Greetings . . . This past spring and summer has been very productive . . . now that it is cold again I thought I would post some updates on build progress in '14.

As I have mentioned previously I am fitting a 235 Hi-Tork crank to the original 216 - stroking it 3/16". Coupled with an overbore of .030 this means it is technically speaking a 230.

One of the details I have puzzled over is the setup of the Jet oiling system given the additional stroke:

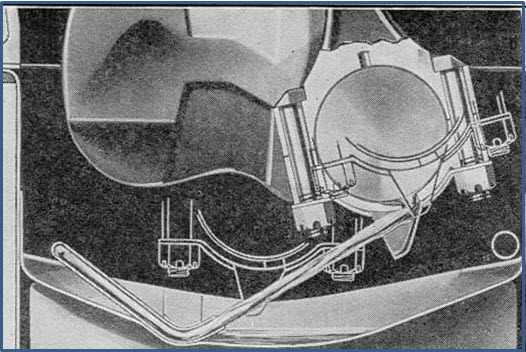

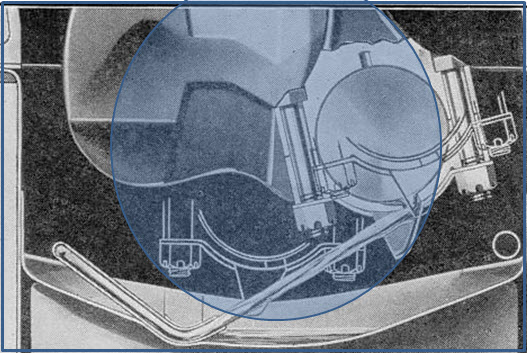

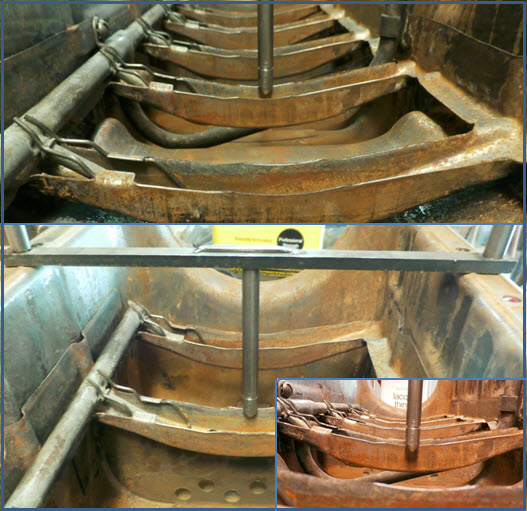

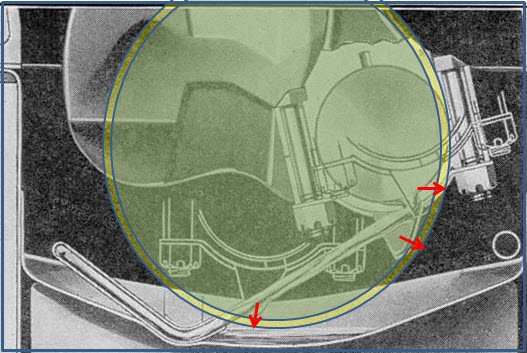

The jets in the pan are 'aimed' based on the position of the dippers on the big end of the connecting rods. Studying this alignment reveals an elliptical dipper motion:

Even more interesting is the fact that the jet is only pressurizing the connecting rod bearing for around 60 degrees of crank rotation:

leaving the rod bearing effectively coasting on 'retained oil' for 5/6ths of the rotation!

My '49 Master Parts catalog shows only one pan for 216s and 235s alike. This ultimately makes sense because the shallow end of the pan shows that there is no room for the jets and troughs to be fitted any lower. But with 3/16" of additional stroke the 235 crank changes the position of the dippers by 3/32" at BDC - with the dippers moving further to the right and lower into the troughs.

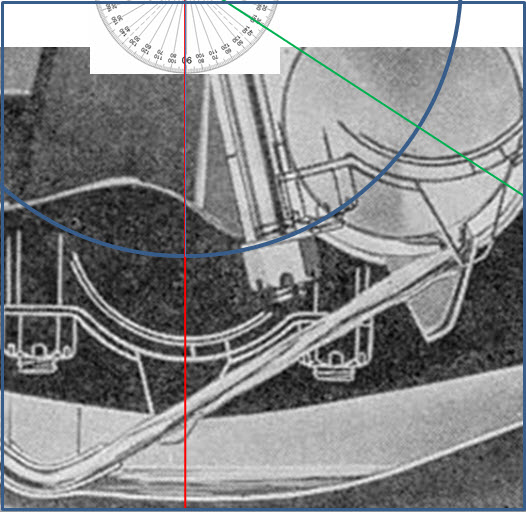

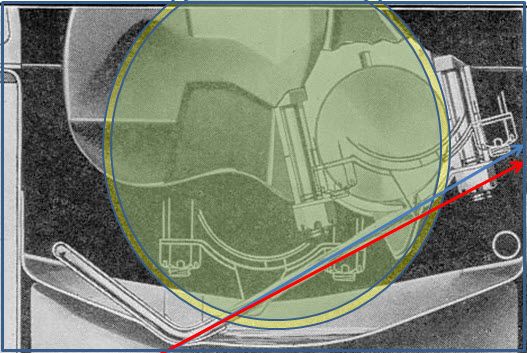

This lead me to believe that the jets should perhaps be aimed lower:

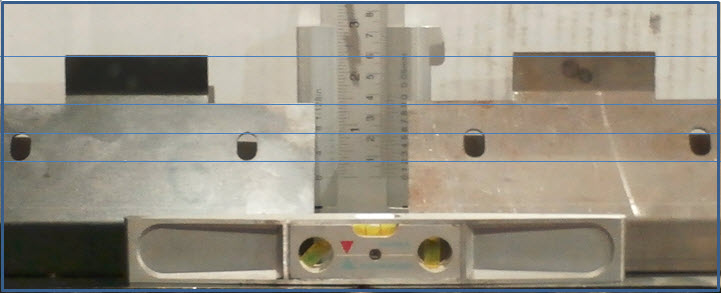

But the Ken-Moore tooling for targeting and alignment suggests otherwise:

Kent-Moore Tooling there is only one pan targeting tool for both 216s and 235s alike.

Chevs Of the Forties rents this tooling - I ordered a set early last spring. Curiously, the shipment included two pan targets each with the same part number. Some side by side photos reveal that one targets/aims slightly lower then the other:

I used the one on the right to check the alignment of my original pan:

I made a few minor tweaks to left-right alignment on the number two rod - but suffice to say that the pan the was basically in-spec as it came off the engine. Pictures don't do the alignment tool justice so I made a brief video:

PanTargetVideo The one difference in the Kent-Moore tooling is the trough depth gauge:

seems the stock '49 216 pan has troughs that are much to deep for the 235 crank. This must be related to low speed operations when oil pressure drops off. There are no drain holes in the troughs so oil must pool there. Perhaps too deep is counter productive?

The other curious result was that the dippers from the original engine where all to short. None extended far enough to touch the 'Go' gauge. I bought several sets of NOS and aftermarket dippers. Some of them seemed to be hammered flat from the factory. Others were rounded proud. Most of the rounded ones reached the 'Go' dimension. Some had to be coaxed with needle nose pliers to sit proud enough.

I think that this taller dipper configuration is what allows the pan jets to be aimed at essentially the same spot for both 216 and 235 engines. The taller dipper comes in contact with the jet at 60 degrees before BDC in spite of the fact that it is further to the right than in the 216 configuration:

Based on the pan trough depth gauge I ground off atleast a 16th of material (semi circle) in the center of the troughs.

I primed the pan with POR 15 and used the balance of the blue-grey enamel as a top coat. The Best Gaskets cork set fits nicely. I used Kopper Coat on both sides for a tacky seal to pan and block.

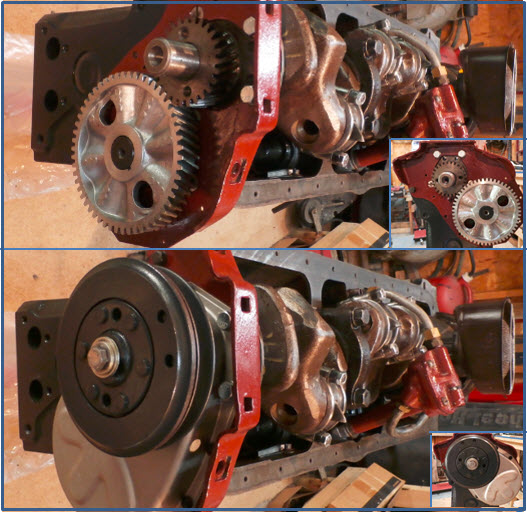

The cam installation was the text book "cam in the freezer" and "cam gear on the barbecue" affair. I put the cam/retainer/key in the freezer overnight. In the morning I heated the cam gear for about 20 minutes in the grill on high (600 plus degrees). It dropped in place with no need for coaxing from my dead blow hammer . . .

With the Pan in place the engine could be righted on the stand - allowing me to proceed with turning it into a long block - the road draft tube being step one.

Complete Short Block (seems there a limit on the number of pics in one post?)

More installments to come . . .

regards,

stock49