|

|

Joined: Apr 2007

Posts: 7

Active BB Member

|

OP

Active BB Member

Joined: Apr 2007

Posts: 7 |

Can I take the head off a 235 and put in on a 261? What is the difference?

|

|

|

|

|

Joined: Feb 2009

Posts: 73

Active BB Member

|

Active BB Member

Joined: Feb 2009

Posts: 73 |

Go to the left side bar, Tech tips - forgotten 261 & follow link to Jim Carter article.

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

All 18 bolt heads can be swapped, but there are some valve gear and oiling differences.

|

|

|

|

|

Joined: Dec 2006

Posts: 39

Active BB Member

|

Active BB Member

Joined: Dec 2006

Posts: 39 |

The 261 has siamesed cylinders and has steam holes drilled in the head for that reason. Many people use a 235 head but drill those steam holes using a 261 head gasket as a template. It is all in the article mentioned earlier.

|

|

|

|

|

Joined: Apr 2007

Posts: 92

Active BB Member

|

Active BB Member

Joined: Apr 2007

Posts: 92 |

The 261 has siamesed cylinders and has steam holes drilled in the head for that reason. Many people use a 235 head but drill those steam holes using a 261 head gasket as a template. It is all in the article mentioned earlier. The article says nothing about drilling the steam holes. Examine your 261 head and you will notice the steam holes are drilled on a 12 degree angle from the head face. If they are drilled straight in using a gasket as a template there is a good chance that 3 of them will not intersect the jacket and be of no use. If you have drilled in 7/8" and still not broken thru you are drilling into the port roof and may ruin it all together. In some places this process contains high drama... Here's a quote from the pre 1958 driveline forum at Canadian Poncho: What ever you do DO NOT USE A 235 HEAD ON A 261 BLOCK! Do not, do not, do not do it brother. If you do you will be crying, kicking and doing a lot of swearing. The 261 had steam holes that surrounded the bores and also had steam holes that matched up on the cylinder head. The 235 did not have these holes in either the block or head. The 235 head will bolt up but, and here is the BIG BUT! Your motor will over heat real bad my brother. 261 motors ran hot normally, hotter than the 235 because the 261 not only had a bigger bore it also had a higher compression. This is the reason and only reason for the steam holes. Let me repeat myself DO NOT PUT A 235 HEAD ON A 261 BLOCK OR YOU WILL BE CRYING LIKE A LITTLE GIRL. That sweet motor will over heat real bad and then blow. You can drill the 235 head by using the 261 head gasket as a template. The only thing is you have to drill on a angle and unless you know what you are doing you will ruin the 235 head. Best thing is to just use the correct 261 head. I sure hope you are taking me seriously because if not you have my condolences on that sweet 261 of yours. I love these motors and have one in my 1957 Pontiac. Check out my 261 and my 57 Pontiac in Members Rides under "My 57 Ride". Good luck with your sweet ride. Cheers. George.

1952 Chev 1300 Cdn. Ĺ ton

|

|

|

|

|

Joined: Apr 2000

Posts: 540

Major Contributor

|

Major Contributor

Joined: Apr 2000

Posts: 540 |

I don't know about that head swap info...but....I drilled the steam holes on a #848 235 head.Drilled them straight in too,no problem.Ran that head on that engine for 5 years.

Panic mentions potential oiling problems when mixing rockers arms and such....Yes,bottom line from my experience is a .062 restriction must be somewhere in the feed to the rocker arms.That's the same size used by GMC which is located in the oil line fitting to the head.

70 Triumph 650 cc ECTA current record holder

|

|

|

|

|

Joined: Apr 2007

Posts: 92

Active BB Member

|

Active BB Member

Joined: Apr 2007

Posts: 92 |

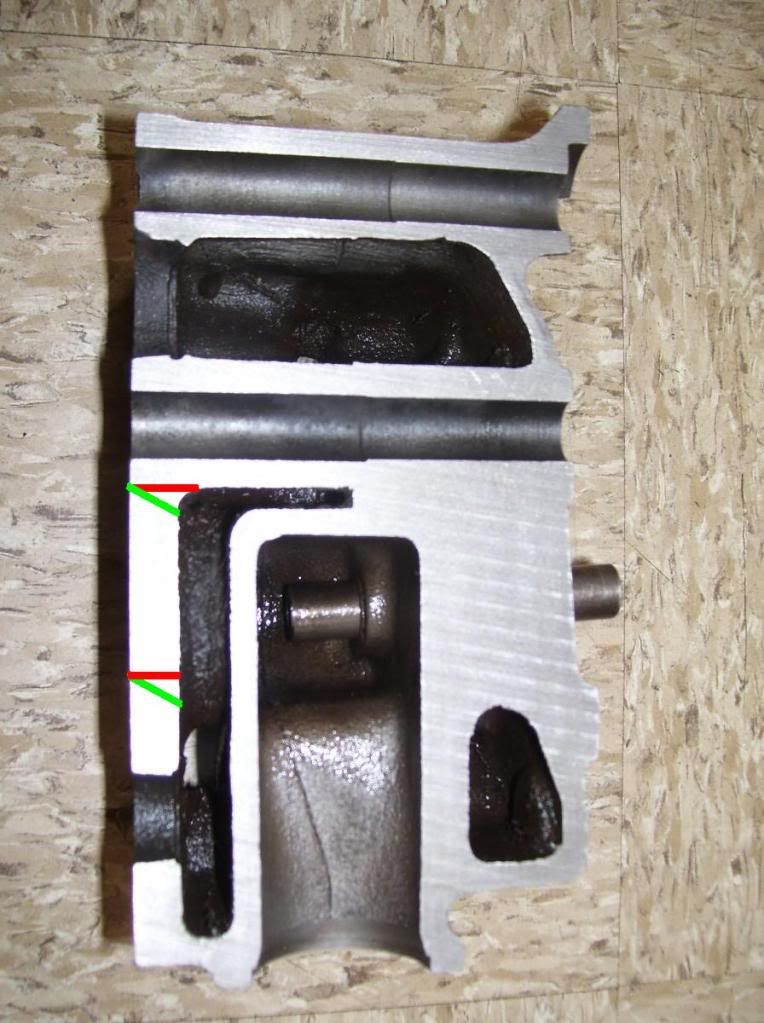

IMO if drilling straight in would reliably intersect the water jacket GM would have done it that way. Take a look at why even a slight angle towards the manifold side will improve chances of flow. Note that 3 of the holes are pretty much canít miss and the other 3 may not exit the head bolt boss if drilled straight. Iím sure there are folks out there that only have flow in 3 of 6 places but possibly that is just enough to get by. GM locations are in green and red shows straight in.

1952 Chev 1300 Cdn. Ĺ ton

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

Curt's point is important: anything that costs money, upsets the production line, or adds parts will be vetoed by the accountants unless it's actually necessary.

|

|

|

|

|

Joined: Apr 2003

Posts: 1,537 Likes: 15

1000 Post Club

|

1000 Post Club

Joined: Apr 2003

Posts: 1,537 Likes: 15 |

Interesting . . . I was under the impression that the 848 head from a 235 was the preferred one . . . right back to Mr. Brown's classic article: Hot Rod May '55 Don't recall any references to the steam holes in that article.

|

|

|

|

|

Joined: Apr 2000

Posts: 540

Major Contributor

|

Major Contributor

Joined: Apr 2000

Posts: 540 |

Curt's point is important: anything that costs money, upsets the production line, or adds parts will be vetoed by the accountants unless it's actually necessary. 15 years ago in an unheated poorly lit garage with the head laying on a messy work bench and using a hand held drill motor I did the deed.That was before I knew of anything of 12 degree angles.So the god of dumbness protected me,I drilled directly into the water passages no problem. I know of more than a few guys who have drilled steam holes in a 235 head and no one mentioned anything special. Now that I know this I will be sure to aim the drill towards the port side to be on the safe side...A good tip.......

70 Triumph 650 cc ECTA current record holder

|

|

|

|

|

Joined: Jan 2010

Posts: 493

Contributor

|

Contributor

Joined: Jan 2010

Posts: 493 |

in the mid sixties I used a '54 pass 235 head on a bored '59 261, used the 261 head gasket and I did not drill the head-- the car did run hot and was a real pain to start with the '54's 6V system. Later in the late '70s I bored a '62 261 and ran a 261 gasket, but used a '56 truck 235 head, again no holes drilled. The truck ran cool as a cucumber. Up to now I had never heard of drilling these steam holes, and knew several others who ran them undrilled as far as I know. And running the pass heads was the trick thing to do for increased comp. ratio. Wish I had another, just to hear the Smithys converse with one another...oh yeah and the cop! ("les' hear 'em boy-- step on 'em---yeah, oh hell yeah, jus' sign here--have a good day now") Yeah right.

As they used to say in Hot Rod Magazine, "Some times you eats the bear, sometimes the bear eats you".

|

|

|

|

|

Joined: Jan 2010

Posts: 493

Contributor

|

Contributor

Joined: Jan 2010

Posts: 493 |

I got dial up, and I'm too old to wait for it-- is that the Frank McGurk dyno tests witnessed by "Racer" Brown article? If so I dont recall any mention of the holes either! This is considered the Holy Grail of old stovebolt motor tests. McGurk also did a similar dyno series witnessed by maybe Don Francisco on rebopped 216 motor (used a pair of Zenith or Stromberg one bbls on his two carb manifold--gave jetting info) I think it was in a 1952 issue of HRM.

|

|

|

|

|

Joined: Apr 2003

Posts: 1,537 Likes: 15

1000 Post Club

|

1000 Post Club

Joined: Apr 2003

Posts: 1,537 Likes: 15 |

I got dial up, and I'm too old to wait for it-- is that the Frank McGurk dyno tests witnessed by "Racer" Brown article? If so I dont recall any mention of the holes either! This is considered the Holy Grail of old stovebolt motor tests. McGurk also did a similar dyno series witnessed by maybe Don Francisco on rebopped 216 motor (used a pair of Zenith or Stromberg one bbls on his two carb manifold--gave jetting info) I think it was in a 1952 issue of HRM. You are correct edski . . . that is the article I cross linked . . .

|

|

|

|

|

Joined: Dec 2004

Posts: 239

Contributor

|

Contributor

Joined: Dec 2004

Posts: 239 |

261 motors ran hot normally, hotter than the 235 because the 261 not only had a bigger bore it also had a higher compression I don't know about canadian pontic 261s, but chev truck 261s in the states ran LOWER not higher compression than a 235. years ago I didn't know any better & ran an 848 head on a 261 with a 235 head gasket without drilling the steam holes. that truck was a daily driver & I never overheated. I have an 848 head on my current 261 which I drilled using a 261 gasket straight in with no problems. however after seeing your cross section next time I'll drill them at an angle.

inliner # 3850

|

|

|

|

|

Joined: Apr 2011

Posts: 40

Active BB Member

|

Active BB Member

Joined: Apr 2011

Posts: 40 |

There is a difference in the required torque on the 261 block as opposed to the 235. If you are using a 235 "848" head don't forget to use the 261 sequence and torque requirements. The block Siamese is why there is a difference. There may be some suggestions about this in the Tech Tips section.

Normbc9

|

|

|

|

0 members (),

364

guests, and

17

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

|