|

|

Joined: Sep 2004

Posts: 5,839 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,839 Likes: 1 |

I have divided a port on my 250 cyl head,it would just kill flow.

The intake port window was too small in doing so.

Only way to make it work good was to make the ports so wide & tall, it would not be made for the street,only for all out racing.

I also talked w/Mike Kirby about dividing the intake ports & he comfirmed my findings as well.

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Sep 2004

Posts: 5,839 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,839 Likes: 1 |

next i will open up the top of the port and the sides to gain back some port volume or runner size. maybe try to do it yet this year to try it. 2nd , i will pull out the bolt in lumps and keep the dividers to make the runners even larger.

tom

Hey Tom just curious if you had done those mods to your cylinder head yet & tried it out? Thanks MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

Hank, your right, it will kill the flow if you leave the lump in the port. And removing the lump, doesn't hurt as much as you have been lead to believe it does.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Sep 2004

Posts: 5,839 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,839 Likes: 1 |

I figured this much.

I had installed port deviders & it did not flow well @ all on a flow bench machine.

Turbo6 (Harry) installed port deviders on his turbo ride for better fuel distribution (he's running carbs)it help his engine from running lean on a couple cylinders ,but had to crank up the boost pressure to make the same HP as before w/out the deviders he installed.

This boost increase was needed because when you install deviders on the intake ports,your intake port window will be too small to flow well.

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Apr 2004

Posts: 3,556 Likes: 35

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2004

Posts: 3,556 Likes: 35 |

Hank,

Have not done it yet. Had the Elco running 2 weeks ago when it was 12 degrees. Been too busy with everything else to take it down. It will get done yet.

Do you remember what your divided head was flowing? Remember, the flow bench can't tell all. Tom

Last edited by tlowe #1716; 12/20/09 06:10 PM.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Dec 2005

Posts: 452

Contributor

|

Contributor

Joined: Dec 2005

Posts: 452 |

Guys,

All of us are guilty of just looking at the peak CFM of head flow, the head has to do a lot more than just flow air.

My 12 port flows 25% less air than my bump port but makes more power. At first I had the boost turned up thinking I needed to compensate for the less flow. But now I am down from 36 psi to 25 psi and going faster, I have changed something on the fuel system that may have the problem with the more boost will find out this spring.

The car is apart to change the roll cage to make it legal for the 9's also on the last run of this year the cast cam broke and took out the engine and trans.

So I have a lot of work till spring.

Harry

Turbo-6

|

|

|

|

|

Joined: Sep 2004

Posts: 5,839 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,839 Likes: 1 |

Guys,

My 12 port flows 25% less air than my bump port but makes more power.Harry Harry, is that 25% less flow with the bump port & intake port deviders you installed? Sorry to hear the engine blew,that sucks. MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Sep 2004

Posts: 5,839 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,839 Likes: 1 |

Hank,

Have not done it yet. Had the Elco running 2 weeks ago when it was 12 degrees. Been too busy with everything else to take it down. It will get done yet.

Do you remember what your divided head was flowing? Remember, the flow bench can't tell all. Tom Tom, I would have to find the flow numbers,this test was done in the mid 80's. When you have too small of an intake port,dose not matter how much air you are trying to pump in there, that will be a restriction no matter how you look @ it. The siamesed port is breathing from two intake ports,so you cannot compare the two heads,a 12 port head & a siamesed port head. Now if Harry devided his siamesed port & made it a 12 port,then you can compare the two on a flow bench,then that would be a better comparision. I will go out on a limb here & say Harry did not flow test his head w/the port deviders & flow 25% more than the 12 port Brazillian head,but that's just a good guess from me I think,but what do I know, my 2 star rating shows I don't know much @ all. ;-) MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

Hank, heres what I know about dividing the ports on a siamese head. In around 1999 or 2000, my good friend Darren Davis who raced and set many NHRA records in several Econo Altered comp classes, was always told by both Sissell and Headrick that dividing the port would never work. He had the idea to try this many times, but always let there advice keep him from trying it. At the close of the 19990 or 2000 race season, he was about to move up to Pro Stock Truck, and leave the 6's behind and move on. He dug a Sissell lump head out of his garage, and took a die grinder and ground the brazed lumps completely out of the head, and made a simple sheetmetal divider, and tack welded them to the header flanges, so they would protrude into the ports when you bolted on the headers. He said it made 50 HP more than the very best lump head he had ever had, and set another record on the next time at an NHRA event. Now, in 2009, no one that even races a Chevy 6 in any NHRA professional class uses a lump port head at all, for something like the lump to have been used so successfully for close to 3 decades by so many, how come it is no longer used in professional racing.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Sep 2004

Posts: 5,839 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,839 Likes: 1 |

Interesting CNC,

that was a normally aspirated engine correct?

When I was going w/forced induction I was not too concerned about peak airflow numbers,more influenced by what size the intake port window was.

I guess I was thinking outside the box also.

Do you have any pics of that cylinder head?

It would be intersting to see if your friend raised or widened the intake port or left it as stock size.

As far as lump port or not to lump port I still think it's a good idea for certain appliacations but not all.

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Dec 2005

Posts: 452

Contributor

|

Contributor

Joined: Dec 2005

Posts: 452 |

My sissel kirby lump port flowed the most of any head I have used.

My stock siamesed head w/ dividers flowed 25% less than the lump port head

My GM 12 port from Brazil flowed the same as the stock head w/ dividers.

I am not a head specialist, and I agree that the lump port improves the short side radius for increased air flow, but I also think the deduction of port size increases air speed and helps fuel mixture.

On a chevy 6 the port choke area is at the port opening like a small block chevy is at the pushrod area. The choke area determines at what RPM your port will become choked because the air speed goes to mach and VE drops real quick. If you keep the RPM below this number you will not have any problems.

I designed my intake to be an extension of the port so it mimics a small block chevy in that the port opening is large and tapers smaller then expands to the valve pocket, unfortunately it will not fit on the flow bench with the intake and exhaust as one part.

Since I run a turbo they like high gearing and I don't need to run a lot of RPM and can get by with a small port area.

This is just my thoughts and what works for me.

Harry

Turbo-6

|

|

|

|

|

Joined: Sep 2004

Posts: 5,839 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,839 Likes: 1 |

Thanks Harry, the stock siameded head w/deviders,,,that did not have a lump in the intake port correct? If you did,,I think the port window might look as small as this. http://img223.imageshack.us/i/p1010123gs8.jpg/ ,which I think is really too small, maybe not on a 194 CI engine. Just my thoughts also. MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

Hank, yes it was naturally aspirated. At that time, his engine made the most HP per cubic inch(2.14 HP/CI) of any N/A inline in professional competition at 535HP out of just 250 CID. The intake ports were in no way stock in size, it was a full tilt 320+ CFM head from Sissell from his peak time in his career, prior to his passing. So if you can picture the head Kirby has of ours that you've mentioned before, just think of the floor being ground out to the point of it being before you put the brass in it, and stick in a divider full depth. I know a racer currently that I have been trying to get some pics from, that is using this same technique, but has welded the divider in place. Of course, nothing is easy, you have to open to ports up, and im sure they are doing other trick things, but he is being vague in some areas, because it is still kinda' secretive to most of them that use it. But from what Darren told me he did 10 years ago, it ain't rocket science if he did it. He just took some tin snips and formed some dividers to tack weld to his header flange, and he saw a pretty big gain from doing just that. But like anything else, some amount of tweaking or R&D, might be needed to evaluate fully the best overall shape or style to make the dividers and ports.

But don't anyone get ahead of me here. I have always been Pro-lumps, either bolt-in or weld-in, because I have a pretty long background with that technology. But if you want to know what works, just look at what the top guy's are running and setting records with right now. There must be something to it, or they wouldn't be doing it, because they race to win, and if it doesn't win, they don't use it. If I can get some pics, i'll gladly put them on here so we all can give it a try.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Dec 2005

Posts: 452

Contributor

|

Contributor

Joined: Dec 2005

Posts: 452 |

No I did not use lumps in the intake.

A port 1" wide by 2" tall has a cross section of 2 sq. in.,

2 sq. in. port will support a :

230 @ 7000 RPM

250 @ 6400 RPM

292 @ 5500 RPM

after this RPM the port will go sonic and VE will drop.

this is a rule of thumb, you really need to measure the air speed

to know what it is, you do not want to go over .6 mach

Harry

Turbo-6

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

Harry, how thick is the divider you are using.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Dec 2005

Posts: 452

Contributor

|

Contributor

Joined: Dec 2005

Posts: 452 |

About 1/4 then widens out for the head bolt area.

Harry

Turbo-6

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

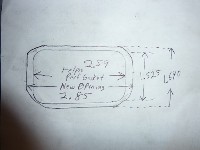

Ok, im doing a brazed head now that is 2.625" wide, by 1.625" tall, and was just curious as to how thick you were making the divider piece.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Nov 2004

Posts: 1,805 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Nov 2004

Posts: 1,805 Likes: 1 |

There is a fix for this head... it just happens to have 4 valve/cylinder....  and GM made it until 1 year ago....

51 GMC 4.2 turbo

Can't solved today's problems using the same technology/thinking that created them

|

|

|

|

|

Joined: Dec 2005

Posts: 452

Contributor

|

Contributor

Joined: Dec 2005

Posts: 452 |

REAL MEN USE PUSHRODS !!!

Just kidding, just kidding

I only wish GM would have kept the original design that Falconer has now. With chevy bell housing etc. But multi

valve heads are the future, anyone just starting out would be nuts to start with anything less.

What's Ironic is back in 1963 when I started the 250/ 292 style had just came out and I thought why are guys still using the old style 235/261 engines now I know.

Anyway as long as it's an INLINE It's cool.

Harry

Last edited by Turbo-6; 12/21/09 09:28 PM.

Turbo-6

|

|

|

|

|

Joined: Sep 2004

Posts: 5,839 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,839 Likes: 1 |

I dont think GM is doing too bad with there 2 valve heads. Stock corvette heads flowing 360 -380 cfm Edelbrock is comming out w/newer replacement heads that will bolt on LS1, LS2 & LS3 blocks & will flow over 400 CFM All pro LS heads been flowing over 400 + cfm 2 valve head. 4,5,& 6 head bolt pattern. Look @ the new Corvette run a 10.7 all stock http://www.youtube.com/watch?v=woOqqfGtqHo&feature=player_embeddedMBHD

12 port SDS EFI

|

|

|

|

|

Joined: Dec 2005

Posts: 452

Contributor

|

Contributor

Joined: Dec 2005

Posts: 452 |

Don't get me wrong I am the biggest small block chevy fan there can be, but in 54 years of R&D it's not much better than a STOCK 4 valve.

When a toyota 180 cu. in. inline 6 can run 6.2's @ 250 MPH in a full bodied car it makes me think .

Harry

Turbo-6

|

|

|

|

|

Joined: Sep 2004

Posts: 5,839 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,839 Likes: 1 |

Just some FYI from a friend.

MBHD

Airspeed in the port will be dependent on demand vs' cross sectional area and length. The "Mach" number will vary along the entire port with the density of the fuel air mix and temp.

It is true that going over a certain "Mach" number will take more energy than you get back and at that point you would start to try to slow down the air.

That is why sometimes engines will make more power with a port that is larger that flows no more air than a smaller one however they do become much more camshaft sensitive.

As to the 2 sq. in. port on the respective engines that would depend assuming the same manifold then the camshaft is what will determine the airspeed for each combo.

As you add duration the airspeed at any given RPM will drop in the port. So each one of the displacements with the same port area could have similar velocities at the same

RPM given different cams (larger In the larger engines)

12 port SDS EFI

|

|

|

|

|

Joined: Dec 2005

Posts: 452

Contributor

|

Contributor

Joined: Dec 2005

Posts: 452 |

Hank,

Please ask your friend a question for me.

As I understand, that when a port goes sonic you need to keep the intake open longer. Does this mean if you close the intake later you can turn more RPM without going choke and lose any power?

As an example: On a 292 chevy with a 2 sq.in.choke area on the intake port the engine will go "mach" at 5500 RPM.

What additional duration do you want and should the exhaust duration follow this increase ?

In fact using this port area what should the cam specifications be for this engine for max performance, the controlling factor being the intake port?

Also what RPM increase would this allow you?

Thanks Harry

Turbo-6

|

|

|

|

|

Joined: Sep 2004

Posts: 5,839 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,839 Likes: 1 |

Harry,Turbo6

His reply,

As a general rule any increase in duration on the intake will lower the velocity so you must balance the area of the port relative to the demand (engine size/RPM)

If one starts out with an engine that has a port designed for limited RPM/HP as in the Chevy 6 cylinder it takes a larger than ideal cam to extend the torque curve (at least with stock type heads) to get to the higher HP numbers.

Most engines of these designs will push the torque up the RPM range about 500 or so as you add 7 to 10 deg. but it also depends on the lobe separation as you start to get to a point of having so much overlap that the type and tuning of the intake and exhaust will narrow the range that runs well in.

Any normally aspirated engines possible power output is limited by the cylinder heads ability to get air into the cylinder and of course the block,crank,rods and pistons capacity to hold together.

But even a well designed engine with the wrong tuning cam,carb and or ignition can run like crap.

As to exhaust relative to the intake it comes down to how well the exhaust leaves. Many 4 valve head motors and small engines that have large breathing capacity like motorcycle engines or the air cooled 911 Porsche motors you see cams that have less timing and lift on the exhaust side as they "blow down" very quickly.

On engines like the 6 cyl Chevy a single pattern can sometimes be used to help make a FAT torque curve but at the expense of top end. adding exhaust duration will extend the torque curve but will soften the rise some.

You will have to decide the real RPM range the motor needs to run well in based on weight,gearing,converter/clutch and how you will be using it.

Remember that the cylinder pressure needs to be within an effective range and load/use at the RPM you want it to pull well at. So a camshaft that might work at 5000 RPM with 9 to 1 compression on pump gas will not be the same as one with 15 to 1 compression even at the same RPM.

The standard for race engines is as much compression as the fuel can take and cam to make the highest torque within the range it runs the most.

Use the lobe separation for width of the powerband (wider will make less peak torque over a broader range) The intake duration and lobe center to tune the peak torque RPM and exhaust duration for over-rev peak HP

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Dec 2005

Posts: 452

Contributor

|

Contributor

Joined: Dec 2005

Posts: 452 |

MBHD,

Thank your friend for the information I really appreciate the help. The lobe separation is what I was thinking about but did not know how much duration to add, and how much it would change the power band.

Harry

Last edited by Turbo-6; 12/28/09 12:57 AM.

Turbo-6

|

|

|

|

|

Joined: Apr 2004

Posts: 3,556 Likes: 35

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2004

Posts: 3,556 Likes: 35 |

On my Bridgeport now, there is a head getting the intake port widened and the roof raised. Over 1/4" wider and 3/16 taller to start. Not going into water either. Next, a nicer port divider will be made. This head is planned to be tested on the dyno 250, I also have a divided intake that could be tested.

Velocity should still be good as the individual port will not be too small or too large. May get pic's on Sunday. Tom

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Apr 2004

Posts: 3,556 Likes: 35

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2004

Posts: 3,556 Likes: 35 |

Here are the pic's, remember this is still on the Mill and not been dressed up (at all). Raised the roof and broadened the sides. Next a bolt in port divider will be made. Any ideas on how to mount it? If the divider is 1/8" thick the ports will be 1.3625 wide X 1.64 tall, giving a 2.2345 sq in opening. What will the port velocity be then?

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Sep 2004

Posts: 5,839 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,839 Likes: 1 |

Mount in some way that I mounted my upper lumps.

An outside bolt through the top of the port where you install your pipe plugs.

Short bolt w/a location pin.

You do not need the devider plate to be just a flat piece of plate aluminum or steel,you can have a little extra material towards the top of the port for mounting a bolt to install.

It does not hurt airflow to have a little bubble of material extra for the a mounting bolt or some type of fastener.

Hope that makes sense.

Port velosity will go up w/the devider, but I think you will find the cfm will go down,because now you will only be flowing from one port instead from the two w/out the devider.

Also you do notice there is not much material left for sealing.

I had opened up my intake port larger than yours is w/even less material for sealing the intake manifold,& it still did not flow that great & was not practicle for me to run it that way for a street car.

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Dec 2005

Posts: 452

Contributor

|

Contributor

Joined: Dec 2005

Posts: 452 |

Tom,

Back in the 60's I had bolt in dividers, and they were held in by the pipe plug at the top. I made a washer about 3/16 thick with a slot in the bottom of it to hold the divider, it went in first then the pipe plug. But my dividers had a wing shape that flared out, back in the bowl area and this helped to hold it in place, the pipe plug and washer just kept it from falling over, worked very good.

As far as air speed I need more info:

cfm@28"

cam lift

cross section area

Mach index:

bore

valve dia.

RPM

stroke

cam lift

cfm@28"

cross section area

Choke point from RPM:

RPM

bore

stroke

Max RPM from cross section area:

cross section area

bore stroke

Example: your cross section area will support a 292 to 5900 RPM and a 250 to 7000 RPM both with 4" bore and stock stroke.

Good Luck

Harry

Turbo-6

|

|

|

|

|

Joined: Sep 2008

Posts: 3,669 Likes: 42

1000 Post Club

|

1000 Post Club

Joined: Sep 2008

Posts: 3,669 Likes: 42 |

Example: your cross section area will support a 292 to 5900 RPM and a 250 to 7000 RPM both with 4" bore and stock stroke.

Good Luck

Harry

Those #'s from your cross section seem about right for most any of either size engine you would want to test within reason.

Class III CNC Machinist/Programmer

|

|

|

|

|

Joined: Apr 2004

Posts: 3,556 Likes: 35

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2004

Posts: 3,556 Likes: 35 |

Chopped up a cracked "194" head. Making the new port plates fit this head and then modify the runner head. Will run the divided head with both a standard intake and a divided intake.

No lumps will be installed. Tom

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Sep 2004

Posts: 5,839 Likes: 1

1000 Post Club

|

1000 Post Club

Joined: Sep 2004

Posts: 5,839 Likes: 1 |

Cool,

by stateing standard intake & divided intake,what intake manifold ,cast iron 1 barrel?

MBHD

12 port SDS EFI

|

|

|

|

|

Joined: Apr 2004

Posts: 3,556 Likes: 35

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2004

Posts: 3,556 Likes: 35 |

Standard intake will be a Offy and clifford, meaning not divided. For divided intakes , have a Clifford and a as cast Brazilian intake.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Dec 2005

Posts: 452

Contributor

|

Contributor

Joined: Dec 2005

Posts: 452 |

Tom, I thought you sold that Brazilian intake, do you have another one? What is the dimension from head intake surace to outside of carb flange in the center of the manifold ?

Harry

Turbo-6

|

|

|

|

|

Joined: Jul 2000

Posts: 4,585 Likes: 19

1000 Post Club

|

1000 Post Club

Joined: Jul 2000

Posts: 4,585 Likes: 19 |

He also has their web intake which came from Mrhotrod6.Which another guy bought and had drop shipped to him.For his 250 testing.

Larry/Twisted6 [oooooo]  Adding CFM adds boost   God doesn't like ugly.

|

|

|

|

|

Joined: Apr 2004

Posts: 3,556 Likes: 35

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2004

Posts: 3,556 Likes: 35 |

Yep , mentioned that in the 250 dyno posts already. That is not a divided intake though.

The Guy that bought it deserves all the credit for getting it to me. He is reaching out to help from New Zealand. Tom

Harry, PM me or give me a call. Tom

Last edited by tlowe #1716; 01/18/10 12:11 PM.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Dec 2002

Posts: 69

Active BB Member

|

Active BB Member

Joined: Dec 2002

Posts: 69 |

Tom, glad to see you are going to use a divided runner intake on some of your dyno tests. Years back I had a '66 chevy truck with a 292 and 4 speed that I installed an Edelbrock SP2P intake manifold on. It was advertised as a fuel mileage manifold but the increase in low and low midrange torque was noticeable and the fuel mileage improved also. The engine was stock except for a split exhaust manifold and the Edelbrock manifold was set up to use the stock 1bbl carb. I'll be interested to see how the Brazilian manifold works with your port dividers.

Gordy

|

|

|

|

|

Joined: Aug 2009

Posts: 52

Active BB Member

|

Active BB Member

Joined: Aug 2009

Posts: 52 |

Well is anything new on the intake port dividers.

|

|

|

|

|

Joined: Mar 2010

Posts: 623

Major Contributor

|

Major Contributor

Joined: Mar 2010

Posts: 623 |

Man. I just read the second page of this and my lack of knowledge depresses me.

69 Buick Special Deluxe. Intercooled Turbo Chevy 250 @ 15psi on a stock long block. It's kinda fast.

|

|

|

|

|

Joined: Dec 2005

Posts: 452

Contributor

|

Contributor

Joined: Dec 2005

Posts: 452 |

Snowman, don't give up a TURBO more than makes up for all of this BS.

Cracked my Brazilian head but it did't work any better than my stock divided head so I'm back to one of these, until I get my 12 port from Mike Kirby.

St.Louis area lost it's track anyway so I put my street tires back on for this summer, too busy to travel this year anyway.

Did run a 9.61, last run last day track was open this past October.

Good Luck

Harry

Turbo-6

|

|

|

|

0 members (),

300

guests, and

38

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

|