Greetings . . .

When I began planning my 216 build I started acquiring NOS parts so that the engine could be fully refurbished. I managed to find a half set of NOS lifters but was never able to complete the set. Later I read California Bills book which suggests that used lifters are work hardened and therefore a more reliable bet. He also, preferred the 37-39 style lifter/push rod package . . . so that was added to the hunt . . . and eventually bagged.

Along the way I decided to stroke the engine and this in turn required a cam-shaft with relief flats for connecting rod clearance. This caused me to search for a 235 cam with the small journal size. I acquired an NOS piece and sent it to Delta for re-grind.

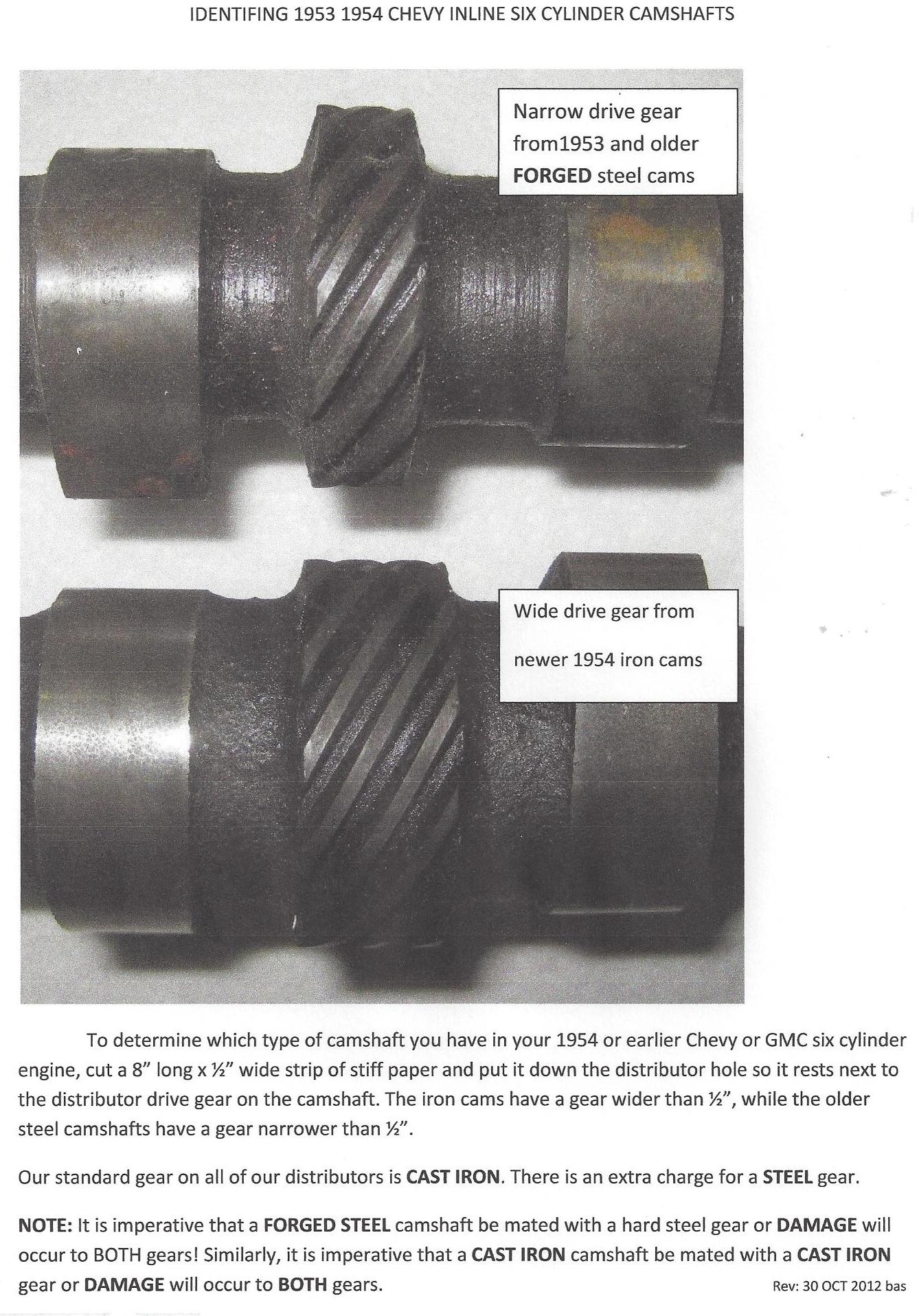

Somewhere along the way I learned that Chevrolet had transitioned from forged-steel to cast-iron camshaft construction (mid-fifties) and that mixing incompatible lifters and cam gears leads to short and disastrous results . . .

The width of the dizzy drive gear confirmed that my re-grind was indeed a cast iron bump stick . . . so neither the NOS nor the used GM parts were an option as the tappet faces are simply too hard. (Image borrowed from Langdon's Tech)

I began to shop and found that the milk bottle style lifters for 216, 235 and early 261 were still being made (circa 05) they are still manufactured today and seem even more plentiful than back then. I found a few posts on HAMB and elsewhere suggesting that these new lifters were/are of low quality and to be avoided. So I began searching for compatible NOS parts . . . either NOS GM parts or NOS aftermarket parts.

It was at this point that interchange confusion set in. There were several different aftermarket-to-GM part numbers being cross referenced as equivalent and fully interchangeable but this defied the change in materials (industry wide) away from forged-steel cams and chilled -iron lifters to cast-iron cams and hardenable-iron lifters. Research suggested that the aftermarket had produced chilled-iron lifters into the early 1960s but production waned with demand as camshaft construction shifted exclusively to cast iron.

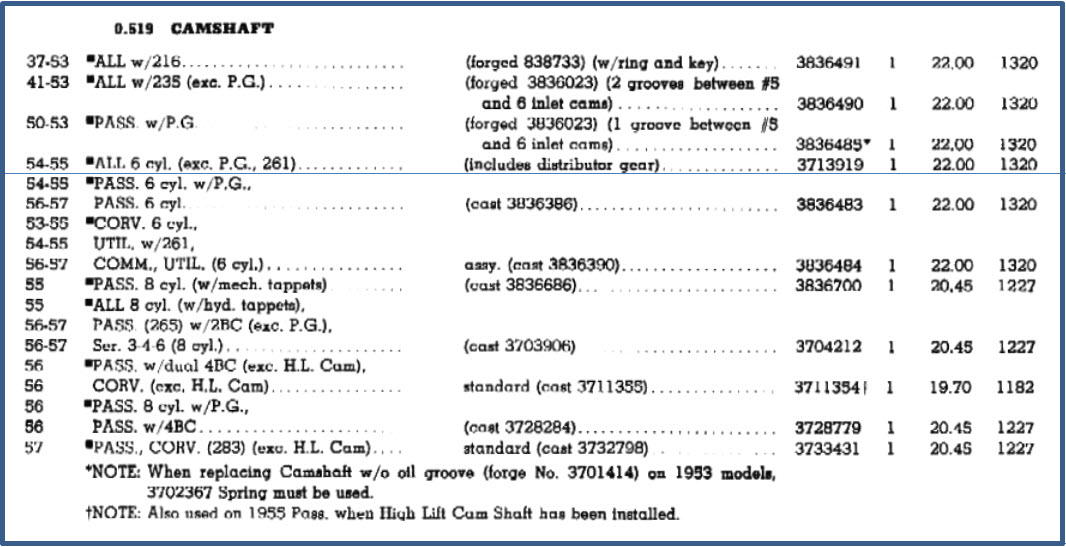

The 57 Chevrolet Parts Master proved the most enlightening (as it details the transition succinctly) calling out forged versus cast construction and in the case of the 54-55 replacement cam it included a compatible dizzy drive gear:

This reveals basic stove-bolt lifter construction/compatibility:

GM 838774 (29 -39 all) cup/bucket style chilled-iron

GM 839263 (40 -52 216) milk bottle style chilled iron (white paint dab on neck)

GM 3660438 (41 -54 235) milk bottle style chilled iron (yellow paint dab on neck)

GM 3836342 (53- 55 Corvette & 54-55 261 ) milk bottle style hardenable iron (single groove around body) rare:

The one groove lifter is the missing link. It appears to be the only milk bottle style lifter made by GM that is compatible with a cast-iron cam:

All other GM NOS parts are useful only with the older GM NOS cams or a re-grind on a forged steel core.

AFAIK the initial aftermarket cross reference for GM part 839263 (216) appears to be:

TRW, MANLEY, MCQUAY NORRIS: VL19

EATON: VL019

HYLIFT JOHNSON, Sealed Power AT708 re-man RMT708

Dana/Clevite 213-1603

among others . . . it is unclear if any of these part numbers were ever of chilled iron construction.

AFAIK the initial aftermarket cross reference for GM part 3660438 (235) appears to be:

TRW, MANLEY, MCQUAY NORRIS: VL71

EATON: VL071

HYLIFT JOHNSON, Sealed Power AT887 re-man RMT887

Dana/Clevite 213-1661

among others . . . though some will have you believe that VL71 is the initial aftermarket offering for GMC part 2194006 (for 248 , 270, 302) I have not researched this but it appears that GMC interchanges as well (and likely went through the same materials transition as Chevy).

The best cross reference publication I have found online is from Clevite:

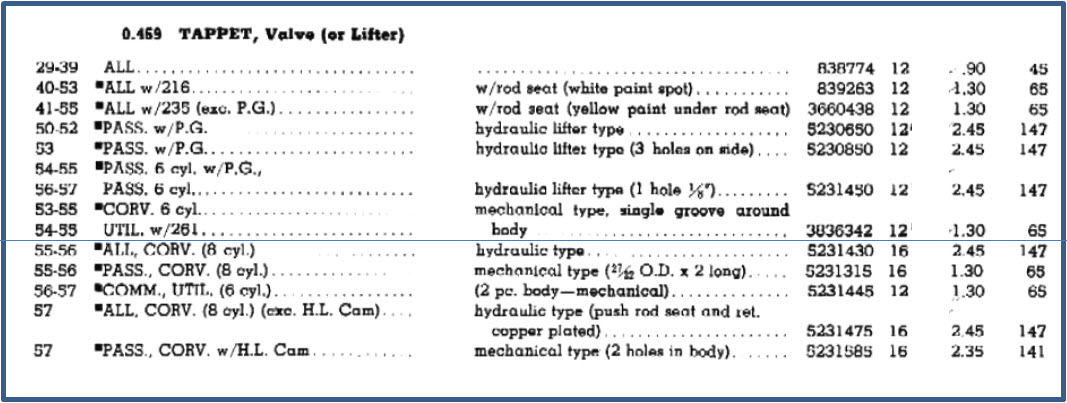

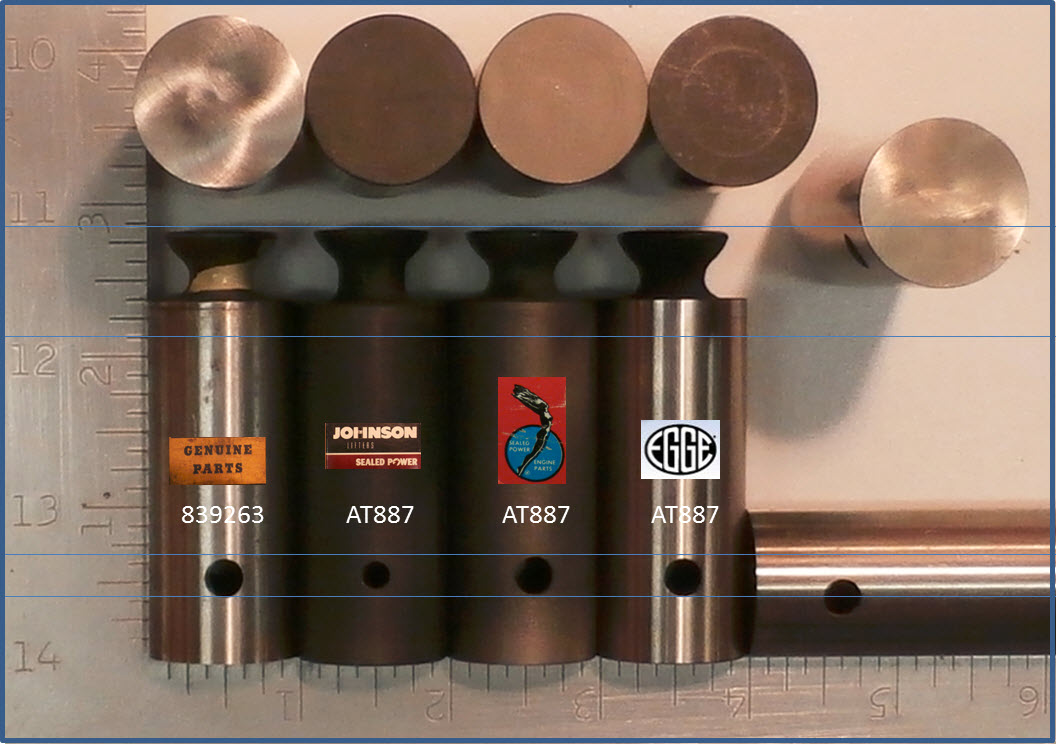

Clevite circa 2006 As far as I can tell the difference between a VL19 and VL71 is the thickness of the shoulder and slightly longer overall height. In side by side comparison the 839263 part appears to use the same basic dimension of the predecessor 838774 with a thin shouldered bottle top rod seat pressed in:

Whereas the later VL71 has a shortened lifter barrel and much stouter shoulder in the bottle top:

The other key difference is the treatment of the tappet face. On the 839263 stock GM part there is an .005 hemispherical micro-polished grind. This is designed to promote lifter rotation as the cam lobe contact is not centered. None of the aftermarket lifters I have in hand exhibit this detail. They are all perfectly flat. One need only place a lifter on a hard smooth surface the wobble is obvious. Some will have you believe that this hemispherical grind is an indication of chilled iron construction. But the used 38 cup style lifters I have do not exhibit this detail. Neither do the lifters removed from my engine during tear down. They are of unknown origin and are also absent oil holes (top and sides) which are said to be present on all stock GM lifters. These unknown tappets were running on a forged steel cam so it is assumed that they are of chilled iron construction (or they would be ruined).

Some time with my calipers and triple beam balance yields the following specifications:

-------------------------------------------------------- Length------------------Weight-------------

Unknown aftermarket lifter from tear down: 2.80 +/- .010 (flat) ---- 91 grams +/- 1 gram

Sealed Power AT887 NOS......................: 2.81 +/- .001 (flat) ---- 91 grams +/- .5 gram

Johnson SP AT887 VL19 NOS..................: 2.82 +/- .005 (flat) --- 121 grams +/- .5 gram

Johnson AT887 VL71 (from Egge)............: 2.80 +/- .005 (flat) --- 174 grams +/- .5 gram

Stock GM part 838774.........................: 2.32 +/- .005 (flat) ---- 77 grams +/- .5 gram

Stock GM part 839263.........................: 2.80 +/- .010 (hemi) -- 89 grams +/- .5 gram

The current production from Egge hefts as if it is made of lead. When I first dumped it out the box I was curious to get it on my scale. An absolute whale in comparison to the stock part . . . The Egge part has a parkerized bottle top and lifter face. The Johnson part is parkerized over its entirety. The Sealed Power part has lighter colored phosphate coating - the lifter face is slightly lighter still.

In my research, I cant find any evidence of an initial aftermarket replacement part for the 29 39 cup/bucket style lifters. So re-using the long 37-39 push rods with softer NOS replacement lifters seems unlikely. But I do see postings on ebay for new lifters built to the old spec:

Ebay Aftermarket Early Stovebolt Cup Style Lifter not sure about the quality of these pieces but they are certainly an option.

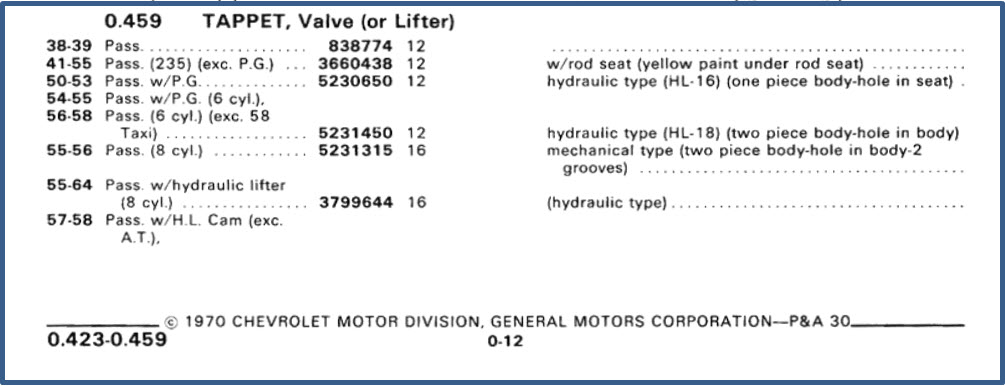

The collapse of part numbers onto an apparent universal interchange appears to coincide with the discontinuation of part numbers by GM. By 1970 the GM Parts Master lists just one milk bottle style solid lifter retaining the oldest 235 solid lifter part number:

but the oldest stock carrying this part number would be chilled iron leading me to wonder if Chevrolet ever really produced a softer replacement tappet using this ancient part number.

In exploring pushrod options I came across a used set of McGurk tubular push rods. These are bit longer then the stock rods for a 216:

Some have written that tubular push rods are both lighter and stronger but I found them only a gram or two lighter (stock being 71 or 72 grams) with none of the McGurks south of 70 grams

In looking at finished lengths it seems the 37-39 package would be a good choice for a reground steel cam in a 216 as the loss in base circle will be taken up by the additional 1/16th inch in finished length. Perhaps this is also a part of the appeal to California Bill.

With the McGurk push rods I will pick up an additional 1/8th . . .

Cant wait for the weather to break here in Ohio.

Regards,

Stock49