How was it that Yogi Berra put it:

"It ain't over until it's over."?

While my 302 rear main seal continues to be dry, another motor proved a little problematic and we cooked up a modification that I think others might benefit from so I'm sharing it here.

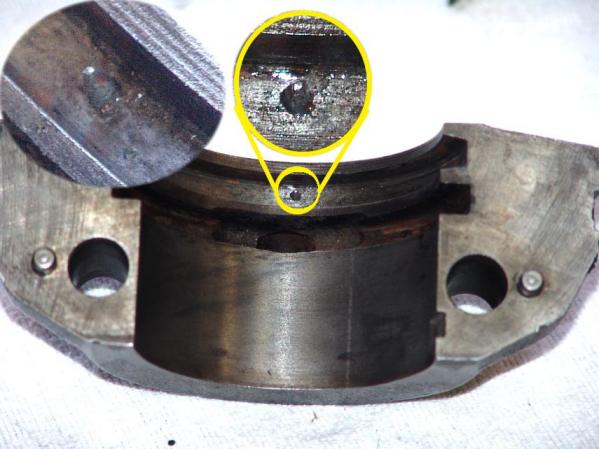

In this case, the Best Gaskets rope seal was in a 270 and shims were used (like my final job on the 302) but it appears in the autopsy that the shims actually provided a slip sheet for the seal to spin and leak. Hard to say exactly what the cause was, but the seal had spun in the pocket and the pocket showed more polished surface that expected indicating the seal was moving. I have seen this in other motors with the old asbestos rope seals, so this is not a new problem in the rear mains. In this case, a small hole was drilled in the bearing cap and then a cut down 5 penny nail was epoxied and driven into the hole with the point sticking up. This grabs the rope so it can't move at all, but is still far enough out of the way that it is not in play with the crank. Another modification to consider...

Also in this case, 250 lb. braided "tuna" fishing line was used to pull the seal up and over the crank since this engine was still in the truck. Took a few tries to get the right knot (blood knot) but it worked like a charm.