|

|

Joined: Aug 2004

Posts: 11

Active BB Member

|

OP

Active BB Member

Joined: Aug 2004

Posts: 11 |

I have a 230 out of a P28 with an 10" clutch and three speed tranny. All of this is going in my 49 burban.

Here is my problem: I do not have a single bolt for the bellhousing, flywheel (eight hole), or pressure plate.

Is there a book or something that will help take the guess work out of collecting these fasteners?

Or do I have to actually do some work and take some measurements?

|

|

|

|

|

Joined: Jun 2005

Posts: 599

Major Contributor

|

Major Contributor

Joined: Jun 2005

Posts: 599 |

Measure it all up and do it nice... cap screws on the pressure plate, grade 8 hex-headed bolts on the bellhousing etc.

When you measure up, err on the side of short, you don't want to bottom bolts out in the back of the block.

|

|

|

|

|

Joined: Aug 2004

Posts: 11

Active BB Member

|

OP

Active BB Member

Joined: Aug 2004

Posts: 11 |

Now it doesn't look like the output or the flywheel are threaded. Do I use a bolt and a nut to mount the flywheel? Split washers?

Its the flywheel that has me really concerned...

|

|

|

|

|

Joined: Jun 2005

Posts: 599

Major Contributor

|

Major Contributor

Joined: Jun 2005

Posts: 599 |

Don't they have studs that come through from the flywheel and you put nuts on the front of them?

I know the nuts go on the engine end, maybe they're only studs when it's a torque converter?

Split washers... maybe Nylock nuts?

|

|

|

|

|

Joined: Feb 2001

Posts: 144

Contributor

|

Contributor

Joined: Feb 2001

Posts: 144 |

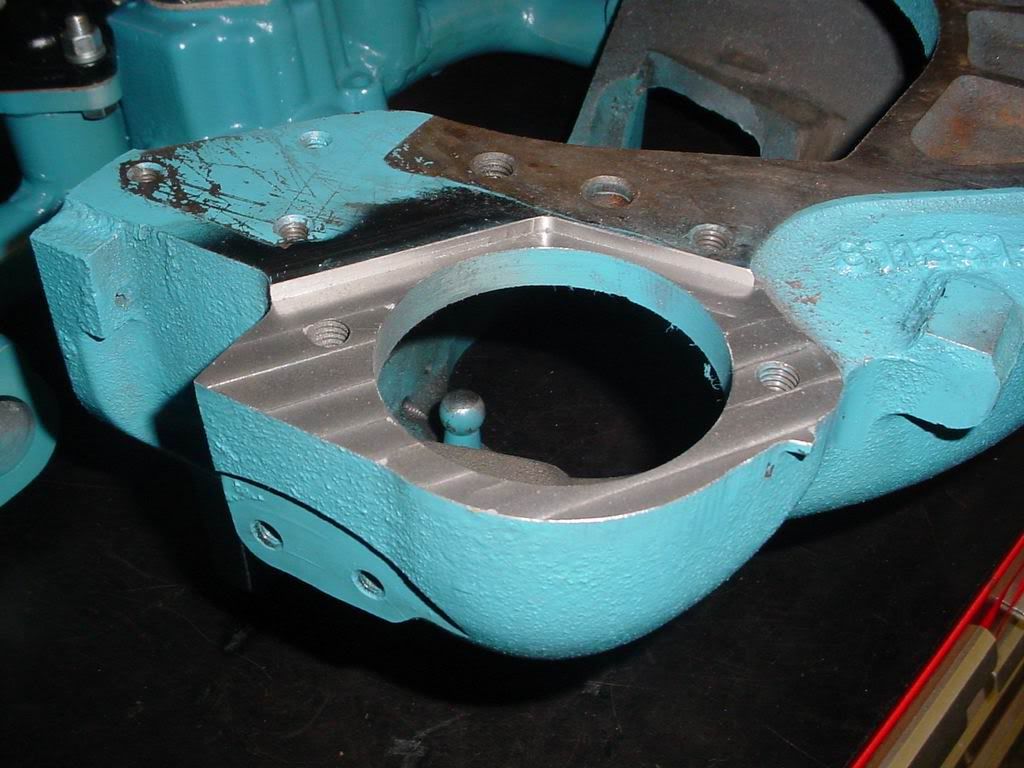

snacks- You can get the correct flywheel bolts from Vintage Power Wagons. These bolts have a round head with a flat shoulder that fits against the recess in the flywheel. The nuts for the 230 go on the engine side, you can't get the bolts in or out of the crank without having the rear main bearing cap off (don't ask how I know...). Here's a pic of the 218 crank that came out of my engine, with the same type bolts still in the holes. On the 218, the bolts go in from the engine side, NOT SO on the 230! the bolts have a non threaded shank that fits the holes. Pete

|

|

|

|

|

Joined: Jun 2005

Posts: 599

Major Contributor

|

Major Contributor

Joined: Jun 2005

Posts: 599 |

4-bolt... not 8-bolt?

Is that an easy identifier? I don't think I've ever seen anything other than an 8-bolt...

|

|

|

|

|

Joined: Feb 2001

Posts: 144

Contributor

|

Contributor

Joined: Feb 2001

Posts: 144 |

Originally posted by Ray Bell:

4-bolt... not 8-bolt?

Is that an easy identifier? I don't think I've ever seen anything other than an 8-bolt... Ray- The pic I posted is the 218 crank that came out of my '50 Plymouth. As far as I know, all the 218 motors except fluid drive cars had four bolt cranks. The 230 and larger engines all had eight bolt cranks, and the bolts go in from the flywheel side, nuts and lock washers go on the engine side. There is also a difference in the thickness of the flange on the crank between the 218 and 230. The 230 crank has a 3/16" thicker flange, and the flywheel has a matching recess to accept the difference so that the starter aligns the same for both. Don Coatney used a 218 flywheel on his 251, and had to machine a 3/16" recess to mount his starter due to the flywheel being set back by that amount since the 218 flywheel doesn't have the recess where it fits to the crank. Pete

|

|

|

|

|

Joined: Oct 2003

Posts: 98

Active BB Member

|

Active BB Member

Joined: Oct 2003

Posts: 98 |

Pete is correct; I had to remove some material from the starter flange on the bell housing in my application.  I have put together a Desoto big block flat 6 using a Plymouth bell housing and flywheel. You can use a 4 bolt flywheel on an 8 bolt crankshaft as long as there is no fluid coupling (standard clutch). And in this application the nuts also go to the engine side.  I bought special bolts for the flywheel as I wanted to make sure the shoulder was long enough. I then had to cut the bolts to length.  I have put close to 5000 miles on my car after this install and it works well to date. Don Coatney

Don Coatney

|

|

|

|

|

Joined: Jun 2005

Posts: 599

Major Contributor

|

Major Contributor

Joined: Jun 2005

Posts: 599 |

Hmmm... well done... I wonder, by the way, if this one will ever look that good?  A friend just pulled it out of a farm shed where it's been for 30 years. But someone else got there the day before and got the bonnet (hood) mascot and the hubcaps. Oh, and the starter.

|

|

|

|

|

Joined: Nov 2006

Posts: 29

Active BB Member

|

Active BB Member

Joined: Nov 2006

Posts: 29 |

Ray, is that a standard deck lid "Down Under" or is that a custom, I like the radius on the lower edge, compared to the flat bottom on all the 46-48 sedans I've seen in the states

|

|

|

|

|

Joined: Jun 2005

Posts: 599

Major Contributor

|

Major Contributor

Joined: Jun 2005

Posts: 599 |

Undoubtedly standard... I believe there were many detail differences in the bodies here.

|

|

|

|

|