|

|

Joined: Apr 2003

Posts: 1,537 Likes: 15

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2003

Posts: 1,537 Likes: 15 |

Greetings . . . I haven’t been very active on the site lately (beyond admin/moderator duties) because I have been heads down in the garage making a final push to get the car back on the road this summer . . . As soon as the weather broke this spring I began to mock up an exhaust system from mandrel bends that I got from Burns Stainless. I will put together a thread with details sometime later . . . stick building an exhaust is fun. My quick update is that the engine is running! Last fall (before the cold set in for good) I got all of the front clip sheet metal refurbished and hung in the garage to cure. So this spring it has been build – build – build . . . mostly clean hands stuff – far more rewarding then some of the dirty dog-work that lead to this point. Here’s some under hood shots from this week:     On Wednesday evening I was finally ready to try to fire things up. I had chased a few fuel leaks down and remedied them; same with coolant. The first attempts at firing were sparkless . . . I suspected that my vintage Shurhit condenser was likely DOA from years on the shelf. There was juice to the coil but no breaker-point events – dead short in the condenser? Swapped it for a modern one and bingo we had sparks albeit a bit early. Retarded the cap the and the engine came to life . . . quickly smoking off the assembly lube . . . Now I am trying to sort through the carbs. When the engine fires it immediately tachs to about 1200 RPM and then slowly climbs to just shy of 3000 revs. Curb idle screws are backed off completely so the throttle plates are fully closed to the factory idle clearances. These Carters use an offset choke plate that is pulled open by air-horn intake velocity. The auto choke springs pull the plates shut at idle and then relax with heat. With the engine trying to rev-away the choke plates are getting pulled open by incoming air. I can throttle the engine by holding the plates nearly closed manually. Not sure where the fuel is coming from. I am going to revisit the metering rod adjustments. More to come. Regards, Stock49

|

|

|

|

|

Joined: May 2016

Posts: 468 Likes: 4

Contributor

|

Contributor

Joined: May 2016

Posts: 468 Likes: 4 |

I know you know this, but look for vacuum leaks!!

It looks fabulous!!

Never use a minor caliber bullet on a major caliber adversary

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

I really like what you have done here. 216s don't get their due respect. I hope you figure it out and I hope it is easy to fix.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Apr 2003

Posts: 1,537 Likes: 15

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2003

Posts: 1,537 Likes: 15 |

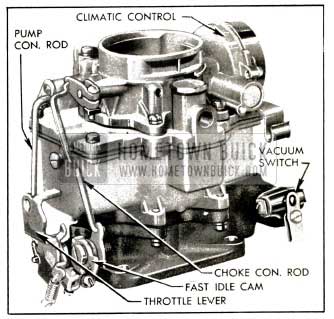

I know you know this, but look for vacuum leaks!!

It looks fabulous!! Thanks Blackwater . . . no vacuum leaks as the carbs contain all fresh or NOS gaskets that are well fitting . . . I hope you figure it out and I hope it is easy to fix. Thanks Beater . . . and the answers are yes and no! Do you remember the old David Letterman "stupid human tricks" segments? These Carters have some really trick 'automatic' features built into them to enhance driveablity . . . but the engineers at Carter never intended them to be run in pairs. My runaway idle issue was due to the fast idle cam stops. There are two screws controlling idle on a Carter WCD - the throttle stop screw and fast idle stop screw. When the carb is fully warmed up the former controls idle RPM. During cold-to-warm operation the latter controls a higher RPM that literally walks down the fast idle cam as the auto choke springs heat up. Very neat. My runaway revving issue was in fact a stupid human trick. When I would clear the front carb off the fast idle cam stop (to close the throttles) the rear fast idle cam stop would engage. With a solid linkage between the two carbs either stop screw holds both throttles open. Duh! I am currently noodling on how to synchronize these fast idle settings. I cannot simply disengage one and use the other to govern both throttle plate openings. The reason being that the Carter engineers designed the fast idle system to govern both the throttle and the choke plate:  When the engine is running on a fast idle cam stop the choke is controlled by the choke control rod - regardless of how warm the auto choke springs may be. I have moved fast-idle syncro to the back burner for now. By managing the warm-up to operating temperature I have managed to get the engine to settle down to ~1200 to ~1500 RPM. I am now on a teeter-totter between initial timing and throttle plate opening. The engine seems to prefer spark advance - but then hates being throttled - popping and rapping the exhaust pipes. Back off the initial timing and the RPM comes down into a rough rich idle that leads to stall . . . The good news is that I am trying to wrest control of a running engine . . . a much better place then trying to figure out an engine that won't run :-)

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

Too complicated for me but I'm glad it's working out.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

Dress the fast idle cam lobe down the same amount on both.

|

|

|

|

|

Joined: May 2016

Posts: 468 Likes: 4

Contributor

|

Contributor

Joined: May 2016

Posts: 468 Likes: 4 |

49,

This is worth a try! Remove the fast idle stop screw from one of the carbs. Use the other carb as "Control" and adjust the cold idle with the control carb. You can slow the fast idle down with one screw to the point that your chokes work and the total air/fuel flow is comparable to a single carb.

I've never run just a pair of 2bbls, only in threes. We would remove the chokes from the front and rear units and run fast idle on the center carb. I always left just enough travel in the linkage, (progressive, of course) to let the front and rear carbs stay at idle until just above the point of fast idle on the center carb.

Think of the twin carb setup like it was a mechanical four barrel that is NOT progressive!

I'm sure you've probably already thought of this, but just in case you haven't.....

Last edited by Blackwater; 06/25/18 09:56 AM.

Never use a minor caliber bullet on a major caliber adversary

|

|

|

|

|

Joined: Apr 2003

Posts: 1,537 Likes: 15

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2003

Posts: 1,537 Likes: 15 |

This is worth a try! Remove the fast idle stop screw from one of the carbs. Use the other carb as "Control" and adjust the cold idle with the control carb. You can slow the fast idle down with one screw to the point that your chokes work and the total air/fuel flow is comparable to a single carb. It's a good idea . . . but there's a hitch. If I remove the fast idle screw (or just back it out of reach of the cam) I loose control over the choke plate on that carb - which is designed to be tethered firmly to the fast idle cam by the choke control rod:  When then engine is cold this will allow the bi-metal spring in the 'Climatic Control' to hold the choke plate closed requiring a smaller throttle blade setting on the fast idle screw in the control carb. Conversely, when then engine starts to warm up the choke plate will begin to hang free. This will let in to much air (on the un-tethered carb)for the fast idle throttle plate setting and lead me back to the original race condition where the incoming air flow pulls the carb off the idle circuit and onto the main meter. Now if I could tether both choke plates to one fast idle cam . . . this would work. But that would be long and clunky linkage and probably require a stronger then stock spring on the control carb fast idle cam. Thanks for sharing ideas. To minds are better then one at solving problems.

|

|

|

|

|

Joined: May 2016

Posts: 468 Likes: 4

Contributor

|

Contributor

Joined: May 2016

Posts: 468 Likes: 4 |

Unless I'm looking at this from the wrong perspective, and I really don't think I am, the choke coil, (the heated element inside the plastic cover which is ordinarily referred to as a "Choke Stove) controls the choke butterfly and the butterfly, by way of the lever on the opposite end of the cross shaft controls the fast idle. You can remove that rod and the choke will still open and close, (Try it! You'll be surprised.) independent of the throttle position.

In fact, if you can find another of those clamp-on levers that fasten to the choke shaft, you COULD attach it to one choke shaft in a vertical position, turn the other carb's choke lever vertical, fabricate a rod to link the two choke shafts and run both chokes off of one choke stove and one fast idle cam.

The rod that connects the two throttle shafts will handle the fast idle for both, so only ONE fast idle cam is needed. The two separate choke stoves are very unlikely to operate at the same rate, especially after a little time and use have occurred. If the throttle link from one carb to the other is tight, (not slack or sloppy) one fast idle cam should be sufficient. That fast idle cam is just a graduated idle stop for the main throttle shaft, nothing more.

Last edited by Blackwater; 06/25/18 02:48 PM.

Never use a minor caliber bullet on a major caliber adversary

|

|

|

|

|

Joined: Apr 2003

Posts: 1,537 Likes: 15

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2003

Posts: 1,537 Likes: 15 |

You can remove that rod and the choke will still open and close, (Try it! You'll be surprised.) independent of the throttle position. I wouldn't be surprised but I think you will be when you look further into the automatic features of these units. General Operation is described here at the Home Town Buick site. What is most intriguing about Cold and Warm Operation is the interplay between the 'position' of fast idle set screw, the throttle control rod, the bi-metal choke spring and the vacuum piston. The choke unload feature also depends on the choke control rod. So I don't think I can just remove it.

|

|

|

|

|

Joined: May 2016

Posts: 468 Likes: 4

Contributor

|

Contributor

Joined: May 2016

Posts: 468 Likes: 4 |

I rebuilt those carbs back before I retired. That vacuum pull-off feature only goes a little ways.

Try this! It'll only cost you a few minutes time. Get the engine started and warm it up until the chokes are full off and adjust your static mixture and hot idle speed(Now is a good time to find the proper timing and base idle throttle settings. Lean out the air/fuel mixture settings if needed to get a good smooth idle and correct acceleration characteristics). Choose which carb you want to be the "slave" carb. Remove the screw that holds the fast idle cam and link and set that assembly aside. Set both carbs so that warm throttle idle position is the same on both. Set the fast idle on the "master" carb. (This will only work "WELL" if your throttle link between the carbs is tight. NO SLACK OR SLOP!! Small "heim" joints and threaded rod is best!) Now set your choke stove assemblies with the throttle opened half way, engine off and cold, so that they barely close, but close all the way. Open the throttle about one quarter and then open the choke on the master carb a little and see if both throttles close slightly farther when released. If they do, you're headed in the right direction.

Now you're ready to try it out. If you do this, let me know how it works. Like I said, I only ever ran three of these at the time and we removed the entire choke assemblies on the front and rear units, blades, rods, stoves, and linkages! I had to plug the choke pull-off vacuum circuits too.

Never use a minor caliber bullet on a major caliber adversary

|

|

|

|

|

Joined: Apr 2003

Posts: 1,537 Likes: 15

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2003

Posts: 1,537 Likes: 15 |

Thanks Blackwater . . . It's definitely worth a try. And your point on linkage is well taken - mine is solid - any setting enforced by a stop screw on one carb will be equally transmitted to the other. And then there's panic's approach: Dress the fast idle cam lobe down the same amount on both. to try to get both fast idle cams to work in concert. I will give both options a try and report back. For now here is where things stand. I have removed the linkage between the two carbs completely in order to prepare for using a sync tool to verify idle balance:  Once if have base timing and idle balance I can experiment with both fast idle options. Which takes me back to the teeter-totter I mentioned earlier. The engine is now under control and idling solely on the idle circuits. I can moderate engine RPM with both the throttle set screws and idle metering screws. If my Sun Tach is calibrated correctly (unknown) idle is controllable between ~900 and ~1200 RPM. The engine seems to prefer 5 to 7 degrees BTDC of initial timing - beyond 7 it is hard to start when fully warmed up. At higher initial advance the engine doesn't seem to want to be throttled. It pops and raps the exhaust pipes and eventually stalls. But throttle response is good. Backing initial timing down to 2 degrees BTDC or even TDC allows me to tune for a lower idle RPM ~900. But it is a rough and stinky idle and the throttle response tends to hesitate if not bog. Vacuum signal is definitely at play here. Above 1000 RPM the vacuum gauge is steady at 16" and the main metering rods remain bottomed out - allowing the idle metering screws to dictate mixture. Below 1000 RPM the the vacuum gauge starts to bounce between 10" and 15" - this in turn causes the metering rods to bounce. Every time the metering rods come off their seats they enrich the mixture beyond the setting of the idle mixture screws. Hence the stinky exhaust. Going to sleep on the problem . . .

|

|

|

|

|

Joined: May 2016

Posts: 468 Likes: 4

Contributor

|

Contributor

Joined: May 2016

Posts: 468 Likes: 4 |

Thinking "Out of the box" here. How radical is your camshaft? Mechanical or hydraulic?? If mechanical, back the lash off a couple of thousandths. With a hydraulic, go zero lash and only an 1/8 turn past! It has the effect of dialing a little retard into the camshaft with little influence on performance, except for WOT. This MIGHT get your vacuum up at a slightly lower idle and give you more leeway for adjustment.

You can go in and retard the camshaft a degree or two at a later date if this works.

Never use a minor caliber bullet on a major caliber adversary

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

Weaker spring at the metering rod

|

|

|

|

|

Joined: Apr 2003

Posts: 1,537 Likes: 15

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2003

Posts: 1,537 Likes: 15 |

I have also considered no springs at all - which would mean that the metering rods would only rise with throttle position. The cam is a long way from stock. Stock spec is 220/231. I found an old Isky spec in his '56 publication:  Specifically the (dual pattern) DP#2 Iskenderian advertised it as a 250/280 affair. I asked the guys at Delta to regrind a cam to the Isky DP#2 spec. The cam doctor report for the stick indicates: 248/264 @ .020 205/233 @ .050 Lift is .41/.40 with stock 1.5:1 rockers. It's a 'moderately tight' stick (from Grumpy Jenkins perspective) with a LSA of 107.5. So I was expecting some lope . . .

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

Can you add some weight to the rod, like split shot?

|

|

|

|

|

Joined: Apr 2003

Posts: 1,537 Likes: 15

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2003

Posts: 1,537 Likes: 15 |

Not much clearance around those rods. But a good idea. Thanks for pondering.

Currently running the vac-advance on a spark port. Going to try an experiment with my vacuum pump to see if I can boost idle timing without hard starting. If so may move to full manifold vacuum.

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

Next thought: short section of brass tube (hobby shop?) fit over non-critical area.

|

|

|

|

|

Joined: Apr 2003

Posts: 1,537 Likes: 15

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2003

Posts: 1,537 Likes: 15 |

Well my vacuum testing revealed that the vac-advance has a slow leak! It doesn't hold steady (leaks down) and hardly moves on 10" of signal. Should have replaced it - the dizzy is NOS - not sure what compelled me to go with the one that was running on the car back in 2010 . . .

|

|

|

|

|

Joined: May 2016

Posts: 468 Likes: 4

Contributor

|

Contributor

Joined: May 2016

Posts: 468 Likes: 4 |

Hey, Bud!! ALL vacuum advances have a leak-down! Just make sure that the leak-down is within specifications. They're made to do that so that the advance doesn't hold under low vac/low idle situations like start-up.

Never use a minor caliber bullet on a major caliber adversary

|

|

|

|

|

Joined: Oct 2009

Posts: 471 Likes: 9

Contributor

|

Contributor

Joined: Oct 2009

Posts: 471 Likes: 9 |

Any chance these rods are the same rods used on the Carter YFs?

Also, just inquiring here, but did you run the nos distributor on a sun or allen machine before you installed it? The reason I ask is that I just recently put an NOS 235 distributor (2403) on my machine and the advance was coming in way later then it should have been. Turns out, even though it was NOS and looked great, all of the NOS grease and lubricant had hardened or thickened up. Advance weights were gooey and gummy. Had to take it all apart and clean it, then it worked as it should. Just thinking here. Hate to see this as a dual carb and distributor issue.

Vacuum advance, is there a number stamped on the advance? Some of them, while looking identical, require a higher amount of vacuum before they start to come in. If the ported vacuum ports for the carbs don't make enough signal (my weber DGEVs do not) you might have to swap over to full manifold vacuum to get the advance to actually work.

Last edited by mdonohue05; 06/27/18 12:38 PM.

|

|

|

|

|

Joined: Apr 2003

Posts: 1,537 Likes: 15

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2003

Posts: 1,537 Likes: 15 |

Hey, Bud!! ALL vacuum advances have a leak-down! Just make sure that the leak-down is within specifications. They're made to do that so that the advance doesn't hold under low vac/low idle situations like start-up. Not this leaky . . . plugging the spark port raised my vacuum by 4" @ 1500 RPM. Alot less metering rod bounce as I try to dial down the RPM toward 1000. No getting idle right until I have the benefit of some vac-advance in the mix . . . Before messing with that I tried disconnecting the choke control rod on the rear carb. This causes the choke plate to slap shut tightly on a cold engine. Opening the throttles puts the front carb on the fast idle cam and unloads the choke - but not so the back carb. The engine was very hard to start and the front carb had to be revved to keep the engine going. Tyring to rev the rear carb resulted in stall. Re-attaching the choke control rod but leaving the fast idle screw backed-off unloads the choke on the rear carb too. Much easier to start - and then smooth with just the front carb on the fast idle stop. Any chance these rods are the same rods used on the Carter YFs? Not sure. The Carter Part number on these is 75-899. The carb sheet indicates that these are a new part for '53 replacing part 75-890 from the previous years. I am hip on the condition of grease after decades on the shelf. I dis-assembled and cleaned all that out. I have the model that Delco created for the 37-39 models years. California Bill preferred these because of the advance curve. Next thought: short section of brass tube (hobby shop?) fit over non-critical area. Good thinking. May not be necessary once I get vac-advance back in the mix. regards, stock49

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

The leak-down is not anything in the advance mechanism, it's the fact that it's open-ended to the intake manifold (no check valve). The can itself should not leak.

The line with the check valve is the brake booster.

|

|

|

|

|

Joined: Jan 2005

Posts: 2,123 Likes: 3

1000 Post Club

|

1000 Post Club

Joined: Jan 2005

Posts: 2,123 Likes: 3 |

A difference in the MR number may be just how it hooks to the other bits, the diameters (actual mixture ratio change), or a height change where the diameter step varies - which changes the vacuum point of cut-in.

|

|

|

|

|

Joined: Apr 2003

Posts: 1,537 Likes: 15

1000 Post Club

|

OP

1000 Post Club

Joined: Apr 2003

Posts: 1,537 Likes: 15 |

The summer has progressed with the same cadence as the rest of the build: major steps forward leading to equally large steps backward . . . The idle was ultimately sorted out a few weeks ago – but not until getting sidelined by vapor lock and then totally stranded on a road test by NOS ignition parts. I had read numerous pieces warning not rely on ‘shelf worn’ ignition bits: “they age even without use – so they are no longer 'ehm' new” . . . but the car seemed to run quite well on my vintage ‘Extra Super’ BAP (Bosch) coil – right up until it quit. Replaced that with a new NAPA Echlin unit and now it runs better then ever . . . With the engine warmed up I disconnected the linkage completely and removed the interconnect rod from the Heim joints. Then I started the car and proceeded to balance the idle between the two carbs using the Uni Syn tool. Then I reconnected the linkage and went to work on the cold fast idle. The rear carb has the fast idle screw backed all the way off. The front carb is two full turns backed off from where it came out of the box. With the firm linkage between the two units when the front carb is on the fast idle cam the engine turns north of 1200 RPM. I think I can lower this but will wait until some late fall cold weather testing to prove this out. Once the engine is warmed up the auto-chokes and fast idle linkage go limp . . . allowing me to further dial things back to a quiet ~ 750 RPM: 216 Idling @750RPM quiet if one ignores the characteristic solid lifter chatter!! I used the vacuum method the set initial timing. Max vacuum called for a little over 15 degree BTDC of initial timing @ 21”. This proved troublesome for hot starting and exhibited a rough idle when attempting to throttle down toward 1000. Testing has resulted in backing off initial advance to just 8 degrees BTDC @ 18’’ of vacuum.

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

Sounds like great progress. Whenever I head out on a real trip in my '53 pickup with a 270 I make sure to stash some stuff under the seat and in the glove box. I keep a complete distributer set up with new ingredients . Also pack a fuel pump, water pump and belt, things I'm not likely to find along the way.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

1 members (stock49),

296

guests, and

20

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

|