|

|

Joined: Mar 2015

Posts: 7

Active BB Member

|

OP

Active BB Member

Joined: Mar 2015

Posts: 7 |

Well hello all,just got my account approved an iv been chomping at the bit to post this to see what others more knowledgeable know about vacuum advance. Iv gone thru every thing I can think of. I have a 74 k10 with 250 and 3speed. Had original motor in it when I bought but fouled plugs so bad I just replaced it with a Craigslist motor. Motor runs strong, got good compression and has the factory valve cover leak haha. I changed points dis to hei and since install(about 4 months) I have not been able to run any kind of vacuum advance, ported or manifold. Manifold vac is where it was first off and that kills the motor instantly when plugged in. Rochester monojet MV is carb. When plugged to ported vac as soon as vacuum is enough to move the pick up coil there is a dead spot in ignition and it misses and pops n the sort. I have no idea other than pick up coil and vac can being bad. Both replaced with no difference.

Any body out there have this issue?/ know how to fix?

|

|

|

|

|

Joined: Feb 2014

Posts: 505

Major Contributor

|

Major Contributor

Joined: Feb 2014

Posts: 505 |

I have a '78 passenger car 250cid with a 3spd manual, Rochester Monojet 1ME, and HEI. The stock vacuum advance is 24 degrees and works fine at vacuum advance keeping it at 30 degrees total, although the 6 degree initial advance the emissions sticker calls for does make it run a little rough at stoplights until warmed up. I'll double check where it is coming off of, but it goes through a thermal valve on the water neck to control the vacuum signal by coolant temp.

I have an adjustable vac advance I'm installing that starts at 20 degree advance, and I'm going to go to a 10 degree initial advance and see if that improves cold idle.

|

|

|

|

|

Joined: Nov 2013

Posts: 482

Contributor

|

Contributor

Joined: Nov 2013

Posts: 482 |

Inside the HEI there is a coil with pointed teeth and 2 wires, one white and one green wire. We always called it a "pole piece". The vacuum advance twists this coil to advance or retard the timing. What happens over time is the wires break inside and lose connection killing the engine. I have seen this with and without breaking the plastic insulation covering the wire. Unplug the coil from the module and check very carefully. Jay6155

|

|

|

|

|

Joined: Apr 2004

Posts: 3,556 Likes: 35

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,556 Likes: 35 |

Is it a used GM dist or a new foreign made unit?

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Mar 2015

Posts: 7

Active BB Member

|

OP

Active BB Member

Joined: Mar 2015

Posts: 7 |

Foreign I'm sure. I have a GM factory also with same result. J78 pole piece is what I know as pick up coil. The odds of 3 different pick up coils being bad is astronomical. But possible. I can't see how valves could have anything do with it, or the carb unless the ports blocked... But I get a full 15in of vacuum from manifold vac. And the advance can is full advance at 15in. Iv been hunting an ignition rabbit but I think in the wrong places. Possibly the balancer spun?!?!?! But there's a key for the balancer shouldn't that keep it from spinning? Obviously its gear drivin timing between cam and crank, couldn't see it running as well as it is being a tooth off at timing gears or at dist. Its set at 10* btdc as all my 250s were. I may be in the dark as to what exactly plays into over all timing. Not talking about "over all timing" per say but what mechanical parts can be faulty to thro it off.

|

|

|

|

|

Joined: Apr 2004

Posts: 3,556 Likes: 35

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,556 Likes: 35 |

The outer ring can slip, causing you to think it is timed, but in reality it is off. Check TDC with a positive stop in the sparkplug hole.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Mar 2015

Posts: 7

Active BB Member

|

OP

Active BB Member

Joined: Mar 2015

Posts: 7 |

Checked that. When timing mark is at 0* #1 piston is TDC.

|

|

|

|

|

Joined: Apr 2004

Posts: 3,556 Likes: 35

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,556 Likes: 35 |

Another thing. Are you using the same dist cap each time. I have seen dist bases with multiple notches to seat/index the cap. Not sure, but it could also be possible a V6 cap could have different indexing than the inline 6. This could cause the spark to arc properly to a sparkplug inside the cap until the timing gets advanced and then "miss" the internal cap conductor causing the engine to quite running.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Mar 2015

Posts: 7

Active BB Member

|

OP

Active BB Member

Joined: Mar 2015

Posts: 7 |

Now that's something new. Thanks. 2 of caps are for 250 the other dis I got came with the motor but not sure about cap. Guy said he had it on his so i can only assume. If spark is happening to late in the cap could the rotor be going to far and missing the contact point? How could you fix this?

|

|

|

|

|

Joined: Nov 2013

Posts: 482

Contributor

|

Contributor

Joined: Nov 2013

Posts: 482 |

I agree that 3 bad "pick up coils" is a loooong shot. The engine just dies the minute that the vacuum advance is hooked up right? Can you idle the engine and hook up the vac can to a hand pump and watch what happens with a timing light? Jay6155

|

|

|

|

|

Joined: Oct 2009

Posts: 471 Likes: 9

Contributor

|

Contributor

Joined: Oct 2009

Posts: 471 Likes: 9 |

Just a thought, but I would probably confirm that the diaphragm in the can is intact and working. Also, the vacuum can may have been replaced at some point, or the wrong value can has been or is installed. GM had cans that all looked the same but worked at different vacuum levels. I am not positive about this, but is the late motor vacuum can the same as a v8 can? If it is, didn't someone make an adjustable can at one time? To me, if the motor runs, the initial static timing is right, the cap and wires are clean and in good shape, and the internals are not all gummed up, and the only time this issue appears is when you hook the vacuum line up, i think, imho, it is a vacuum advance issue you are chasing which my require you to either get a vacuum pump to apply vacuum to the can and sort out what value the can you have is working at and see if your motor supports that value, or obtain a couple of different value cans or an adjustable can, and play around a bit and see if there is any improvement. Just some thoughts.

|

|

|

|

|

Joined: Feb 2014

Posts: 505

Major Contributor

|

Major Contributor

Joined: Feb 2014

Posts: 505 |

The vacuum advance can has the degrees of advance marked on them behind the diaphragm housing. Mine was rusty and needed cleaning to see the 24 stamped on it.

|

|

|

|

|

Joined: Feb 2014

Posts: 505

Major Contributor

|

Major Contributor

Joined: Feb 2014

Posts: 505 |

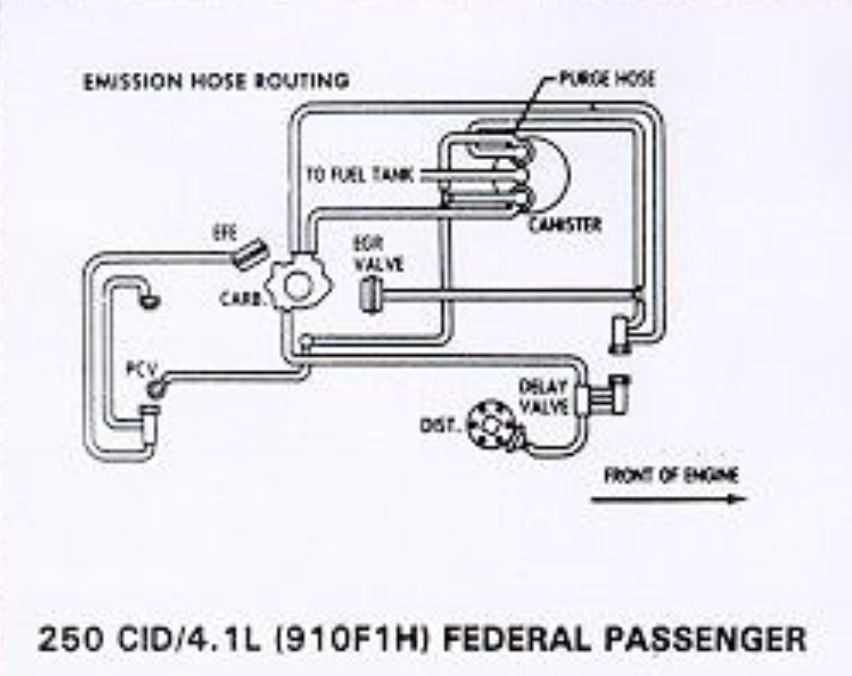

Checked my vacuum hose setup on the Monojet (I confirmed the proper connections originally on my assembly manual). There are 4 hoses coming off the carb. The large one coming off the top on the left in front of the others goes to EVAP canister. The line on the top right port leads to the delay valve on the lower water neck which leads to both the EVAP valve and EGR valve. The port on the lower left has a T on it with one line leading up to the THERMAC air cleaner, and the other leading around to a delay valve on the top of the water neck which leads to the HEI vacuum advance.  Here's a diagram of the layout (THERMAC air cleaner and vacuum line missing):

Last edited by Lifeguard; 03/24/15 10:56 PM.

|

|

|

|

|

Joined: Mar 2015

Posts: 7

Active BB Member

|

OP

Active BB Member

Joined: Mar 2015

Posts: 7 |

Iv used pump and at 15 in vac it is fully engaged, and 9in vac begins to move. It is adjustable and iv gotten it screwed in all the way and the truck runs but runs just like poopoo. I have never noticed a *rating on the can it self I'll check it out in the morning. As to vac lines to and fro the carb the only one that's ever been hooked up is the advance line, with both motors. Will also be hooking up timing light again and re checking #s. Will post results. Don't think it got covered yet: is it possible for a motor to start and run well a tooh off in any direction if you have enough manipulation from the distributor to bring it to a decent * of timing? Just a hairbrainidea. And thanks for the replys.

|

|

|

|

|

Joined: Feb 2014

Posts: 505

Major Contributor

|

Major Contributor

Joined: Feb 2014

Posts: 505 |

I tried to take a picture of it months ago when I had the HEI apart, but it came out blurry. You can just make out the "24" stamped on it behind the diaphragm housing:

|

|

|

|

|

Joined: Apr 2004

Posts: 3,556 Likes: 35

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,556 Likes: 35 |

This is a problem I have seen before. It is what I described earlier. The base problem is ussually the pickup rotor is not clocked properly to the spark rotor. Somehow messed up when distributors are made new (aftermarket) or rebuilt by A-1 Cardone. I think they make the shafts from a different distributor. From my website. http://www.12bolt.com/distributor_blueprintingI did look thru Georges Old distributor and found exactly what is described above. Testimonial from George in Wisconsin, I own a 1957 GMC 100, a ˝ ton pickup truck. After buying it and driving it for five years, I removed the tired 270 inline six and 4-speed manual transmission. I then removed the truck’s front clip and welded in a Fatman Mustang II front end with rack and pinion steering and 13” front disc brakes. Next, I lowered a GM 292 inline six with lump port head connected to a TH 350 automatic transmission. I bought a distributor for the 292 from e-bay. When everything was ready, the engine started and ran well until I tried to hook up a vacuum line to the distributor. The engine would often backfire when I let up on the gas, and it would bog when I took off from a standing start. I’ve had neither problem whatsoever since I installed Tom Lowe’s distributor. The engine conked out immediately each and every time I tried to hook up the hose from a different vacuum source. I figured the e-bay item just wasn’t up to the task. So, I ordered a Summit distributor for $200, or very close to that price and installed its distributor. Guess what? The engine conked out each and every time I hooked up the distributor to vacuum. I thus drove the truck with a distributor. minus a vacuum line hookup for a year and one-half. When Tom Lowe was told of the problem, he promised he could build a distributor that I’d be able to hook up to vacuum. Personally, I didn’t believe him, but I said if his distributor didn’t work as promised, he’d have to refund me my money plus shipping, no questions asked. He agreed. After his distributor arrived, I installed it, hooked it up to a vacuum line at 18 inch Vacuum. Voila, the engine purred like a randy lion. Better yet, the truck has run a lot better at Interstate-plus speeds, it gets better gas mileage, and I’ve driven it every day since May and have had no problems whatsoever. Tom Lowe’s distributor has made a believer out of me. George

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Mar 2015

Posts: 7

Active BB Member

|

OP

Active BB Member

Joined: Mar 2015

Posts: 7 |

Mr.Lowe can you tell me more about blue printing a distributor? I imagine its the same way with motor? I take it your the man that builds em? BTW. I checked the #s you talked about. One can said 24 just like yours, one said 54, the adjustable said nothing I take as because it was adjustable. Hooked up pump and set adjust can all way out at 13 turns and will run but yes runs like crap. And gives about 2* advance with mechanical adv not engaged. With mech adv engaged and 14in vac same result. Will check out your web site tlowe thanks. And thanks to all again.

|

|

|

|

|

Joined: Apr 2004

Posts: 3,556 Likes: 35

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,556 Likes: 35 |

Basically, tear it down to the raw components. Clean it. reassemble with all new electronics. Weld up the mech advance and adjust for proper advance at rpm with proper springs/weights. Set the vacuum advance where it needs to be for cruise. New cap/rotor/ HP coil and you are good to go.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: Mar 2015

Posts: 7

Active BB Member

|

OP

Active BB Member

Joined: Mar 2015

Posts: 7 |

Well tom I think you hit it right on the money, I put the old points distributor back in it and it runs just fine. So I'll be getting with you in the next month with the specs for distributor build. Thanks

|

|

|

|

0 members (),

420

guests, and

30

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

|