|

|

Joined: Dec 2018

Posts: 518 Likes: 18

Major Contributor

|

OP

Major Contributor

Joined: Dec 2018

Posts: 518 Likes: 18 |

What she probably means is the ol' Beater has his share of stuff in THEIR yard. My school teacher wife is quick to point out that we have a yardfull too!! Beater definitely has more truck stuff than I do, but I have quite a bit myself, mostly machines. Look what showed up today...I wouldn't say this was quick, had to wait over a couple months, but AFAIK I will be the first person to have an adapter for a Chevy '37-'53 bell housing (narrow) to either an '83-'92 S10 Chevy bolt pattern (wide) or a '93-'96 S10 WC T5 which has the Ford Bolt Pattern. I have the Ford Bolt Pattern and the older bell housing. For anyone reading along if you use your original bell housing you don't need to do anything to support your pedals, Chevy mounted them on the bell housing. People do mod them, but this is just as well...A big thanks go out to Dave Farwell at Vintage Metalworks.

TT

Keroppi - 1946 Chevy 1/2 Ton Pickup

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

Yeah, It was a reference to what my wife referenced once as my private wrecking yard. She doesn't view it as yard art.  That is a cool adapter and I think a wise choice for you so you don't have to mess with the pedals. My '26 has the pedals mounted to the bell housing and it is stamped steel. I would like to keep them there because I'd like to be able to swap in an older Chevy 4 if I decide to build one.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Dec 2018

Posts: 518 Likes: 18

Major Contributor

|

OP

Major Contributor

Joined: Dec 2018

Posts: 518 Likes: 18 |

Yeah, It was a reference to what my wife referenced once as my private wrecking yard. She doesn't view it as yard art.  I gotta call foul on that, my wife is similar. Me, my wife and both kids were having a conversation about our lake property...nobody was ecstatic over it like I was. Very similar to the yard art, since art is in the eye of the beholder. I just like old stuff in the yard...  Everyone suggested I give it up. My sisters, Mom, nobody seemed to see what potential the property had. Now my own wife and kids realize how much it means to me, and even my wife is warming up to having it as a 2nd home...More importantly they are seeing the value of what I did. Maybe I will have a shop with a lift in it in the next few years. I've always wanted one. I would love to be able to work on cars the right way, with a lift.  That is a cool adapter and I think a wise choice for you so you don't have to mess with the pedals. My '26 has the pedals mounted to the bell housing and it is stamped steel. I would like to keep them there because I'd like to be able to swap in an older Chevy 4 if I decide to build one. It's not that difficult to fabricate something up that attaches to the frame, but I think it's cleaner to do it this way as all the pedal parts are all the same as original. I agree it was worth having them make it for me, although I had half of what I needed, if anyone had a bell housing to match up to this, a template to overlay over the crankshaft/pilot-bushing hole would be what is needed.

TT

Keroppi - 1946 Chevy 1/2 Ton Pickup

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

They are not making any more land. Well that is mostly true, but we are using it up faster than it's being made. A property that is away from a big city with access to water & water rights could become your family's greatest asset and will never be worth less than what you put into it. Tough times are coming. Yard art will be another resource.

When I get to mounting my Chevy II 4 cylinder I want tiotry to use the stock mount positions. and try to put the pedals in a place so linkage will connect. A brake master cylinder will have to me placed somewhere. With Chevy inlines the left rear gets crowded with a mount, brake & clutch linkage, and exhaust. Don't know if I can make it work or not.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Dec 2018

Posts: 518 Likes: 18

Major Contributor

|

OP

Major Contributor

Joined: Dec 2018

Posts: 518 Likes: 18 |

The one thing that was done to my '46 before I bought it was the brakes. A dual reservoir master cylinder and brake lines were added, but I may need to swap it out, or swap the lines, seems the big reservoir is going to the rear. I'll need to check that. I plan for yard art at the lake. I have a big hill my property sits on top of and could use a couple pieces of clapped out farm equipment.

TT

Keroppi - 1946 Chevy 1/2 Ton Pickup

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

Dual reservoir masters are a good thing. I've never had a master cylinder fail but a backup is better.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Dec 2018

Posts: 518 Likes: 18

Major Contributor

|

OP

Major Contributor

Joined: Dec 2018

Posts: 518 Likes: 18 |

Dual reservoir masters are a good thing. I've never had a master cylinder fail but a backup is better. You know, here's the funny thing. I struggle with what I want to get for towing, grasping over a pickup rather than the flatbed I have, but the towing truck always gets down to something I really only need occasionally, I only tow a handful of times a year. However, as far as having a truck to drive, it seems I keep coming back to my '46. My style is probably not for everyone, but I'm hoping that in the end my '46 will be scooting down the highway with tunes going away in the background...and most of my hauling will be able to go in the back of the '46. But this drivetrain conversion is going to be key to have the truck I want with my '46. I don't need any other pickups, I have the one I want right here.

TT

Keroppi - 1946 Chevy 1/2 Ton Pickup

|

|

1 member likes this:

DoubleDingo |

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

My old '53 has always been used for hauling. It was our only pickup for many years. It gets to by my hot rod buddy when we have a day off. It will never be pretty but I'm not afraid to use it.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Dec 2018

Posts: 518 Likes: 18

Major Contributor

|

OP

Major Contributor

Joined: Dec 2018

Posts: 518 Likes: 18 |

Oh, I will always need some type of hauler, I just buy too much heavy stuff, but most of what I do doesn't require hauling, that's limited to a handful of times per year. My flat bed is probably just fine for most of my hauling that doesn't require a trailer, when I can get a forklift on the loading end.

Let me ask you this. My '46 is a 1/2 ton, does that imply that I am able to haul 1000 lbs? Isn't that how trucks are designed? So much discrepancy between payload, GVRW, tongue weight, et al...

TT

Keroppi - 1946 Chevy 1/2 Ton Pickup

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

Basically that is the idea. 1/2 ton a thousand pounds and 3/4 1500 but GVWR is a newer and far more confusing designation. I use it as a suggestion.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Apr 2003

Posts: 1,537 Likes: 15

1000 Post Club

|

1000 Post Club

Joined: Apr 2003

Posts: 1,537 Likes: 15 |

Here in Ohio we have a 10,000 pound GVW threshold - which demands a commercial truck plate (significantly higher fees - including a visit to the scales). Go above 26,000 pounds gross and one needs a CDL to drive it.

|

|

|

|

|

Joined: Dec 2018

Posts: 518 Likes: 18

Major Contributor

|

OP

Major Contributor

Joined: Dec 2018

Posts: 518 Likes: 18 |

Here in Ohio we have a 10,000 pound GVW threshold - which demands a commercial truck plate (significantly higher fees - including a visit to the scales). Go above 26,000 pounds gross and one needs a CDL to drive it. I'll share these pics, but don't want to de-rail this thread entirely, this is an Inline 4 actually, it's a Cummins 4B in this, but this was my mess back on Sept. 20th. Let me preface this. You can see trans fluid under the flat bed, but as it turns out I think I lucked out and it just overheated and blew fluid out the overflow/breather. I lost a tire and wheel on the freeway, but able to get off...and lost the 2nd wheel and tire trying to pull it up that stupid driveway. Flat bed was towed to my yard, this happened up in Vacaville, CA, 100 miles from my yard. The trailer and crane were pulled into a parking lot for Sachs 5th Ave. which closed during the pandemic. This was over 22,000 lbs. for the trailer and crane, and I do have a brake controller, but still too much weight, and I have retired from doing any heavy moving in the future.  Last Sat. a rigger saved my bacon, I was on pins and needles for 2 weeks as I had just picked this up from an auction purchase in Sacramento.   All that said, I am hoping to get back working on the T5 and rear axle this Sunday. As you can see, I've been a bit occupied to work on the T5 or axle...

TT

Keroppi - 1946 Chevy 1/2 Ton Pickup

|

|

|

|

|

Joined: Dec 2018

Posts: 518 Likes: 18

Major Contributor

|

OP

Major Contributor

Joined: Dec 2018

Posts: 518 Likes: 18 |

Ok, thinking what panic mentioned to me a week or so back, keep doing this and it will get easier. Lucky I didn't break the gear on the countershaft, I did kill my Harbor Freight 12-ton import hydraulic press...maybe a good opportunity to get a better press and get rid of this crap I paid $25 for. I know why the guy only charged $25 now...but to be fair, I've used it for at least a half dozen projects. I ripped it up pretty good with a 3' pipe used as a breaker bar...  I tried to heat the bearing with my map torch, but no go...then a friend suggested I use a tig torch to heat it on the race itself...and when I went out I realized I had killed the press...so I went to his house and he started to press it on his press and something just didn't seem right, the videos I saw showed them destroying the bearing and using the top of the race to pull it off the shaft...I told him I wonder if none of those gears come off...so we used a couple small pry bars and whola, it came off. Lesson in all this, counter shaft only has the bearing on it. Nothing else comes off. I would have been buying a new counter shaft had I busted this one...whew...ok panic, I learned another piece, but I'm gonna have to trust you that this stuff will get easier, I hope you're right!  Luckily I have a fair amount of tools, otherwise I would probably be breaking more stuff...that could have cost me a countershaft, about $150 on Ebay...whew...slipped that one...    At least I got it off of there. I have a new one so no big deal on destroying it. I got it off whole, so the heat must have helped to loosen any locker. You can see the cage started to pull up on one side. As I said, I have a replacement in the rebuild kit.

TT

Keroppi - 1946 Chevy 1/2 Ton Pickup

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

Straighten the press out and weld the frame up. You won't be trying to separate the cluster gears again. It that press won't take something apart it likely doesn't come apart.  One problem guys like me have is that the things I learn will likely not be used again. Build it, fix it and I'm off into the unknown again.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Dec 2018

Posts: 518 Likes: 18

Major Contributor

|

OP

Major Contributor

Joined: Dec 2018

Posts: 518 Likes: 18 |

Straighten the press out and weld the frame up. You won't be trying to separate the cluster gears again. It that press won't take something apart it likely doesn't come apart.  Probably so, and I could probably use some 6010/6011 and blow through the paint. I'd rather find a decent one to replace it with, not a lot for under $1,000 for a decent Carolina. Welding will get it back together...until I can replace it. Waiting for a call back from this one to see what it is, but with no-name it's probably imported. He did buy it 24 years ago, so it might be decent. I buy auto parts from Winchester, they're a part of Napa. https://sfbay.craigslist.org/scz/tls/d/santa-cruz-automotive-shop-tools-snap/7392408053.htmlI'd probably trade it for your 000-18...j/k (kind of, I'd do it! LOL)  One problem guys like me have is that the things I learn will likely not be used again. Build it, fix it and I'm off into the unknown again.  I will be honest, I resemble that remark.

TT

Keroppi - 1946 Chevy 1/2 Ton Pickup

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

That looks like the one my son has. it's pretty tough. I don't think the 000-18 would do as good of a job as the Harbor Freight press. The wood is pretty thin.

Last edited by Beater of the Pack; 10/18/21 08:13 PM.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Dec 2018

Posts: 518 Likes: 18

Major Contributor

|

OP

Major Contributor

Joined: Dec 2018

Posts: 518 Likes: 18 |

That looks like the one my son has. it's pretty tough. I don't think the 000-18 would do as good of a job as the Harbor Freight press. The wood is pretty thin.  This one is not that rigid. I don't think the 000-18 would do very good at it either...but I think I'm gonna just pull those nuts and bolts out of there, clamp it with a couple C-Clamps and weld it with cellulose rod. Otherwise it will take a bit of cleaning to be able to tig it. I only have tig/stick welders.

TT

Keroppi - 1946 Chevy 1/2 Ton Pickup

|

|

|

|

|

Joined: Dec 2018

Posts: 518 Likes: 18

Major Contributor

|

OP

Major Contributor

Joined: Dec 2018

Posts: 518 Likes: 18 |

Here in Ohio we have a 10,000 pound GVW threshold - which demands a commercial truck plate (significantly higher fees - including a visit to the scales). Go above 26,000 pounds gross and one needs a CDL to drive it. stock, Missed that before I think, but in California we have to have a commercial plate on any truck in order to haul anything in the bed. Even my '46 is required to have a commercial plate in order to carry even a bag of groceries in the bed. Minimum is about $160/year nowadays for a commercial plate, I *think*, I'm sure they can find reasons to charge more, I don't want to inquire to them...LOL EDIT: We also need a CDL over 26,000 but also need a commercial plate for a pickup. As long as I stay within 10k on my flat bed, I am not required to pull into the scales. It's only when I have a trailer on the back of the flat bed that you are required to stop. I think it would be hard for them to determine if you were hauling 2500lb or 4000lb. to make you pull in...(my flat bed is 7500lb). The problem is I do need to use a trailer to get most of my machines up to the lake.

Last edited by TraditionalToolworks; 10/20/21 05:21 PM. Reason: CDL is required here also.

TT

Keroppi - 1946 Chevy 1/2 Ton Pickup

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

Any progress on the pickup? Is the transmission together?

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Dec 2018

Posts: 518 Likes: 18

Major Contributor

|

OP

Major Contributor

Joined: Dec 2018

Posts: 518 Likes: 18 |

Any progress on the pickup? Is the transmission together? No, have been busy...drove up to Lake County to take care of my expired septic permit, added a 30'x40' shop onto the septic permit so I can have a bathroom and utility sink in the shop, and run into the same septic. Will pull a separate building permit for the shop/garage, but the septic will not need to be redone. Environmental Health is happy, County is happy, I'm happy as I'll be able to save another septic permit by parlaying this on the same septic permit. I also finished my job on Thurs. and start a new position on Monday. The company didn't want to save me, so they watched me walk. This is why I needed to do this on Fri. as the County is only open during the week. Since I start a new job on Monday, I really wanted to take care of this before I start the new job. So all of this hasn't lent very well to getting any progress on the T5, but I was planning to look at some of it this weekend and/or get the hydraulic press welded together so I can use it still. PS - did I mention my wife is nagging me with a honey-do-list also? She got new carpet last Sat. and I had to hire a piano moving to move the piano from the living room to the family room and back after we got the carpet installed. S&G Carpet wouldn't touch the piano. Now she has a few other things it's hard for me to say no when she looks at me with those sad eyes...  Life is crazy...

TT

Keroppi - 1946 Chevy 1/2 Ton Pickup

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

The old saying, "A happy wife means ...........". However we finish that reflects on our own situation/wife. No explanation necessary.  There are hoops that need to be jumped through unless you crave a constant battle. No fun or piece in that. Good luck on the new job! How familiar are you with septic systems? Be careful what goes into your shop sink. Septic systems are real world organic. Our has not needed to be pumped in it's life of almost 50 years.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Dec 2018

Posts: 518 Likes: 18

Major Contributor

|

OP

Major Contributor

Joined: Dec 2018

Posts: 518 Likes: 18 |

The old saying, "A happy wife means ...........". However we finish that reflects on our own situation/wife. No explanation necessary.  Truth! Good luck on the new job!

How familiar are you with septic systems? Be careful what goes into your shop sink. Septic systems are real world organic. Our has not needed to be pumped in it's life of almost 50 years.

Oh, I will be very careful about what goes down the utility sink, but I need to be able to clean parts and such, so even in the case I need to dispose of the hazardous material, I'll drain/dispose of it, that stuff won't be going into the leach field. I was most excited to find out I can have even a bathroom in the shop, cause you need a place to wash your hands if possible, it would suck to have to go into the house to do that each time. Although I guess I could put a sink outside without having to plumb the shop, having a shower there with hot water would be ideal, hot water for the utility sink as well. A few good things in regard to my truck project is that I will be looking for a lift after I can get the shop in place. I really want to have a lift to be able to work on cars/trucks with. I'm fed up with crawling on the garage floor. And thanks for asking, I do need to get myself back on track with this project, the past couple weeks have been pretty hectic, last week our house was torn apart getting new carpet (that Happy Wife deal...), interviewing on video and doing a 3 hour in person interview, has taken a toll on me. I sure hope I can sort out and get this T5 back together. Most everything will be getting replaced with the rebuild kit. I could probably even tap the end bearing on the input shaft with a dead blow and a bearing seat. Maybe I'll do that rather than using the hydraulic press. Would be nice to have the press though, there's a couple other bearings that need to be pressed on (or BFH) as well. I'm looking around the workbench, there's a lot of parts, bearings, seals, lube, sealer, et al to put it all back together. Probably need to get things cleared and spread out a bit better so I can organize it better.

TT

Keroppi - 1946 Chevy 1/2 Ton Pickup

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

Sounds like you have plans. Keeping bad stuff out of the septic is not easy. Adding to the bacteria is good. I use the mice I take out of traps. Keeping roots out of the leach field is important too.

Look up some tips about putting the input shaft in the freezer overnight and heating the bearing. You have to work pretty fast nut the hot bearing will go on much easier.

Good luck with the new job!

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Dec 2018

Posts: 518 Likes: 18

Major Contributor

|

OP

Major Contributor

Joined: Dec 2018

Posts: 518 Likes: 18 |

I haven't dropped off the planet yet, but been swamped with a new job, traveling about 2-1/2 - 3 hours per day (1.25-1.5 hour one way) on the freeway...I'll be working at home most of the time, but needed to go in this week as my new manager left today to go on vacation for pretty much the rest of the year. I'll only be required to go into the office once a week if needed after I get everything setup...do it's a pretty good deal.

I cheated on the hydraulic press, I picked one up last night inside the Haight, damn good thing I had my phone as I would have never found that place without it. Typical SF City, up, down, up down, one way, left, people jumping out in front of you, more up, down, up down, another one way...I hate the city...so anyway, it's not ideal but the best I could find that was within what I would spend. It's an Arcan, I think they used to be sold by Nothern Tool, who quit selling them. This one is made in America, but the new ones on Ebay are Chiwanese. There are no press plates, but I have some cheapos from the HF press, I'm pretty sure they're cast but I can use them for now. Also no pins to hold the head plate, the portion that slides up and down and sits on the pins. In general it's way more heavy duty than what I have, and it's a 20-ton. It has a bottle jack, so not a lever/pump setup, but I was able to get it for $250. Not sure that's a good deal considering it's missing the pins and plates, but to be honest I don't see much under $1k that looks decent. The new 12-ton HF has a better bolt setup, looks more rigid and I'm sure stronger than the one I have which pulled apart, but I'd rather have this unit in my shop. It's in the pickup outside, it's drizzling so good I got the bottle jack in the tool box. Will get it out tomorrow, and hope to be able to make progress this weekend on the T5.

TT

Keroppi - 1946 Chevy 1/2 Ton Pickup

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

You sound busy. It sounds like the new job will settle down in a while.

I need to do some work on my HF press. It's good enough for what I do and my son has a better one of I need it. Several years ago I was doing a "quick" job at a friend's shop using his much abused HF press. You know the story it broke while I was using it so I drove home and took the piece off of my almost new one to replace the broken part on his. The big pin that does the pressing broke off at the top weld probably because the working end was mushroomed out of shape. Well, I never got his piece fixed and all his tools went away so I still have the broken one. I have thought of welding a fixture in there hat would accept impact tips like pickle forks, punch, ........& a flat tip like the original one.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Dec 2018

Posts: 518 Likes: 18

Major Contributor

|

OP

Major Contributor

Joined: Dec 2018

Posts: 518 Likes: 18 |

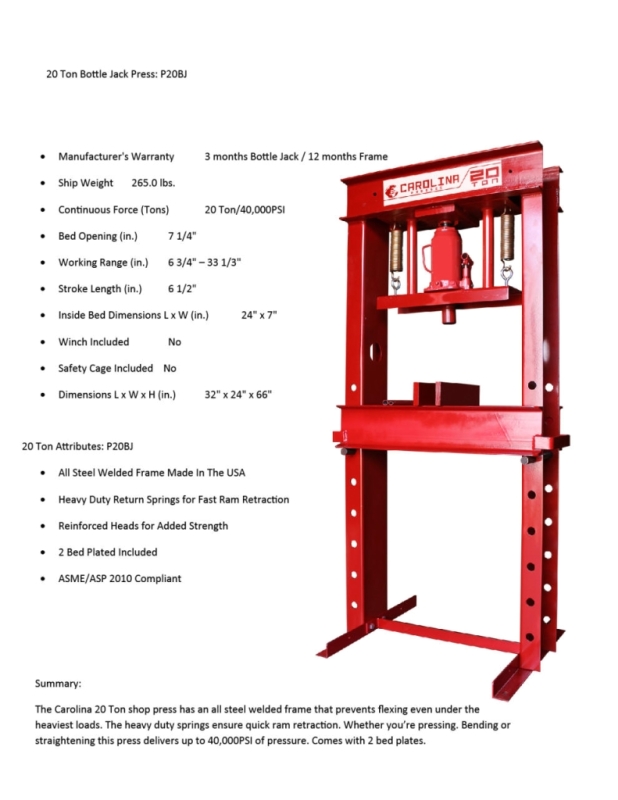

I have been super busy, Last Wed. as I was just heading onto the freeway on my way home, my wife called that the main drain was backed up...Nobody will tell you how much over the phone, I don't get it. Just tell me how much you'll charge to clear it, it happens every couple years and I typically do it myself, but in this case I need to head out early in the morning. Fri. I finally got to work at home, but had to do the long travel 4 days. Ok, I made out pretty good on this press after all is said and done. It doesn't say made in USA on it, but it is exactly the same press as made by Carlina in Travelers Rest, SC.   NOTE: stock, these images are 800x600.

TT

Keroppi - 1946 Chevy 1/2 Ton Pickup

|

|

|

|

|

Joined: Dec 2018

Posts: 518 Likes: 18

Major Contributor

|

OP

Major Contributor

Joined: Dec 2018

Posts: 518 Likes: 18 |

This is the press I bought. No plates and the head plate is down at the bottom, I have some pins in the garage. Will use the HF 12-ton plates for the time being.

TT

Keroppi - 1946 Chevy 1/2 Ton Pickup

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

Looks plenty stout. You can break all your tranny parts with that.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Dec 2018

Posts: 518 Likes: 18

Major Contributor

|

OP

Major Contributor

Joined: Dec 2018

Posts: 518 Likes: 18 |

Looks plenty stout. You can break all your tranny parts with that.  Indeed! I was thinking the same thing...great minds thinking alike and all that...

TT

Keroppi - 1946 Chevy 1/2 Ton Pickup

|

|

|

|

|

Joined: Dec 2018

Posts: 518 Likes: 18

Major Contributor

|

OP

Major Contributor

Joined: Dec 2018

Posts: 518 Likes: 18 |

Getting back in gear, for lack of a better analogy...as I keep saying...I'm kinda talking out loud as I'm going alone but would welcome any advice on this one small piece of the puzzle, the Input shaft. First, the back history on the T5 if I haven't mentioned this. A guy with a Ford truck bought this to put into his 60s F-100. This is exactly what he wanted, a WC T5 with a Ford Bolt Pattern on it to mate up to his Ford bell housing. Not being easy to find, he was going through the salvage yards and found this which he thought was a '93 S10. It is a '95, but they're the same T5, and they use electric speedos. However, the gears inside match up to Ford gearing and to get the input shaft for a Ford, it has a different spline, same issue I am solving. However, this has the Chevy gearing in it that I want, so even though I need to get a clutch fab'd for me with a 26 spline in my diam, I can solve that piece. This is the only way to get a WC T5 in an S10 front mount shifter T5 needed for bench seats. (whew, that was a mouth full in itself) He bought another Ford T5 and sold this to me for $350. Now, the cheapest thing to do would have been to use the T5 as-is, because it turns out it was rebuild already as I saw a grinder mod that PaulC recommends on the shifter shaft. But I never want to have to go into this T5 again, so though I would just rebuild the entire thing and replace all the wearable parts. I don't believe the rebuild kit includes any parts for the input shaft, and older vintage input shafts were 11 spline, and the '95 T5 I have has a 26 spline which is pretty much what a modern date input shaft may use, I'm not clear, but there was an intermediate spline count after 11 but less than 26. Since I don't have any parts, I as leaning to just getting a new input shaft which was about $50 last I checked, but need to figure that out. There is some type of rubber seal in the bottom, and a bearing at minimum that I will need, and I can probably get the old bearing off, I don't know about the seal in the bottom of the cover, which is really crap'd up. Probably won't be pretty if I wire wheel and clean it up, but nobody is gonna be able to see inside the bell housing. I may need to cut about 3/4" off, that I'm not sure of yet, but I don't have a problem cutting a new one. Theory on why it look like it does. I believe water got into the bell housing and/or when the S10 was sitting in the salvage yard from the shifter opening. I think it happened before since it was rebuilt, but I think whoever rebuilt it cheaped out and used the original input shaft to save some coin. Then I believe the S10 was in another accident and went to salvage at that point. I am going to look for that seal and bearing to see if I can refurb the one I have, or find another one. Since my vehicles are different years than the specific model, I can't find which one has the manual T5 with overdrive, so having a difficult time finding the correct spline...I need a 26 spline input shaft assembly for a 1995 Chevrolet S10, and don't any offers for what would be a manual. ![[Linked Image]](https://www.inliners.org/ubbthreads/ubbthreads.php?ubb=download&Number=646&filename=IMG_4923.JPG) ![[Linked Image]](https://www.inliners.org/ubbthreads/ubbthreads.php?ubb=download&Number=647&filename=IMG_4924.JPG)

TT

Keroppi - 1946 Chevy 1/2 Ton Pickup

|

|

|

|

|

Joined: Dec 2018

Posts: 518 Likes: 18

Major Contributor

|

OP

Major Contributor

Joined: Dec 2018

Posts: 518 Likes: 18 |

I did do some research on this and found an input shaft, which says it's for a GMC Sonoma (sister to the S10). It also says WC transmission, '93-'95. Perfect, I believe, mine is a '95 T5. I have a 21 tooth gear with a 26 spline on the input. I counted the teeth on the input shaft gear, which mates up to the main shaft. I think I'm gonna order a new one. I found the input shaft seal at O'Reilly's but it's $35 for the seal only. https://www.oreillyauto.com/detail/.../a/4206/automotive-truck-1995-gmc-sonomaAnd I see an entire new input shaft for $60. https://ampdistributing.com/collect...rg-warner-tremec-world-class-input-shaftEDIT: checking with Dave Farwell to see if it makes sense to go with a 10 spline, 21 tooth input shaft and use my existing clutch. I was planning to use the 26 spline and have a custom clutch made, but that would cost about $125. If anyone here has any thought on the input shaft being the same or not I'd appreciate it. EDIT2: Oh wait, I just remembered that I do have an extra 3 speed Muncie transmission which has an original '55 input shaft, I can measure and count the splines to make sure of this.

Last edited by TraditionalToolworks; 03/29/22 09:14 PM. Reason: Mention 10 spline 21 tooth input shaft

TT

Keroppi - 1946 Chevy 1/2 Ton Pickup

|

|

|

|

|

Joined: Dec 2018

Posts: 518 Likes: 18

Major Contributor

|

OP

Major Contributor

Joined: Dec 2018

Posts: 518 Likes: 18 |

Ok, it's always good protocol to answer your own question on the Internet I'm told... NOT!Bolts were not that tight, easy to get the input shaft off...first a little quote from Lynyrd Synyrd...just to go along with the rancid organic oil smell...  Ooooh that smell Ooooh that smell

Can't you smell that smell

Ooooh that smell

The smell of death surrounds youThe answer is NO, you can't swap out the input shafts and I suspect why Dave Farwell told me to use the 26. Here's the pic of each, side-by-side. You can see the bearing/race is completely different, the old 10 spline being a roller bearing and the newer GMC being a tapered roller bearing. I will be ordering a new 26 spline 21 tooth input shaft to replace the original. ![[Linked Image]](https://www.inliners.org/ubbthreads/ubbthreads.php?ubb=download&Number=648&filename=IMG_4927.JPG)

TT

Keroppi - 1946 Chevy 1/2 Ton Pickup

|

|

|

|

|

Joined: Dec 2018

Posts: 518 Likes: 18

Major Contributor

|

OP

Major Contributor

Joined: Dec 2018

Posts: 518 Likes: 18 |

Good news is Dave Farwell has some seals, he said they come in the rebuild kit. So I may have a seal in my Transparts Warehouse overhaul kit, I do see a rear tail shaft output seal, but the parts are in cryo pack so I'm not sure. I don't see any instructions or info at all, just parts. I was under the impression the overhaul kit doesn't include the input shaft parts as there could be different engines that the T5 adapts to. When I open the rebuild kit, I will compare the seals vs this one after I take it out. Definitely want to get that out whole without tearing it, just in case the seal is not there. Just in case I need to reuse it. I was hesitant to reuse this, as the retainer is so gunked up, but I can clean that off the outside and paint it with the same silver paint I painted the case/tailshaft/cover, spraying that on the outside and clean up the bottom, replace the seal, and use some anerobic gasket maker, and call that good to go. I just can't tell if this seal is in the overhaul kit just yet. I want this to be the last time I need to go in and rebuild this T5, it should last for the rest of my life, but my son will be getting my pee-cup and I don't want to force him with repair something, although he will have my shop after I get it done...if I end up with a lift, that would be sweet for him...  ![[Linked Image]](https://www.inliners.org/ubbthreads/ubbthreads.php?ubb=download&Number=649&filename=t5-input-shaft-retainer.jpg) ![[Linked Image]](https://www.inliners.org/ubbthreads/ubbthreads.php?ubb=download&Number=650&filename=t5-input-shaft-retainer-seal.jpg)

TT

Keroppi - 1946 Chevy 1/2 Ton Pickup

|

|

|

|

|

Joined: Dec 2018

Posts: 518 Likes: 18

Major Contributor

|

OP

Major Contributor

Joined: Dec 2018

Posts: 518 Likes: 18 |

I have to claim ignorance, not knowing that Tremec has a manual on their site. This looks to have all the info for both NWC and WC T5s. This could be useful for many people with vintage pee-cups as the T5 is most likely the most popular manual overdrive transmission put into them, the S10 being the most popular for bench seats. This link came courtesy of Dave Farwell at Vintage Metalworks. https://www.tremec.com/anexos/TRSM-T5-0510-R1_173.pdf

TT

Keroppi - 1946 Chevy 1/2 Ton Pickup

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

I've done two of these one Ford WC for my son's Studebaker and the now WC in my '53 pickup. Both long enough ago that I don't remember the details. For my pickup I do remember searching the clutch & pressure plate books when I worked a CarQuest. I did find some that worked but don't remember what they are. I can't locate the notes either. The are in the shop I'm cleaning. Pretty sure it is 21 alpine 11" and the pressure plate had the diaphragm release. There is a long & short throwout bearing too. I made an adapter/spacer for mine so I didn't have to cut anything. It is an S10 but didn't have a GM or Ford bolt pattern.

You seem to be plugging right along.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Dec 2018

Posts: 518 Likes: 18

Major Contributor

|

OP

Major Contributor

Joined: Dec 2018

Posts: 518 Likes: 18 |

Beater, I didn't realize you had a T5 in your '53, and didn't know your son had a Study, that's cool, I have always kinda liked the Study pickups, natural lines to chop the top. The S10 WC was only in the '94-'95 as I recall. Did you use digital gauges? I went to the hassle of getting the tailshaft converted so I could connect it to my mechanical speedo and keep the original look in the cab. The are in the shop I'm cleaning. Pretty sure it is 21 alpine 11" and the pressure plate had the diaphragm release. If you find it let me know, I'm curious what it is and how long the shaft is.There is a taper in this WC retainer and the input shaft has a taper that mates to it. You can see the taper in the phots above, the bottom seal has a taper under it, so the seal slipts over the shaft and the taper mates to the inner taper underneath. There is a long & short throwout bearing too. The length is an issue on some trucks also, and 3/4" needs to be cut off. I am not clear if this will be needed on mine or not. BTW, the old 10 spline input shaft I have, has loose roller bearings inside, no race. So they are entirely different, with a enclosed roller bearing on the front. WC uses mostly tapered bearings, like Timkens. You seem to be plugging right along. Thanks, but I'm probably the slowest mechanic on the planet!

TT

Keroppi - 1946 Chevy 1/2 Ton Pickup

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

The Studebaker is a '54 station wagon. The part that needs to be cut is the tip of the input shaft that goes in the pilot bearing. Mine was 3/8". Since my bolt pattern didn't match I made an adapter from 3/8" plate and didn't trim it. You can make a spacer even if your pattern matches. Just be sure the clutch plate full engages the splines in the input shaft. Trimming the shaft is no big deal either & easier than making a spacer. ![[Linked Image]](https://www.inliners.org/ubbthreads/ubbthreads.php?ubb=download&Number=652&filename=100_0272.JPG) Mine has a mechanical speedo but the plastic gear either moved on the shaft or is slipping. Friend who built trannys helped build mine and did a WC upgrade.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Dec 2018

Posts: 518 Likes: 18

Major Contributor

|

OP

Major Contributor

Joined: Dec 2018

Posts: 518 Likes: 18 |

The Studebaker is a '54 station wagon. Oh, it's not a woodie is it? Study did make some woodies...slap me a surfboard that there and let's go on safari! I feel like I'm in high school again! The part that needs to be cut is the tip of the input shaft that goes in the pilot bearing. Mine was 3/8". Since my bolt pattern didn't match I made an adapter from 3/8" plate and didn't trim it. Yes, in fact this is why I said I don't know if I'll need to trim mine. My adapter plate that Dave Farwell made me should account for the difference. However, I'm not clean on the stickout, I need to measure to see. But mine might be different than the one from the '55. I will try to have it ready to swap in, but will measure mine when I pull the 3-speed out. Originally I was thinking I could use the 2 clutches I have if I was to use the 10 spline. That was my reasoning to ponder the 10 spline/21 tooth, but it's not going to work. Mine has a mechanical speedo but the plastic gear either moved on the shaft or is slipping. Friend who built trannys helped build mine and did a WC upgrade. What Dan has is a piece of spring metal that the end fits in the hold in the shaft, and it seems that all main shafts have this hole for the mechanical speedo, even the electric ones. But the tailshaft case is not so simple. I'm not exactly sure what he did, it's sealed up so you can't see. I'm pretty sure he does that on purpose, otherwise everyone would convert their own. I was really pleased with his work, he bead blasted the tailshaft and had it ready for clean/paint. Do you just use an hoist when you do a rebuild? I wasn't sure if a engine stand was needed or not? I have a 2 ton gantry going in the new shop, with an electric hoist, so in the future that won't be an issue, but I do have a couple engine hoists. I was under the impression that most people removed the engines with a hoist and then moved them to a stand, some are pretty elaborate with water and power to test the engines. I know all that is not needed, but if I ever find a good deal on a lump I'd consider learning to rebuild it.

TT

Keroppi - 1946 Chevy 1/2 Ton Pickup

|

|

|

|

|

Joined: Oct 2007

Posts: 5,015 Likes: 47

1000 Post Club

|

1000 Post Club

Joined: Oct 2007

Posts: 5,015 Likes: 47 |

Last edited by Beater of the Pack; 03/30/22 05:41 PM.

"I wonder if God created man because he was disappointed in the monkey?" Mark Twain

|

|

|

|

|

Joined: Dec 2018

Posts: 518 Likes: 18

Major Contributor

|

OP

Major Contributor

Joined: Dec 2018

Posts: 518 Likes: 18 |

Here's the Conestoga Fewer that 2000 of this model were built but OT here it's a now supercharged version of that V8 model. I like that, even though not a woodie, it's cool and I would still strap a surfboard on top and go on safari! LOL By the way CNC DUDE makes an engine stand fixture foe Chevy & GMC sixes. Good to know. I'd probably buy one if I was rebuilding one, although the setup you had with bolts on the top of the head hanging on chains looks like it was working, a stand would be safer and more stable when you work on it. The stand is how a real mechanic would do it.  Your '47 had a 235 bolted to the stock bell housing I think. The difference in these bell housings are with mounts, pedals, clutch arm, starter attachments .....As far as I know the distance from the back of the block to the face of the transmission is the same. So what you had before is what you want and measuring what you have will give you what you need. Just include the adapter thickness in the mix. You may come out like I did with no shaft cutting needed. Yes, (really '46, but I'm not in a mood to split hairs) and the thing about that is that since the pedals are connected to the bell housing, I want to keep my bell housing that is in there so I don't need to modify anything for the pedals and if I ever did want to replace the engine, I could still have my pedals if I adapt to my bell housing. I suspect this T5 will stay in there, AND the 235 will stay in there for pretty much the life of the truck, however long that may be...it's gonna have to make it through my abuse, and then my son's for the life I can see for it today.  EDIT: Damn that 270 really looks nice in your '53!

Last edited by TraditionalToolworks; 03/30/22 08:17 PM. Reason: Wow, that 270 in the '53 sho' do look nice!

TT

Keroppi - 1946 Chevy 1/2 Ton Pickup

|

|

|

|

0 members (),

295

guests, and

49

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

|