John,

Actually, I installed the latest seal precisely in accordance with Best's very detailed instructions. They provide a shim and cutoff tool to in fact leave the ends proud of the cap. The ends were NOT trimmed flush with the top of the cap.

I carefully inspected the NOS rope seal ends as this is where one would obviously expect the seal to first let oil slip by. Remember that this is splash oil not pressure oil.

The NOS Rope seal showed no signs of oil sneaking by the ends at all. Both the top and bottom were very carefully installed, and the cap was removed after installation multiple times to ensure that the ends were not jammed under the cap.

The Best Seal is not one which lends itself to trimming in the way you describe and I am a bit baffeled by your approach as I've now been horsing with this particular seal extensively and trying to trim a smashed seal is like trying to trim your beard with a chainsaw! It's too difficult once the seal ends are mashed.

In fact, Best's instructions state specifically to NOT do what you suggest, but at this point I'll try anything. I will say that each round of the seal dance consumes on entire day, so this is not an insignificant event. By the time you get the truck up and the chassis components that are in the way of pan removal removed and then pan off and the gasket surfaces cleaned, you've lost a good 4 hours. Then a few more on the install side.

I had two guys at my shop today who collectively have over 60 years of inline engine experience; one as a mechanic and one an engine shop owner and rebuilder. They are both stumped as well.

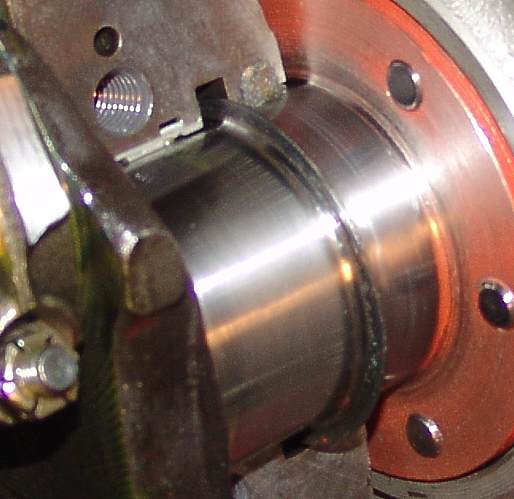

John, here's what the crank looks like with the upper half asbestos rope seal installed, and as you can see it sits just a whisker proud of the surface in the "relaxed" position. I was VERY careful in my inspection of the cap upon removal and I am 99% certain that oil is not sneaking by the ends of the seal - any seal - and I'm pretty confident on the end surfaces being tight. There wasn't a lick of oil anywhere on that portion of the cap or the block on removal. If it was leaking there, I'd think that you'd see some oil on that surface.

I dunno. I'm lost. The next rounds will all be done on an engine stand as this sucker is coming out because that's the only way to deal with this I think.

------------------

JimmySix:

Excellent suggestions and I'm with you on the runout issue. I will be putting a good dial indicator on this sucker and finding out exactly what I have. Packing those rope seals into the pocket is pretty difficult, and Mike (the engine shop owner) had mentioned that he's had seals that he has used a variety of types and thicknesses of shims in similar circumstances under the seal cup/retainer to help them raise the seals up and tighten the seal.

We also talked about machining the block and cap to accept a small block neoprene seal.

I dunno but sure appreciate everyone's ideas!