least 1.84/1.6 to see a change. Are you saying that the lumps do benefit even a stock valve?

|

|

|

|

|

Joined: Jul 2000

Posts: 4,585 Likes: 19

1000 Post Club

|

1000 Post Club

Joined: Jul 2000

Posts: 4,585 Likes: 19 |

Yes But once again Bigger the valve the better the gain.

And If I remember right it was like 204-6cfm at 500 lift.

And Is what I got out of my heads with My first Lump design an a stock valve.

Larry/Twisted6 [oooooo]  Adding CFM adds boost   God doesn't like ugly.

|

|

|

|

|

Joined: Apr 2004

Posts: 3,556 Likes: 35

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,556 Likes: 35 |

Lifeguard,

My tests with lumps/ no lumps were on a dyno. That was with stock valve sizes and only the lump to modify anything. There was no power gain. Bigger valve and port work, then your talking. Power gain.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Nov 2013

Posts: 482

Contributor

|

Contributor

Joined: Nov 2013

Posts: 482 |

Moregrip, thank you and all others here for your service. I'll gladly wait until you get the time. Jay 6155

|

|

|

|

|

Joined: Feb 2014

Posts: 505

Major Contributor

|

Major Contributor

Joined: Feb 2014

Posts: 505 |

Lifeguard,

My tests with lumps/ no lumps were on a dyno. That was with stock valve sizes and only the lump to modify anything. There was no power gain. Bigger valve and port work, then your talking. Power gain. That's right, you mentioned no power gain with stock valves and lump, but you didn't have flow bench results for that combo, just dyno. I know you guys want to sell lumps, but for those of us building a 250 for the street on a budget, what's the difference between a valve job with bosses on the stock valves versus 1.84/1.6 with valve job and bosses? Does the bigger valves make a difference with the bosses in place or are they they only useful once you remove the bosses and put the lumps in.

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

Lifeguard, here's a quick run down on how these dyno tests came to be. I had some good magazine connections from back when I used to write engine building tech columns for several national magazines. I was going to write and get published some articles for Tom on his lumps and the various stages of mods that you can do to them.

I ended up getting some face time with the then editor of Hot Rod magazine in 2009 through a mutual acquaintence that was the former VP of Hot Rod. After a couple of calls and emails, he told me point blank that for an article segment such as this, that flowbench data by itself was totally worthless and meaningless to any magazine publication. He said that for any professional magazine publication to be interested in such a story it had to be carried to completion and dynoed before that flowbench data would have any meaning. He said they won't even do comparisons for SBC heads in his mag without doing dyno comparisons as well, because comparing two heads by themselves is meaningless without seeing the end result.

So he challenged me to include a series of dyno builds along with the lump porting build-ups and he would make a series of articles out of it.

Long story short, as the magazine industry goes, he was axed from Hot Rod before all the dyno tests were completed.

But back to the question, dyno results say it all, flowbench data does not.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Jul 2000

Posts: 4,585 Likes: 19

1000 Post Club

|

1000 Post Club

Joined: Jul 2000

Posts: 4,585 Likes: 19 |

Lifeguard,

My tests with lumps/ no lumps were on a dyno. That was with stock valve sizes and only the lump to modify anything. There was no power gain. Bigger valve and port work, then your talking. Power gain. That's right, you mentioned no power gain with stock valves and lump, but you didn't have flow bench results for that combo, just dyno. Let me say this first off I never said their was a power gain. The Question was did they improve flow and that question got answered. Now to answer the question is their a gain with bigger valves and the boss in place Yes. Again bigger valve helps improve air flow because more open area for the air to get into the chamber. Just like adding more lift more air & Fuel can into the chamber But may not always mean more HP. I know you guys want to sell lumps, but for those of us building a 250 for the street on a budget, what's the difference between a valve job with bosses on the stock valves versus 1.84/1.6 with valve job and bosses? Does the bigger valves make a difference with the bosses in place or are they they only useful once you remove the bosses and put the lumps in.

Larry/Twisted6 [oooooo]  Adding CFM adds boost   God doesn't like ugly.

|

|

|

|

|

Joined: Feb 2014

Posts: 505

Major Contributor

|

Major Contributor

Joined: Feb 2014

Posts: 505 |

Lifeguard,

My tests with lumps/ no lumps were on a dyno. That was with stock valve sizes and only the lump to modify anything. There was no power gain. Bigger valve and port work, then your talking. Power gain. That's right, you mentioned no power gain with stock valves and lump, but you didn't have flow bench results for that combo, just dyno. Let me say this first off I never said their was a power gain. The Question was did they improve flow and that question got answered. Now to answer the question is their a gain with bigger valves and the boss in place Yes. Again bigger valve helps improve air flow because more open area for the air to get into the chamber. Just like adding more lift more air & Fuel can into the chamber But may not always mean more HP. I know you guys want to sell lumps, but for those of us building a 250 for the street on a budget, what's the difference between a valve job with bosses on the stock valves versus 1.84/1.6 with valve job and bosses? Does the bigger valves make a difference with the bosses in place or are they they only useful once you remove the bosses and put the lumps in. Sorry, I misquoted you too. Improved flow but that does not necessarily mean increased power. It's all in having a matched parts combo.

Last edited by Lifeguard; 02/27/14 01:34 PM.

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

[/quote]Improved flow but that does not necessarily mean increased power. It's all in having a matched parts combo.[/quote]

Well, first and foremost, dyno testing says it all, flowbench testing does not!

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Aug 2013

Posts: 78

Active BB Member

|

OP

Active BB Member

Joined: Aug 2013

Posts: 78 |

It's all in having a matched parts combo. I've read several articles over the years, and more so in recent years, that suggest the best way to plan a engine build is to start with the cylinder head and build your motor around that. I realize that that logic has not always been "en vogue" so to speak but what I can say from first hand experience, is that when I applied that train of the thought on my last motor build the end result was it absolutely hauled the mail.

Last edited by moregrip; 02/27/14 08:00 PM.

|

|

|

|

|

Joined: Aug 2006

Posts: 232

Contributor

|

Contributor

Joined: Aug 2006

Posts: 232 |

Lifeguard and Moregrip, do you have Tom Lowe's dyno testing results? From observing y'all's level of interest and understanding, having access to the results would be very informative.

By Lifeguard

"..... what's the difference between a valve job with bosses on the stock valves versus 1.84/1.6 with valve job and bosses? Does the bigger valves make a difference with the bosses in place or are they only useful once you remove the bosses and put the lumps in."

To be specific, nobody has answered your question for these exact conditions, and I do not recalled any dyno data with exactly these conditions posted in the past. A little digging may find something. The question is relevant though.

Last edited by Winter; 02/28/14 12:32 PM.

|

|

|

|

|

Joined: Nov 2013

Posts: 482

Contributor

|

Contributor

Joined: Nov 2013

Posts: 482 |

Winter, I to would like to know the power difference with just a valve size change. I wasn't around here when the dyno tests were done. How does a person get the results? I would be willing to donate to help pay for them as these tests cost a lot to do. I hope that a valve change only test was done. Jay 6155

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

Jay, here is the long version for both the 250 and 292 tests. There were over 200 tests conducted with both engines and not all of the results are discussed in the posts for the reasons mentioned in them, but what you are asking was tested. The gains from installing larger valves with the bolt bosses remaining intact are still gains none the less, but not as much as from removing the bosses entirely or by adding lumps. But you might see it mentioned in the posts. Tom can tell you if you still need that info though. Also, the long awaited printed and published version of these tests is arriving soon. 292 Dyno results 250 Dyno results

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Aug 2006

Posts: 232

Contributor

|

Contributor

Joined: Aug 2006

Posts: 232 |

Jay, to contact Tom Lowe for the dyno tests: Send him a personal message, he has posted on this thread as "tlowe#1716" Or contact him at his website, http://www.12bolt.com/I have Tom's results and graphs from e:mails, but I would be very interested in any published results that CNC-Dude just mentioned.

Last edited by Winter; 02/28/14 04:21 PM.

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

Yes, its been a long awaited moment, but it has finally come to the forefront and in sight.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Nov 2013

Posts: 482

Contributor

|

Contributor

Joined: Nov 2013

Posts: 482 |

I hope the results will be published soon. Any Idea of when? I would like to own a copy. Jay 6155

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

Jay, I recently started my own publishing company to fulfill my many own automotive book publishing needs and Tom is onboard to have me bring this to fruition in a printed book form. But don't worry, it will be the most complete and concise compilation of data that has ever been published on the subject.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Sep 2004

Posts: 5,839 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,839 Likes: 1 |

Is most of the info based off of engine dyno results & no actual results of testing @ a track, G-Tech meter, or grudge racing on the street, or any chassis dyno sessions? (actual engine/s installed into a car or truck?

Thank you.

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

They are the results from the dyno testing done a few years ago that was intended for magazine articles.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Nov 2013

Posts: 482

Contributor

|

Contributor

Joined: Nov 2013

Posts: 482 |

CNC Dude that reminds me to get the first stovebolt book from you also. The one with the 56 Chevy on the cover. Will you be kind enough to let us know when they can be had? Any rough idea? Thanks Jay 6155

|

|

|

|

|

Joined: Apr 2004

Posts: 3,556 Likes: 35

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,556 Likes: 35 |

Is most of the info based off of engine dyno results & no actual results of testing @ a track, G-Tech meter, or grudge racing on the street, or any chassis dyno sessions? (actual engine/s installed into a car or truck?

Thank you.

MBHD Yes it is. When you or anyone else steps up to do their own testing, then it can be critiqued also. There are many ways to gather data. The dyno is a very good measure and the way it was done was deliberate to show power changes with part changes. CNC is ready to help get this dyno info put into a book. It will be great info to have for future engine builds.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

That will be a good thing. Put me on the list.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

CNC Dude that reminds me to get the first stovebolt book from you also. The one with the 56 Chevy on the cover. Will you be kind enough to let us know when they can be had? Any rough idea? Thanks Jay 6155 Jay, im just polishing up a few last minute details with the cover design and some final pics for the Stovebolt book. I already have my first book published and in my hands about a month ago, so im ready to start cranking out more and more, as the demand has never been higher for them than now.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

Is most of the info based off of engine dyno results & no actual results of testing @ a track, G-Tech meter, or grudge racing on the street, or any chassis dyno sessions? (actual engine/s installed into a car or truck?

Thank you.

MBHD Yes it is. When you or anyone else steps up to do their own testing, then it can be critiqued also. There are many ways to gather data. The dyno is a very good measure and the way it was done was deliberate to show power changes with part changes. CNC is ready to help get this dyno info put into a book. It will be great info to have for future engine builds. How true Tom! Since 1948 when Hot Rod magazine was first on the book shelves, it has always featured dyno comparisons like every other automotive magazine has as well. I personally think just like Hot Rod and other magazines did, that the millions of persons reading this info for the last 65+ years will also be smart enough to figure out how this info can better apply to them personally and help them reach their own personal goals.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

That will be a good thing. Put me on the list. I think your already on the list. Tom will be in charge of distribution.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Aug 2013

Posts: 78

Active BB Member

|

OP

Active BB Member

Joined: Aug 2013

Posts: 78 |

Lifeguard and Moregrip, do you have Tom Lowe's dyno testing results? From observing y'all's level of interest and understanding, having access to the results would be very informative

No I do not, was researching previous posts but it was difficult to compare results from the different threads. Is there a one stop shop? I was able to read about various combos in the power book and that gave me a sense of how some successful builds where spec'd. I'm looking forward to more info for sure though. Maybe I'm wrong, but I tend to think all data is good data. Starting with machining processes, balancing of internal parts, cylinder head flow and/or velocity, supporting components like induction and exhaust, where to make compromises, dyno testing both at the flywheel and to the wheels, and lastly where it's supposed to all come together, in how your combination runs in your vehicle whether that be on the street, at the strip, or both!

|

|

|

|

0 members (),

325

guests, and

48

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

|