|

|

Joined: Nov 2006

Posts: 217

Contributor

|

Contributor

Joined: Nov 2006

Posts: 217 |

Gary,

Glad your making progress on the Jimmy. I ordered my pistons today and my unground cam is on the way to me. I think I'll have Dema Elgin grind it for me. Are you going to dyno your engine?

Ron

|

|

|

|

|

Joined: Oct 2006

Posts: 185

Contributor

|

OP

Contributor

Joined: Oct 2006

Posts: 185 |

Ron, I am not planning on dynoing the engine because of the turbo installation. I will probably run it on a chassis dyno like we did with the big block Chev. Have you purchased a transmission adapter yet?

|

|

|

|

|

Joined: Oct 2006

Posts: 185

Contributor

|

OP

Contributor

Joined: Oct 2006

Posts: 185 |

I just ordered pushrods today from Manton. They are 3/8" dia. x .095" wall thickness x 10-3/4" long. The next thing to purchase is the trans adapter and flywheel.

|

|

|

|

|

Joined: Nov 2006

Posts: 217

Contributor

|

Contributor

Joined: Nov 2006

Posts: 217 |

Gary,

I mailed a blank cam, 12 used and 12 new lifters to Dema Elgin this morning for him to grind. He's also testing the lifters for hardness and checking for the radius on the contact surface. I was very impressed with him after talking to him about my cam requirements.

Ron

|

|

|

|

|

Joined: Oct 2006

Posts: 185

Contributor

|

OP

Contributor

Joined: Oct 2006

Posts: 185 |

Ron, let me know how that comes out. I met Mr. Merrit from Humansville that other evening, he is coming back this afternoon. I loaned him the pattern for the copper intake/exhaust gasket. He is going to loan me his aluminum adapter plate so I can make a pattern of it. I got the pushrods from Manton last week, they look great. The engine is all but done. You need to come down this was some time, I'll take you for a ride in the Studebaker, it has a passenger seat with a seat belt.

|

|

|

|

|

Joined: Nov 2006

Posts: 217

Contributor

|

Contributor

Joined: Nov 2006

Posts: 217 |

Roy Merrit is a hell of a nice guy with lots of drag racing experience and a fantastic memory. We have his GMC block at the shop and awaiting pistons from JE. He and I are building almost the same engine. I finally had to use 308 inch Hudson rods and modify the hell out of them to get a decent piston in our engines. I'm still trying to get my money back from Howards but I'm not holding my breath.

I'll take you up on the visit. What's a good day to come down?

By the way, you can email me direct at "goldenri@aol.com".

Ron

|

|

|

|

|

Joined: Oct 2006

Posts: 185

Contributor

|

OP

Contributor

Joined: Oct 2006

Posts: 185 |

I bought an SFI approved flywheel for a big block Chevrolet, welded up the dowel pin hole and had the center machined out to the diameter of the GMC and the 6 holes drilled to fit the GMC. Now I can work on the adapter plate.

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

GH and Ron, What are the updates on these engines? It would be handy to get all the info for these in one spot. What a resource and time saver. Vendors of gaskets, pistons, rods, cams, lifters, pushrods, rockers, etc. Interchanges for flywheels, dampeners, valves, springs would be great.

Ron did you get your ride?

GH, Is the Jimmy in the Stude?

What trannys were you adapting?

Thanks, Beater

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Oct 2006

Posts: 185

Contributor

|

OP

Contributor

Joined: Oct 2006

Posts: 185 |

Beater of the Pack, my GMC is completed as far as I can go before it goes into a car. I have offered my 53 Stude up for sale. I am planning on building a new car for the GMC 6. Copper head gasket from Horsepower Engineering, pistons from Venolia, rods from Howards, cam reground from Donnie Johansen, stock lifters resurfaced, pushrods from Manton, stock rockerarms, ATI super dampner, SBC valves and springs, big block chev flywheel reworked. All balanced with Cloyes timing set that is not marked correctly for the GMC, you have to degree the cam and remark it.

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

GH, Thanks! I'm in the process of planning a 302 build to run at Bonneville. It will be in a GMC pickup, the most time & $$$ friendly for me at this time. I like Studes too My son drives a '54.

Last edited by Beater of the Pack; 11/18/08 08:35 PM.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Nov 2006

Posts: 217

Contributor

|

Contributor

Joined: Nov 2006

Posts: 217 |

Beater,

321" GMC (+0.125")Block is filled with HardBloc to water outlet.

308 Hudson rod (8.115" C-C)

0.880" Pontiac pins, 84 grams lighter than GMC.

JE 11.5:1 piston (400 grams lighter than GMC)

Stock main brgs.

CR90P rod brgs ( 1940-1950"s Chrysler)

2.02/1.60 SB Chevy valves

#983 cylinder head, ported. 264 cfm @ 0.600" lift

Dema Elgin did the cam based on everything else in the engine.

I wouldn't consider anyone else grinding a cam for this engine. Pulls like a freight train above 3500 rpm.

Aluminum roller rockers we made. (1.85:1 ratio on a 1.00" shaft)

I saved 1.25 POUNDS per cylinder with the piston/pin/rod.

Bearings look good after 20 pulls on the dyno and 6 runs down the strip.

Smith Brothers Pushrods, Bend, Oregon. 5/16, 0.125" wall. Beautiful work and delivered on THE day promised.

My partners and I threw together a set of zoomie headers for the car so we could make the nostalgia race. That hurt the low-end TQ. This winter I plan to get the engine back on the dyno and build a 4x1 header and a better intake manifold.

Hope this helps.

Ron (Goldenri@aol.com)

Last edited by Ron Golden; 11/19/08 01:30 AM.

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

Ron, thanks for taking time to post this! It is exactly the kind of information I need. You and Gary have helped a lot. Man 1.25 lbs. Per cylinder. I'd sure like to see/hear it make a pass! how far do you take it above that 3500 rpms? I'm going back through old posts looking for info and sorting piles and drawers of parts to see what I need. Thanks again, Tom

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: May 2000

Posts: 1,464

1000 Post Club

|

1000 Post Club

Joined: May 2000

Posts: 1,464 |

Gary, I found the same problem on some Cloyes gears for the 300 Ford. The advance and retard keyways were marked incorrectly.

FORD 300 inline six - THE BEST KEPT SECRET IN DRAG RACING!

|

|

|

|

|

Joined: Nov 2006

Posts: 217

Contributor

|

Contributor

Joined: Nov 2006

Posts: 217 |

Tom,

Glad to help. We redline the engine @ 6000 just to be safe. With the piston/rod/pin weight reduction and Fluidampr I think the crank will be safe at that rpm. By the way, a SB Chevy Fluidampr bolts on without any modification.

Panic,

I'll look for some pictures of the combustion chamber.

8.115" is the stock 308 Hudson rod C_C and the CB-90P bearing fits the rod without modification. You will have to turn the GMC rod journal to the Hudson size and narrow the rod to fit the GMC rod journal. The small end of the rod will usually hone to a Pontiac pin. I had to get Pontiac pins that were 0.884' (0.004 oversize) because I screwed up one of the rods and honed it too much.(asleep at the wheel).

If you port the head you need to get the intake valve lift above 0.600" to make the best power. In that case I'd talk to Dema Elgin to get the best cam.

Hope this helps guys.

Ron

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

Thanks Ron, Where else would racers share hard learned "secrets" with guys that might turn up in the next lane? With me it's all for fun. I gave up being famous a while back! Right now I just want to make a serious pass on the salt. Then I'll get Pissy!

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

1.94 intakes from a 235 Glide head can be made to work. Also 2.02 or larger can also be made to work from a SBC.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

Bill Fisher recommended 1 15/16" intake and 1 11/16" exhaust valves in all 4 styles of GMC heads. That's 1.9375 & 1.6875. There were no SBCs back then so I don't know if he would have used the 2.0 valves.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

Im speaking of today's technology. Im going to flow my GMC head with the 2.02's and even 2.05's to see what the max is that can be achieved. Plus, adding "lumps" to both the 235 and GMC head will help im sure.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

I'm with ya'! I'm really interested to see what the lumps do.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

Yeah, the siamese exhaust is fair, but the single port is pretty bad! There are several companies that have the common SBC valves with a blank stem so you can cut your grooves if you choose to. Im also going to test a 5/16" stem and 7mm just to see what the airflow advantage is for these heads. Its pretty substancial on SBC race stuff, and with these heads, any extra you can get, is that much more than you had. Overkill maybe, but thats the point of this exercise, to take these heads where no man has gone before....

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

The GMC valves have a 0 degree angle relative to the deck. The Chevy head has the exhaust valve angled, but not canted. I dont have the Chevy head handy to check the angle of it right now, but I can if you need it. I have already plotted all the valve centerlines on the GMC head, and the intake and exhaust ports and bolt holes so I can make header flanges and intake flanges for sheetmetal intakes...

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

Probably will have to be custom made.As you mentioned there isn't really anything close to working or even modified. Since I have CNC capability,and could design something pretty quickly with my CAM software, I was going to buy some cheap roller rockers just to rob the roller tips and axles, and pushrod cups out of, and at some point make the shaft stands and shaft similar to what Ron did with his GMC.....at some point in my spare time(ha ha)!

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

I love this! I don't understand it, but I love it!

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

Once again I'll get a little sappy and say what a great thing it is to be privy to these discussions and to have guys take time to educate those of us who need it. I literally grew up in the "garages" my dad worked in and the parts houses and automotive machine shops where he had free run of all resources. Also my uncles service stations and wrecking yard. I know a lot about some things but there are HUGE holes in between knowledge pockets! This is like looking over Wayne Horning's shoulder while he's talking to California Bill. Well for me it is! This is exactly why I joined Inliners. Thank you to all who are posting here and sharing your hard won expertise!

Last edited by Beater of the Pack; 12/16/08 02:33 AM.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

I am going to make a rocker stand similar to what Jesel makes,and eliminate the factory type shaft. You could either drill and tap the plate for rocker studs or use a more modern shaft mount rocker like they offer as well. You can block off the oil port in the head, and use conventional oil-thru-pushrods to get the oil to the rockers. Of course you will also have to have oil-thru-lifters to do this. That is also an area I am looking into, boring the existing lifter bores to use modern SBC type lifters(roller)and hyd. and flat tappet as well. BHJ makes a lifter-tru plate to correct the lifter bores for the SBC's, I've used it many times, and am considering making one to do this for the Stovebolts and GMC's. That would open up many more doors of opportunity for cam choices, as well as provide a more economical way to use a roller cam in these engines....

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Jul 2004

Posts: 365

Contributor

|

Contributor

Joined: Jul 2004

Posts: 365 |

Lifter bore is the same as the early Chevy at just a tad under 1 inch, you could use the lifters out of a Keith Black hemi!. The hardest part is finding a rocker long enough to bridge the distance as they are longer than even a BBC or Ford. Arias and Jerry Weigt both make roller rockers.

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

Its common to install brass bushings into the bores after you correct the lifter bore centers with the BHJ fixture. So you have the option of make it accept any lifter size that you want to. The purpose is to provide a commonly available inexpensive roller lifter to help offset the added expense in other areas of the roller setup! Where would you find an application specific roller lifter for a 235/261? Isky can make a set for a Flathead Ford for $600,the Stovebolts and GMC's would fall into that same price category as well. A SBC is 1/2 that much or less! You can find them used all day on Ebay for $100-$150 bucks. You cant even find Stovebolt ones at all. So it definately provides a new venue for them to explore, and hopefully raise the HP potential for them....

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

Just preference mostly. Most anything with Hemi attached to it also carries many more $$$$$, Chevy stuff is more common used if someone prefers that route, but the size itself is insignificant, its the open door to apply this technology to these engines that is being overlooked. It is the route I personally am going to use,and if others choose a different approach for their needs or tastes, then they can take it.There are many lifter size possibilities that can be used, I just prefer the SBC/BBC size.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Mar 2007

Posts: 92

Active BB Member

|

Active BB Member

Joined: Mar 2007

Posts: 92 |

I think there is some HP gains by straightening the lifter holes. As I mentioned in another thread when I put my mule motor on my friends spintron, I was shocked by all the movement in the valve train. The end rocker wobbled and their was almost a 2% deflection. Thats why I built a girdle for the rockers, basically the bottom half of my valve cover. For all out racing applications valve terrain stability among other things is key.

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

I think before we are through, we will have uncovered many things people didn't think was possible with these engines! I have always thought that a more rigid platform for the rockers would be a benefit. I think if you made a plate to bolt to the existing rocker stand bosses, you could also make a similar pedestal mount shaft rocker like Jesel offers, or install a conventional rocker stud setup and put a stud girdle on it if you still need more support for deflection. It would have to be an improvement, especially if increased spring pressures are used in performance cams, and even with rollers like we are discussing...

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Mar 2007

Posts: 92

Active BB Member

|

Active BB Member

Joined: Mar 2007

Posts: 92 |

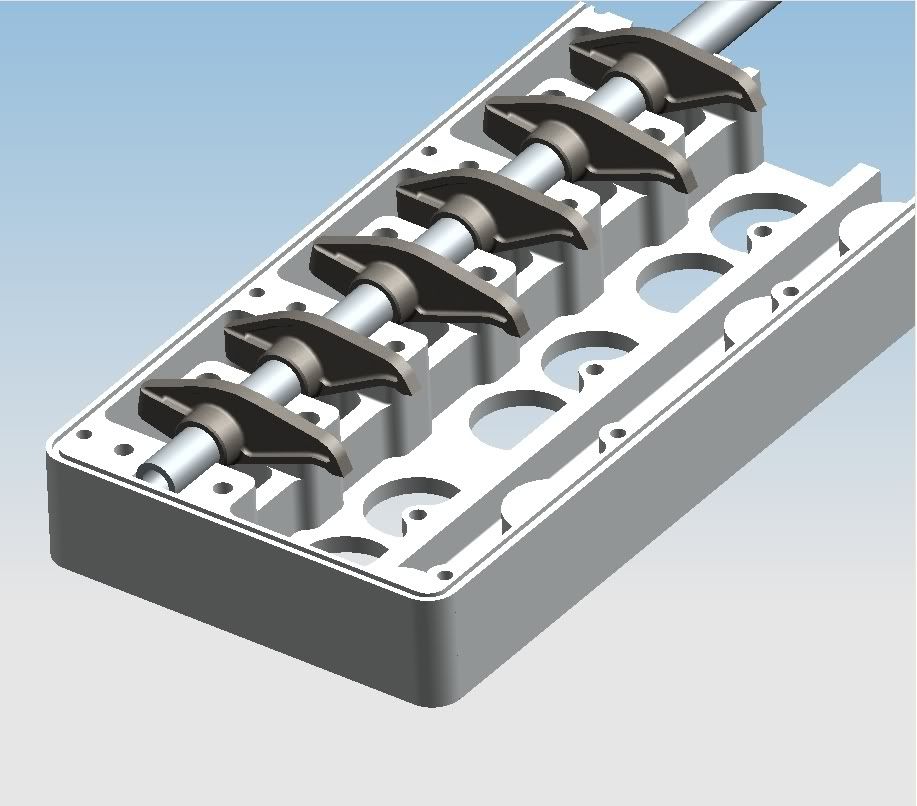

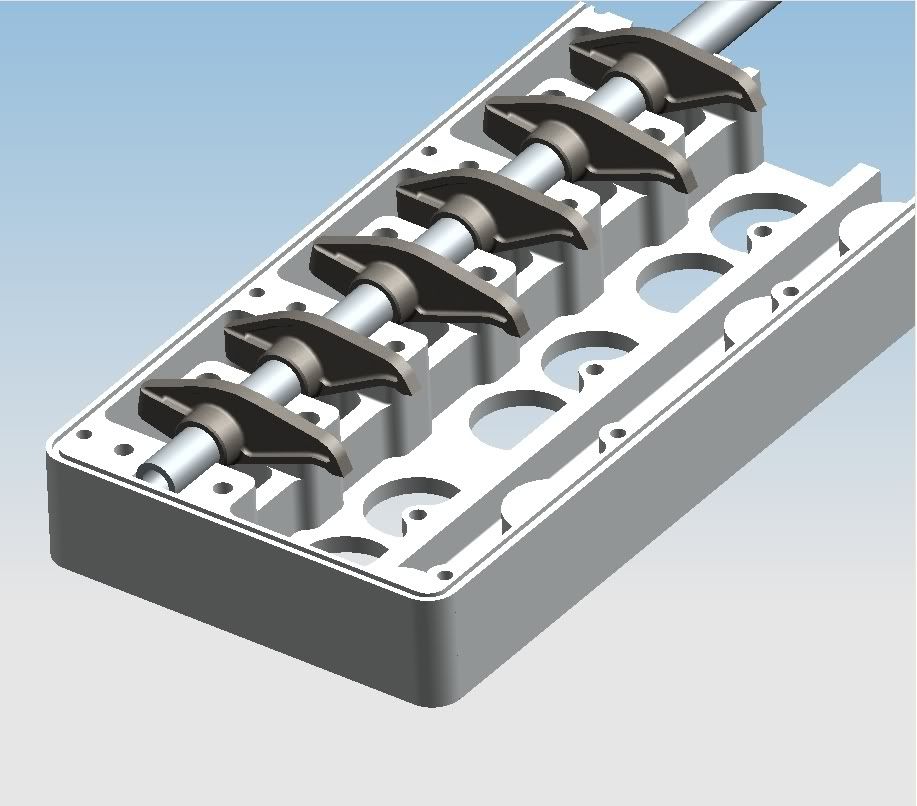

This is what I did for my rockers and girdle. After running the design through a FEA program the rocker came out looking very similar to the Del West Style thats in NASCAR. The shaft is also smaller than a stock GMC. A lot of work on a spintron went into this.

|

|

|

|

|

Joined: Jun 2007

Posts: 1,411

1000 Post Club

|

1000 Post Club

Joined: Jun 2007

Posts: 1,411 |

I'm confused:

"boring the existing lifter bores to use modern SBC type lifters" (smaller than .842") vs.

"just a tad under 1 inch, you could use the lifters out of a Keith Black hemi" (.904")

I thought the .901" was a standard Chrysler size (B-RB, some Hemis) I'm not sure about the A-LA, but the Magnum small blocks (5.2/5.9, 4.7 probably, but don't know if it's the same diameter) were suposedly roller equipped. Anyone know their lifter diameter?

My, what a steep learning curve. Erik II#5155

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

This is what I did for my rockers and girdle. After running the design through a FEA program the rocker came out looking very similar to the Del West Style thats in NASCAR. The shaft is also smaller than a stock GMC. A lot of work on a spintron went into this.  Thats a nice looking set-up! I would say that is plenty ridgid enough. What ratio rocker did you end up using!

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

The stock 235 lifter size is around .990! Most of the time when you correct the lifter bores in a SBC with the BHJ Lifter-Tru plate, you obviously go to a larger diameter to correct the angles and centerlines of the lifter bores.Then you install brass bushings into the oversized bores to retain the SBC .842 lifter size. Also using a .875 Ford lifter in a SBC is also a popular mod as well.You will need to bore to over 1"(depending on bushing OD), and then bush it back to .904. Compare a set of new SBC roller lifters to a new set of Chrysler roller lifters! Chevy is still less expensive. It still opens the door to make any number of lifter size selections you choose.

Last edited by CNC-Dude; 12/05/08 03:32 PM.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Jun 2007

Posts: 1,411

1000 Post Club

|

1000 Post Club

Joined: Jun 2007

Posts: 1,411 |

I've seen a block (alloy SBC) with those bushings. Would there be enough metal around the lifter boss to move it that much?

I ask as I figure you would have to go with a billet cam core or one that's been hard faced. I don't know which would be cheaper. As there isn't a large market for the billets and you would likely want a larger base circle (with a commensurate larger core diameter to stiffen the cam) a custom billet could be made to bring the lobe directly under the tappet. As the flat tappet lobes are offset from the center of the lifter bore some to facilitate tappet rotation (or at least it looks like it).

That would reduce the need to offset the bores as far.

Would you want to use a vertical link style roller tappet, or the kind with the rivets in it to engage a raceway (keyway, pilot groove, ???)? The riveted ones are somewhat more expensive (from what I've seen) but you wouldn't need custom link bars for them (not sure it that's a big enough PITA to care about when you're that far in).

My, what a steep learning curve. Erik II#5155

|

|

|

|

|

Joined: Jul 2004

Posts: 365

Contributor

|

Contributor

Joined: Jul 2004

Posts: 365 |

Stock Chrysler Hemi's use a .904 lifter. Keith Black and many others use a 1 inch lifter, so do some Fords (I think). GMC 302 Lifter bore = .9905 - .9915 Lifter diameter = .989 - .990 clearance = .004 There is a link here at Inliners that will take you to the Classic Truck site where all this is listed. http://www.oldgmctrucks.com/page0311.html

Last edited by Armond, II#298; 12/05/08 03:32 PM.

|

|

|

|

|

Joined: Jul 2004

Posts: 365

Contributor

|

Contributor

Joined: Jul 2004

Posts: 365 |

I just took a quick look at my Jimmy block and it looks entirely possible. It will be close next to the main bearing web but will fit. Another idea would be to use 1 inch .125 wall aluminum tubing to make your lifter bushings. It is a good bearing material (like VW cases) and is much cheaper. Maybe a chamfer up top to hold oil next to the lifter. What about the push rod tips?

|

|

|

|

|

Joined: Jul 2004

Posts: 365

Contributor

|

Contributor

Joined: Jul 2004

Posts: 365 |

Well, a stock Jimmy pushrod is 12 and 13/16ths inches long and the head has a .550 inch hole for it to pass through. One would have to be very careful to use a cam that will match the lifter material as Jimmy's used both steel and cast iron cams throughout the years. Tom Langdon at Stovebolt would be a good person to ask. Personally, I'm sticking to the 1 inch roller lifters on my work bench and with Jesel style rockers. Good luck

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

Reason for my question: There is an intermediate step (not "green", and no longer favored as an advantage) that has been used for 75 years - the mushroom tappet. The maximum velocity a flat tappet can reach (which determines how much valve open area you can fit into a specified duration) is roughly proportionate to the tappet's contact surface length: Maximum velocity per degree Of rotation = (tappet diameter - .040”)/114.6so the .904" and .875" are favored over the .842" for V8 because they allow hotter profiles. For many V8s this has limits because the tappets are so close together, but it appears that the stovebolt & GMC spacing is more generous. There is no complex machining, because the gallery appears fairly open and only clearance to permit the upper (non-critical) surface of the "foot" to rise farther. The cam can be any cam that works as to material (no steel, billet, etc.), but the grinds can be far more aggressive, especially the "split" between nominal IVC vs. effective (.050") IVC (which balances compression bleed-down against inertia fill), and nominal EVO vs. effective EVO (which balances pumping loss against duty cycle %). How about the tappet price? Just use the VW Type I (air-cooled opposed 4) 31mm (1.22", over 24% more area than a .990" stock tappet) mushroom, still made new & cheap by EMPI, by bushing the tappet opening down to .748" (19mm). The tappet still rotates as normal with the tapered lobe. No linkage, no tie bars.  I myself, had completely forgotten about the mushroom tappets as an inexpensive alternative,good thinking! Someone that didn't want the expense of trying to use a roller setup, might explore that possibility.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Jun 2007

Posts: 1,411

1000 Post Club

|

1000 Post Club

Joined: Jun 2007

Posts: 1,411 |

The VW tappets are an interesting option, I see your picture is of the high perf ones with the direct lobe oiling (nice holes  ). I would still expect the cam core needs to be bigger (to stifen it) if you are building a race engine, as that's what I keep hearing / reading. Stands to reason as long as it is.

My, what a steep learning curve. Erik II#5155

|

|

|

|

0 members (),

325

guests, and

48

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

|