|

|

Joined: May 2011

Posts: 378

Contributor

|

OP

Contributor

Joined: May 2011

Posts: 378 |

So I have this Rochester 2-Jet 2bbl carb sitting here in my living room, and I'm planning to sit it on top of the single barrel 230 intake with a self made adapter. Have not started work yet, but it just occurred to me that this 2-jet has no ported vacuum fitting. Only a large manifold vacuum fitting at the bottom, and another smaller intake vacuum fitting below the fuel bowl that runs through to below the throttle plates.

What gives? Should I try to run manifold vacuum for the distributor? I never understood why anyone would want to.

Now to see a carb with NO ported vacuum available is a first to me.

I have other options too, Holley 2280 with the same narrow bolt pattern. I have one in rough shape and another one coming. Should end up with one good rebuilt 2280, and those have vacuum fittings out the yin yang, like the original MonoJet I'm running now.

|

|

|

|

|

Joined: Apr 2004

Posts: 3,556 Likes: 35

1000 Post Club

|

1000 Post Club

Joined: Apr 2004

Posts: 3,556 Likes: 35 |

I always use manifold vauum to the distributor. Idle will be better. And engine runs cooler.

Inliner Member 1716 65 Chevelle Wagon and 41 Hudson Pickup Information and parts www.12bolt.com

|

|

|

|

|

Joined: May 2011

Posts: 378

Contributor

|

OP

Contributor

Joined: May 2011

Posts: 378 |

Yea its the age old debate, from where I'm coming from, thats backwards. You don't get vacuum boost in advance when you need it, instead it goes retarded. I do realize some cars were built like that. Retarded

|

|

|

|

|

Joined: May 2000

Posts: 1,464

1000 Post Club

|

1000 Post Club

Joined: May 2000

Posts: 1,464 |

Your logic is seemingly correct, but somewhat flawed.

When you step on the gas and open the throttle the cylinder fills more completely from the increased manifold pressure. This increased volumetric efficiency creates more pressure upon combustion. Higher pressures mean the flame front travels more rapidly, thus less spark advance is needed for optimum torque. Likewise, higher pressures raise the propensity of the engine to knock, so if excessive amounts of WOT spark are used the engine will be more prone to detonate.

I realize that direct manifold vacuum to the distributor sometimes creates a "hole" or stumble on acceleration. That is where a ported signal can help you out. But in the absence of a ported signal it is better to have manifold vacuum to the distributor than no vacuum signal at all.

FORD 300 inline six - THE BEST KEPT SECRET IN DRAG RACING!

|

|

|

|

|

Joined: May 2011

Posts: 378

Contributor

|

OP

Contributor

Joined: May 2011

Posts: 378 |

The ported vacuum is there to help give an initial advance "bump" just as you start to open the throttle, to help burn the sudden rush of air and fuel. It peaks just as the butterfly cracks open a little. By 1/8 - 1/4 throttle it has weakened significantly. If you push the pedal deeper, ported vacuum DIMINISHES and eventually goes away almost completely if not 100, so there is NO vacuum advance at WOT or high throttle openings. It is there only when it is needed: when you just crack the throttle open to help you get going, AND at cruising speeds when the throttle remains barely cracked open, and the load is low. This gives you better throttle response in the first scenario, and better fuel mileage while cruising, second scenario. This is how, and why, it was used in the vast majority of engines that used vacuum advance distributors. They were designed to run this way. Using intake manifold vacuum for advance is (excuse me) retarded, to me, because you have high vacuum at idle, and as you crack the throttle open, it starts diminishing, and only keeps going away the more throttle you give it. I'm tempted to say it does not help at any point... but not yet. It allows you to run more initial timing at idle, and I guess that in theory at least helps you get moving if you open the throttle slowly, and the vacuum diminishes slower.. but then the engine falls on it's face when you need it to pick up speed and react to throttle. But, there are engines that were designed to run it this way, and they would not (necessarily) run well with ported vacuum, all else being stock. One does not work in another, necessarily. I would assume it would require many changes in jetting and advance curves etc. to change an engine designed for manifold vacuum, to start running ported vacuum. Which is kind of what I am after. I have built countless engines based on ported vacuum, stock, street and race. But I have only dabbled in manifold vacuum engines. Mainly because they seem to be crude and unsophisticated choked-to death iron lumps with low IQ and low power for the CC's  I wouldn't mind if I could find a fully adjustable mechanical only distributor for this engine for cheap. Done that too on many ported-vacuum engines with BIG cams. Anything is adjustable though, just needs more work when you have to start with a stock distributor and experiment...

|

|

|

|

|

Joined: Apr 2003

Posts: 1,537 Likes: 15

1000 Post Club

|

1000 Post Club

Joined: Apr 2003

Posts: 1,537 Likes: 15 |

This is a widely misunderstood topic. And the plumbing for the vacuum source is not a tell - so it is not as simple as "on the carb" versus "on the manifold". Many carburetors provide full manifold vacuum from a fitting on the carb base that is below the throttle plate. The term 'ported' vacuum refers specifically to a vacuum fitting that is above the throttle plate. To FTFs point the the vacuum advance is designed to advance spark timing when the charge is lean - a condition found at idle or when cruising on the freeway at part throttle. Manifold vacuum signal addresses both driving situations. "Ported" vacuum only addresses the latter - and was an early emissions fix that was coupled with completely different centrifugal advance curves and initial timing settings. A great article on this topic can be found here: Chevellestuff

|

|

|

|

|

Joined: May 2011

Posts: 378

Contributor

|

OP

Contributor

Joined: May 2011

Posts: 378 |

I agree with just about everything you said. Ported vacuum means the hole is just a hair above the throttle plate, so it is "open" and active as soon as you open the throttle a tiny bit. This fitting can be virtually anywhere on the outside of the carb. The internal drilled passage is what counts. Same goes for the manifold vacuum fitting. The said Rochester 2-jet I have, has manifold vacuum fitting coming out from under the fuel bowl, WAY above the throttle plate. But the passage goes downwards from there, ending up well below the throttle plates, on the mounting flange. Here's whats what:  As for ported vacuum being "only" an emissions aid, that I don't agree with. It has the same job as any advance mechanism, providing advance when it is needed, and NOT when it could be harmful. There is no need for "extra" advance at idle once you have the base timing set. (again, in an engine designed to run ported vacuum). It won't run lean at idle if you set the idle mixture correctly. Easily verified on carbed engines with an O2 sensor. All my builds have one. So *idle* vacuum advance has no function. Therefore ported advance does not provide any at idle. It only comes into play when the throttle is opened a small amount. If it created advance at idle too, then you would have no "bump" when you open the throttle, it would stay the same or the difference would be very small. Some engines used a distributor with ONLY vacuum advance. It would then have a stronger vacuum pod, able to retain some advance at bigger throttle openings so you would not try to run the engine solely on base timing alone. Yes ported vacuum. And thus, not only an emissions thing. The initial bump or spike in vacuum advance as you start cracking the throttle open, does help burn the suddenly momentarily lean mixture when air flow increases rapidly. That's when it leans out. Air moves quicker than fuel, because fuel has much more mass. So it takes a split second for the fuel to get drawn in and balance the mixture out. The quick advance bump helps burn through the lean spot without a stumble. The accelerator jet helps keep the mixture richer as well but it too is momentarily slower than air flowing through the carb.

|

|

|

|

|

Joined: Apr 2003

Posts: 1,537 Likes: 15

1000 Post Club

|

1000 Post Club

Joined: Apr 2003

Posts: 1,537 Likes: 15 |

Great diagram. I agree it is all about the setup and having the dizzy mech-advance-curve, vac-advance-can, vacuum source and carb(s) working together as a system. I realize that a lot of modern cars have ported vacuum designs - but as I understand it - these designs involved de-tuning previous generation systems to meet emissions: Colorado Corvette Crazies including severely retarded initial timing. The challenge I have always had with sticking to the compromise of a 'ported' vacuum setup (when hot rodding) is the amount of initial advance that is required (especially when camming). In my experience it makes for hard starting when the engine is hot and risk of pinging at WOT under load.

|

|

|

|

|

Joined: May 2011

Posts: 378

Contributor

|

OP

Contributor

Joined: May 2011

Posts: 378 |

YOu run into too much initial timing issues if your distributor total advance is not enough, and you have to give it more intial advance to get the top end where you need it. That's why the distributors need to be tweaked so you get quick response, easy advance at idle, and more at higher rpms as needed. Many big cams change the vacuum signal too, it could be too weak at idle or off-idle to operate a stock vacuum canister. I often go to a fully mechanical distributor in high performance engines, and get rid of vacuum altogether. Sometimes I get my hands on adjustable vacuum canisters, which helps tweak it to match the engine. You can adjust total advance from the vacuum canister, and by swapping springs you can adjust the sensitivity. Same with the centrifugal weights. Many guys opt for the easy and cheap route and just drop in an aftermarket dizzy and leave it as is. And then wonder why the engine falls on its face when they try to drive nicely  Race engines don't need to pull strong from idle though...

Last edited by 70Nova; 12/03/15 01:35 PM.

|

|

|

|

|

Joined: May 2011

Posts: 378

Contributor

|

OP

Contributor

Joined: May 2011

Posts: 378 |

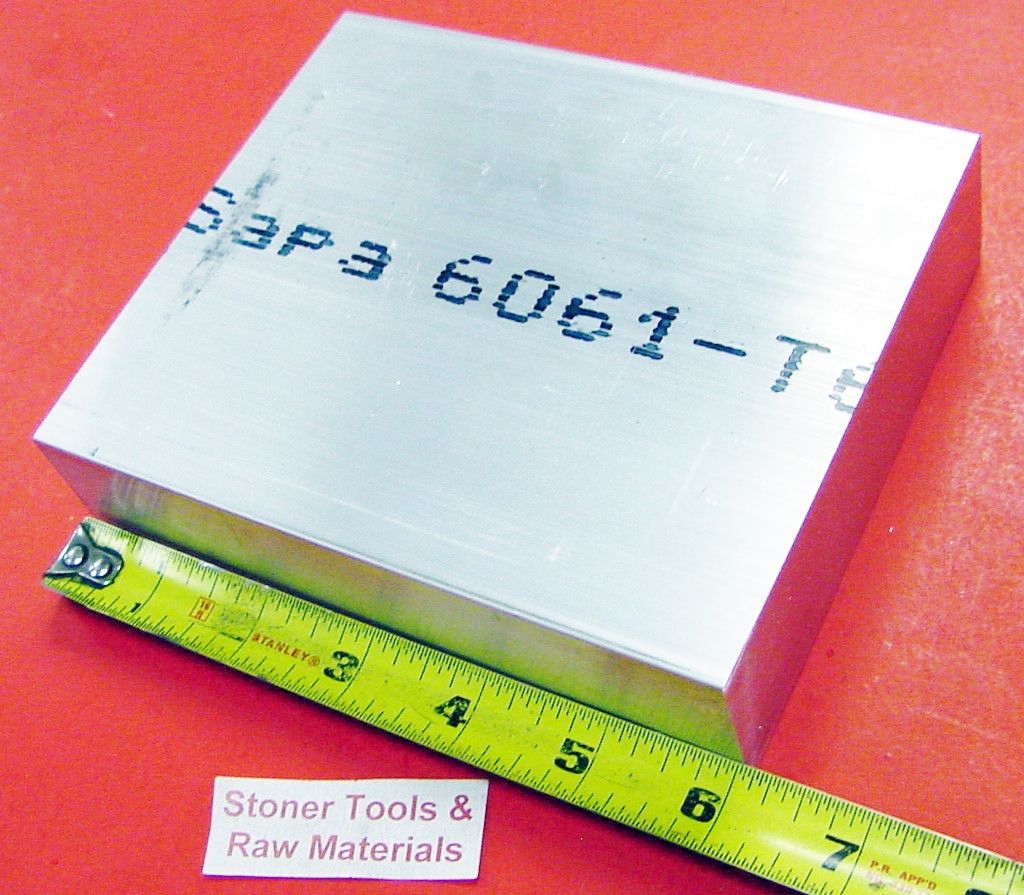

In case anyone needs one.... found these on Ebay, different size aluminum plates. I ordered a 1x5x6 milled piece, should make two 2bbl -->1bbl adapters...  $17 with free shipping.

Last edited by 70Nova; 12/03/15 03:19 PM.

|

|

|

|

0 members (),

345

guests, and

45

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

|